1- Introduction| Abaqus Gurson-Tvergaard-Needleman (GTN) damage model Simulation

The GTN damage model, developed by Gurson-Tvergaard-Needleman, is a continuum damage model used to simulate ductile fracture in materials. It considers a damaged material as a continuous medium and includes a constitutive equation with a damage parameter called porosity. The porosity parameter ranges from zero for undamaged material to one for completely damaged material.

The GTN damage model offers several benefits over other models, such as:

- Comprehensive Fracture Analysis: The GTN model can record different stages of ductile fracture, including nucleation, growth, and coalescence of microvoids, providing a detailed understanding of the fracture process.

- Accurate Damage Prediction: By incorporating the porosity parameter and hydrostatic stress, the model can accurately predict the growth and expansion of cracks in materials.

- Versatility: You can apply the model to isotropic materials and use it to simulate various loading conditions, making it versatile for different types of materials and scenarios.

- Enhanced Simulation Capabilities: The GTN model allows for the simulation of the elastic-plastic-damage region, providing a more comprehensive analysis of material behavior under stress.

- User Subroutine Integration: Users can implement the model in numerical simulations using user subroutines like VUMAT, enabling custom material behavior definitions and advanced analysis.

What are the applications of the GTN damage model?

According to the mentioned benefits, the GTN model has found many applications in engineering fields. For example, we can refer to the following instance.

- Material Design and Testing (Especially Tensile Test): Engineers use the GTN model to design and test new materials, particularly those that need to withstand high stress and strain conditions.

- Failure Analysis: Engineers use the model to predict and analyze the failure of materials in various applications, such as aerospace, automotive, and civil engineering.

- Structural Integrity Assessment: The model helps in assessing the structural integrity of components and structures, ensuring they meet safety and performance standards.

- Research and Development: It is widely used in R&D to study the fundamental mechanisms of ductile fracture and to develop new materials with improved properties.

- Simulation of Manufacturing Processes: The GTN model can simulate manufacturing processes that involve significant deformation, such as metal forming and machining, to predict and mitigate potential defects.

Why is numerical simulation of the GTN damage model important?

The GTN damage model is a powerful tool for understanding and predicting material behavior, leading to safer and more efficient designs in various engineering applications. Note that, numerical simulations are powerful tools to implement GTN model for different applications. So, the GTN model is widely used in numerical modeling to predict the behavior of materials under various loading conditions, particularly in the context of ductile fracture (GTN model Abaqus).

Using the GTN damage model in numerical simulations comes with several challenges. The first challenge is that the implementation of GTN model requires a good understanding of finite element analysis (FEA) and proficiency in programming languages like Fortran, as well as the ability to link these with simulation software like Abaqus. Moreover, detailed nature of the GTN model, which includes tracking the nucleation, growth, and coalescence of microvoids, can lead to high computational costs. This can be particularly challenging for large-scale simulations or simulations requiring high resolution. Accurately calibrating the model parameters, such as the porosity parameter and other material-specific constants, can be difficult and often requires extensive experimental data.

In conclusion, effectively using the GTN model Abaqus requires a high level of expertise in material mechanics, numerical methods, and the specific simulation tools being used. This can be a barrier for new users or those without a strong background in these areas.

Is Abaqus applicable for simulating the GTN damage model?

Abaqus is a powerful tool that helps us to implement the Gurson-Tvergaard-Needleman damage model. However, despite the software’s capabilities, simulating the GTN model in Abaqus is challenging. This is because Abaqus itself does not have the GTN model in its material library. Therefore, we need to implement Abaqus subroutines to define the model. A subroutine that helps users write their own material models in Abaqus is VUMAT, which is provided for explicit solvers. Thus, we have used this subroutine in the tutorial to define the GTN damage model in Abaqus. Despite this challenge, Abaqus remains a powerful tool for simulating the GTN model. It offers advanced capabilities for detailed and accurate analysis of ductile fracture and material behavior.

How to simulate the GTN damage model with VUMAT subroutine?

VUMAT allows users to define the mechanical constitutive behavior of materials, which is essential for implementing the desired damage models. This includes specifying how the material responds to stress, strain, and damage evolution. VUMAT can handle solution-dependent state variables. They are crucial for tracking the evolution of damage and other internal variables in the GTN model. Moreover, VUMAT can use field variables to account for spatial variations in material properties or environmental conditions. So, it helps us to enhance the accuracy of the Gurson-Tvergaard-Needleman model.

Despite these benefits, using the subroutine to implement the GTN model in Abaqus is a challenging task. It may be due to different aspects. For example, VUMAT is written in Fortran, so proficiency in Fortran programming is required. Moreover, the material properties used in the GTN model need to be defined and imported into the VUMAT subroutine. On the other hand, GTN model involves complex mathematical formulations for damage evolution and plasticity. You need to accurately implement these in the VUMAT subroutine.

