Fretting Fatigue Failure Simulation with Scripting in Abaqus

€ 290.0

This Package offers a comprehensive tutorial on using Abaqus for Fretting Fatigue Failure Simulation. To do so, it combines theoretical knowledge with practical application in Finite Element Method (FEM) simulations. The package guides users through both detailed lessons and interactive workshops. In fact, it focuses on developing 2D Fretting-Fatigue models in Abaqus with three core areas: model creation with exclusively designed meshing methodologies, the development of custom Field Outputs for detailed analysis, and automated parameter selection and post-processing through Python scripting.

Throughout the tutorial, participants master critical aspects of Fretting Fatigue Failure simulation. It includes basics from mesh refinement techniques and step control optimization to complete workflow automation. The program distinctively integrates command prompt operations for extracting Field Outputs and modifying simulation parameters. For example, we can refer to the Coefficient of Friction (CoF). Users gain practical experience in creating robust models while understanding the fundamental principles of the Fretting Fatigue Failure phenomenon.

Upon completion, participants will acquire the skills to independently develop and analyze Fretting Fatigue failure simulations. Moreover, they can automate post-processing tasks, and implement custom analysis parameters for precise fatigue prediction in mechanical systems.

| Expert | |

|---|---|

| Package Content |

.inp ,.py ,video file |

| Tutorial video duration |

98 minutes |

| language |

English |

| Level | |

| Package Type | |

| Software version |

Applicable to all versions |

| Subtitle |

English |

Introduction to Fretting Fatigue Failure

Finite Element Method (FEM) simulations are indispensable for understanding and predicting fatigue behavior in mechanical systems. This tutorial package, on Fretting Fatigue failure Simulation, equips researchers and engineers with tools to model, analyze, and automate simulations of Fretting Fatigue failure phenomena. By combining step-by-step guidance with theoretical insights, the package bridges the gap between academic knowledge and practical application.

