Optimization of Composite Pressure Vessel with Semi-Geodesic winding using scripting

Customer project carried out by CAE Assistant team

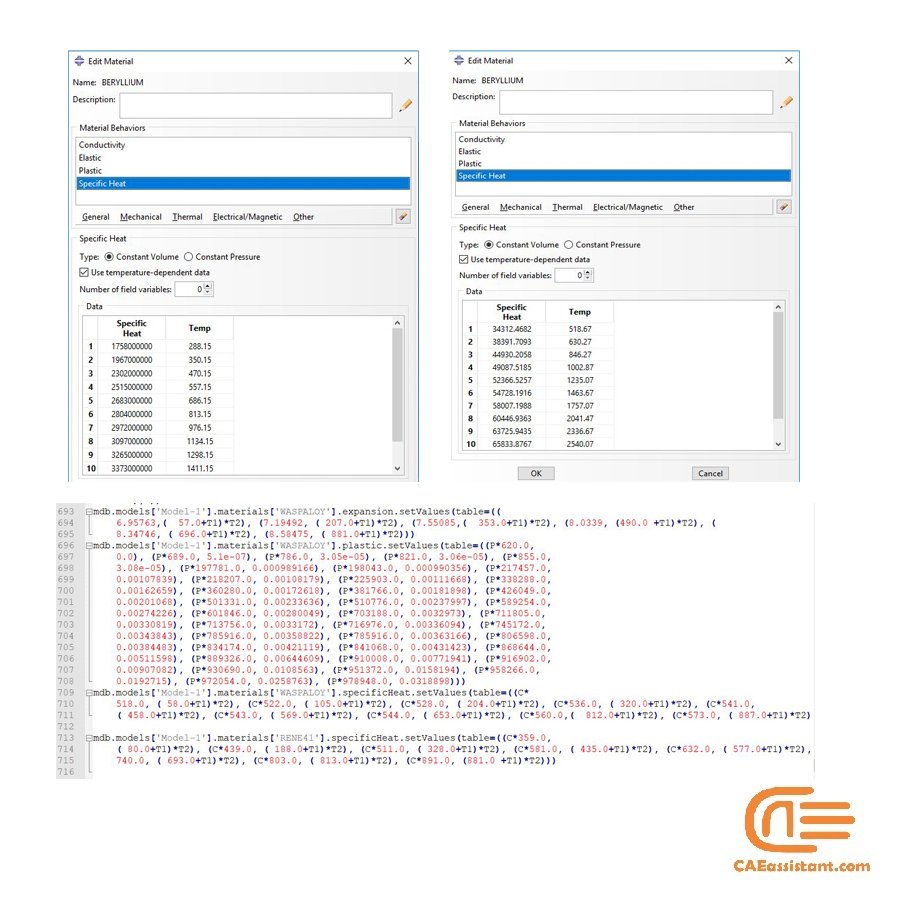

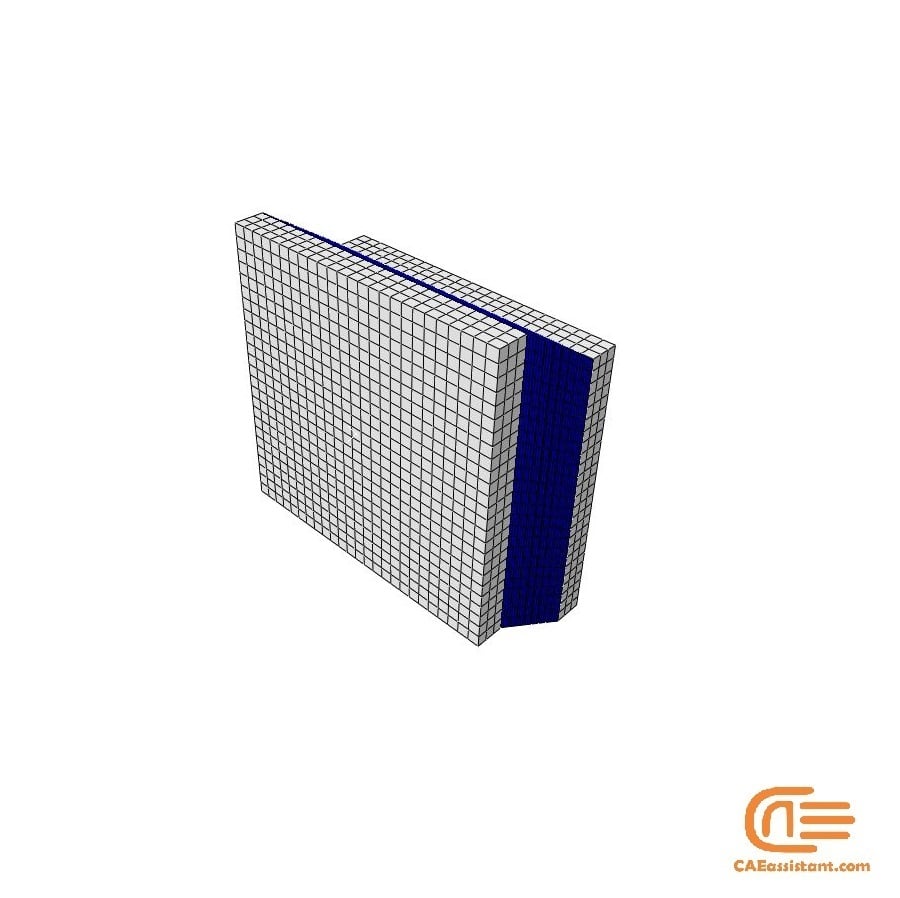

