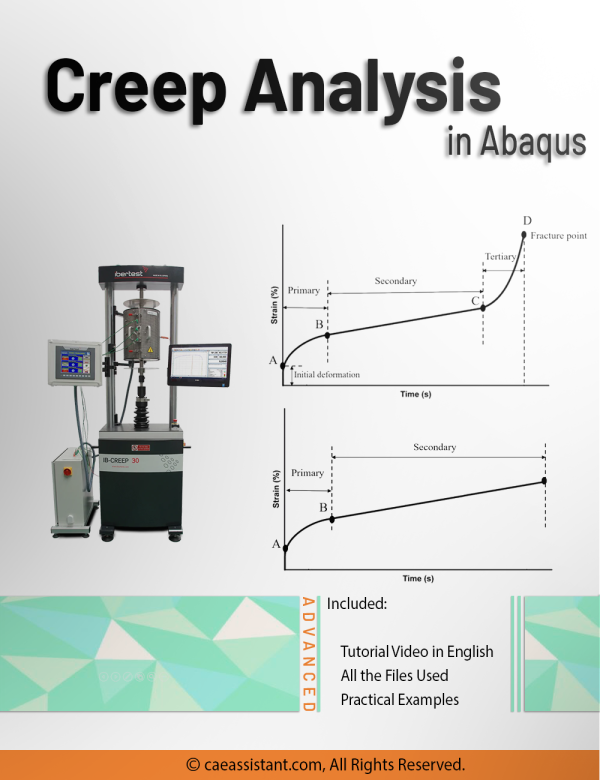

Steel damage mechanism in Abaqus

A mechanical, chemical, physical, or other processes that causes equipment or material degradation is referred to as a damage mechanism. Damage processes lead to imperfections and flaws that affect the structural integrity of process piping, vessels, and other equipment. Steel damage Abaqus simulation is fully described in this project package.

Steel is a material that is nearly universally used in construction, from your home to the vehicle you drive. Therefore, it’s crucial to understand how these structures are damaged when they undergo various loads, like impact, cyclic load, etc.

In this package you will learn how to deal with damage in steel structures; for instance, the bolt failure simulation on the connection between the steel beam and column is examined in the first workshop. The bolts, steel beam, and column have parts that are modelled in three dimensions. Reinforced concrete containment must be constructed and maintained in order to protect the populace and environment from an uncontrolled release of radioactivity in the event of a serious internal or external accident occurrence, such as large fires, earthquakes, or jet aircraft impacts, which may be anticipated during the plant’s lifetime; so in the second workshop, a reinforced concrete containment by steel bars under internal explosion is analyzed. Another practical example is in the fourth workshop, in which you can learn how to model a high-velocity impact on a ceramic plate reinforced by a steel plate. You can read more detail about the workshops below.

