Lesson: Pitting corrosion mechanism simulation in Abaqus

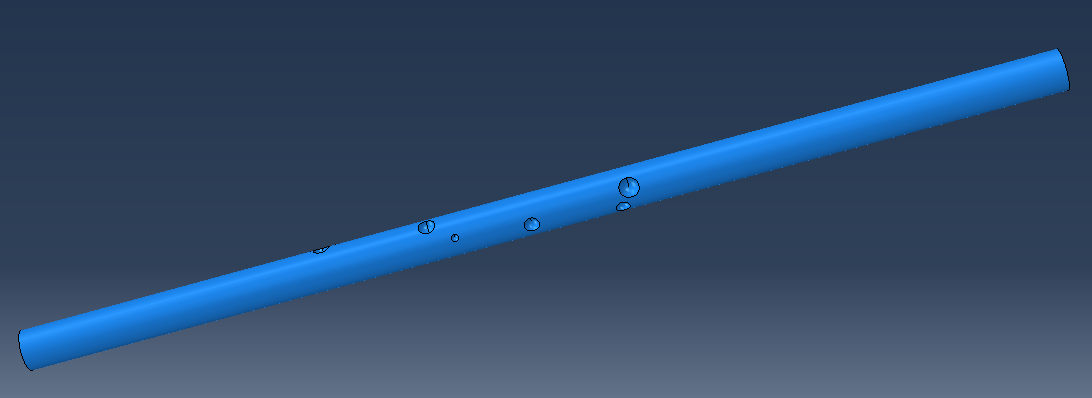

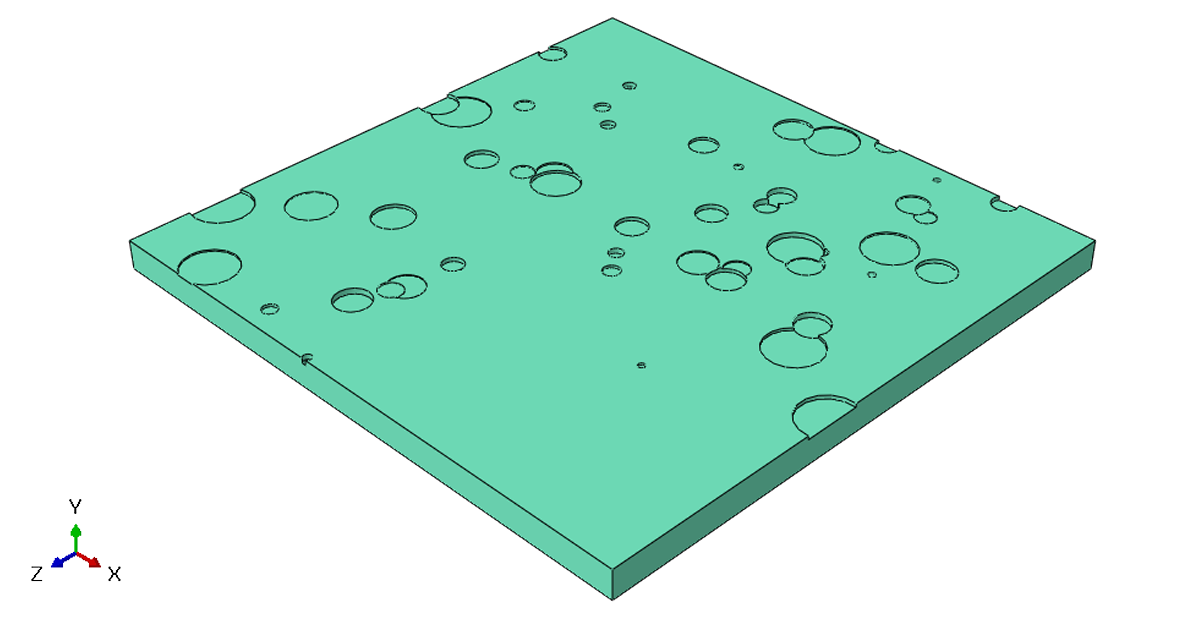

Analyzing and predicting pitting corrosion mechanism is important because it helps in detecting and diagnosing corrosion early. So, it can prevent severe damage to structures. For instance, we can predict and detect this phenomenon and enhance the durability and safety of structures such as storage tanks, shafts, tubes, pipes, and other industrial components.

Not predicting pitting corrosion correctly can have significant consequences, including:

- Reduced Fatigue Strength: this phenomenon can reduce the fatigue strength of materials, such as the Al2024 alloy, by at least 40% at 10^5 cycles.

- Formation of Fatigue Cracks: it can lead to the nucleation and propagation of fatigue cracks under sustained cyclic loading.

- Decreased Material Strength: The perforations caused by pitting result in increased stress concentrations. They reduce the strength properties of the material.

- Shortened Fatigue Life: it can reduce fatigue lives by a factor of 6-8.

- Increased Risk of Structural Failure: In critical applications like aircraft and offshore structures, failure to predict pitting corrosion can lead to unexpected structural failures due to the degradation of material strength and fatigue life.

