What are Abaqus UHARD & VUHARD subroutines? | When do we need them?

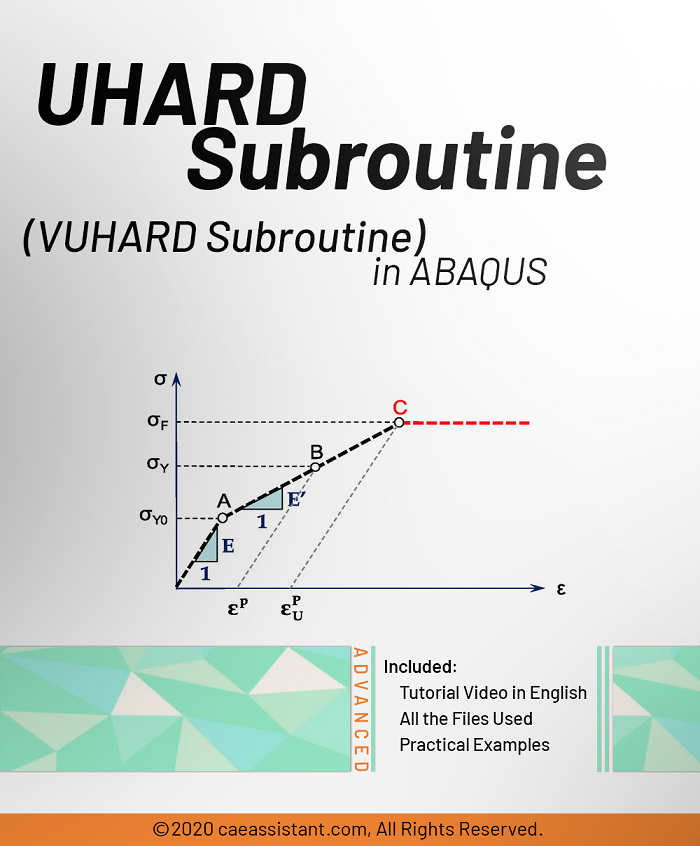

When you want to define the plastic area of the stress-strain curve, the Abaqus gives you several options to do that. It labels these options “Hardening”; some of these hardening models are Isotropic, Kinematic, Johnson-Cook, Combined, etc. Suppose you need to define a hardening that doesn’t exist in the ABAQUS, or you need to change the available hardenings. In that case, that’s where you use the Abaqus UHARD subroutine and VUHARD subroutine.

UHARD & VUHARD subroutines in Abaqus

UHARD stands for user-defined hardening models. For isotropic plasticity or combined hardening models, UHARD is a user subroutine to define the yield surface size and hardening parameters. The UHARD subroutine is for the Standard solver, and the VUHARD is for the Explicit solver. You will learn the differences between these two in the workshops.

User subroutine UHARD is called at all material calculation points of elements for which the material definition includes user-defined isotropic hardening or cyclic hardening for metal plasticity. It can be used to define a material’s isotropic yield behavior. Moreover, you can define material behavior dependent on field variables or state variables; or even you can combine it with the UMAT subroutine, which there is a workshop about it (workshop 3) in this package.

Workshop 1: Implementation of UHARD Subroutine for isotropic hardening (formulation based) in a simple model

In the first workshop, there is a cube with the dimension “L”. One end of this cube is fixed, and at the other end, we have displacement “U”. The Hardening in this example is formulation-based. This means you must define the formula you want to use in the subroutine.

Workshop 2: Deep Drawing simulation with VUHARD Subroutine or isotropic hardening Data-based with element removal

In the second workshop, we have a deep drawing process. In this workshop, we want to apply the VUHARD subroutine for isotropic hardening Data-based. Note that the VUHARD subroutine uses the Explicit solver. The Data-based method uses the plastic strain and yield stress data as inputs, while in the previous workshop, we used a formulation. Also, we have element removal in this workshop.

Two models will be analyzed. In the first model, the deep drawing process will be done with the Abaqus GUI, and the hardening model is isotropic and data-based. The second model is the same process, but this time the hardening will be modeled by the VUHARD subroutine, and the data will be applied by the subroutine. In the end, two models will be compared to validate the application of the VUHARD subroutine.

Workshop 3: Simulation of material under pressure with UHARD Subroutine as internal subroutine combined with UMAT

In this workshop, we have a rectangle axisymmetric model which subjected to displacement “U” to apply pressure on it. Two models will be analyzed; one of them is called “builtin” which is for verification purposes, and the other is called “userMAT” which uses the user subroutine. In the first model, the elastic and plastic properties are defined through the Abaqus GUI and data table. In the second model, material properties are defined through the UMAT and UHARD subroutines. First, the UMAT subroutine defines the material properties and when it comes to define the yield stress and hardening, it calls the UHARD subroutine to do this job. In fact, the UHARD subroutine will implement as an internal subroutine combined with UMAT.

