Introduction to High velocity impact Analysis

High-velocity impact analysis is a field of study that focuses on understanding and predicting the behavior of materials and structures when subjected to extremely rapid and intense impacts. It plays a crucial role in various industries, including aerospace, automotive, defense, and structural engineering. The importance of high-velocity impact analysis lies in its ability to assess the performance and safety of structures and components under extreme loading conditions. By simulating and analyzing the effects of high-speed impacts, engineers can evaluate the structural integrity, energy absorption capabilities, and potential failure modes of materials and systems. This information is vital for designing robust structures that can withstand impact events such as collisions, explosions, or projectile impacts.

High-velocity impact analysis also aids in the development of protective measures and safety standards. It enables engineers to optimize the design of armor systems, ballistic protection, and crashworthy structures, ensuring the highest level of safety for personnel and assets. Additionally, this analysis supports the advancement of materials and manufacturing techniques, as it provides valuable insights into material response, deformation, and failure mechanisms.

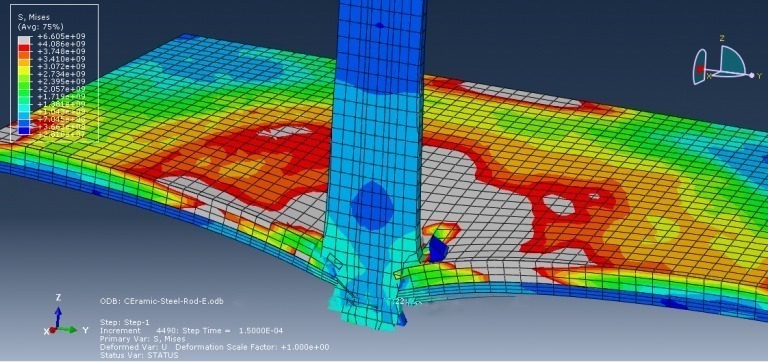

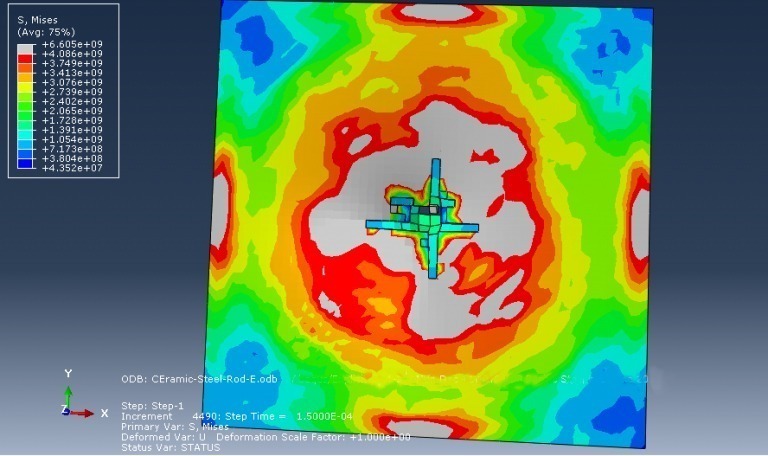

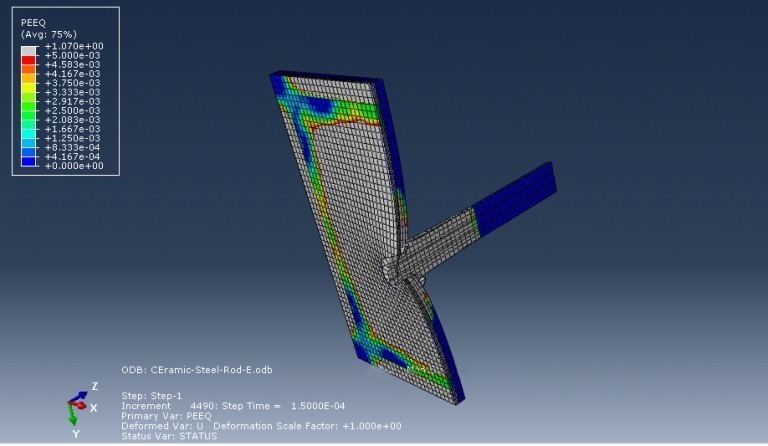

Workshop 1: High-velocity impact simulation to a ceramic plate reinforced with steel plate in Abaqus

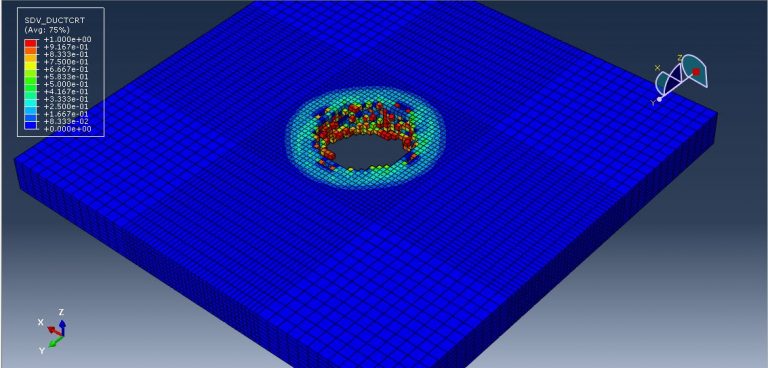

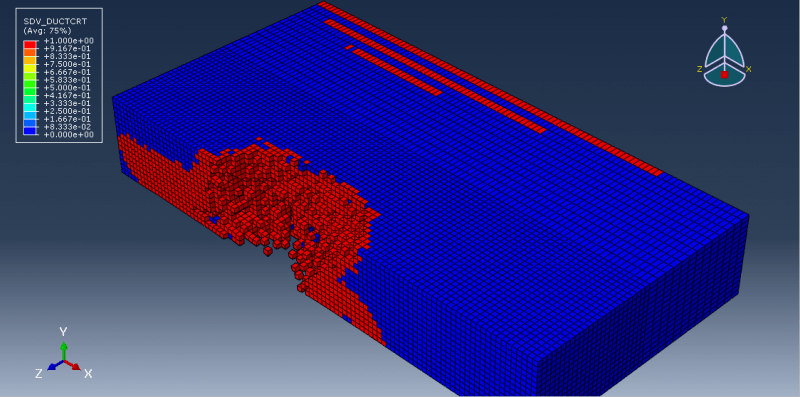

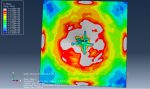

This tutorial provides a comprehensive explanation of the high-velocity impact of a steel projectile onto a ceramic plate that has been reinforced with steel, using Abaqus software. Both the steel projectile and steel plate are represented as deformable components, and a material model incorporating ductile and shear damage with progressive damage evolution is employed. Similarly, the Silicon plate incorporates ductile damage with evolution, Drucker-Prager plasticity with hardening, and the Us-Up equation to determine the fracture zone. The dynamic explicit procedure is deemed suitable for this type of analysis. In the load module, fixed boundary conditions are applied to the plates, and an initial velocity is assigned to the projectile. It is important to note that the quality of the mesh at the impact zone greatly influences the results.

