Introduction to Glass Fracture Analysis

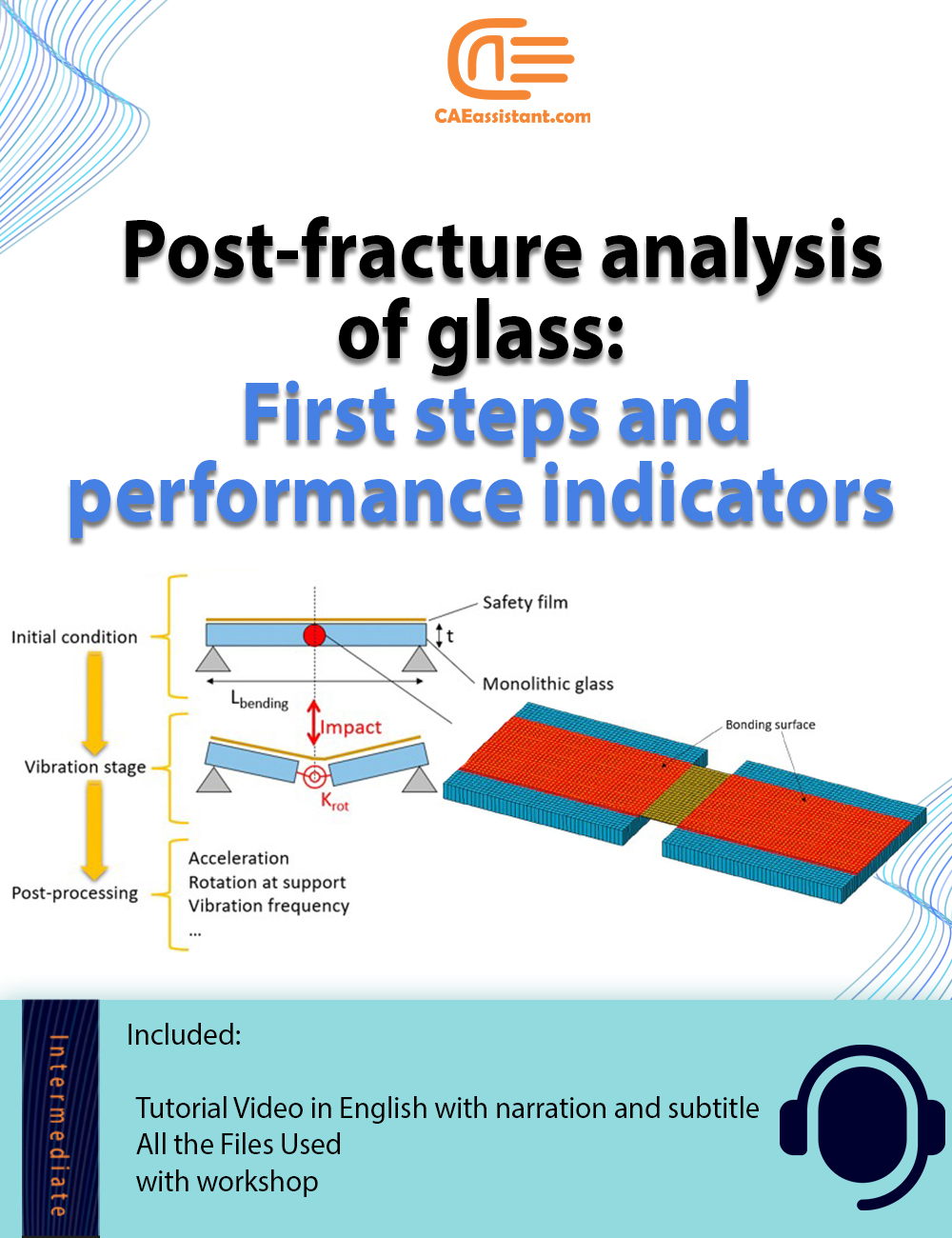

In structural engineering, glass elements are widely used for their aesthetic appeal and load-bearing capabilities. However, once fractured, glass loses much of its structural integrity, which raises concerns about its residual performance. This tutorial on glass fracture analysis, based on the research article “Effects of post-fracture repeated impacts and short-term temperature gradients on monolithic glass elements bonded by safety films,” offers a comprehensive guide to modeling the post-fracture behavior of glass elements retrofitted with safety films using Abaqus.