Workshop 4: Simulation of incremental forming with VUHARD Subroutine Dharmasena modified Based

In this workshop, we will simulate the incremental forming with the VUHARD subroutine on a model named Dharmasena modified based. First, the stress-strain curve and the hardening parameters will be completely explained. Also, the formulas and the theory behind it is explained. After that, the subroutine file will be opened and explained line by line with a flowchart to fully understand the code. In the end, the settings in the Abaqus GUI are explained, and the results are discussed.

It would be useful to see Abaqus Documentation to understand how it would be hard to start an Abaqus simulation without any Abaqus tutorial.

The Abaqus user subroutine allows the program to be customized for particular applications unavailable through the main Abaqus facilities. You should write a user subroutine if you could not run your analysis by ABAQUS built-in models for materials, loads, properties, elements, etc., for example, if you need to model a user-defined nonlinear stress-strain relation, which is not provided by Abaqus, then look for UMAT user subroutine. A more advanced subroutine is UHARD, which allows the creation of user-defined hardening behavior. If it is your first time writing a subroutine like UHARD, please read the Start Writing an Abaqus Subroutine: Basics & Recommendations article. After reading this post and watching this tutorial’s demo video, you will definitely decide to save time in Abaqus modelling and get this UHARD training package. If you have questions, ask here on our live chat on the left side of this page.

Basic steps to write a subroutine:

Generally, to write a newly developed UHARD, you should follow these steps:

1. Knowing well the material model theory for our UHARD

2. Getting Familiar with UHARD parameters (Inputs/Outputs)

3. Developing FORTRAN code of the UHARD in Abaqus

4. Implementation in Abaqus & Compilation

5. Testing and debugging UHARD subroutine

6. Examining UHARD results and verification

- Mg-RE-Zn alloys (RE=rare earth elements) have attracted increasing attention in the fields of military and civilian applications because they possess a remarkable combination of low density and high strength, unlike magnesium (Mg) and commercial Mg-Al-Zn alloys, which suffer from poor strength at room and elevated temperatures. In a study, the strain-compensated Arrhenius model was used to examine the hot deformation behavior of homogenized Mg-8.5Gd-4.5Y-0.8Zn-0.4Zr alloy under specified deformation conditions (differing combinations of temperatures and strain rates). The user subroutine of UHARD in ABAQUS software was applied to code the constructed strain-compensated Arrhenius model.

- Important hot deformation techniques for metals include forging, rolling, and extrusion. These techniques have an impact on the end products’ dimensional correctness and mechanical qualities. As a result, a lot of study has been done on the behavior of materials during hot deformation in order to control the forming process and, as a result, get desirable microstructure and mechanical properties. A strain compensated Arrhenius model was used to describe the hot deformation behavior of homogenized 5052 aluminum and AZ31 magnesium alloys. The strain compensated Arrhenius model’s User Subroutines UHARD were then programmed into the ABAQUS program to simulate hot compression.

- Construction of lightweight metallic structural components may be designed and created instantly thanks to additive manufacturing (AM) technologies. This is conceivable because parts from 3D CAD models can be printed or manufactured instantly on a powder bed table utilizing an electron beam source for electron beam melting (EBM) or a laser source for selective laser melting (SLM)/direct metal laser sintering (DMLS). The goal of the work was to create a numerical model based on the predominant mechanisms of deformation of AM Ti6Al4V (ELI) microstructures over a wide range of temperatures and strain rates. User-defined material models are necessary to describe and simulate a non-linear analysis that takes into account massive displacements and the behavior of elastoplastic materials. Therefore, in this study, the constructed, calibrated, and verified analytical constitutive model based on microstructure and dislocations is implemented as a user material subroutine in ABAQUS using VUMAT and VUHARD subroutines. While the VUMAT subroutine explains a material’s entire (elastic-plastic) behavior, the VUHARD subroutine is used to describe a material’s plastic deformation.

- In scientific applications, the use of machine learning algorithms to anticipate material behavior offers a significant improvement over traditional numerical approaches. In this study, the flow law of a metallic material is defined as a function of plastic strain, plastic strain rate, and temperature using an Artificial Neural Network (ANN) model in a finite element formulation. The VUHARD subroutine is used to apply this formulation in the finite element software.

Users ask these questions

In social media, users asked questions regarding Abaqus UHARD issues, and we answered a few of them; you can see them below.

I. Unable to extract X,Y,Z coordinates from abaqus subroutine explicit analysis?

Q: I am currently working on the project of single-point incremental forming by using Abaqus explicit analysis. for given path to the tool i have used subrutine. I have successfully run the simulation and generated results. In my simulation magnet is rotating. I want to generate the path of Magnet in the form of X, Y, and Z Coordinates so that I can implement it on CNC machines. If anyone have idea about how to extract coordinates from analysis or from the subrutines please share with me. Thank you.

A: Hi, I don’t know how did you do your simulation. I mean, did you use a function to give your tool a path to do the forming process? Or used displacement and amplitudes to give a path to your tool? If you used a function to do the simulation, you just need to give this function to software like MATLAB to plot the X, Y, and Z coordinates against time. Then, use this data for the CNC machine. Also, you can check this link. An incremental forming simulation is presented with full details: UHARD Subroutine (VUHARD Subroutine) in ABAQUSBest luck.

Reviews

There are no reviews yet