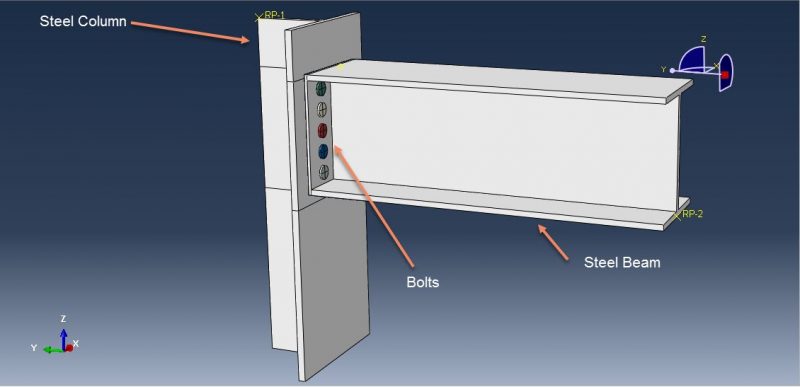

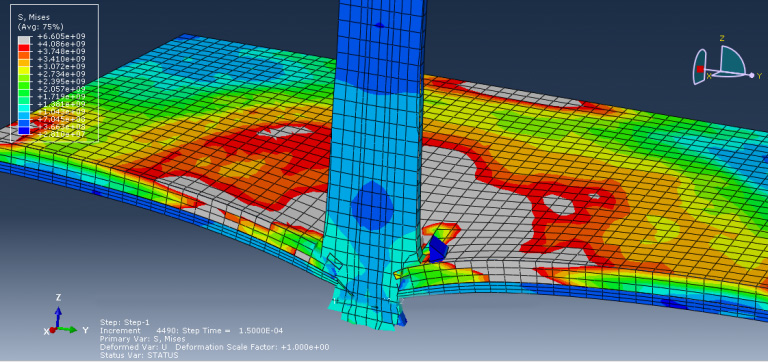

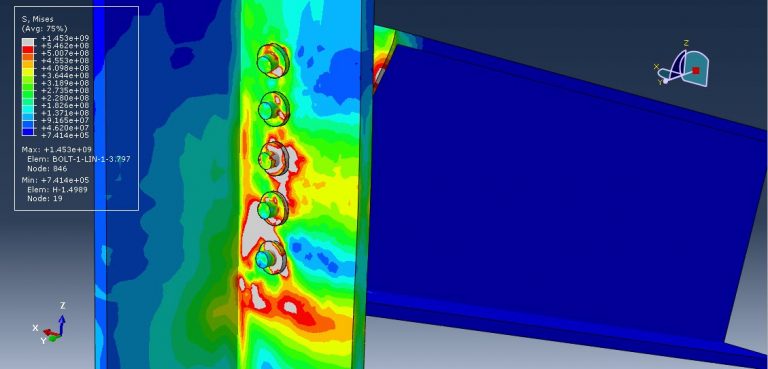

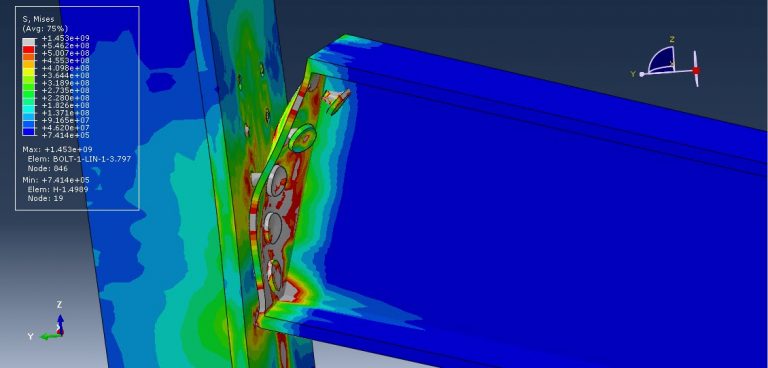

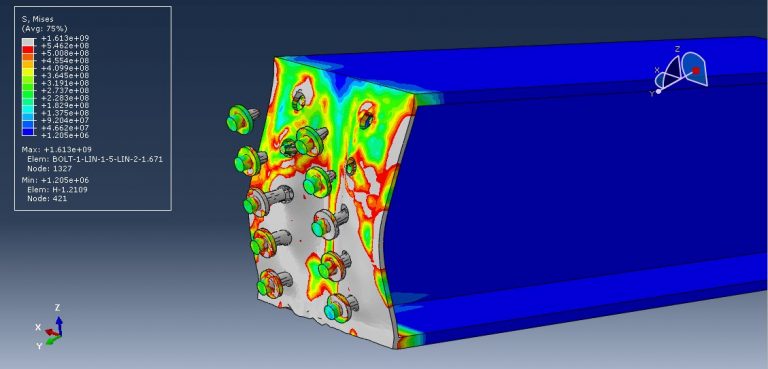

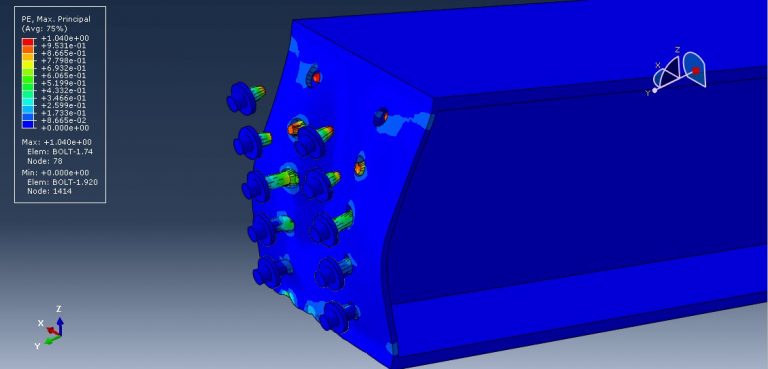

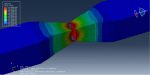

workshop-1: Bolt failure simulation on the steel beam and column connection in Abaqus

This lesson looks at the bolt failure simulation on the steel beam and column connection in Abaqus. Three-dimensional portions of the bolts, steel beam, and column are modelled.