To help you overcome these challenges, we have provided a step-by-step guide on writing the subroutine in this project. We hope you find it helpful.

2 – Finite Element Modeling of GTN Damage (PDF File) | GTN Model Abaqus

The GTN damage model (GTN Model Abaqus) captures the different stages of ductile fracture, including the nucleation, growth, and coalescence of microvoids. This model allows for the analysis of various parameters influencing the damage process. Gurson-Tvergaard-Needleman original model is a continuum damage model that treats the damaged material as a continuous medium, incorporating a damage parameter called porosity f, which ranges from zero (undamaged) to one (completely damaged). Designed for isotropic materials, this model can effectively estimate and simulate the growth and expansion of cracks by calculating hydrostatic stress. Tvergaard and Needleman later modified Gurson’s model to address its limitation in predicting the final instability caused by microvoid coalescence at the end of the fracture process. The enhanced model can predict the nucleation, growth, and coalescence of voids more accurately.

In the PDF, we have provided an in-depth discussion of the GTN model, its formulations, and its implementation in Abaqus. To illustrate this, the VUMAT subroutine code is introduced to demonstrate how to simulate the GTN damage model (GTN model Abaqus) for predicting crack growth in a specimen under tension.

Project Scope and Objectives

This project aims to improve participants comprehension of accurately simulating crack growth using the GTN damage model with the VUMAT subroutine. We will achieve this by utilizing the VUMAT subroutine to simulate crack growth in a specimen under tension.

Prerequisites

- Fundamentals of finite element analysis (FEA)

- Basic principles of Abaqus software

- Proficiency in the Fortran programming language

- Comprehension of material properties and their impact on structural behavior

- Fundamental knowledge of mechanics of materials

Problem Description

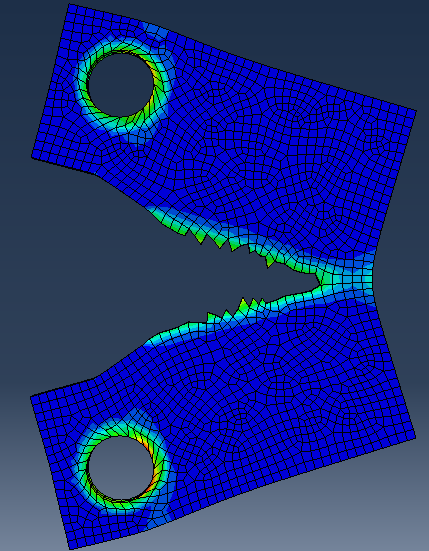

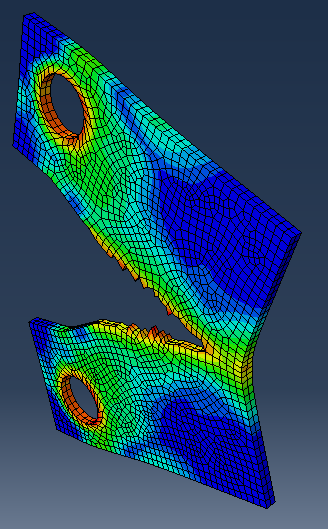

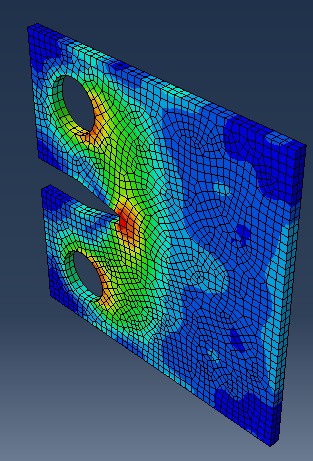

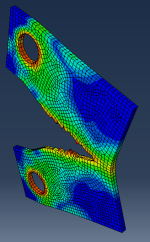

The project discusses the modeling and simulating of ductile fracture in materials using the GTN (Gurson-Tvergaard-Needleman) damage model. To do so, we include a three-dimensional analysis of ductile crack growth in a Lagrangian part subjected to tension. Where, the analysis procedure for this example is non-linear “Dynamic, Explicit”.

Overall, the project aims to enhance the understanding and predictive capabilities of the GTN damage model for simulating ductile fracture in materials.

