Introduction

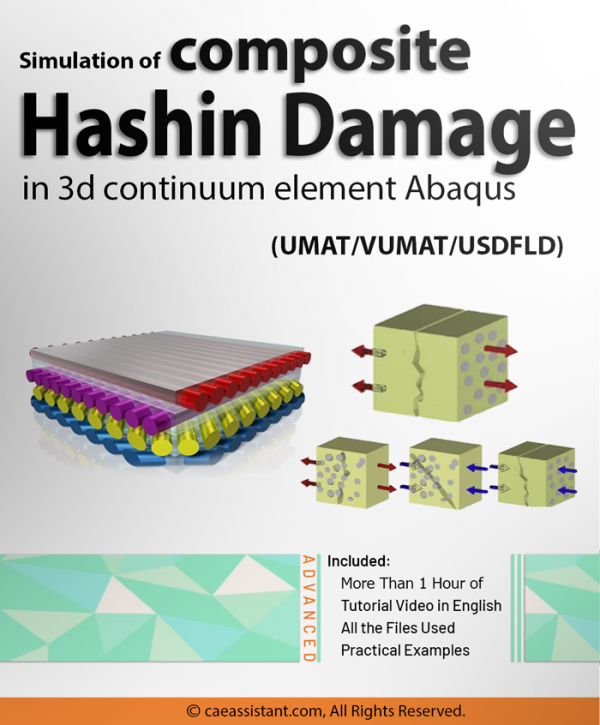

Three-dimensional damage in composite materials is one of the most widely used cases in today’s industry. However, there is no damage initiation for Three-dimensional composite materials in ABAQUS software. Therefore, coding is required to simulate the damage in these materials, which we have discussed in this project.