The steel structure is made up of several components that must be joined or secured together, such as beams, columns, and plates. The main objective of connection design is to create a joint that is secure, affordable, and straightforward. A structure’s connections should be standardized, and it should be designed with enough room for adjustment to account for any fit issues. It should also resist corrosion, be simple to maintain, and have a reasonable appearance.

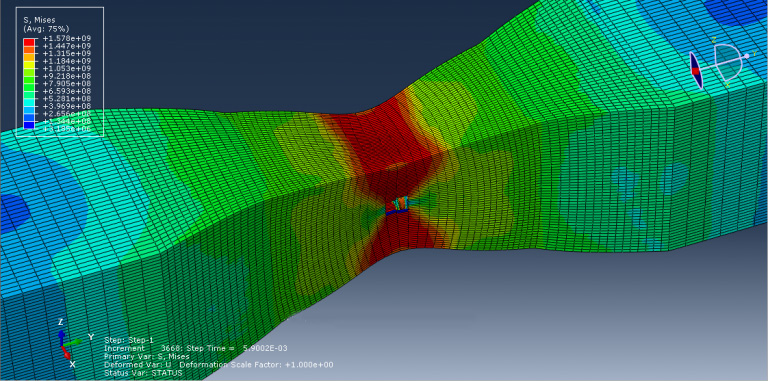

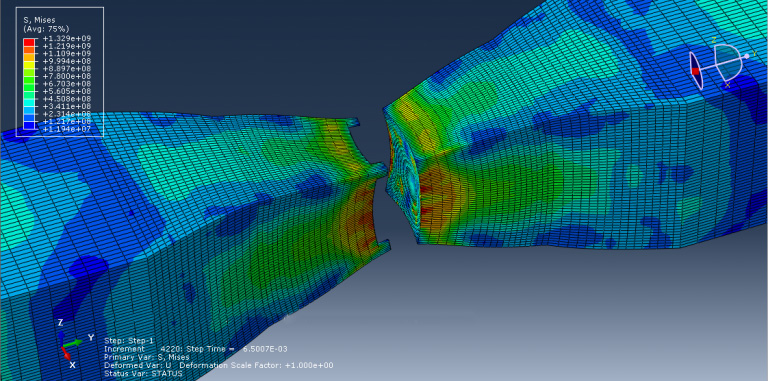

Steel is represented as an elastic-plastic material with ductile and shear damage criteria to monitor damage and failure on the pieces due to the failure of the bolt or column. Due to the significant deformation, standard analysis using the static solver is ineffective for this kind of study, making the dynamic explicit step acceptable. All pieces’ surface-to-surface interaction is taken into account. As contact properties, we have friction coefficient and hard contact property. The smooth step amplitude is used to apply the fixed boundary condition for the column’s end and displacement as a load for the beam. It is necessary for all sections to have a correct mesh, and in order to do so, each part must use numerous partitions. Stress, strain, damage, failure, and other results may be accessible following the simulation. The movement of the beam in the Z direction severely damages the bolts, and as a result, some of the bolts fail and are removed from the structure. (Steel damage Abaqus)