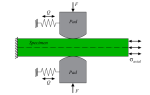

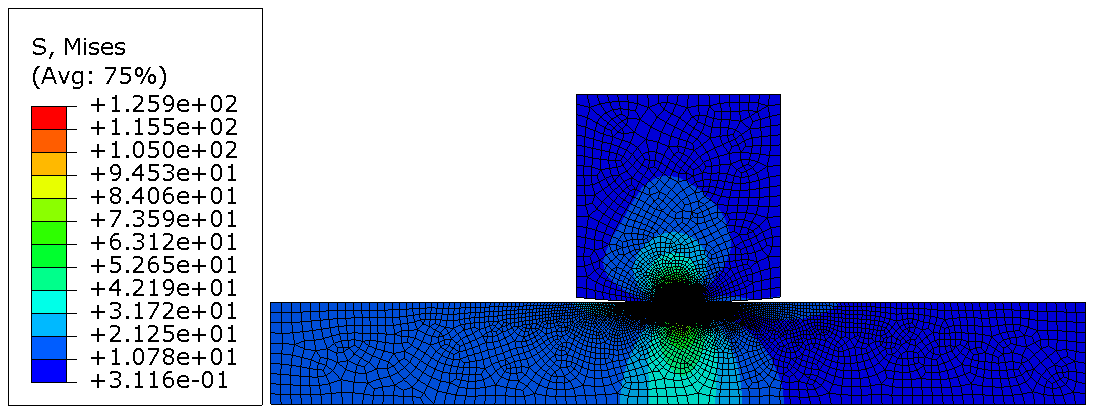

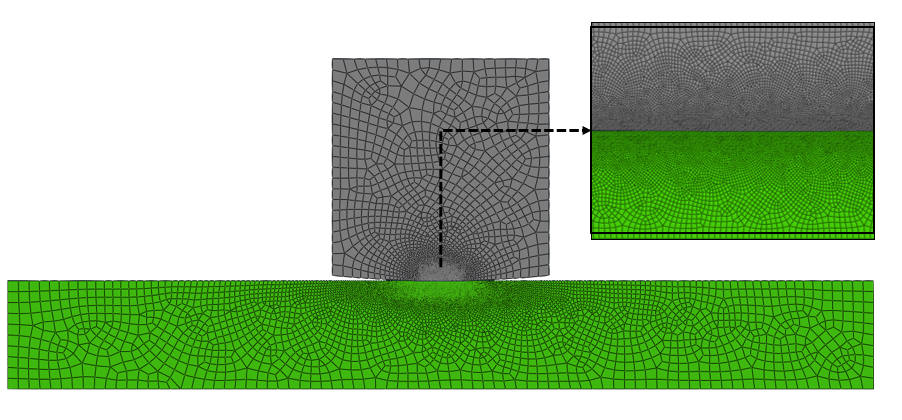

The main objective is to develop a 2D Fretting Fatigue configuration in Abaqus, focusing on creating models, refining mesh methodologies, and obtaining accurate contact stress data. A unique feature of this package is its emphasis on the use of the command prompt for automating post-processing tasks. You can use this tool to extract Field Outputs and create custom Field Output parameters based on simulation results. Additionally, users will learn automation techniques to modify key simulation parameters, such as the Coefficient of Friction (CoF), submit different simulation scenarios, and extract Output data from every simulation.

FEM is an indispensable complement for Fretting Fatigue since it is a robust tool for solving complex engineering problems involving stress, strain, and fatigue. On the other hand, Fretting Fatigue Failure is a phenomenon developed from small oscillatory movements between contacting surfaces. It creates a unique challenge in predicting crack nucleation. This package emphasizes understanding this challenge and applying advanced FEM techniques to address them. This makes it a valuable resource for anyone working in materials science, mechanical design, or structural integrity analysis.

Lesson 1: Package Overview

The first lesson introduces the Fretting Fatigue Failure Simulation Package and provides a foundation for the topics developed in posterior lessons and workshops. It covers key concepts such as the Fretting phenomenon, its causes, failure modes, its impact on engineering components, and the available techniques to predict crack nucleation on the components. The roadmap of the simulation workflow guides users through geometry and material definition, loading steps and boundary condition setup, meshing techniques, and various methods to automate simulation parameters and results extraction using Python scripting. This overview prepares users to explore the theoretical and practical aspects in the following sections.