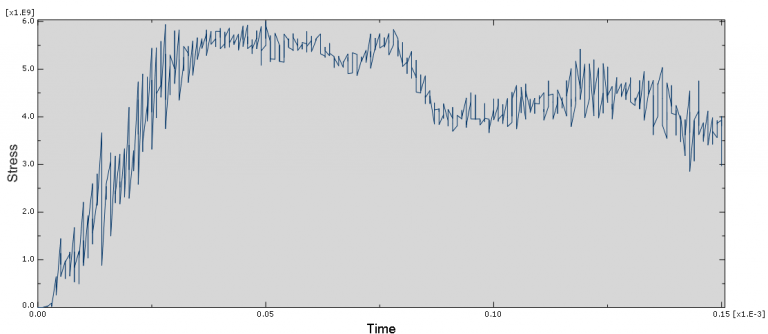

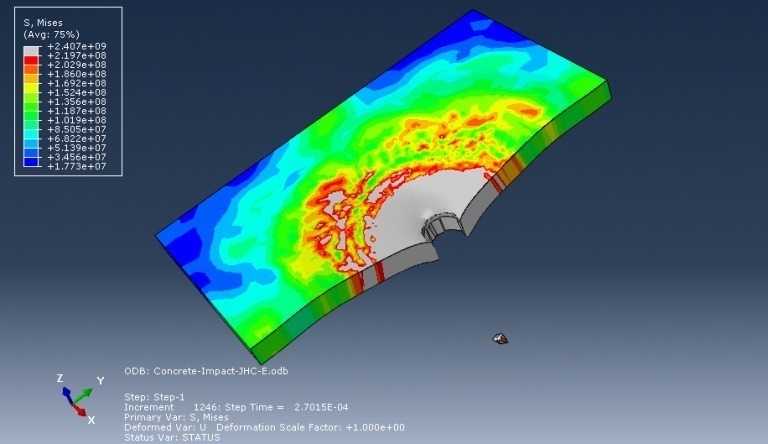

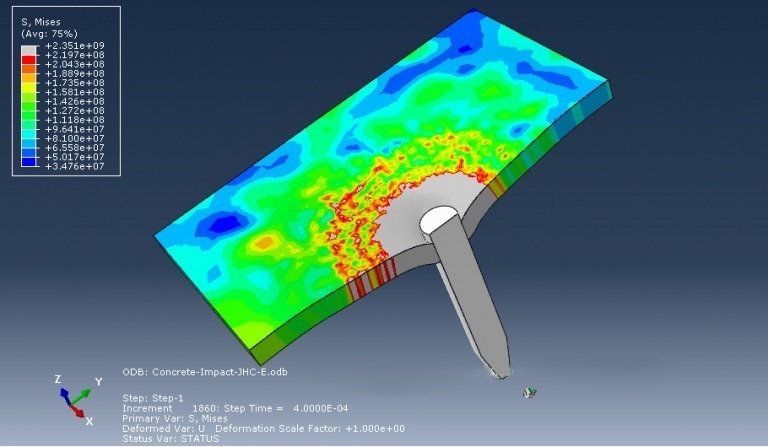

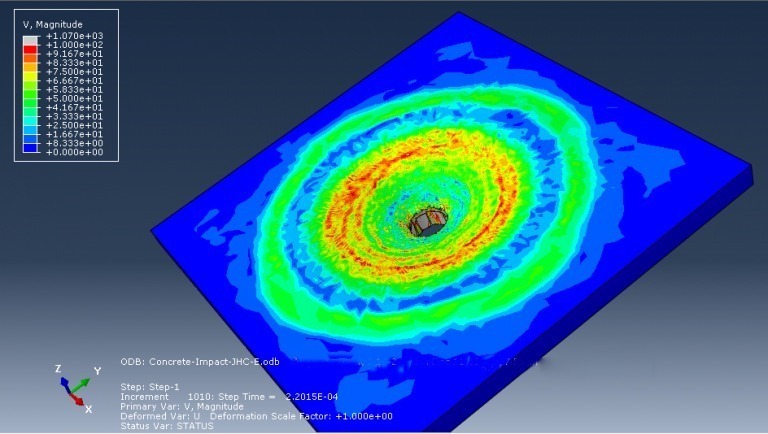

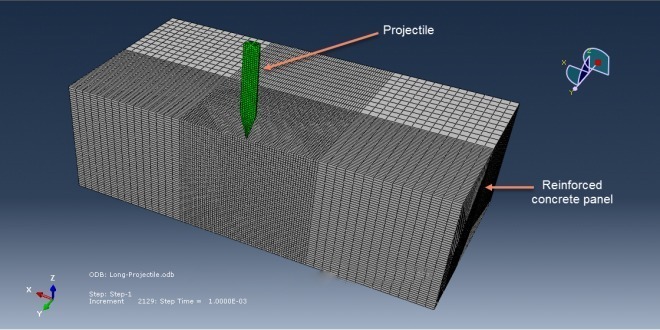

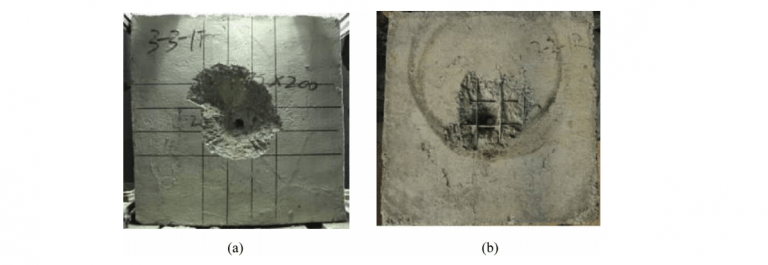

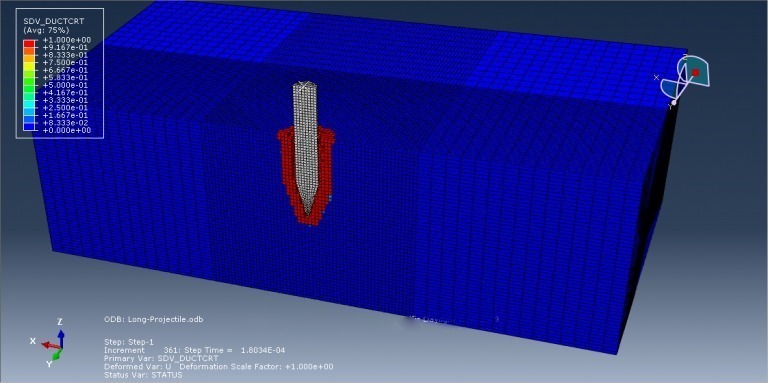

Workshop 2 : High velocity bullet impact simulation to the concrete wall

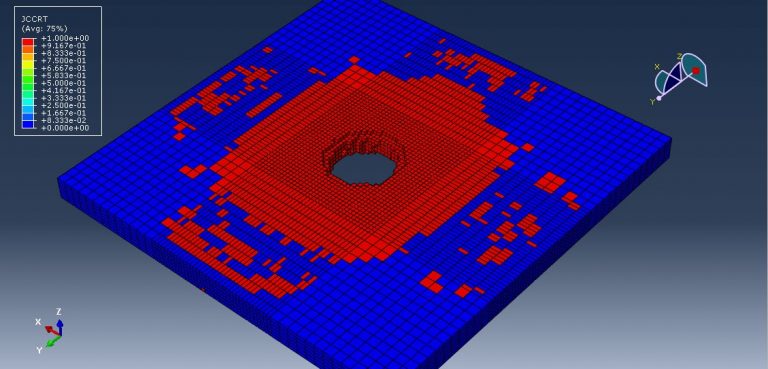

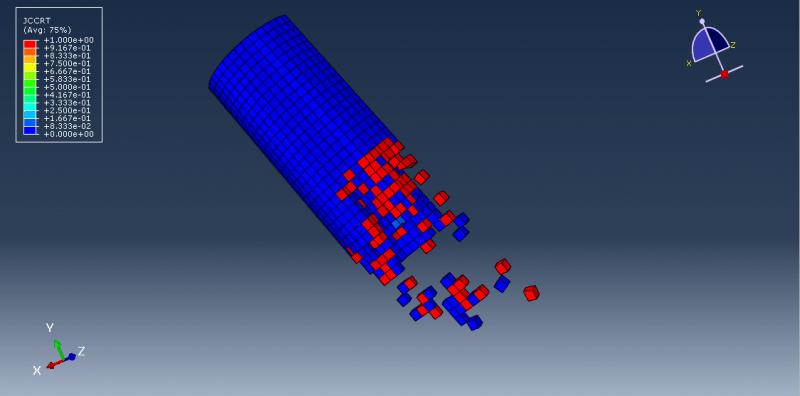

This tutorial provides a detailed demonstration of a high-speed impact on a concrete wall using Abaqus software. The bullet is represented as a Lagrangian part, and the JHC material model is employed to simulate the behavior of the concrete under the impact. Throughout the analysis, the bullet penetrates the concrete wall, resulting in significant damage.