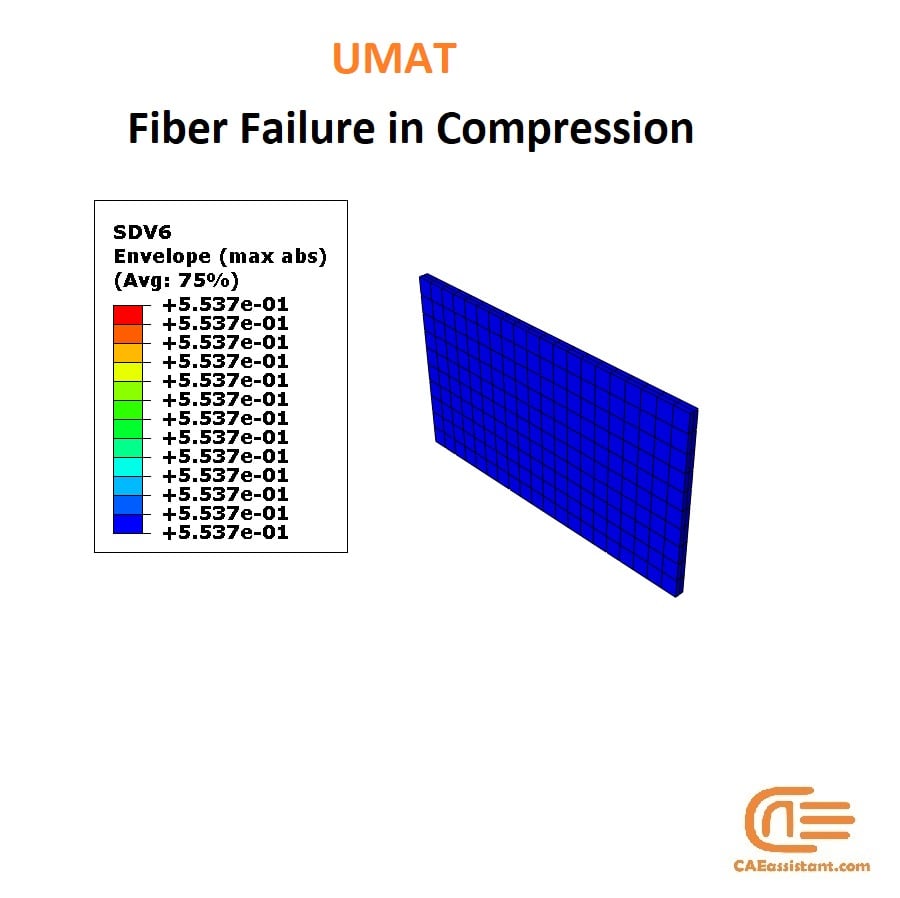

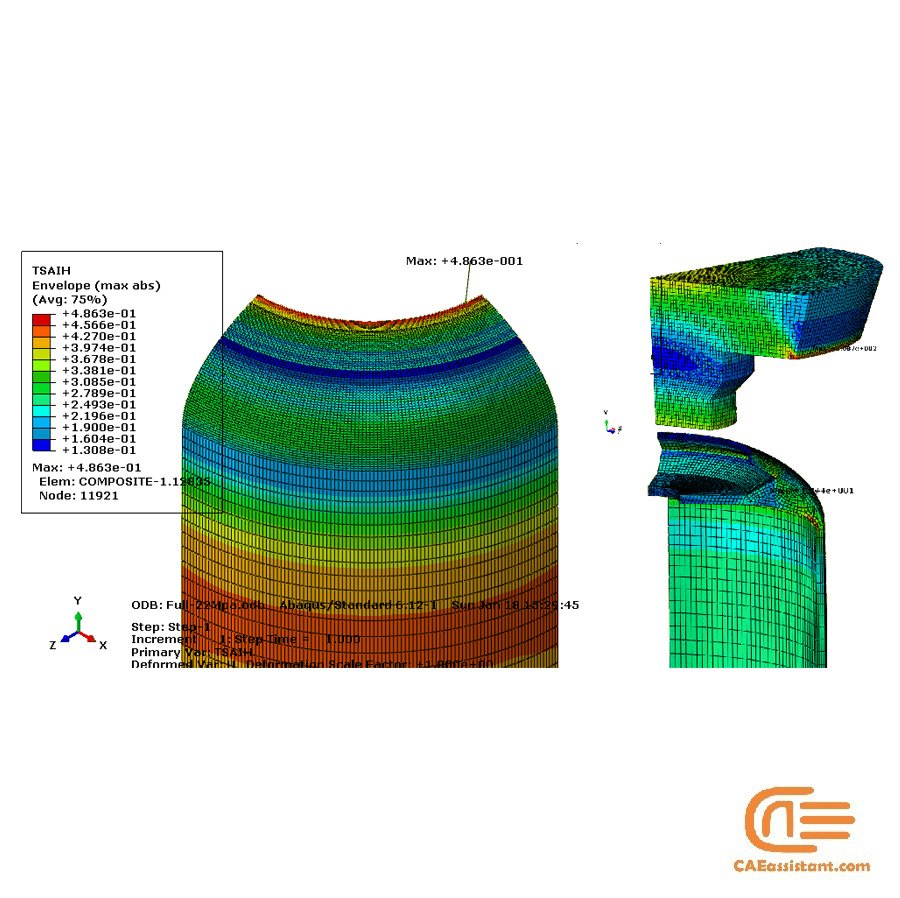

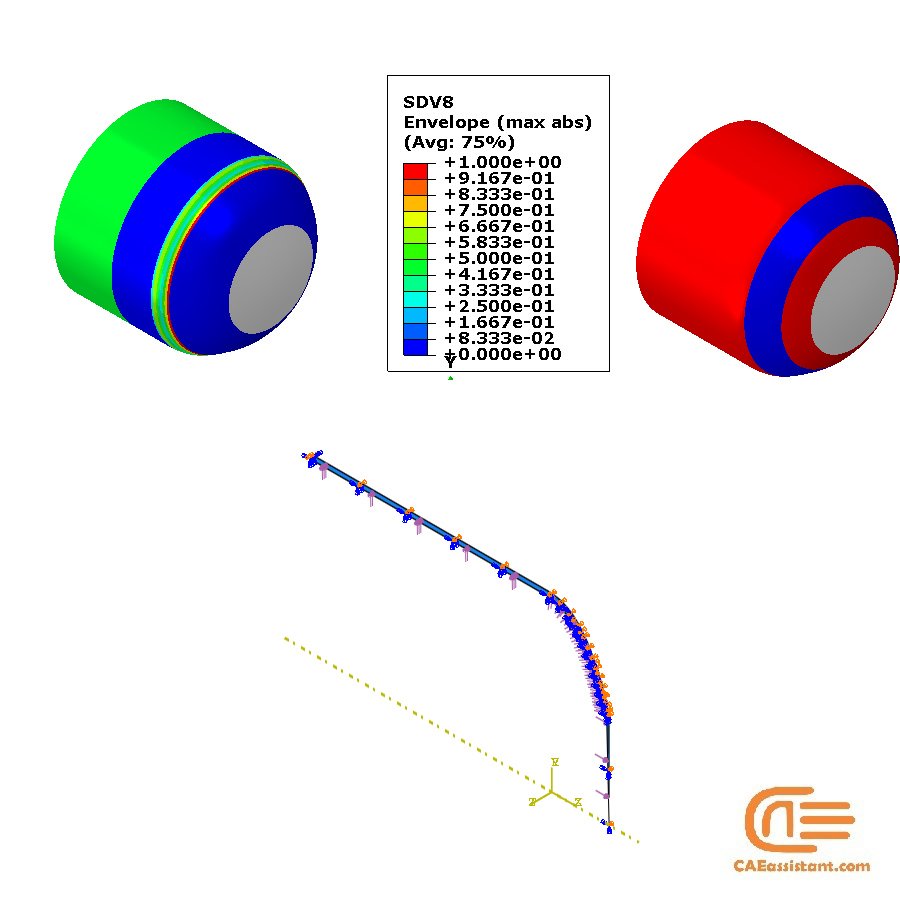

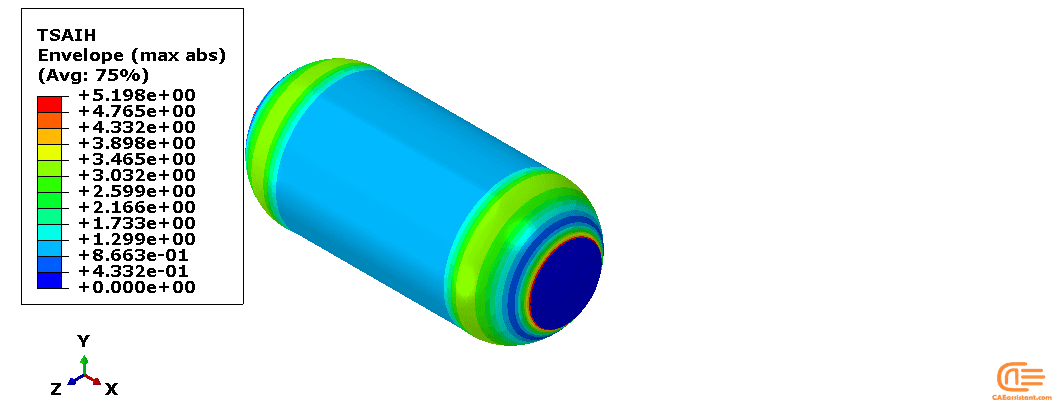

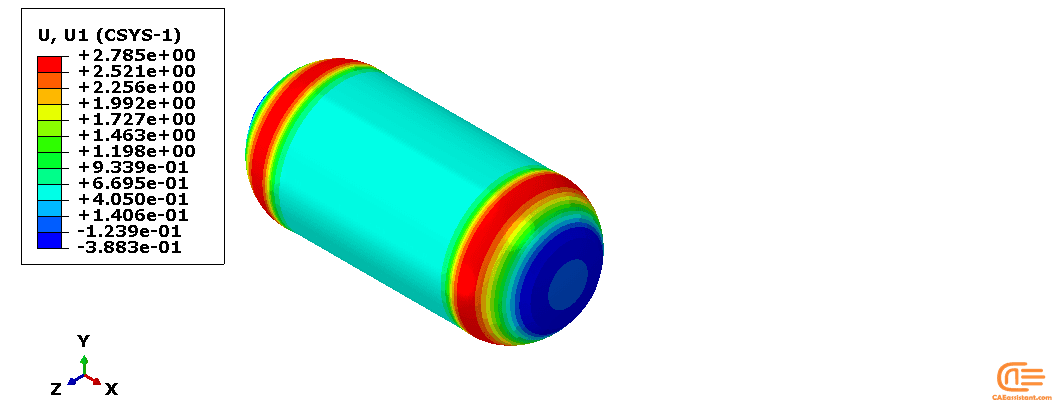

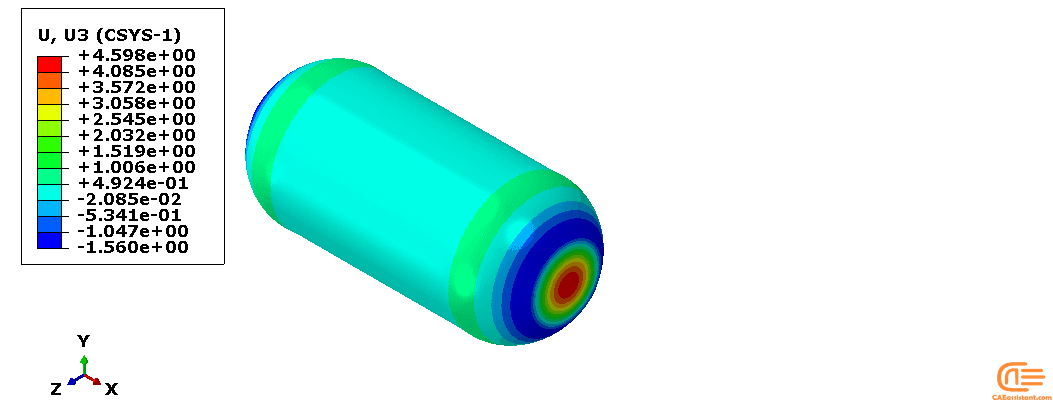