Lesson 2: Fretting Fatigue Failure Phenomenon

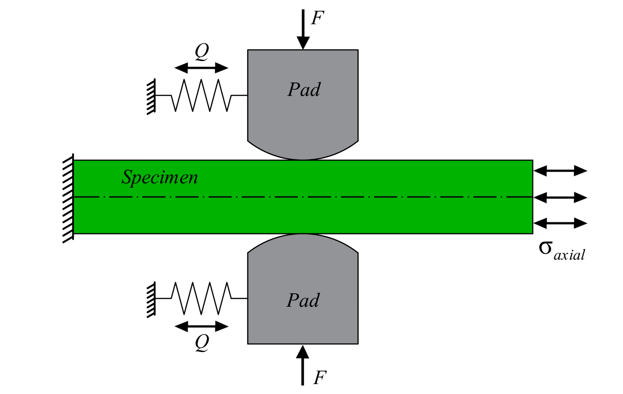

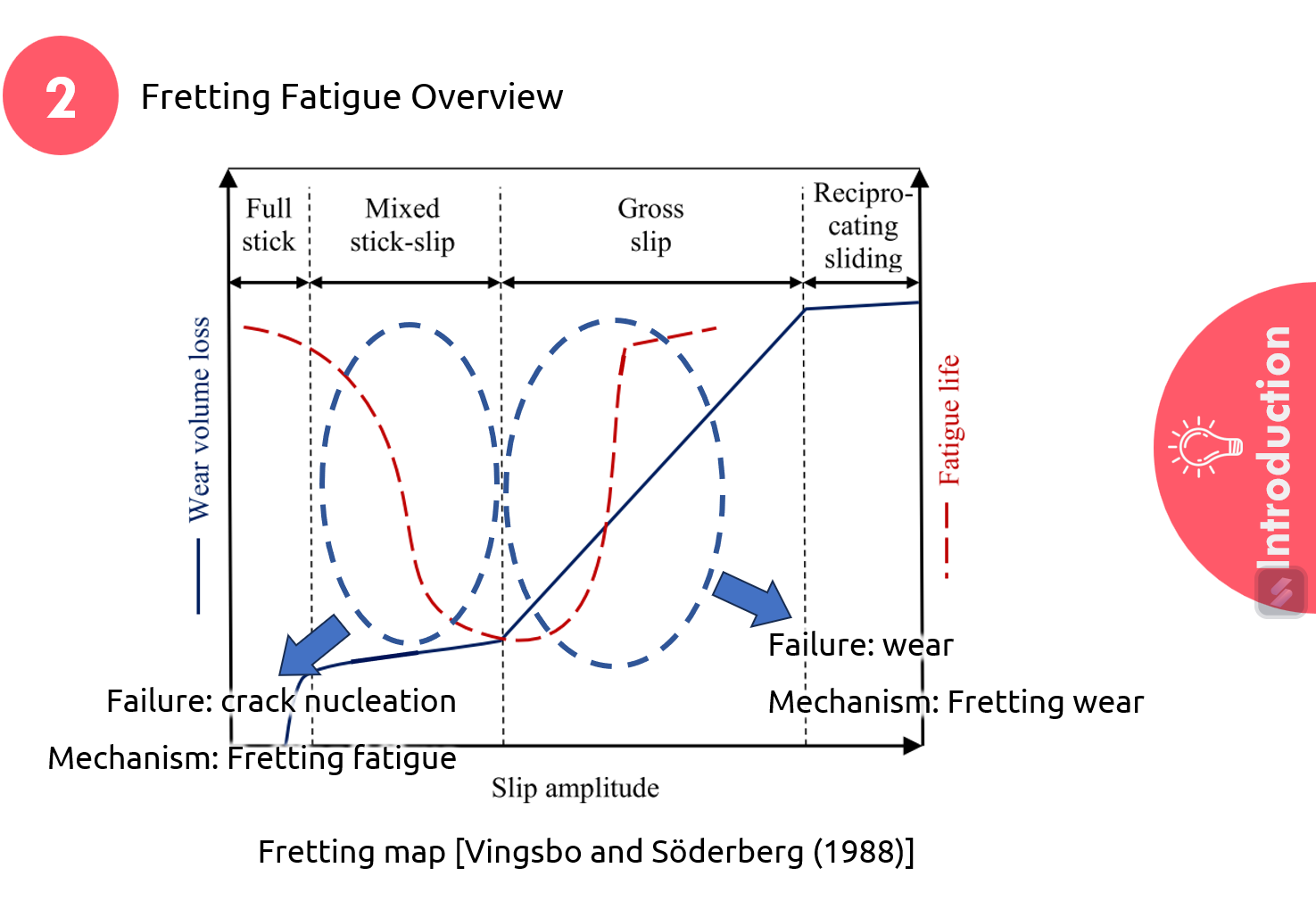

The second lesson deepens into the fundamentals of Fretting Fatigue failure and its implications for mechanical components. We analyze the phenomenon of fretting in detail, examining the conditions under which it occurs and its associated failure mechanisms. For instance, we commonly observe fretting in aerospace components, where cyclic loading and micromovements degrade contact surfaces.

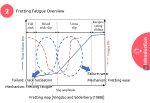

Key parameters influencing Fretting Fatigue failure severity, such as contact pressure, slip amplitude, and the Coefficient of Friction are thoroughly discussed. Real world examples, like the failure of dovetail joints in turbine blades, illustrate these principles.

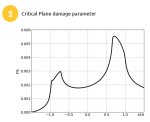

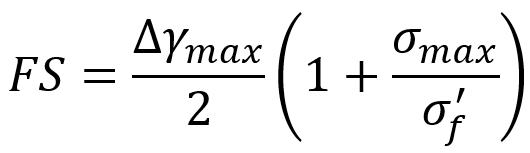

Additionally, we will provide students with an exploration of the different methods and parameters used to predict Fretting Fatigue crack nucleation. We introduce users to Critical Plane (CP) parameters, emphasizing their unique characteristics that make them indispensable in Fretting Fatigue Failure analysis. We explain the diverse types of CP parameters and their applications in predicting crack nucleation.

- What do we learn from this package?

- What tools we need for developing the course

- What is Fretting?

