John Garcia is a highly skilled professional with expertise in writing various types of subroutines in Abaqus. He has made significant contributions to the field of computational mechanics and has a deep understanding of finite element analysis. With his exceptional programming abilities and extensive knowledge of Abaqus, John has emerged as a leading expert in the industry.

Early Life and Education:

Born and raised in a small town in the United States, John developed an early interest in mathematics and computer programming. He excelled in his academic pursuits and earned a Bachelor’s degree in Mechanical Engineering from the prestigious Massachusetts Institute of Technology (MIT). During his undergraduate years, John was drawn to the field of computational mechanics, which fueled his passion for developing innovative solutions using advanced numerical methods.

Career and Professional Accomplishments:

After completing his education, John joined a renowned engineering consultancy firm, where he quickly established himself as a valuable asset. His expertise in programming and finite element analysis caught the attention of industry leaders, and he was soon working on challenging projects in the aerospace, automotive, and civil engineering sectors.

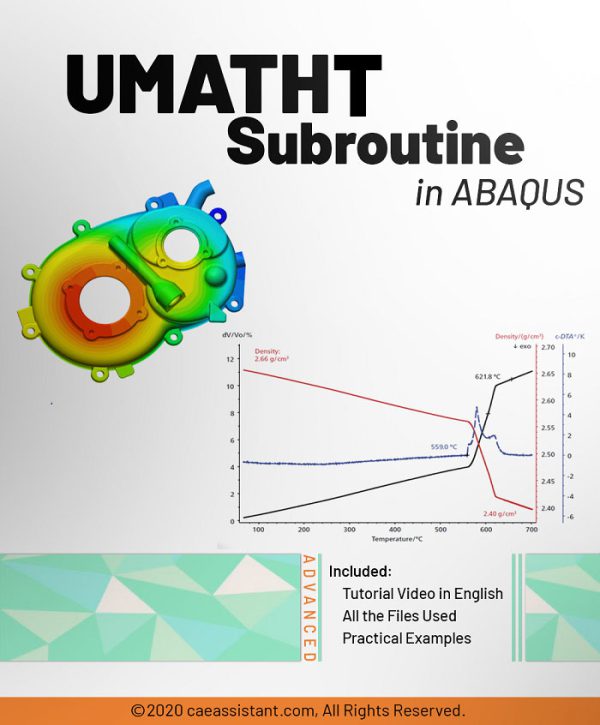

John’s career reached new heights when he started specializing in writing subroutines for Abaqus, the industry-leading finite element analysis software. His ability to develop customized subroutines for complex simulations became his trademark. His subroutines enabled engineers to perform advanced analyses, such as material modeling, contact mechanics, and dynamic simulations, with improved accuracy and efficiency.

To further enhance his knowledge and stay at the forefront of the field, John pursued a Master’s degree in Computational Mechanics from Stanford University. His research focused on the development of advanced constitutive models and their implementation in Abaqus subroutines. His work received accolades and was published in reputable journals, solidifying his reputation as an expert in the field.

Expertise and Contributions:

John’s expertise lies in writing different types of subroutines in Abaqus, including user-defined material models, element types, and boundary conditions. He possesses an in-depth understanding of the Abaqus scripting interface, Fortran, and Python programming languages, enabling him to create robust and efficient subroutines tailored to specific engineering problems.

Throughout his career, John has collaborated with numerous clients and engineering teams, providing them with his expertise and support. His ability to grasp complex engineering challenges, translate them into mathematical models, and implement them within the Abaqus framework has been instrumental in solving critical problems and optimizing designs.

John is also a passionate educator and has conducted workshops and training sessions on Abaqus programming. His ability to explain complex concepts in a clear and concise manner has made him a sought-after instructor in the field. He believes in sharing his knowledge and empowering others to leverage the full potential of Abaqus for their engineering projects.

Personal Life:

Outside of his professional endeavors, John enjoys spending time with his family and exploring the great outdoors. He is an avid hiker and finds solace in nature, which helps him maintain a balanced perspective and fuels his creativity. John is also passionate about giving back to the community and actively volunteers in organizations that promote STEM education for underprivileged youth.