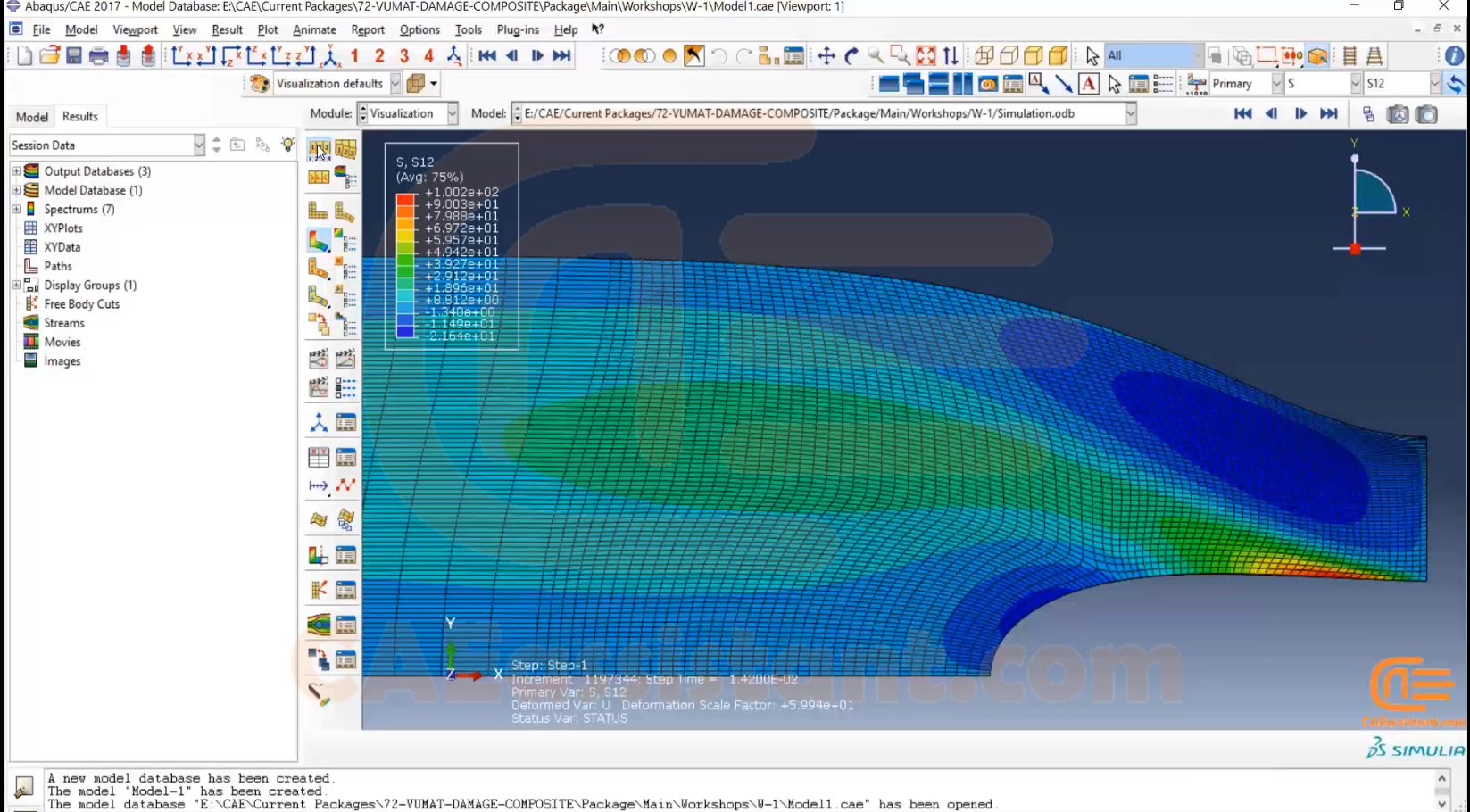

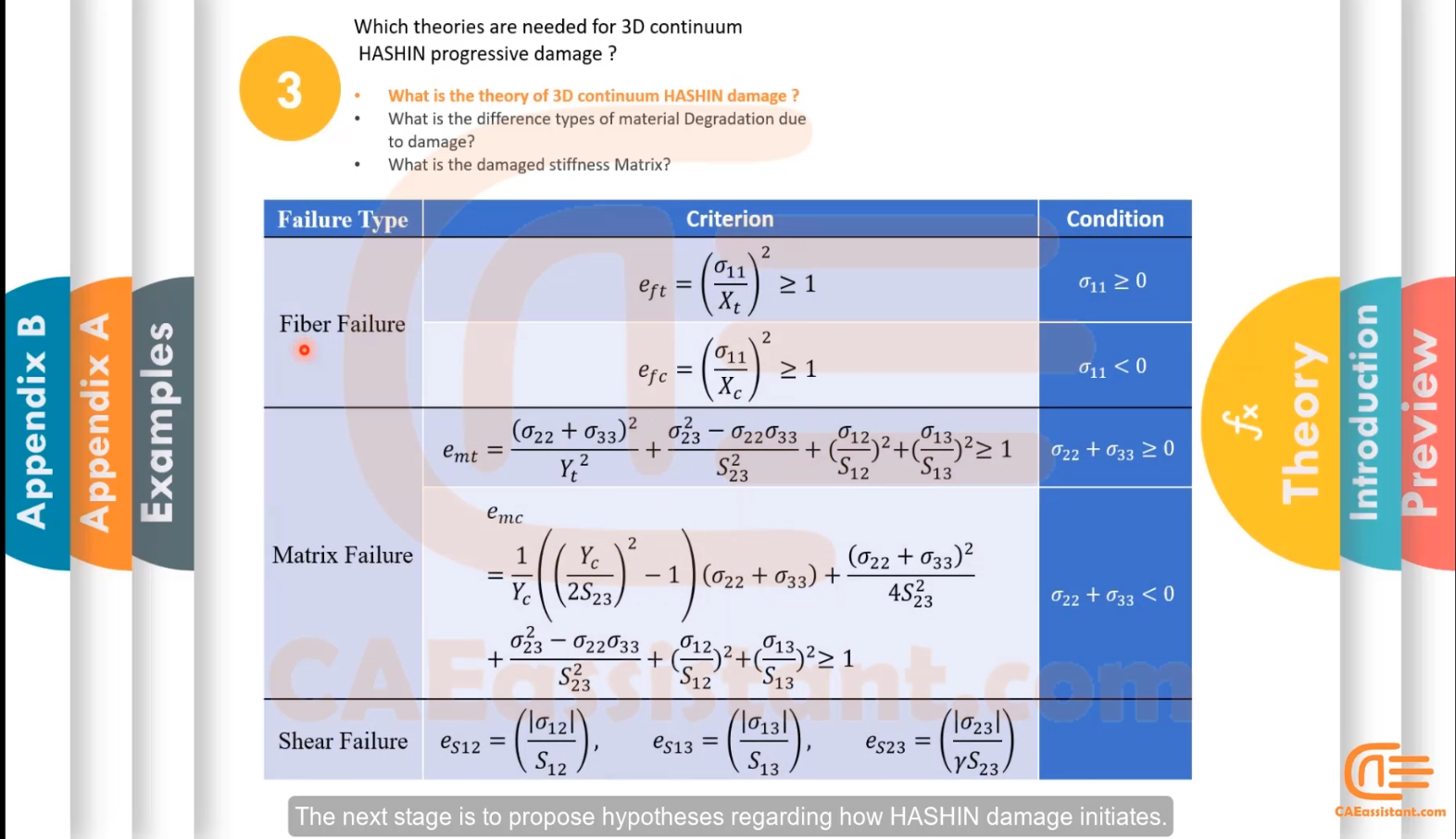

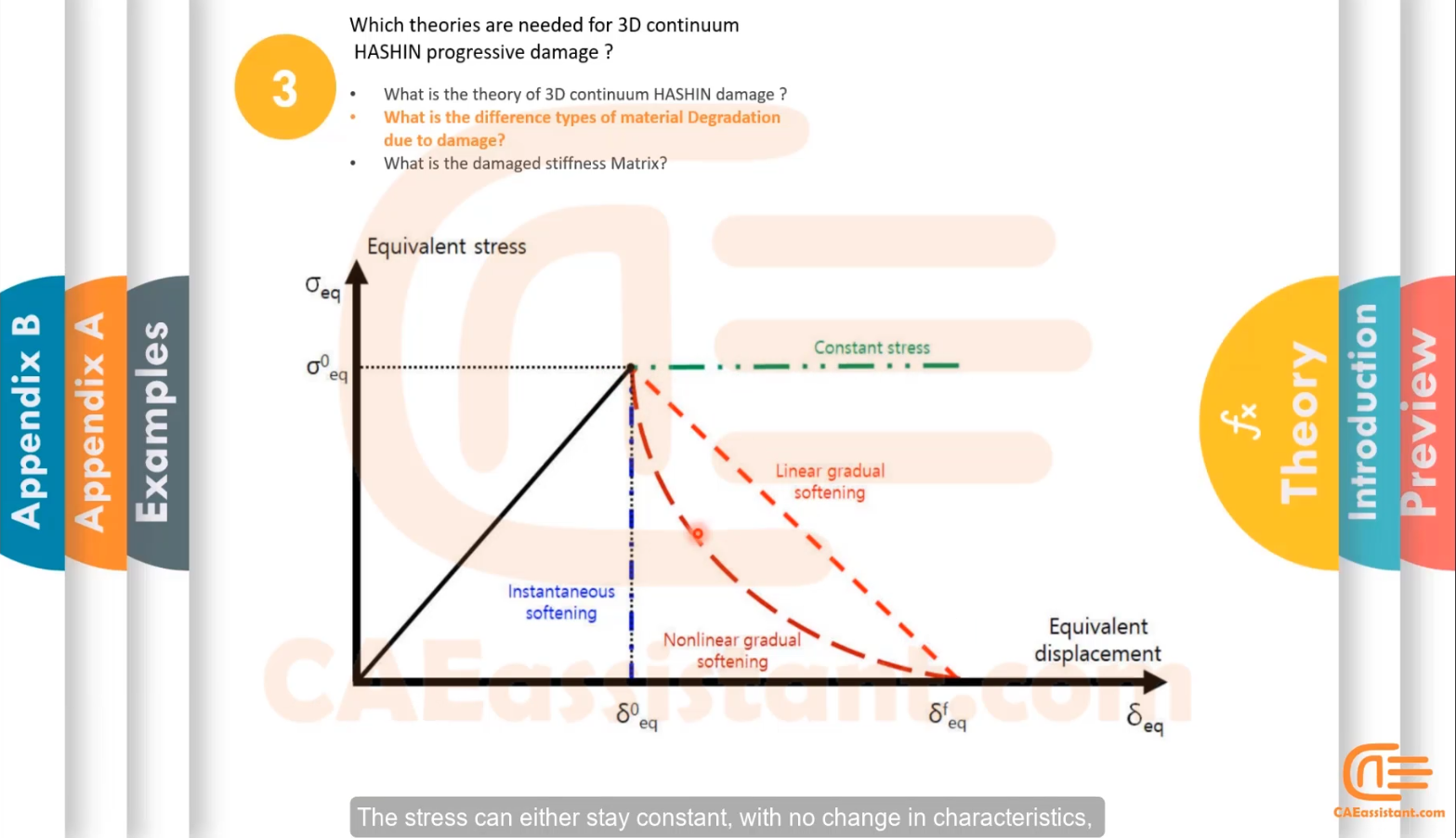

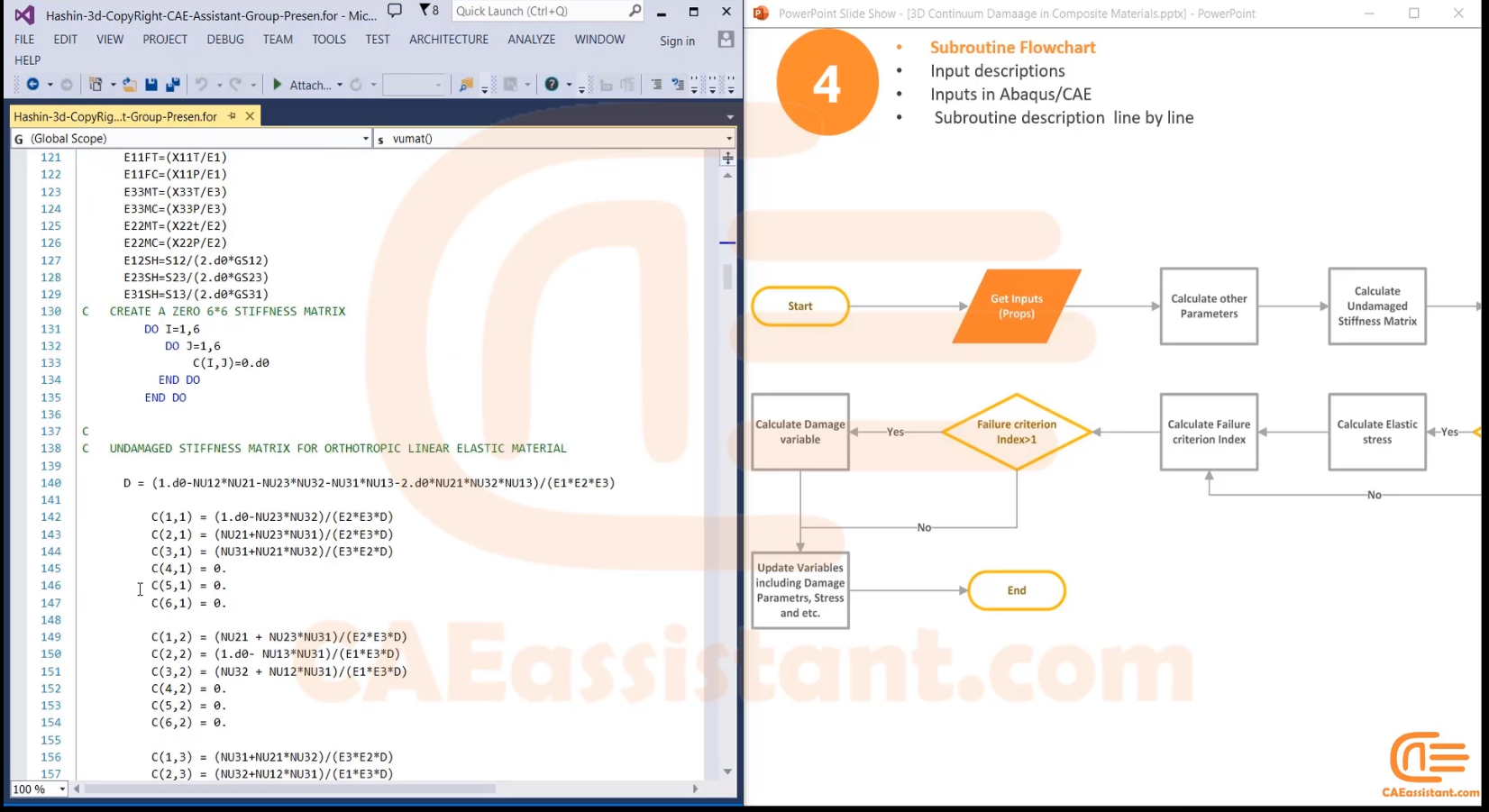

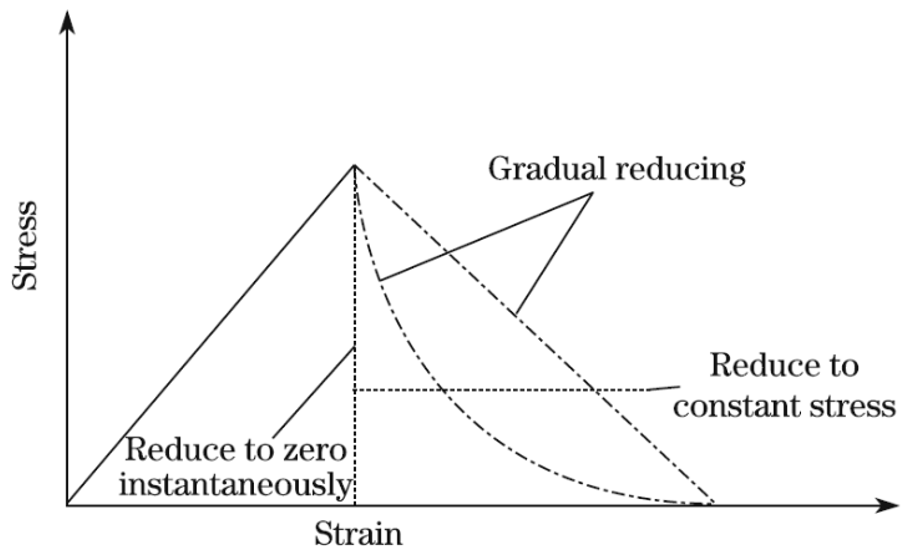

There are different criteria for damage initiation as well as how to reduce the mechanical properties for composite materials. Three-dimensional HASHIN damage, which involves detecting damage to fibers, matrix, and delamination, is very common among others. It should be mentioned that progressive damage can be done by reducing the properties gradually with different energy methods or equations, according to the next figure.