Abaqus is a powerful FEM software designed to handle complex simulations, making it ideal for analyzing the vibration response and residual capacity of cracked glass members. The focus is on simulating post-fracture dynamics under various operational conditions, including repeated impacts and thermal gradients. This tutorial is aimed at beginners and intermediate users who want to delve deeper into FEM simulations involving glass fracture analysis and retrofitting techniques.

Key Steps in the Simulation Methodology of Post-Fracture Analysis Glass

- Glass Modeling and Material Properties

The first step involves creating a finite element model of a monolithic glass element in Abaqus. For effective post-fracture analysis of glass (Post-Fracture Analysis Glass), the glass is modeled using linear-elastic material properties, with elastic modulus and Poisson’s ratio set according to the properties of annealed glass. For this tutorial, the key material properties for glass include:

- Elastic Modulus: 70 GPa

- Poisson’s Ratio: 0.23

- Density: 2500 kg/m³

The safety film, typically made of Polyethylene Terephthalate (PET) and Pressure Sensitive Adhesives (PSAs), is another critical component. These materials are assigned to simulate the mechanical behavior of the post-fracture system.

- Applying Boundary Conditions and Subroutines

After assigning material properties, the next step involves setting up the boundary conditions. The glass element is modeled under simply supported conditions, with repeated low-amplitude impacts applied to the cracked section. This simulates the real-world scenario where broken glass is held together by the safety film.

To better simulate the impacts, a subroutine is implemented to account for the dynamic nature of the imposed loads. The tutorial will guide you through writing and implementing the subroutine for more accurate control over the dynamic loading cycles.

- Meshing and Element Selection

Mesh generation is crucial to obtaining accurate results. For this simulation, a fine mesh is created using shell elements for the glass and brick elements for the safety film. The mesh quality is validated through a mesh convergence study, ensuring that the solution remains stable across various element sizes.

The crack propagation and post-fracture behavior are modeled using cohesive elements along the fracture path, which allow the simulation of bonding degradation in the presence of the safety film.

Analyzing Post-Fracture Behavior

- Dynamic Vibration Response of Cracked Glass

One of the primary goals of the tutorial is to analyze the vibration response of cracked glass elements retrofitted with safety films. This section focuses on the fundamental vibration frequency of the system, which serves as a key indicator of the residual load-bearing capacity.

Using dynamic identification techniques, the tutorial explains how to interpret the frequency reduction in cracked samples and what that indicates about the structural integrity of the safety film in post-fracture scenarios. This analysis is critical in understanding the broader implications of glass fracture analysis.

- Impact of Temperature Gradients

Thermal effects are significant in glass fracture analysis, especially when safety films are involved. The tutorial includes a heat transfer analysis to simulate the short-term temperature gradients (e.g., cooling the samples to 5°C or -20°C) that impact the bonding between the glass and the film.

This analysis demonstrates how temperature changes affect the bonding stiffness and the vibration frequency, highlighting the importance of considering ambient conditions in real-world applications.

- Frequency Sensitivity Analysis

A critical part of the tutorial involves conducting a frequency sensitivity analysis, where the vibration response is measured under different impact conditions and temperature variations. This step allows users to explore how factors such as crack depth and safety film properties affect the overall performance indicators.

The analysis will show how the fundamental frequency varies with film stiffness and glass thickness, providing insight into the most influential parameters in post-fracture scenarios.

Reviews

Clear filtersThere are no reviews yet.