Conclusion:

John Garcia ‘s expertise in writing different types of subroutines in Abaqus, combined with his educational background and professional accomplishments, has made him a highly respected figure in the field of computational mechanics. His ability to develop custom solutions, his dedication to knowledge sharing, and his commitment to empowering others have solidified his position as a leading expert. Through his contributions, John continues to push the boundaries of what is possible in the realm of finite element analysis, making a profound impact on engineering practices and enabling innovative solutions to complex engineering problems.

DISP and VDISP Subroutines in ABAQUS

UMAT Subroutine (VUMAT Subroutine) in ABAQUS-Free Version- UMAT Abaqus example

"UMAT Subroutine (VUMAT Subroutine) introduction" is used when the material model is not available in ABAQUS software. If you follow this tutorial package, including standard and explicit solver, you will have the ability to write, debug and verify your subroutine based on customized material to use this in complex structures. These lectures are the introduction to writing advanced UMAT and VUMAT subroutines in hyperelastic Martials, Composites, and Metal, and so on. Watch Demo

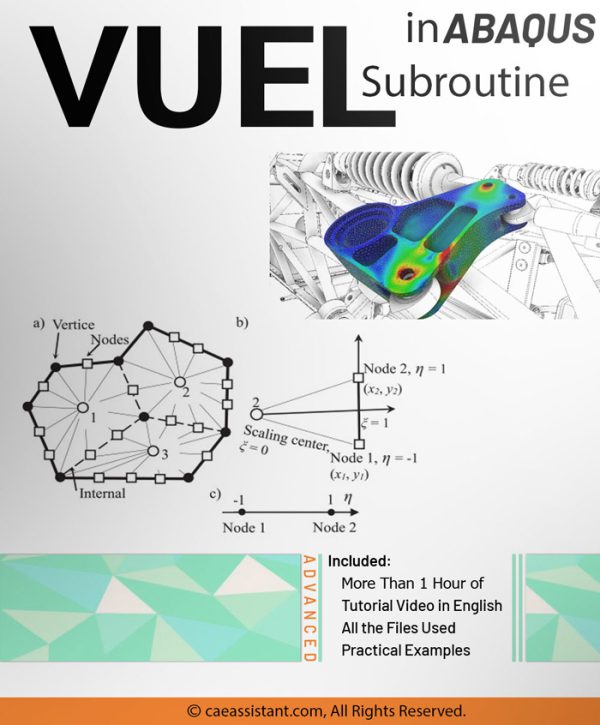

"Advanced UMAT Subroutine (VUMAT Subroutine)" training package helps Abaqus users to prepare complex UMAT and VUMAT subroutines. This training package is suitable for those who are familiar with subroutine or want to learn UMAT/VUMAT subroutine Professionally. Equations for computational plasticity based on kinematic stiffness are also discussed. In addition, metal damage has been implemented based on Johnson Cook's model. Watch DemoIntroduction to VUEL Subroutine in ABAQUS

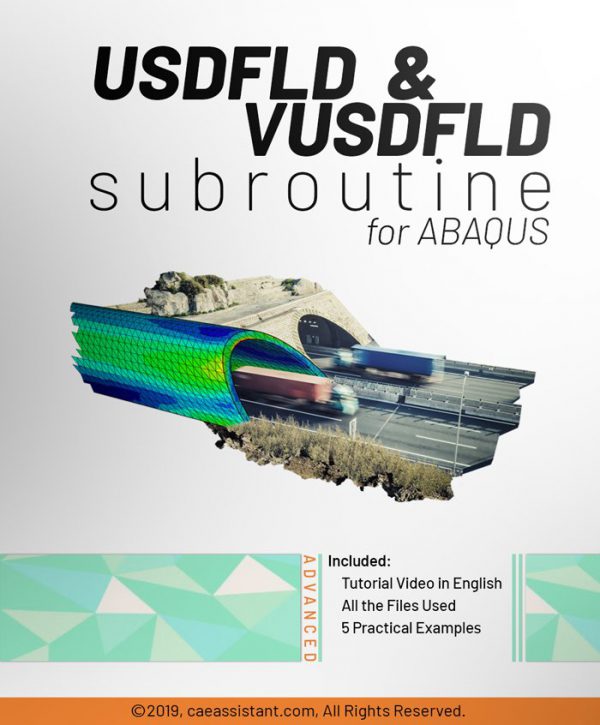

Introduction to USDFLD and VUSDFLD Subroutine

In this usable tutorial, the material properties can change to an arbitrary dependent variable. One of the most important advantages of this subroutine is simplicity and applicability. Various and high usage examples are unique characteristics of the training package.