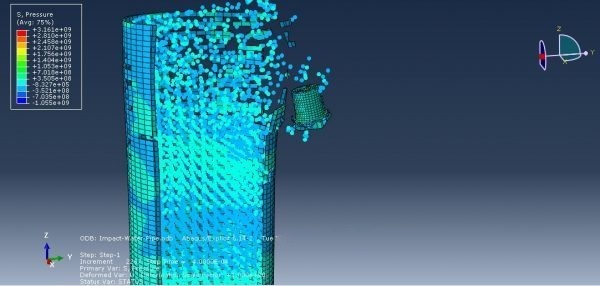

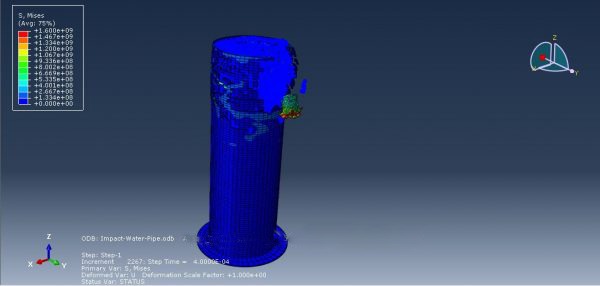

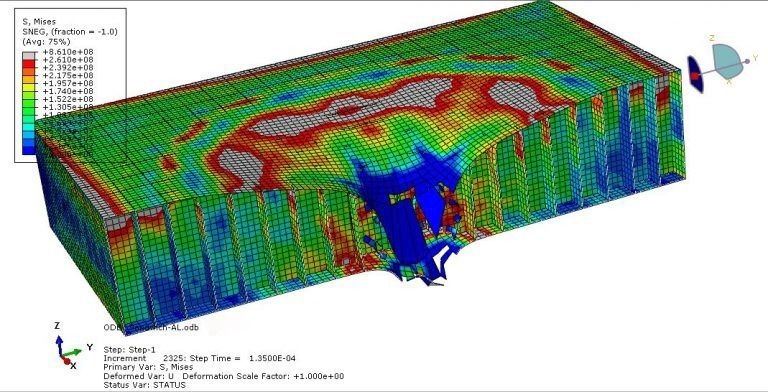

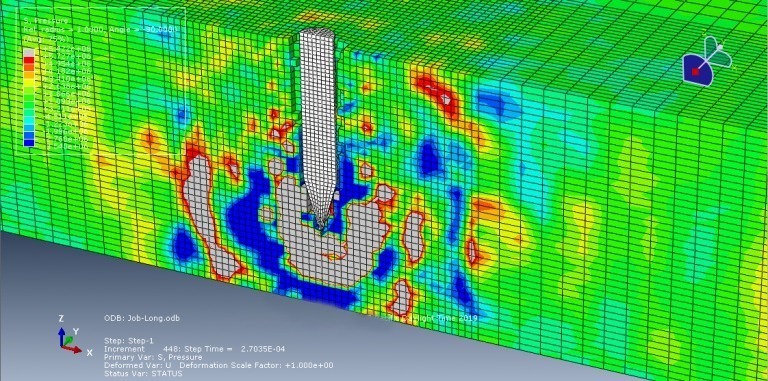

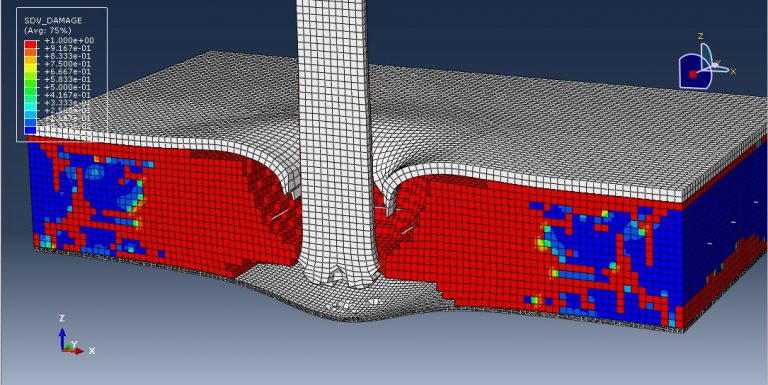

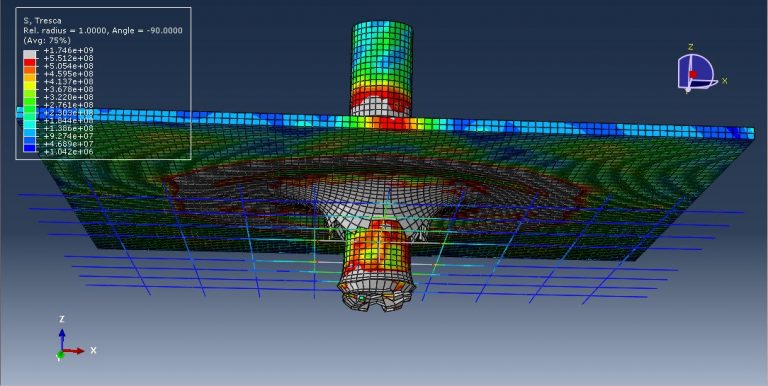

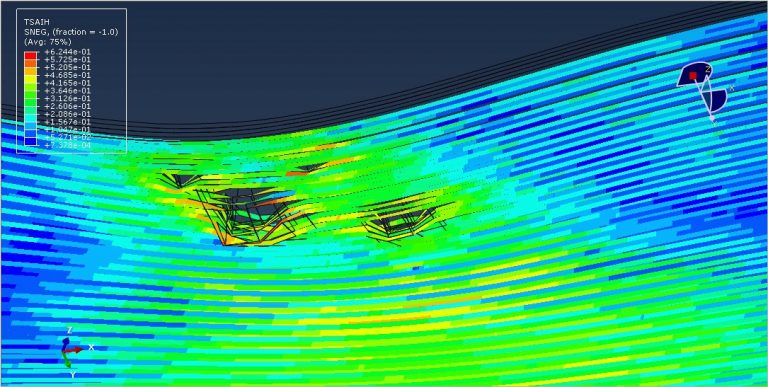

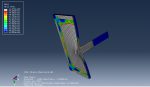

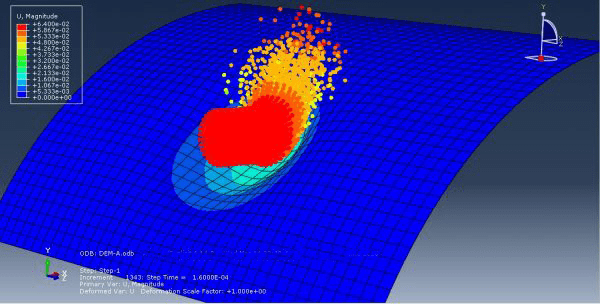

Workshop 3: High velocity impact simulation to fluid-filled containers utilizing FEM with adaptive coupling to SPH

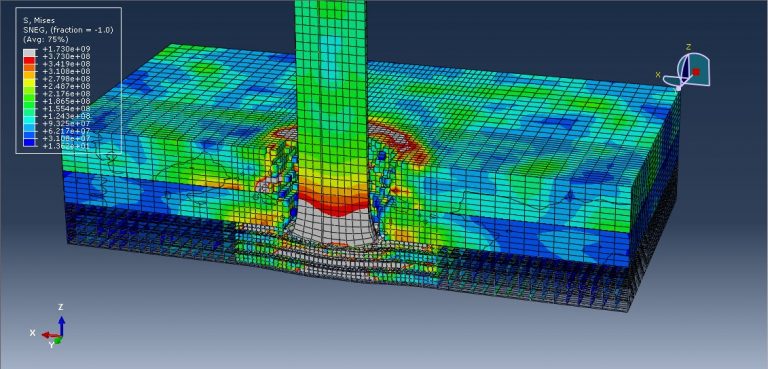

This tutorial showcases a numerical investigation into the simulation of projectile impacts on a container filled with fluid. All components are represented as three-dimensional parts, with the projectile modeled using steel material and the container using aluminum. Johnson-Cook plasticity and damage models are employed to forecast damage propagation in both metal parts. The water inside the container is modeled using the Us-Up equation of state, and a Smoothed Particle Hydrodynamics (SPH) model is utilized to predict its behavior. The explicit procedure is deemed suitable for analyzing high-velocity impacts.