- Important Fretting parameters

- How to predict crack nucleation lifetime

- Different Critical Plane parameters for Fretting Fatigue cases

- Create the geometry and materials

- Configure loading steps

- Define boundary conditions

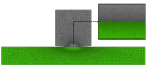

- Evaluate different meshing techniques on the components

- Set contact conditions

- Extract contact stresses and evaluate theoretical results

- Create custom Field Outputs

- Automate the modification of simulation parameters

- Submit simulations and wait for completion

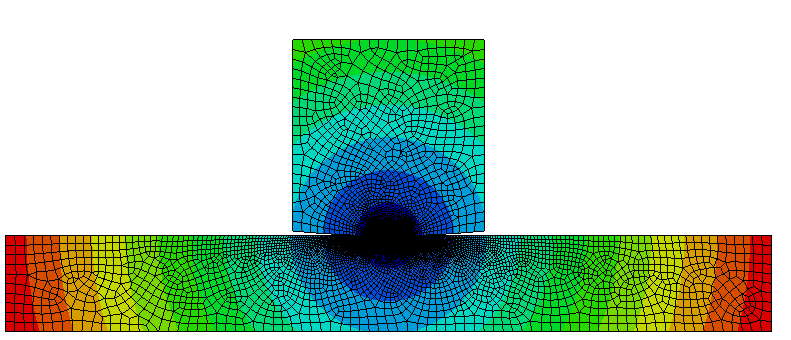

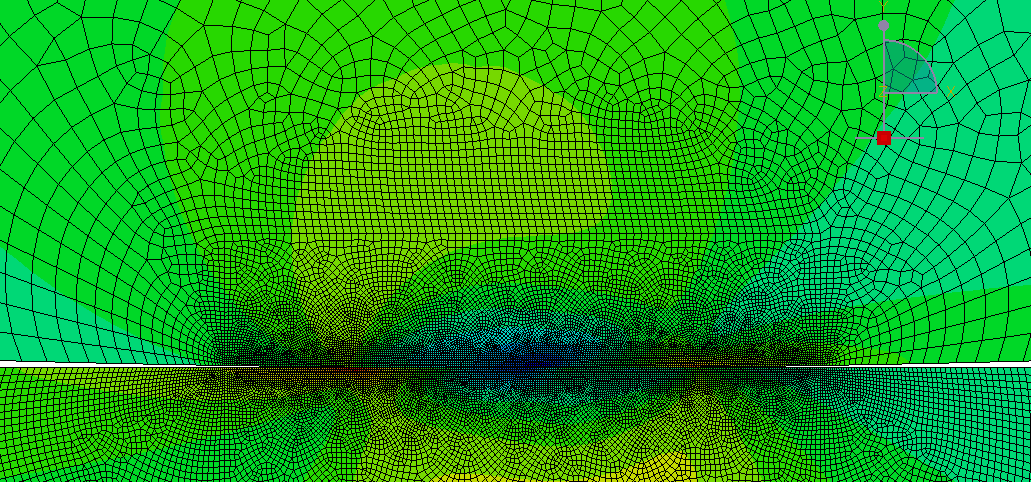

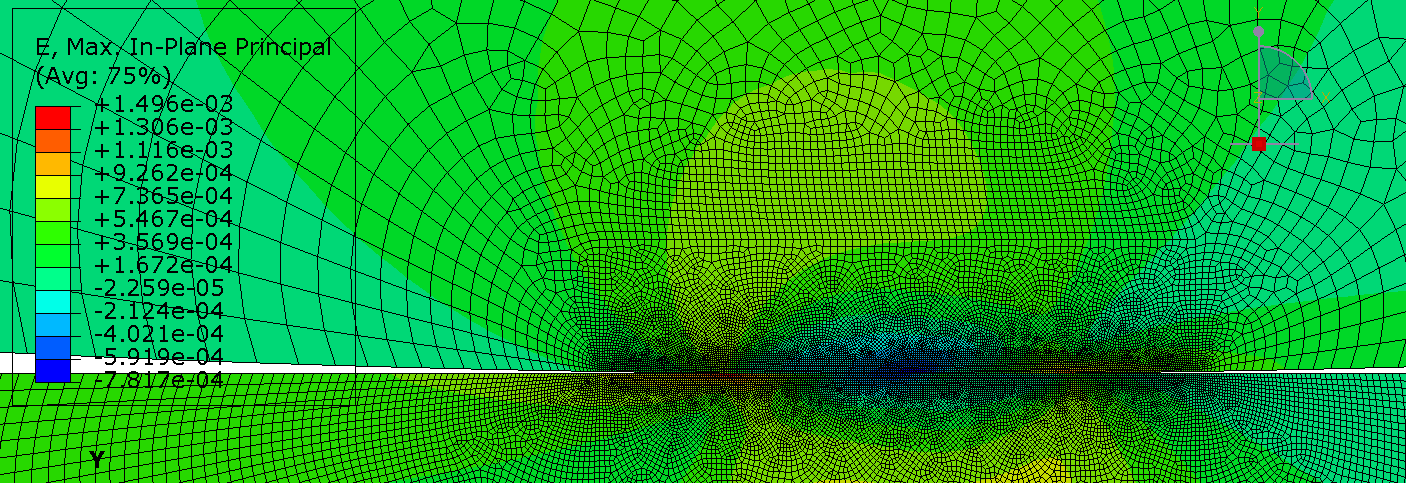

Workshop | Part 1: Building the FEM Model and Mesh Methodologies

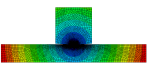

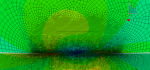

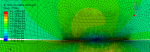

The first part of the workshop provides direct experience in setting up a Fretting Fatigue Failure simulation in Abaqus. Users will learn how to define the geometry and materials for Fretting components, as well as how to define the boundary conditions to accurately simulate Fretting conditions. We place special attention on defining loading steps and contact conditions, ensuring appropriate increments and parameters for accurate convergence. Additionally, we explore mesh strategies in detail, including mesh refinement techniques specific to Fretting problems. Participants will learn to define areas for finer meshing and compare the effectiveness of three different meshing approaches under varying conditions. Manual and automated methods for post-processing stress data are demonstrated, enabling participants to extract and analyze critical parameters efficiently.