Based on the provided details, the inability to accurately predict pitting corrosion mechanism can compromise the safety and integrity of structures and components. So, early detection allows for planning preventive maintenance. It helps us to extend the life of materials and structures, and avoiding catastrophic failures such as pipes bursting or reduced resistance to internal pressure. Predicting and analyzing pitting corrosion experimentally does come with several limitations, including:

- Complexity of Corrosion Phenomenon:

Corrosion is a highly complex phenomenon that is difficult to predict precisely due to the numerous variables involved, such as environmental conditions and material properties.

- Empirical Nature of Anti-Corrosion Measures:

Much of the anti-corrosion measures adopted in practical applications are derived from experience and empirical evidence rather than deterministic models.

- Non-Trivial Characterization:

Deterministic characterization of pitted surfaces is a non-trivial task due to the intricate physical and chemical interactions between the material and the environment.

- Variability in Pit Geometry:

The geometry of corrosion pits can vary significantly, making it challenging to create accurate and consistent experimental models.

- Limited Literature:

There is currently very limited literature regarding the systematic characterization of pitted surfaces or the efficient use of numerical methods to assess its effects. Numerical simulations play a crucial role in predicting pitting corrosion by providing reliable results that can be compared with experimental data. That is to say, these simulations help in understanding the effects of this phenomenon on various properties of materials. For example, simulations have shown that corrosion pits slightly increase transverse vibrations. By using finite element methods (FEM), numerical simulations can model the geometrical properties of corroded structures and predict how different factors, such as the amount and location of corrosion, affect the material’s behavior. This predictive capability is essential for planning maintenance and preventing failures in industrial applications.