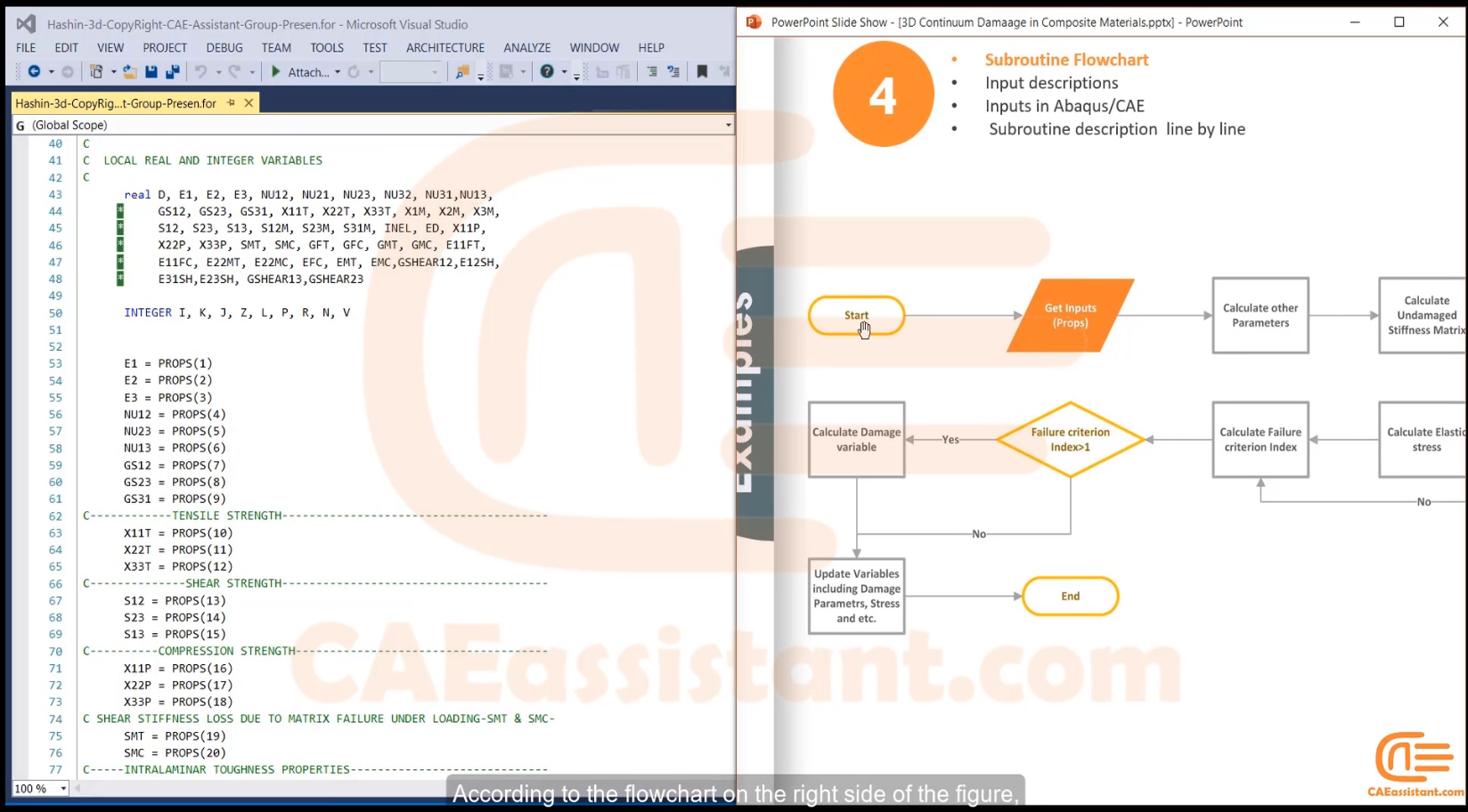

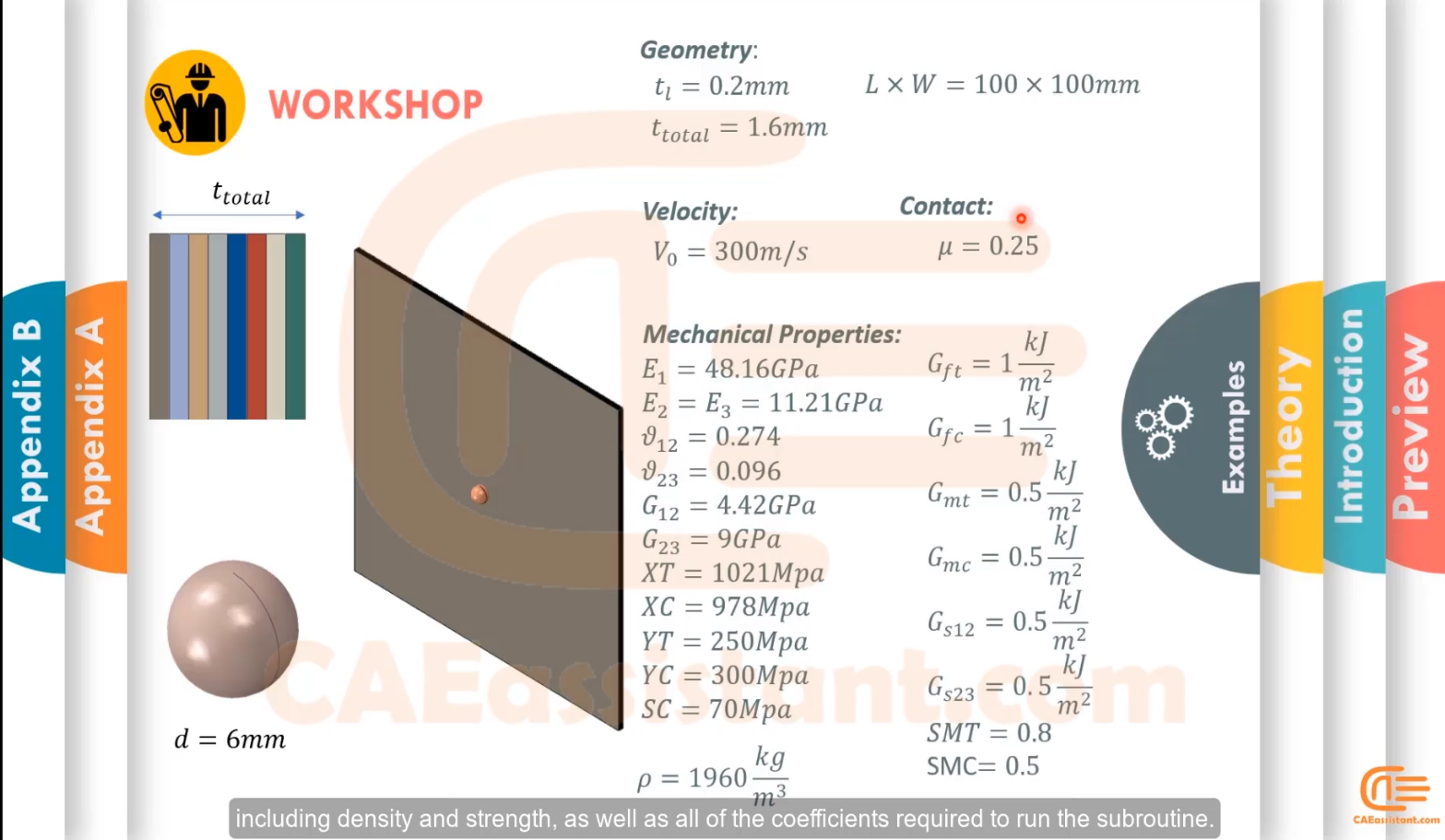

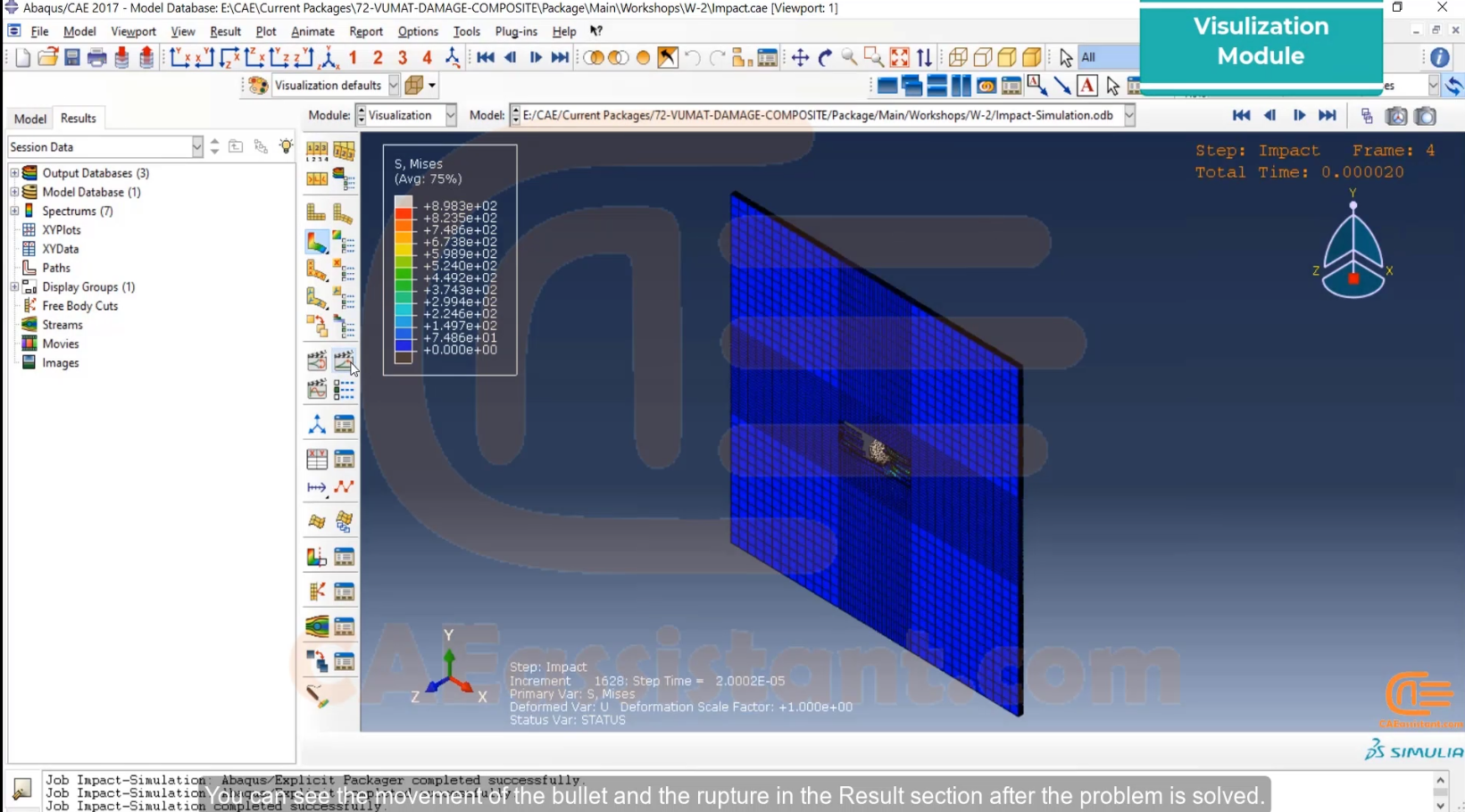

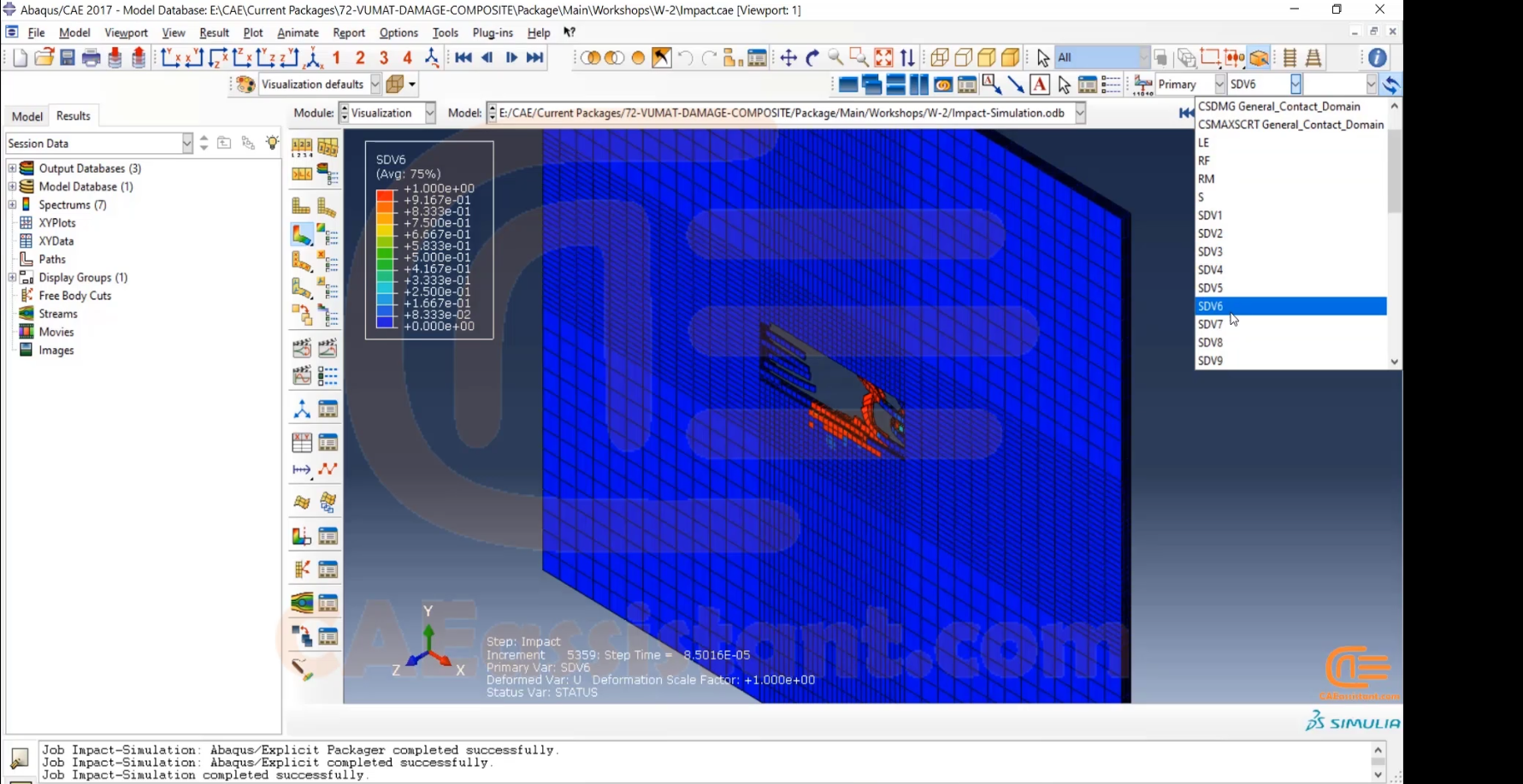

In this package, our focus is on the implementation of progressive damage, in contrast to our other package, which considers instantaneous damage, based on the Hashin criterion in Abaqus. However, to familiarize you with the foundation of this criterion and others, we first discuss the formulation theories for various composite failure criteria. This will provide you with a solid understanding of the fundamental concepts. Next, we move on to the Abaqus model, covering topics such as modeling 3D composites in Abaqus, defining damage criteria for composites within the software, and related concepts. Additionally, workshops are included to guide you in practically defining these models and even writing subroutines. The following is a more detailed explanation of the content of this package.

An overview of different damage initiation and progressive damage theories for composite materials

In general, each damage criterion is intended to predict two different aspects in the process of analyzing the behavior of a composite material.

The first criterion is the initiation of damage. The damage initiation term refers to the point where, depending on the stress or strain state of the material, the composite begins to experience damage. The second criterion is the propagation of damage, which occurs after the initiation of damage and represents the reduction in load-bearing stiffness or other physical characteristics of the material due to the creation of damage. This can happen either instantaneously or gradually. Therefore, an Abaqus model must be capable of predicting both the initiation and propagation of damage for composite analysis. Considering the importance of this topic, we have provided different criteria for damage initiation and propagation in composites, along with the related theory and formulations in this package. This will help you master the theory behind the subject, in addition to the Abaqus modeling discussion, which can be highly beneficial.

How to model 3D composite materials in ABAQUS?