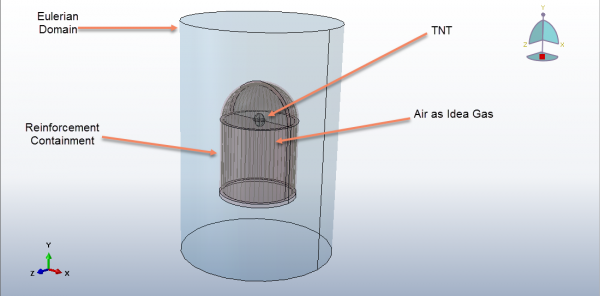

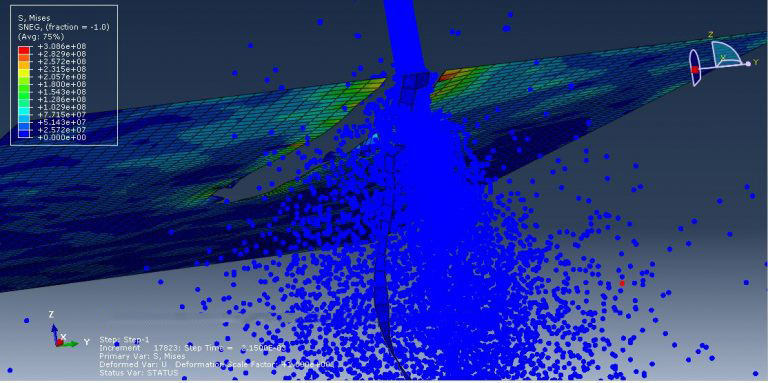

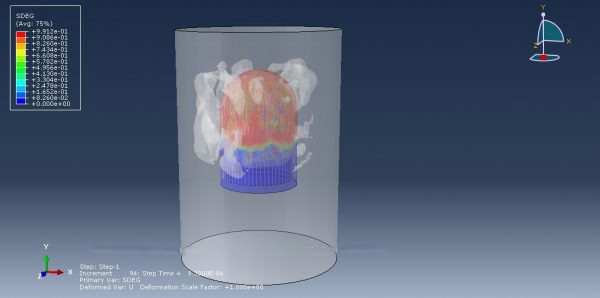

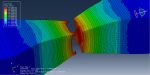

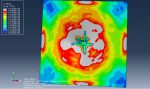

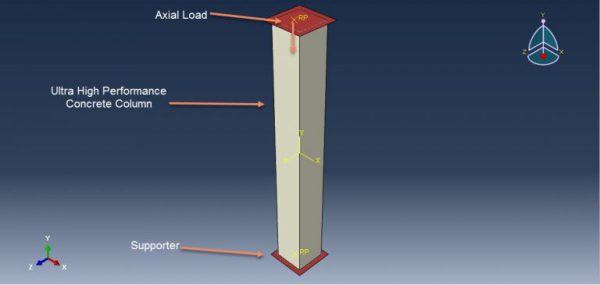

Workshop-2: Damage mechanism and response of reinforced concrete containment structure under internal explosion

In order to safeguard the populace and environment from an uncontrolled release of radioactivity in the event of a serious internal or external accident occurrence, such as large fires, earthquakes, or jet aircraft impact, which might be anticipated during the plant lifetime, reinforced concrete containment must be built and operated. In order to accurately determine the reaction, numerical simulation of the blast loading parameters for a certain scale distance for reinforced concrete confinement is crucial. The majority of the parameters for simulating the interactions between blast shock waves and different factors have been expressively presented. Investigated under internal blast loading at various scale distances are the reinforced concrete containment’s dynamic reaction and damage mechanism. The level of concrete cracking, the force on steel bars and concrete after yielding and deflections have all been used to illustrate the impact of the explosion inside the confinement. This tutorial has looked into the CEL explosion that took place inside the RC Concrete vessel. The volume fraction approach has been introduced to model the Eulerian explosion.

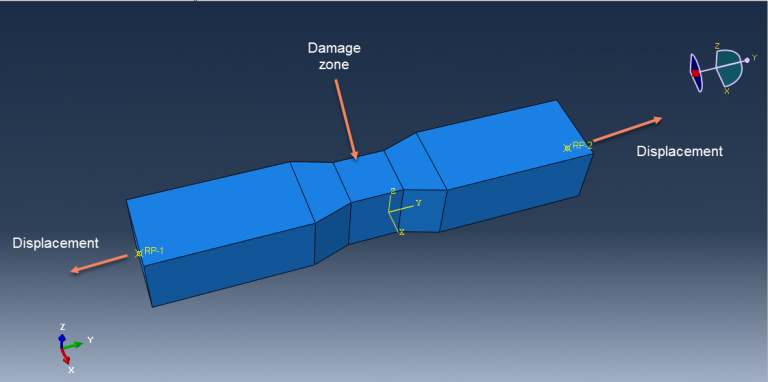

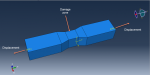

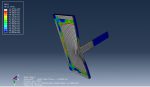

Workshop-3: Dynamic simulation of tensile test of a steel piece under axial deformation in Abaqus

This Steel damage Abaqus course examines the dynamic simulation of an axially deformed steel item undergoing a tensile test in Abaqus. Steel geometry is modeled using a three-dimensional portion.