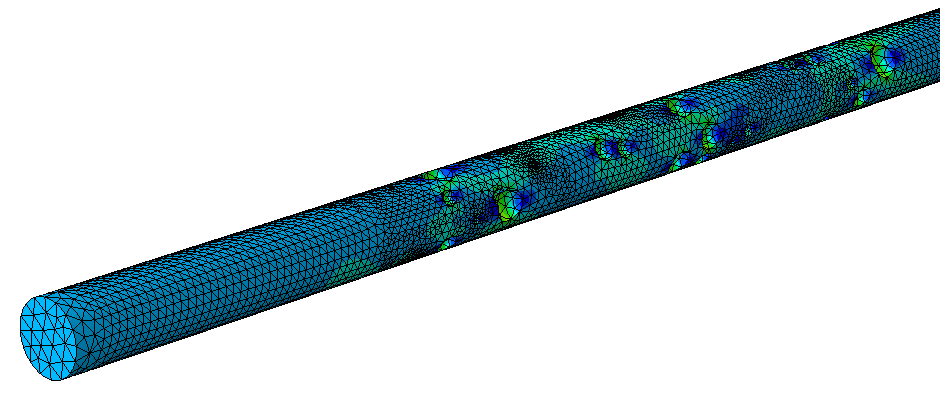

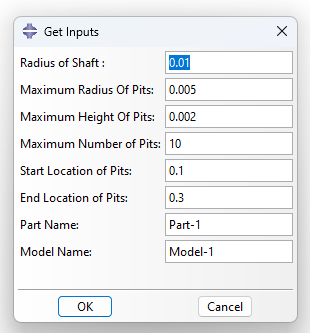

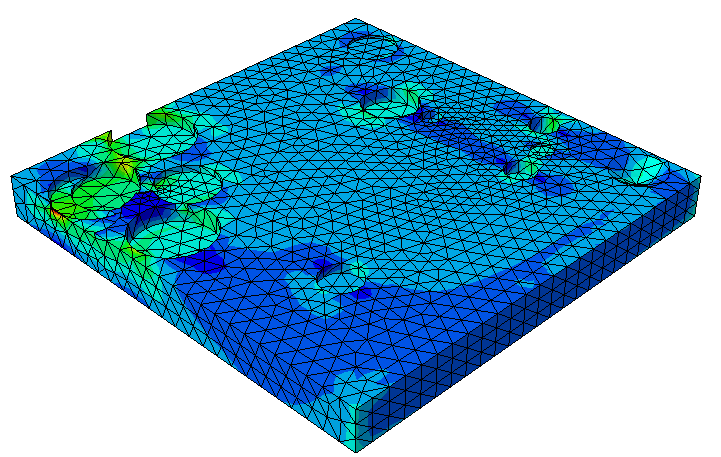

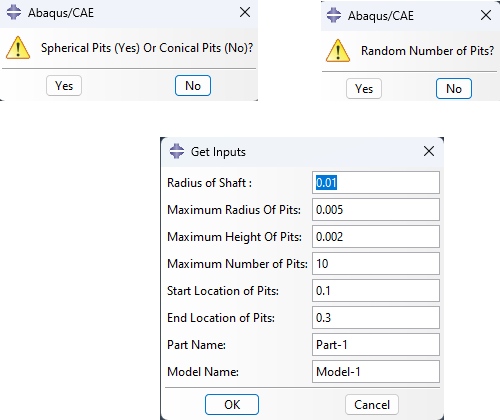

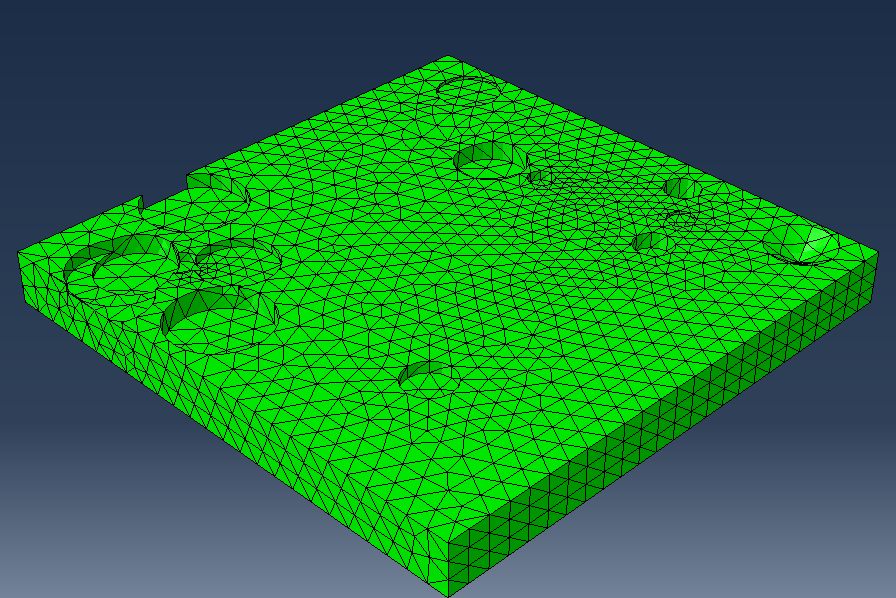

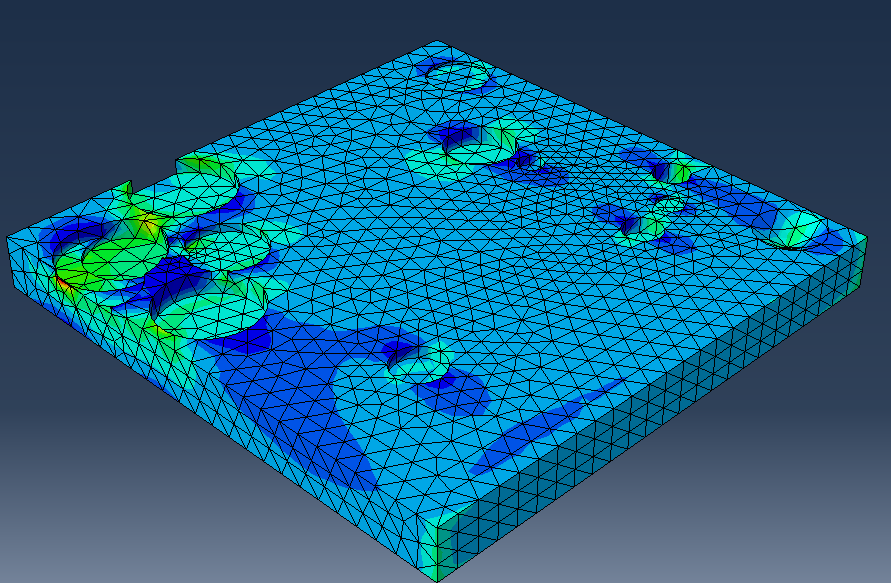

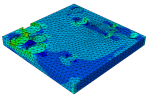

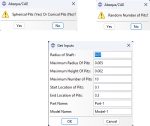

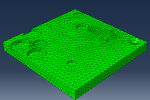

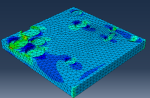

Abaqus is a commercial finite element software that helps to analyze pitting corrosion mechanism by providing accurate results for the stress distribution around the pits. Based on the papers in the literature, Abaqus pitting corrosion simulation shows accurate results with a maximum error of only 8% for analyzing models with surface pits. So, the software can be used to develop the geometry of the pits. In other words, it allows for a detailed analysis of the stress concentration and the effects of pit geometry on the material’s behavior under load.

The tutorial helps you in understanding the impact of pitting corrosion and developing strategies to mitigate its effects, thereby enhancing the durability and safety of structures. To do so, we have discussed the Abaqus pitting corrosion mechanism simulation aspects for analyzing the plates and shafts.

Thandiwe –

I was impressed by the robustness of this pitting corrosion simulation package. The initial setup was straightforward, and the simulation accuracy has been excellent.

Lindiwe –

The results I achieved with this simulation tool were beyond my expectations. The combination of usability and depth in the scripting features has allowed me to address specific research questions effectively.

Aminata –

I’m really pleased with how the pitting corrosion simulations turned out using this package. It allows for quick iterations and provides comprehensive results that are easy to understand.

Sipho –

I am impressed with the overall quality of this simulation package. The detailed outputs have provided new insights into my projects, and the customer support has been fantastic.