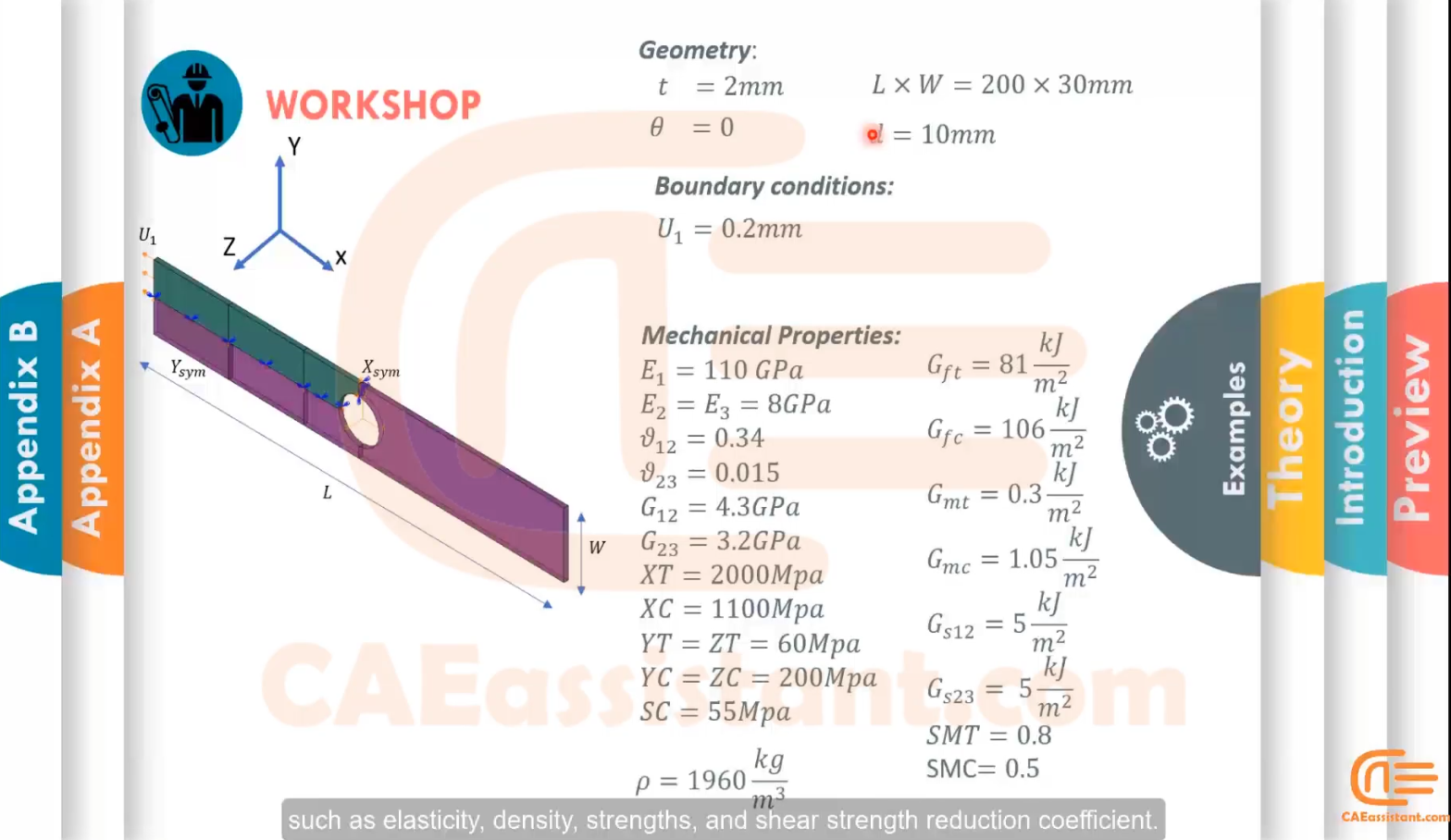

One of the main aspects of our work in this project is modeling composites in Abaqus in a 3D space. Given the importance of this topic, we have provided a detailed discussion on it in this package. After watching the video, you will be able to model composite samples in Abaqus without any particular challenges. However, this is just the beginning. The next challenge that arises in this field is defining damage criteria, such as the Hashin criterion, which we address in the following.

What are the different different types of damage initiation criteria for composite materials in ABAQUS?

As mentioned at the beginning, Abaqus provides the ability to use certain failure criteria, such as the Hashin criterion, through its material library by default. While damage initiation based on this material model is only applicable to 2D elements, it’s helpful to review these capabilities to become more familiar with Abaqus’s features. With this in mind, we have provided a detailed discussion on the topic in the educational video. This will help you understand how to apply the default damage initiation criteria within Abaqus for a given problem.

An overview of sudden and gradual degradation of mechanical properties for composite materials in ABAQUS

A topic that you may find useful and which could be a common challenge for many is damage propagation models. Different theories generally use various models for instantaneous and progressive failure analysis. However, you might wonder: when does a material experience an instantaneous stiffness reduction, and when does it experience a gradual stiffness reduction? What are the common patterns of gradual stiffness reduction after damage initiation? And other related questions. Considering these points, we have provided a detailed discussion in the video on how to incorporate such models into Abaqus, with a focus on composite behavior due to damage initiation.

Eymen Kucuk –

Thanks. It was a very nice experience in using the VUMAT subroutine to use damage initiation based on Hashin criterion and progressive damage in the 3D continuum element of composite structures. It works well. I have received all software files and the subroutine. When the video training will be ready?

Experts of CAE Assistant Group –

You can find it on your dashboard soon(About one week later)

Experts Of CAE Assistant Group –

It is available

Luc Janssens –

It works well and I have used that for my project. I need the flowchart of the subroutine. Could you give the flowchart of this subroutine?

ava.gray –

Thanks! That was helpful for my project. How can I have more examples and data to practice with this subroutine? Which packages do you recommend me?

heitor.larson –

What about other damage criteria? Do you have any packages for them as well?

heitor.larson –

What about other damage criteria? Do you have any packages for them as well? I would be grateful if you could introduce me as soon as possible

heitor.larson –

Nowadays many things are made of composites and industries should know how to work with FEM software. Does this package is good enough for industries? I would be grateful if you could introduce me as soon as possible.