This training package includes 5 workshops that help you to fully learn how to use USDFLD and VUSDFLD subroutines in Abaqus software. By means of these subroutines, you will have expertise redefine field variables at a material point by the solution dependence of standard and explicit, respectively.Abaqus DLOAD Subroutine and VDLOAD Subroutine

UHYPER Subroutine in ABAQUS

Introduction to VFRICTION and VFRIC Subroutines in ABAQUS

This tutorial help you in cases where the classical Columbian equations are more complex and cannot be implemented by the graphical ABAQUS environment. This package introduces and teaches how to write these two subroutines. This introduction contains explaining different optional and mandatory parameters of VFRICTION and VFRIC subroutines.

Advanced UMAT Subroutine (VUMAT Subroutine) – Abaqus UMAT tutorial

Introduction to UEL Subroutine in ABAQUS

UMESHMOTION subroutine in ABAQUS

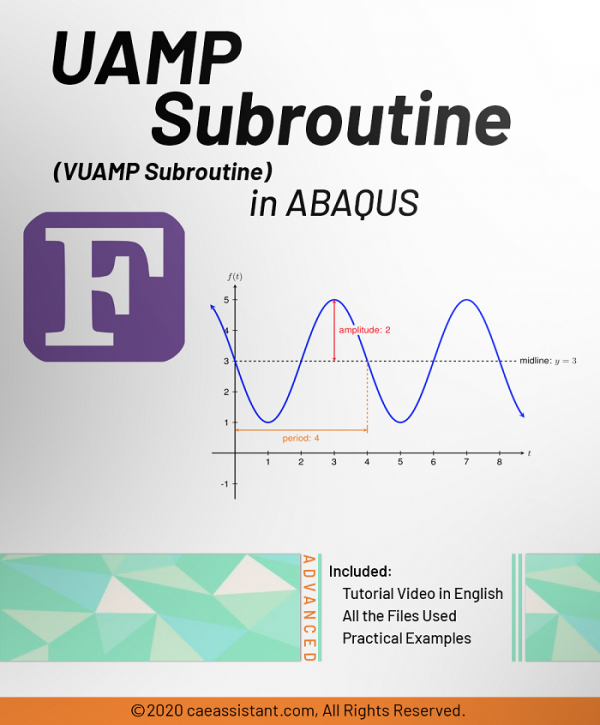

UAMP subroutine (VUAMP subroutine) in ABAQUS

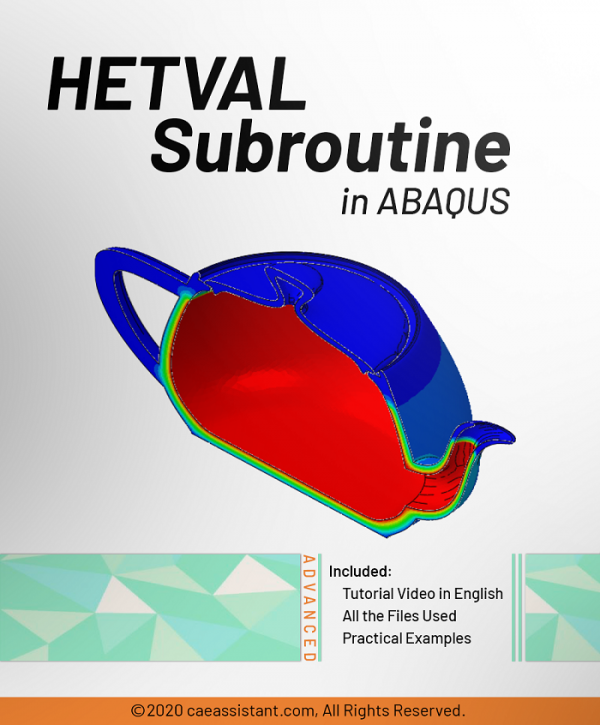

HETVAL subroutine in ABAQUS

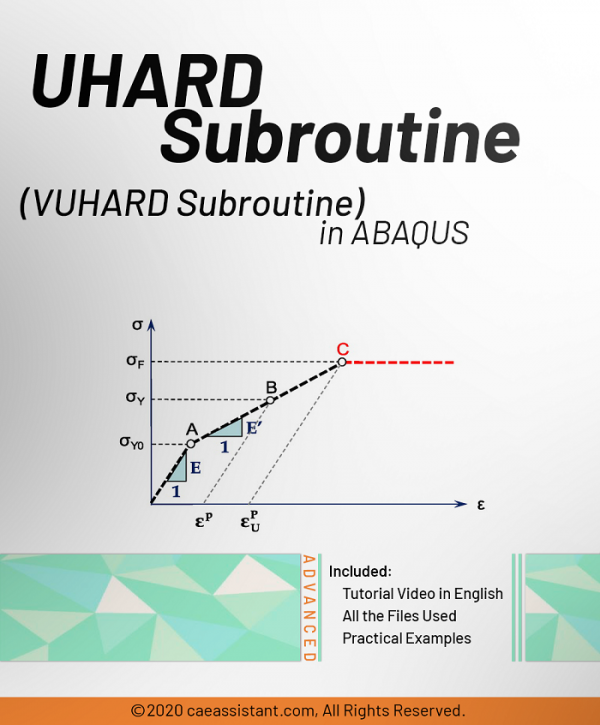

UHARD Subroutine (VUHARD Subroutine) in ABAQUS

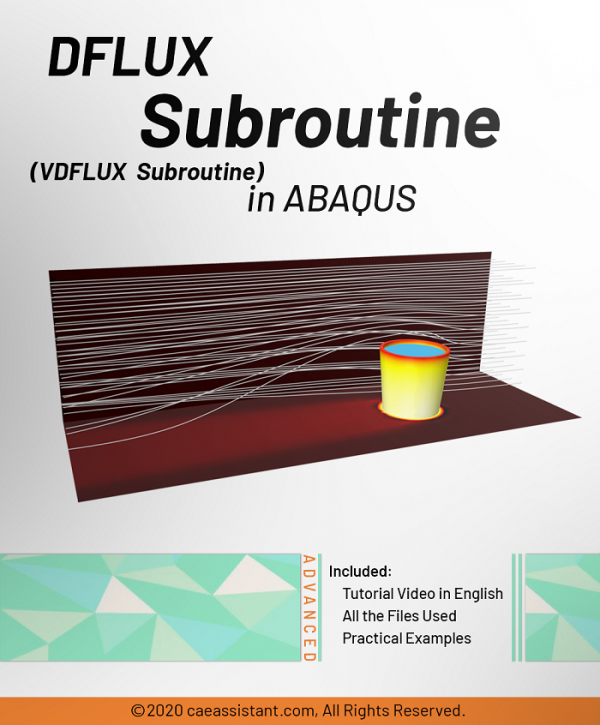

DFLUX Subroutine (VDFLUX Subroutine) in ABAQUS

UVARM subroutine in ABAQUS

UEXPAN and VUEXPAN Subroutine

In this tutorial, how to define increments of thermal strains, in order to model thermal expansion, is taught. The implementation of thermal expansion in model is done with UEXPAN and VUEXPAN subroutines for Abaqus/Standard solver (implicit method). In user subroutines UEXPAN or VUEXPAN, the increments of thermal strains can be defined as functions of predefined field variables, temperature, and state variables.

UEXPAN and VUEXPAN are called for all integration points of part elements where the definition of material or gasket behavior includes user-subroutine-defined thermal expansion.

The subroutines are used when the material’s thermal expansion behavior is too complex to model with the "EXPANSION" option in the Abaqus software environment. For example, the subroutines are used in problems where the thermal strains are complexly dependent on temperature, predefined field variables, and state variables, and there is a need to update these variables.

The user subroutine UEXPAN is called twice per element point in each iteration during coupled thermal-electrical-structural or coupled temperature-displacement analyses.