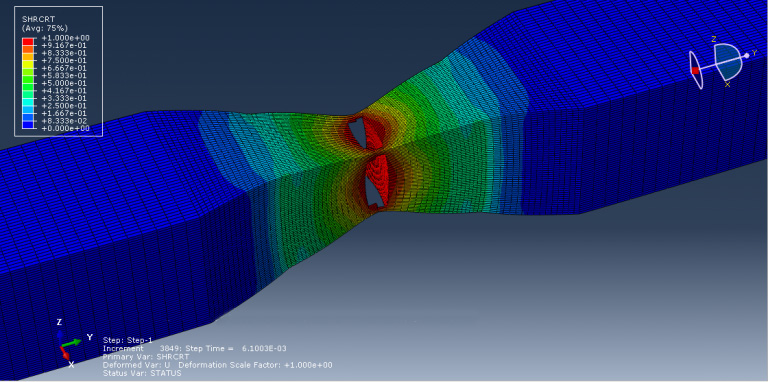

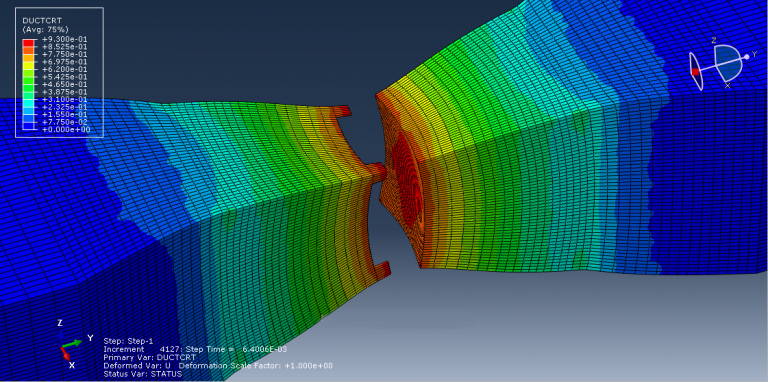

Isotropic plasticity with strain rate dependent has been utilized to simulate the evolution of the failure behavior of steel component shear and ductile damage. The information was taken from the Abaqus documentation. Both static and dynamic analysis can be performed on this model. In this illustration, a dynamic explicit step has been employed to observe damage and failure. The mass scale of the simulation is accelerated using a time target. The front and back surfaces of the steel component are thought of as rigid surfaces, and a load or displacement is applied to them. The mesh quality in the center of the component is crucial.

Following the simulation, the separation and damage are clear.

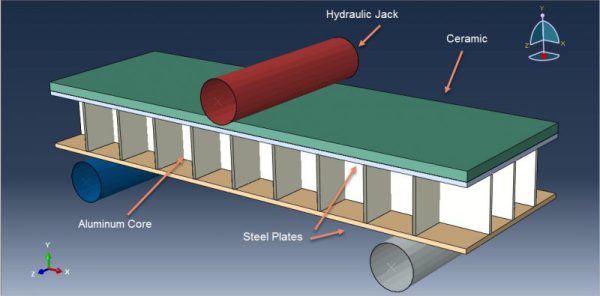

Workshop-4: High-velocity impact on ceramic plate reinforced with a steel plate

This Steel damage Abaqus complete video explains the high-velocity impact of a steel bullet on a steel-reinforced ceramic plate using Abaqus software. Steel plates and projectiles have been represented as deformable parts using ductile materials with shear damage coupled with damage evolution. Drucker-Prager plasticity with hardening coupled with Us-Up equation for fracture zone for Silicon plate ductile damage with evolution. This kind of analysis is ideal for the dynamic explicit method. The load module assigns the plates’ fix boundary condition and the projectile’s beginning velocity. The impact zone mesh quality has a significant impact on the outcomes.

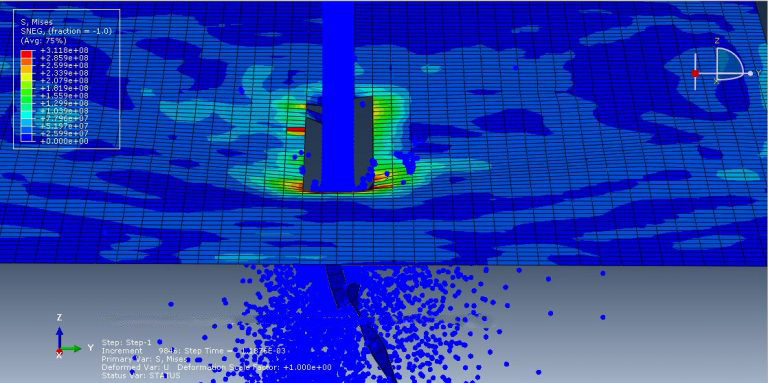

Workshop-5: Simulation water jet cutting in Abaqus

This video shows how ABAQUS was used to simulate a water jet effect across a thin plate. The Us-Up equation has been implemented for material modeling and the SPH approach for modeling water. The plate has an elastic-plastic characteristic and is modeled as a shell element. The ability of the Edit Keyboard to generate a damage model has been utilized to model plate failure during the impact. I hope you have got enough information about the steel damage Abaqus simulation; if you have any questions about this tutorial, contact us via online chat here on the left side of the page.

It would be helpful to see Abaqus Documentation to understand how it would be hard to start an Abaqus simulation without any Abaqus tutorial.

Reviews

Clear filtersThere are no reviews yet.