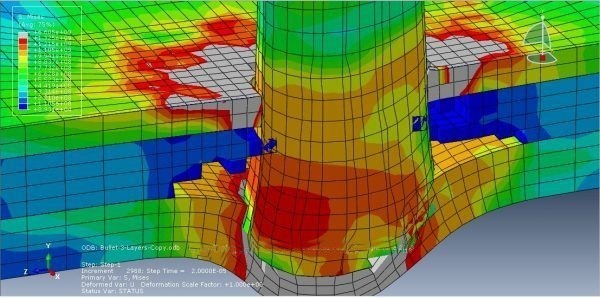

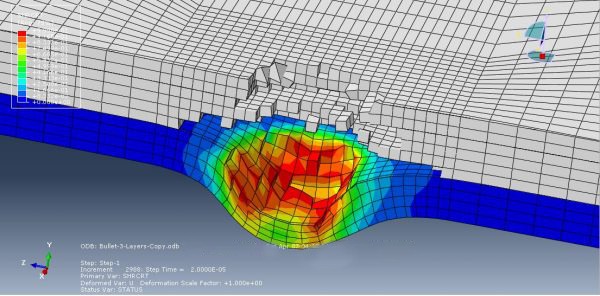

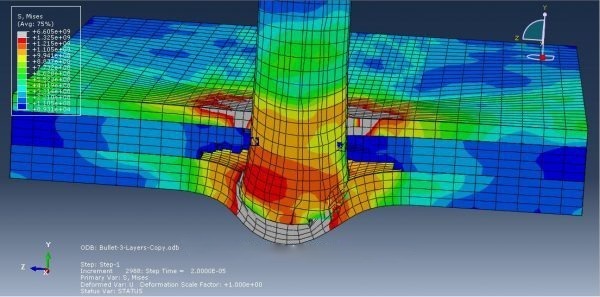

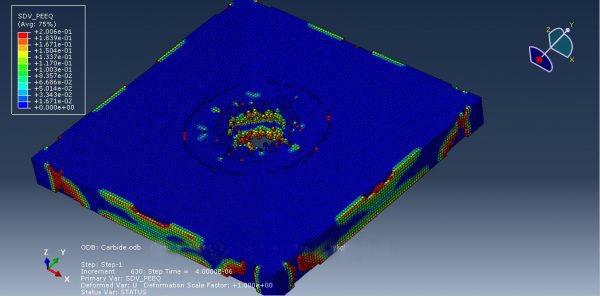

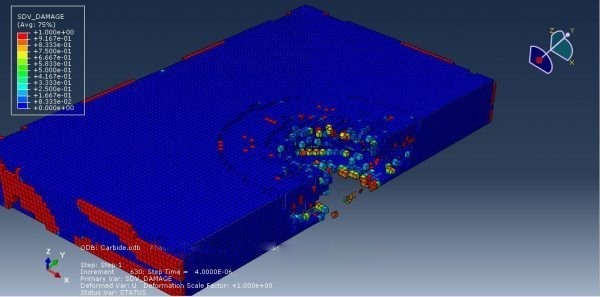

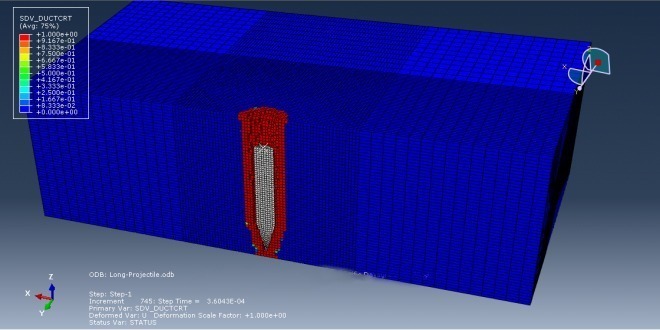

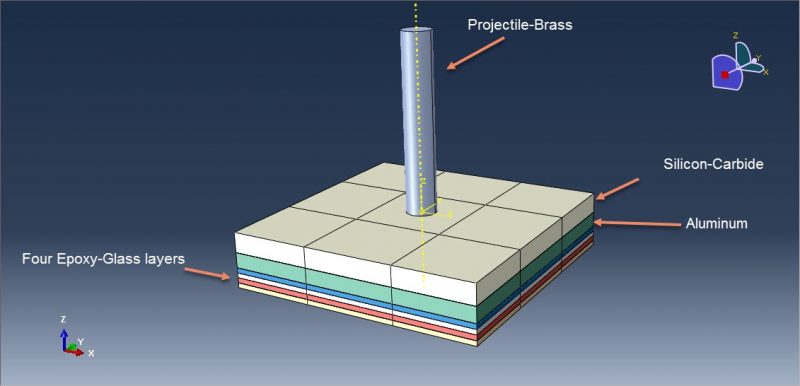

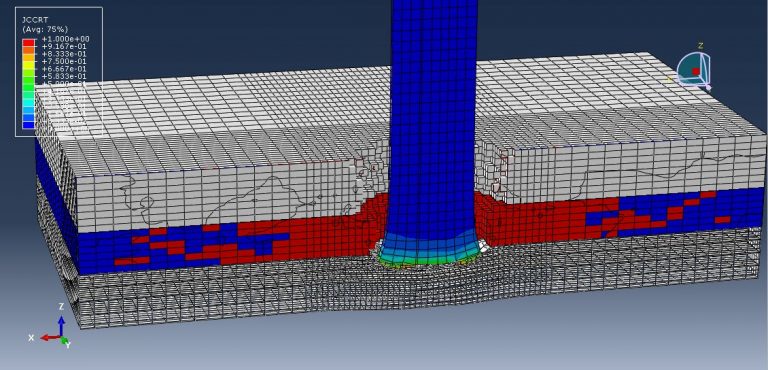

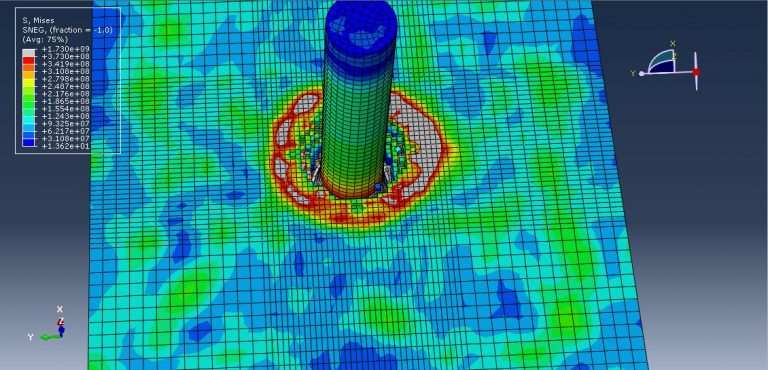

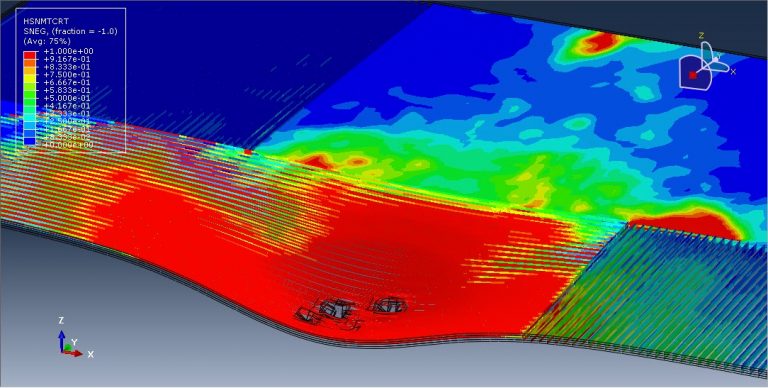

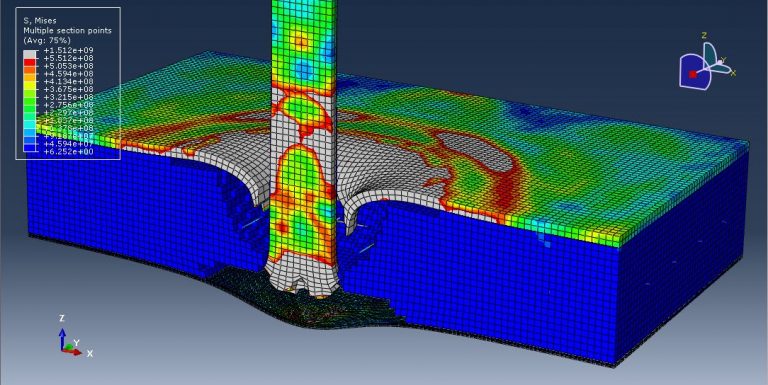

Workshop 4: Bullet impact simulation to the three-layered plate

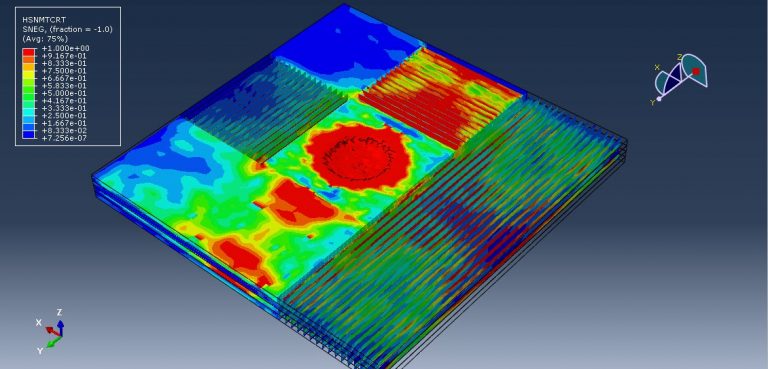

This tutorial explores the investigation of high-velocity bullet impact on a three-layered plate. The modeling of the entire structure was done in a three-dimensional space. Different damage and plasticity models were employed to accurately represent the behavior of steel, aluminum, and silicon carbide. Specifically, ductile and shear damage with evolution were used for modeling steel, Johnson-Cook damage and plasticity were employed for aluminum, and ductile damage coupled with Drucker-Prager plasticity were utilized for silicon carbide. The dynamic explicit procedure was deemed suitable for conducting this type of analysis. Adequate interaction and boundary conditions were applied to all components.