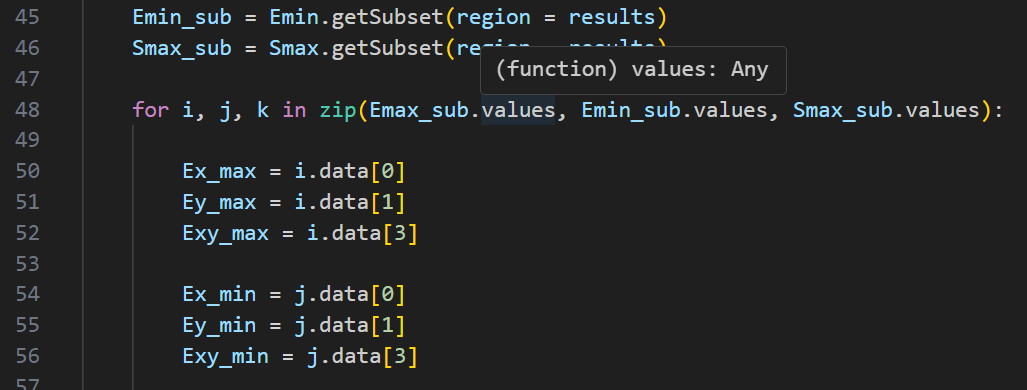

Workshop | Part 2: Custom Field Outputs and Automation

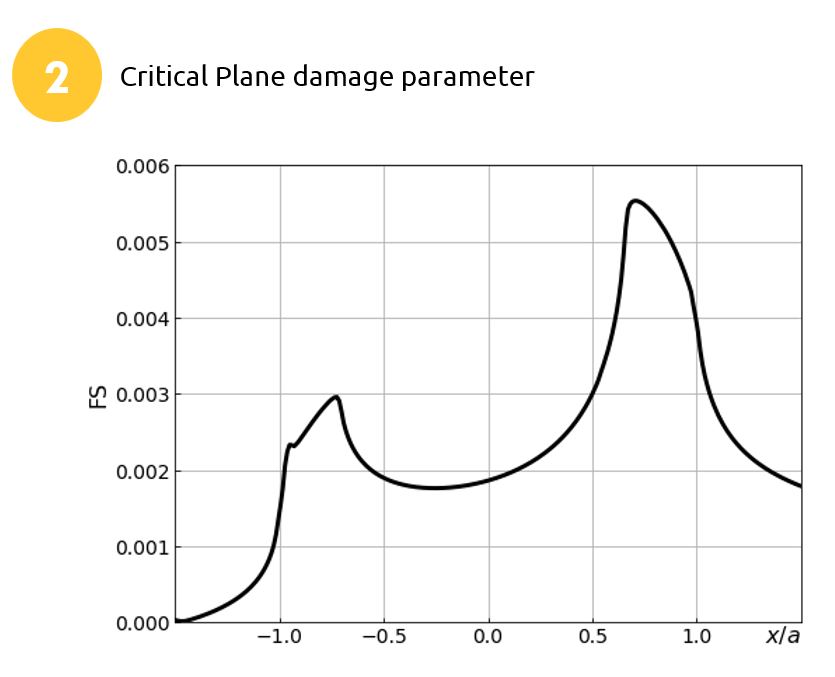

The second part of the workshop focuses on using Python to enhance analysis capabilities and automate workflows. Participants will create custom Field Outputs designed to specific analysis needs, such as CP damage parameters. Each line of the Python script is explained, ensuring users can customize the code for other parameters or component’s regions. During this part, we will explain how to obtain the values of the Fatemi-Socie Parameter (FS), a CP damage parameter, in the contact zone.

Fatemi-Socie Parameter:

Each of these parameters is explained during Lesson 2.

Finally, three Python automation techniques for simulation workflows are also covered. Participants will learn to modify simulation parameters, such as the Coefficient of Friction, automate the submission of multiple simulations, and extract results. These skills simplify the simulation and results processes, enabling users to handle large datasets and complex scenarios with ease.

Expected Outcomes

By completing this tutorial package, users will:

- Master the setup and execution of 2D Fretting Fatigue simulations in Abaqus.

- Understand the theoretical principles of Fretting Fatigue and CP parameters.

- Create and apply custom Field Outputs to analyze simulation results effectively.

- Automate simulation processes, including parameter variation and simulation submissions.

These skills are invaluable for researchers and engineers aiming to predict Fretting Fatigue behavior with precision and efficiency.

Why Choose the Fretting Fatigue Simulation Package?

The Fretting Fatigue Failure Simulation Package is more than a tutorial. It is a comprehensive guide that integrates theoretical knowledge with practical tools. By mastering FEM simulations, automating processes, and developing custom analysis parameters, users will gain a competitive edge in addressing complex engineering challenges. Whether you aim to explore the intricacies of fretting fatigue or advance your automation skills in Abaqus, this package is your comprehensive guide to success. Moreover, the project will guide you to a great extent through the finite element modeling of Fretting fatigue, as presented in the following paper:

Fretting fatigue crack nucleation analysis under a variable coefficient of friction

All the package includes Quality assurance of training packages. According to this guarantee, you will be given another package if you are not satisfied with the training, or your money is returned. Get more information in terms and conditions of the CAE Assistant.

All packages include lifelong support, 24/7 support, and updates will always be sent to you when the package is updated with a one-time purchase. Get more information in terms and conditions of the CAE Assistant.

Notice: If you have any question or problem you can contact us.

Ways to contact us: WhatsApp/Online Support/[email protected]/ contact form.

Projects: Need help with your project? You can get free consultation from us here.

- Online payment: with MasterCard, VisaCard and etc.

- Offline payment: In this payment method, you should pay via PayPal and send your payment receipt as an attached file in the offline payment form.

- via download link After purchase, a download link will be sent to you a zip file included training videos, documents and software files.

- Send us your machine ID

To access tutorial video run the .exe file on your personal pc and send the generated code to [email protected] and wait for your personal code, which is usable only for that pc, up to 24 hours from CAE Assistant support.

Here you can see the purchase process of packages: Track Order

None

None

You must be logged in to post a review.

Reviews

Clear filtersThere are no reviews yet.