Results

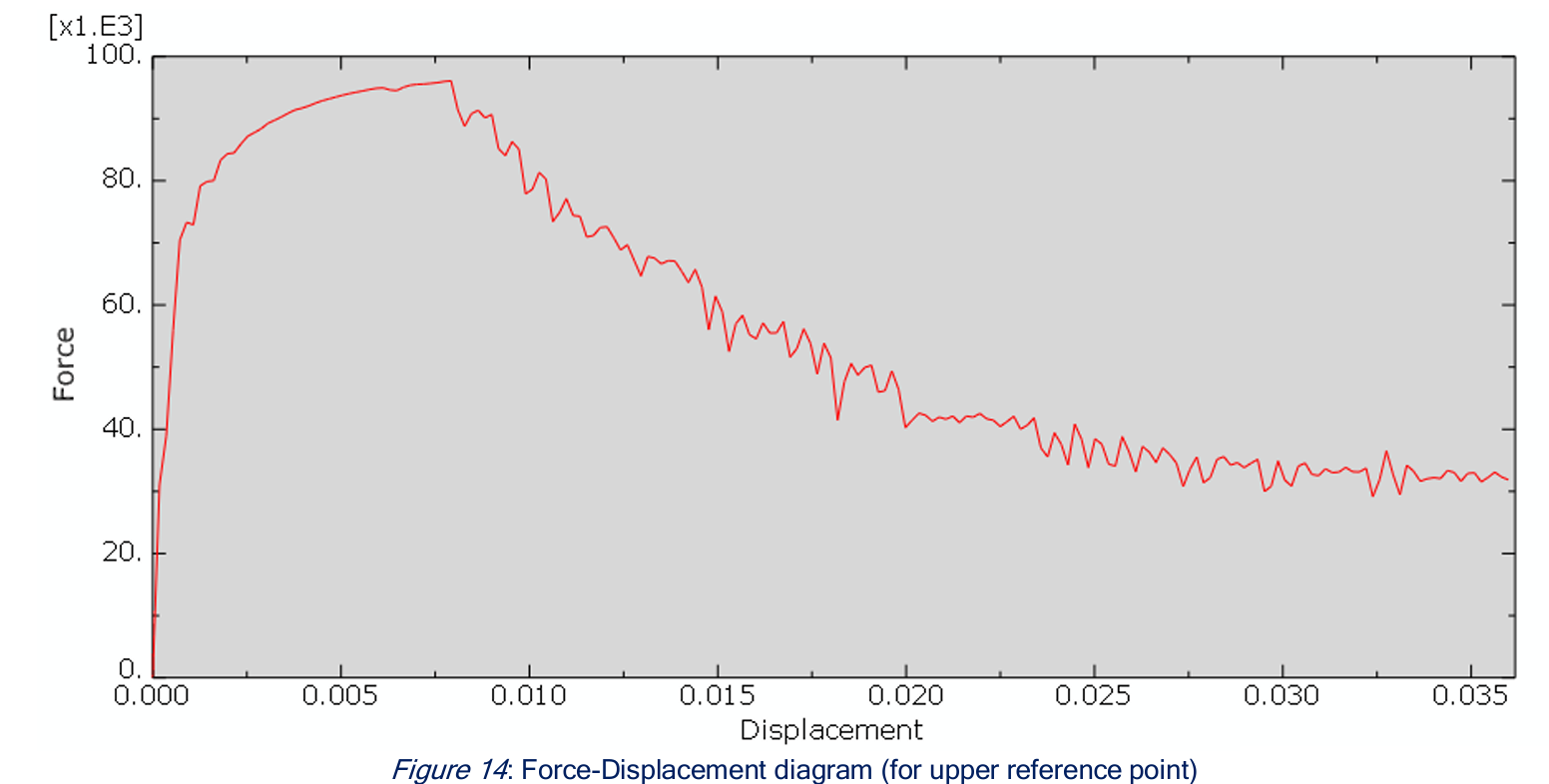

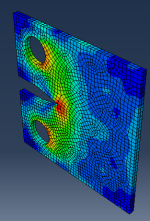

To check the model, we have explored different results in this tutorial. For example, we can refer to the stress distribution field (S), nodal temperatures distribution (), displacement distribution field (U), yield stress (

), plastic strain (

), principal strains and strain rates (

), flow potential (ϕ), the void volume fraction (f), etc. These results are extracted from the analysis to evaluate the material behavior and its performance under different conditions.

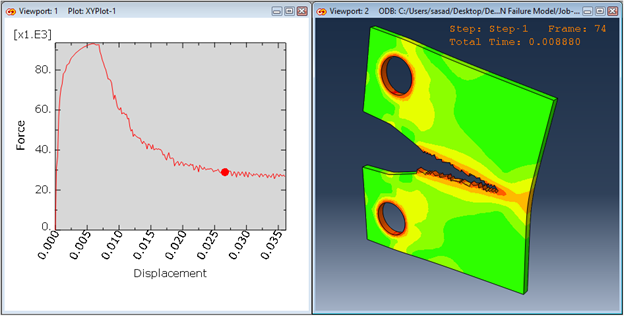

Figure 1: Force-Displacement diagram

Figure 1: Force-Displacement diagram

3- Workshop (Video file): A step-by-step guide on the simulation of the GTN damage model

The workshop offers a comprehensive, step-by-step video guide to simplify the implementation of the GTN model in Abaqus. It includes detailed instructions for simulating the steps in Abaqus, and a block-by-block explanation of the Fortran code.

Reviews

Clear filtersThere are no reviews yet.