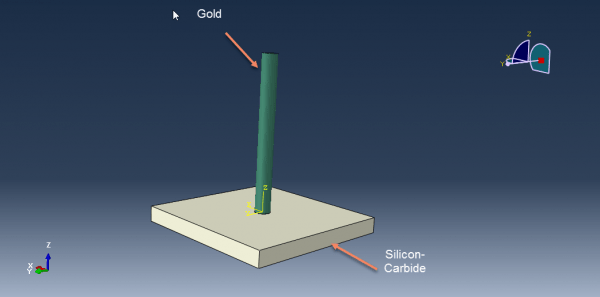

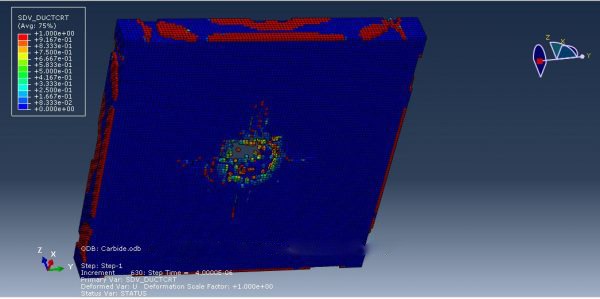

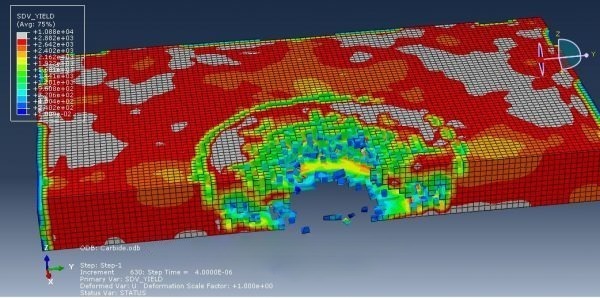

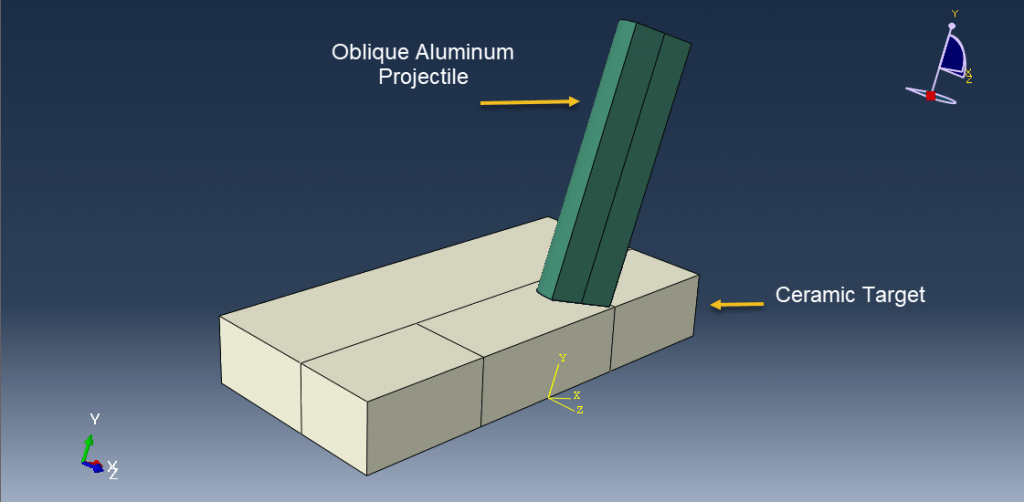

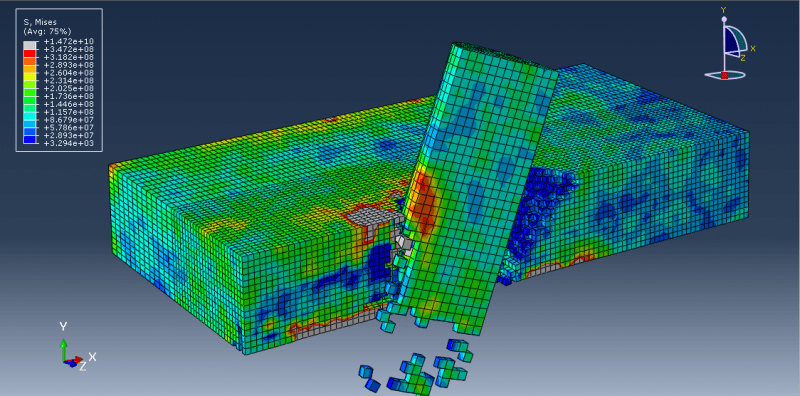

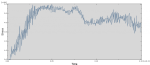

Workshop 5: High-velocity impact simulation with Johnson–Holmquist model to a ceramic target

This tutorial focuses on the simulation of the high-velocity impact of a ceramic target using the Johnson-Holmquist material model. Ceramic materials are commonly employed in armor protection applications. Over the years, Johnson, Holmquist, and their colleagues have developed constitutive relations to simulate the behavior of ceramics when subjected to large strain, high-strain rate, and high-pressure impact conditions. In this particular case, the JHB and JH-2 material models are investigated to analyze the penetration velocity of a gold projectile striking a silicon carbide target. The computed results are compared with previously published findings by Holmquist and Johnson. The target material, silicon carbide, is exceptionally hard and primarily used in compressive load situations, with limited ability to withstand tension. It finds applications in bulletproof vests and car brakes due to its high durability. The material’s strength is influenced by pressure, and in high-speed impact scenarios, damage to the material significantly affects its strength evolution. When silicon carbide is completely failed, it cannot sustain any load. On the other hand, the projectile is made of gold, which is comparatively soft compared to the target material.

Both the projectile and target are described using the Lagrangian approach. In all three cases, general contact with surface erosion is implemented. The analysis takes into account element deletion and node erosion. Specifically, the JH-2 model is utilized. Unlike the JHB model, the JH-2 model assumes that the damage variable progressively increases as plastic deformation occurs. In other words, according to the JH-2 model, the damage variable gradually grows alongside plastic deformation.