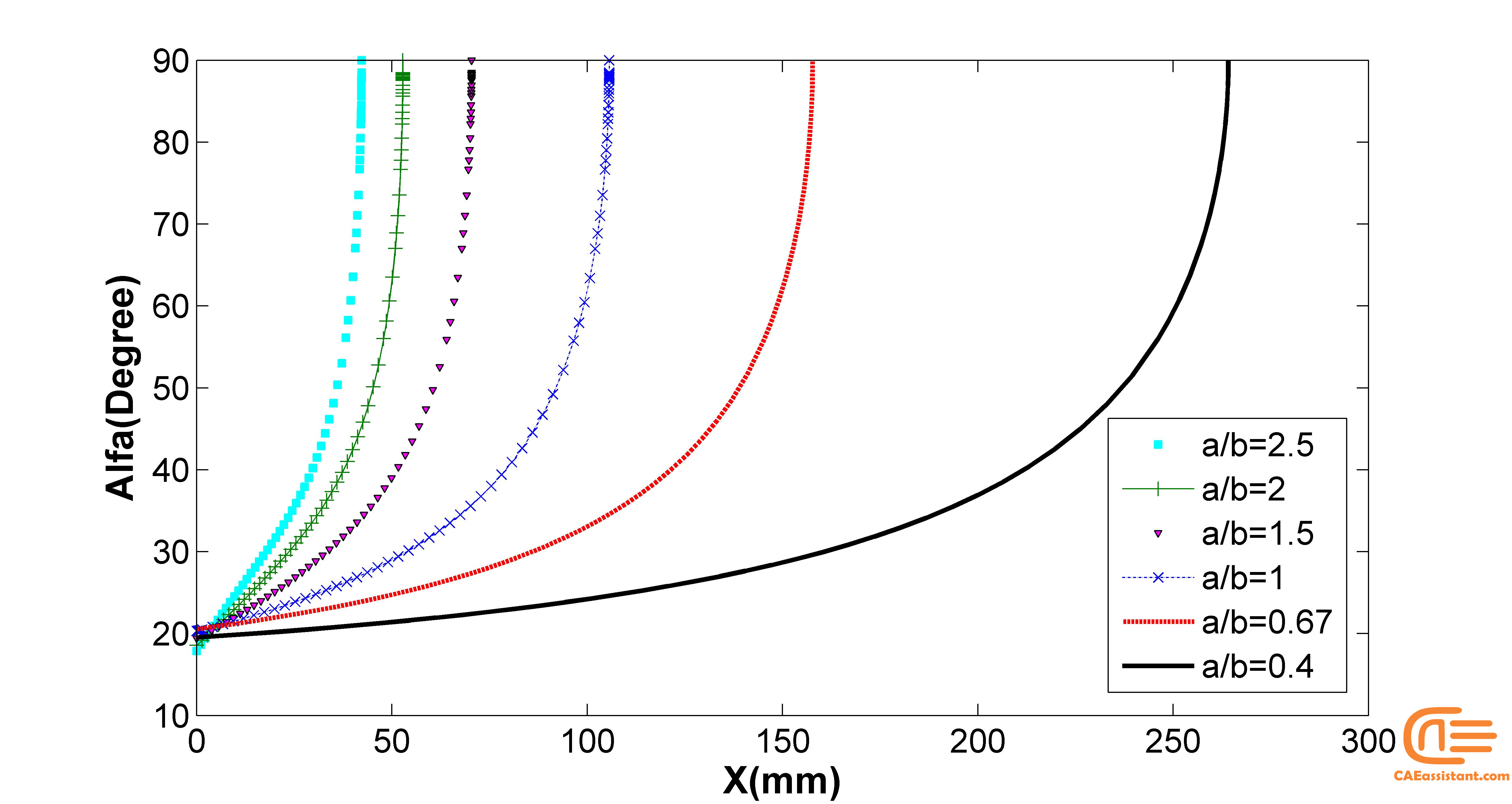

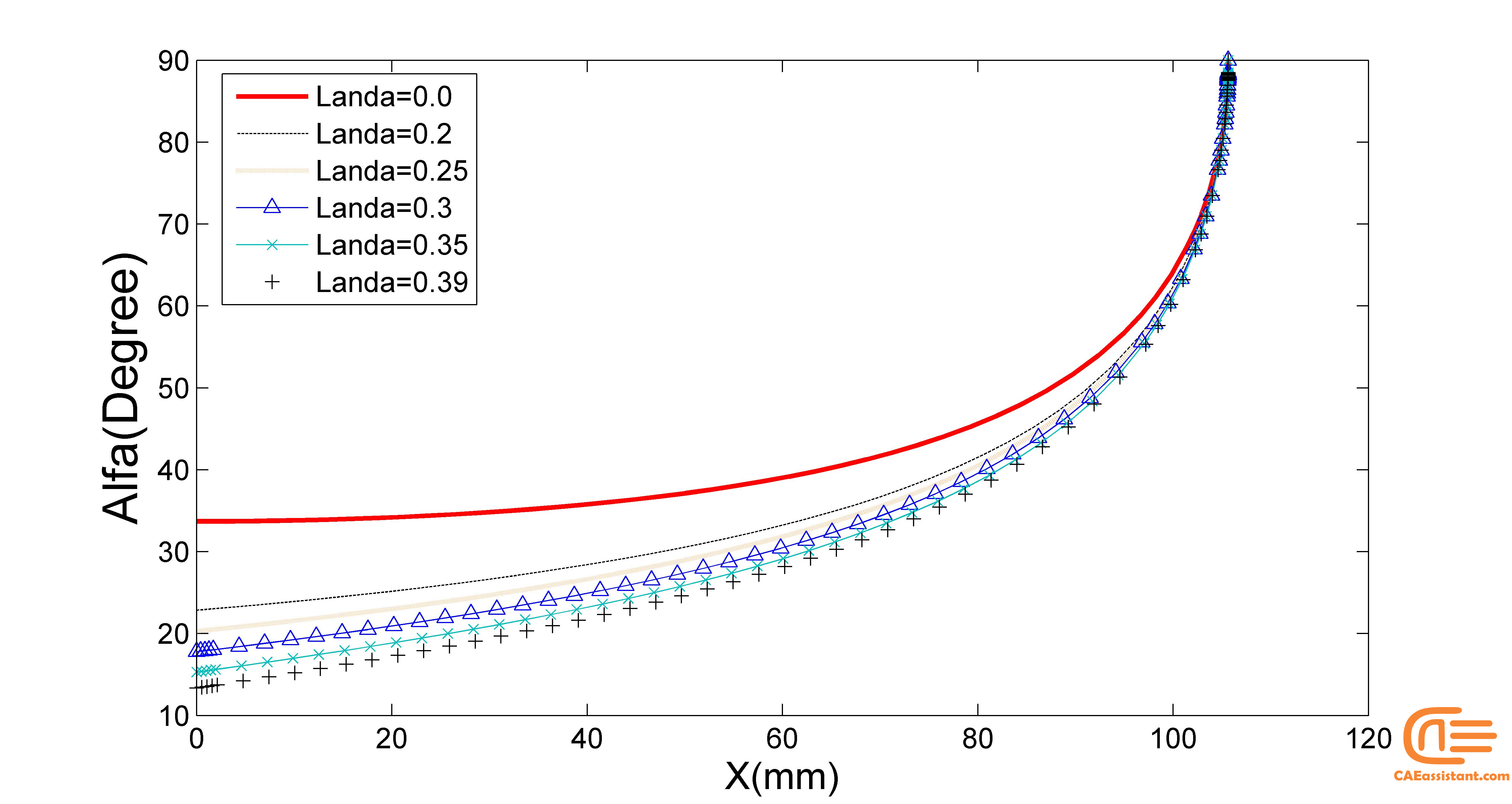

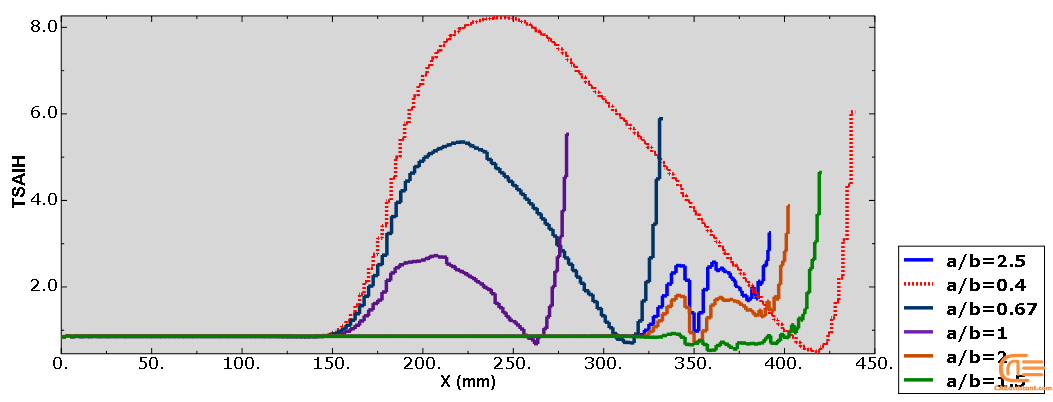

In Optimization of Composite Pressure Vessel with Semi-Geodesic winding using scripting , the Composite Pressure Vessel wounded by Semi-geodetic method is optimized. As you know, in dome region of composite pressure vessels, the thickness and angle windingt in the dome area changes. In the semi-geodetic method, which is one of the common methods in CPV winding, there is friction between fiber and mandrel, and the fibers are laid on the mandrel in such a way that this friction is greater than their slip. Due to the need for high accuracy and also with the aim of optimizing and automating modeling in layup simulation due to changes in angle and thickness in the dome area, Python scripting has been used.

Two main tutorial packages for CPVs:

Composite pressure vessel analysis with Semi-Geodesic winding

Keywords: Static, Composite, ABAQUS, Composite Pressure Vessel, CPV, Scripting, Optimimisation,Shell.

| Type of Model | Shell |

|---|---|

| Solving Method | Standard |

| Materials | Composite |

| Provider | CAE Assistant Team |