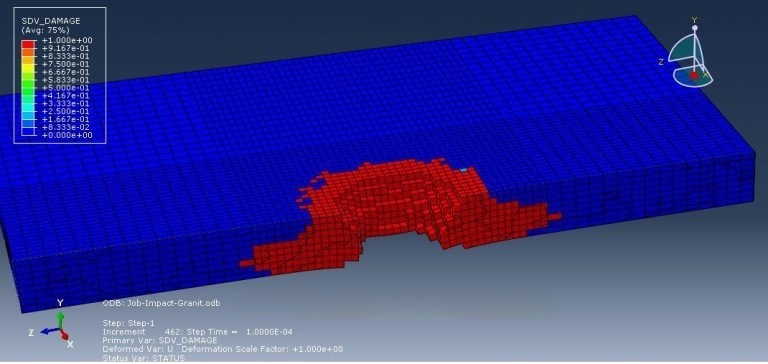

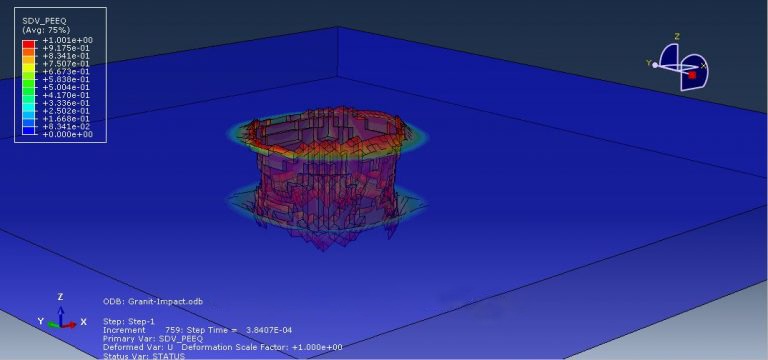

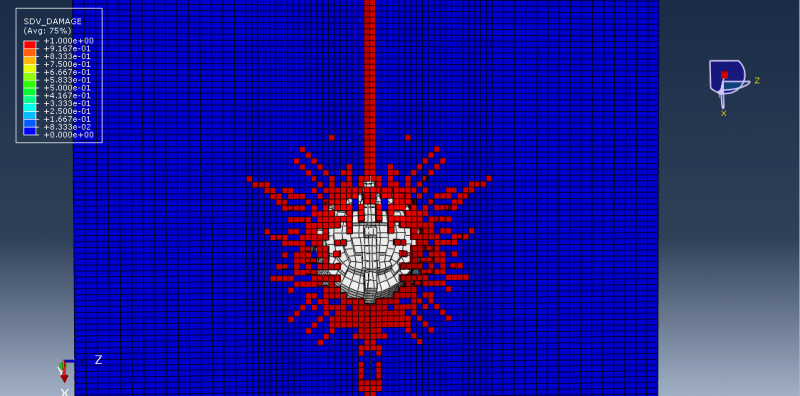

Workshop 6: Impact simulation on Granite stone

The constitutive relationship of a material is not just a summary of experimental data; it also plays a crucial role in numerical simulations. It aims to accurately represent the physical and mechanical properties of materials, thereby improving the accuracy of simulation results. As the demand for numerical simulations increases, various constitutive models for materials are constantly being developed and optimized. For materials subjected to large strains, high strain rates, and high pressures (LHH), dynamic constitutive models tend to involve more complex parameters, including physical properties and sensitive coefficients such as rate effects and strength coefficients. Consequently, determining these parameters has become increasingly challenging.

The JH-2 constitutive model was initially designed to simulate the behavior of brittle materials, particularly ceramics. It incorporates softening characteristics and includes pressure-dependent strength, damage, fracture, significant strength after fracture, bulking, and strain-rate effects.

The JH-2 model assumes that the strength of both intact and fractured material relies on pressure, strain rate, and damage. The relationship between strength and these parameters is defined by a set of constants derived from standard measurements conducted under dynamic and quasi-static conditions.

In this simulation, the high-velocity impact of a rigid projectile on granite stone is investigated. An explicit step is employed with a general contact method, considering internal damage and erosion through the use of an inp file. Throughout the analysis, the damage variable for granite is prominently observed.

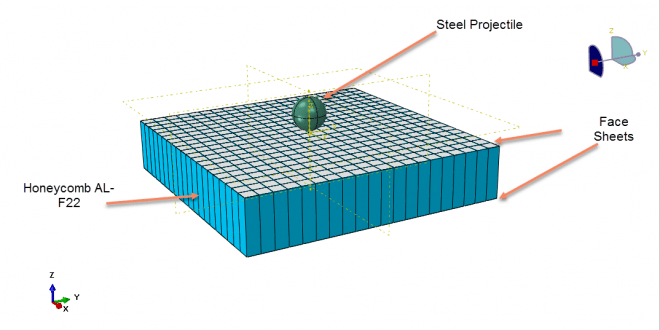

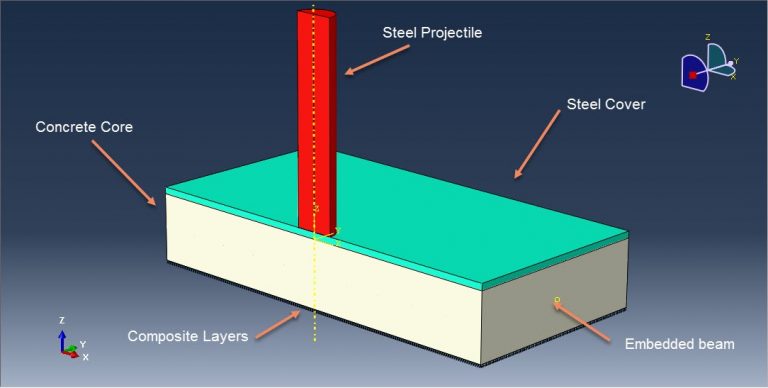

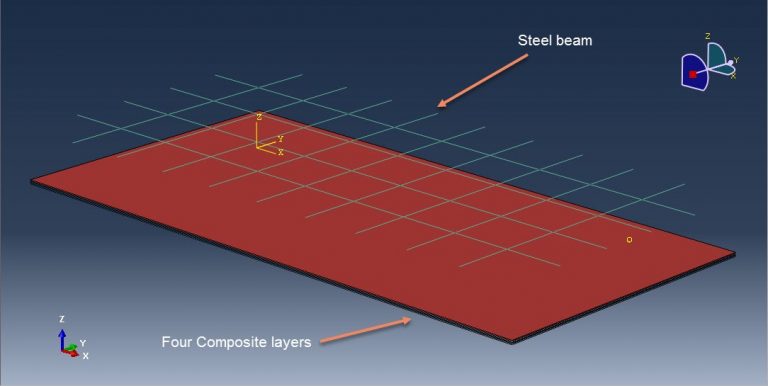

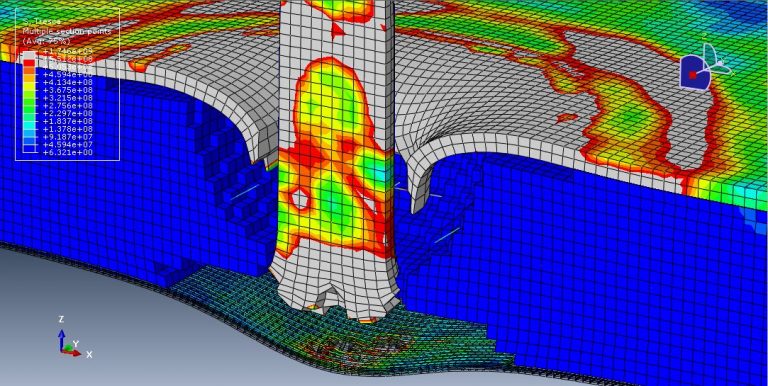

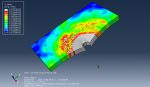

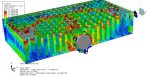

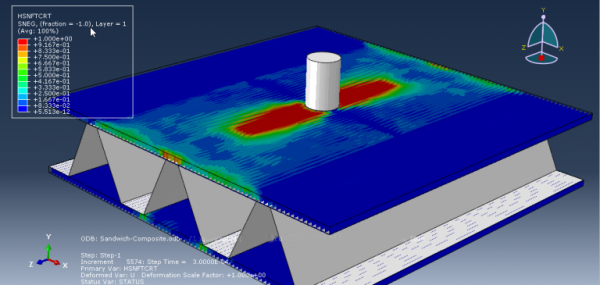

Workshop 7: Impact simulation to aluminum honeycomb sandwich panels

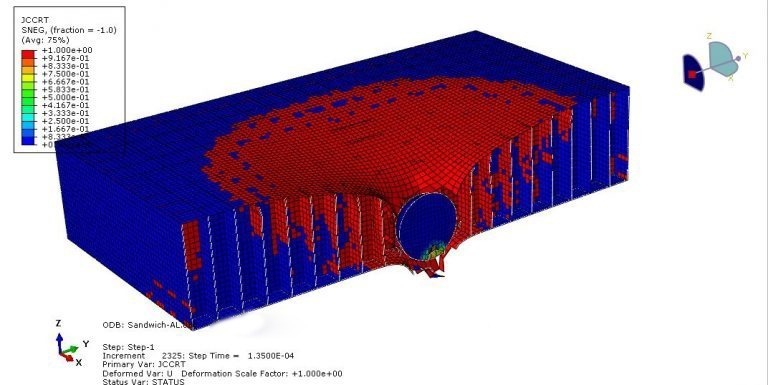

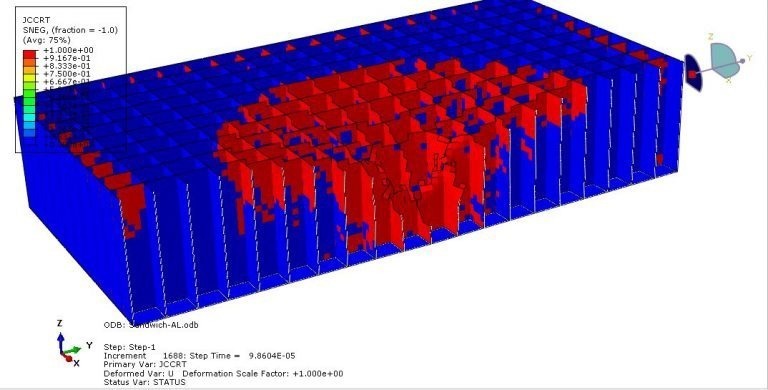

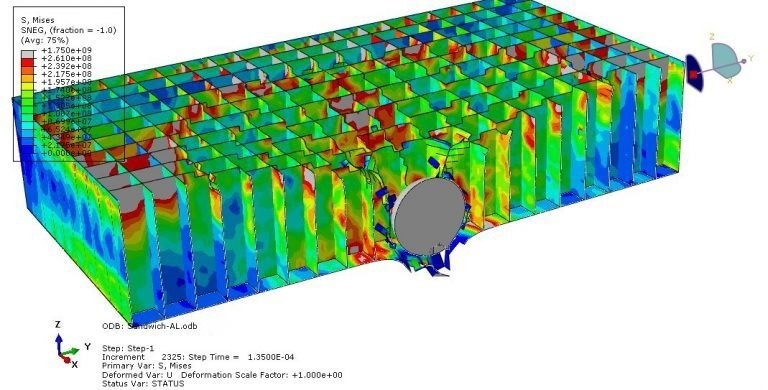

Sandwich panels are extensively utilized in lightweight construction, particularly in the aerospace industry, due to their high specific strengths and stiffness. Throughout the service life of a sandwich panel, impacts are expected to occur from various sources. For example, debris can be propelled at high velocities during aircraft takeoffs and landings, tools may accidentally drop on the structure during maintenance, or collisions with birds can happen. While visual inspection may reveal minimal damage on the outer facesheet of the sandwich panel, significant damage can occur within the impacted region between the facesheet and the core. This damage can lead to a reduction in structural stiffness and strength, which can further propagate under additional loading. Consequently, there has been an increasing focus on understanding the behavior of sandwich panels under impact.

Finite element modeling is a popular and cost-effective approach employed in the study of sandwich structures. To achieve computational efficiency, the core of sandwich structures, which consists of a large number of cells, is often replaced with an equivalent continuum model. Analysis of sandwich panels is then conducted based on their effective properties rather than considering the intricate cellular structure. Several experimental and analytical techniques have been proposed to predict the effective continuum properties of the core, taking into account its geometric and material characteristics. Researchers have modified the classical laminate theory and applied it to a unit cell to derive the equivalent elastic rigidities for honeycomb cores. However, deriving the theoretical formulation for effective elastic constants of the core can be complex or even impossible if the sandwich construction is highly intricate. Even if it is feasible, the mathematical derivations for one type of sandwich core may not be applicable to other types.

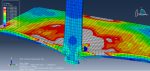

In this simulation, the projectile is represented as a three-dimensional component made of steel material, while the honeycomb structure with two facial sheets is modeled as a three-dimensional shell using aluminum material. Both bodies are characterized by the application of Johnson-Cook plasticity and damage models. The dynamic explicit procedure is deemed suitable for conducting this type of analysis. The contact between the honeycomb and facial sheets is assumed to be perfect, while the contact between the projectile and the upper surface involves surface-to-surface interaction with contact properties. Due to the high initial velocity of the projectile, noticeable deformation and damage occur on the sandwich panel, and the Johnson-Cook damage parameter becomes available for examination after the impact.

Christopher –

With these tutorials, I can accurately analyze and predict the behavior of materials and structures under high-velocity impacts. This information can be highly useful in designing safer and more resilient systems. As an engineer, I have personally utilized these tutorials and achieved highly effective results. I highly recommend this package to anyone seeking high-velocity impact simulation.

Experts Of CAE Assistant Group –

Thanks for valued review,Christopher!