Introduction | Bolting Steel to Concrete in Composite Beams

From a sustainability perspective, traditional composite beams with welded stud shear connectors are difficult to disassemble and reuse. Instead, Bolting Steel to Concrete (BSC) offer a more sustainable alternative. By using this method, we will acquire a reliable connection. Engineers value concrete-steel bolted shear connections for their fatigue resistance, secure connection, and ease of disassembly. These connections find extensive applications in steel structure construction, reinforcement, and reconstruction, as well as in steel-precast concrete composite beams. The bolts serve as crucial components that are vital for ensuring the bond between steel and concrete in composite structures.

Bolting Steel to Concrete: The Importance of Careful Design

Careful design of bolting steel to concrete is crucial for several reasons. The shear performance of bolts is essential for ensuring the desired mechanical behavior of steel-precast concrete composite beams. Moreover, a proper design of bolting steel to concrete ensures the effective transfer of shear forces between the components. Additionally, we use high-strength bolts for their fatigue resistance, making thorough design necessary to preserve this characteristic. It is vital for the structure’s lifespan and durability.

Ensuring a tight connection while also allowing for convenient disassembly is crucial for both the initial construction and future modifications. Therefore, a proper bolting steel to concrete design must consider different factors to achieve the desired concrete-steel bolted shear connection. For example, we can refer to the tensile strength of the bolts, their diameter, and the strength of the concrete. Moreover, adequate clearance between the bolts and the holes in the precast concrete slab and steel beam is necessary. This prevents excessive slip and ensures the stability of the connection when bolting steel to concrete. It’s important to note that improper alignment in these criteria can lead to reduced performance. By considering these factors, designers can ensure that concrete-steel bolted shear connections are safe, efficient, and durable. Experimental and numerical methods are powerful tools that help engineers analyze bolting steel to concrete under different loads. They enable engineers bolting steel to concrete and create reliable and efficient designs.

The Methods of the Design of BSC

Each of the experimental and numerical methods of bolting steel to concrete has its limitations and benefits. Among the limitations of experiments, we can point out that they are expensive due to the need for equipment. Additionally, setting up and performing experiments can take a significant amount of time. Experiments often focus on specific conditions and may not cover all possible scenarios. Finally, experimental setups may pose safety risks.

Numerical methods, on the other hand, offer several benefits for the design of concrete-steel bolted shear connections. Most importantly, they can reduce the need for extensive physical testing, thereby saving costs associated with materials, labor, and equipment. On the other hand, engineers can perform simulations relatively quickly compared to physical experiments. Moreover, we can easily adjust simulations to explore a wide range of parameters, such as bolt sizes and material properties. Overall, by reducing the need for physical prototypes and tests, numerical methods contribute to more sustainable engineering practices.

Besides the benefits, numerical methods come with several challenges. For example, they may not always accurately capture the behavior of connections, especially under complex loading conditions. On the other hand, validating numerical models against experimental data to ensure accuracy can be time-consuming. Moreover, bolted connections often exhibit nonlinear behavior due to material plasticity, contact interactions, and large deformations, making accurate modeling difficult. Finally, developing and running numerical simulations requires specialized expertise in both the software used and the physical phenomena involved. Despite these challenges, numerical simulations remain a valuable tool in the design of concrete-steel bolted shear connections. They become even more valuable when used in conjunction with experimental methods.

Modeling Concrete-Steel Bolted Shear Connection Using Abaqus

ABAQUS plays a significant role in addressing the challenges of numerical simulation of bolting steel to concrete through its capabilities. It provides robust tools for creating detailed finite element models for concrete-steel bolted shear connection. So, the software helps us to validate the results for concrete-steel bolted shear connection against experimental data to ensure accuracy. Moreover, ABAQUS efficiently handles large and complex simulations, leveraging high-performance computing resources to reduce computation time. It supports advanced models and nonlinear analysis, enabling accurate simulation of the complex behaviors exhibited by concrete-steel bolted shear connection.

By using these features, ABAQUS helps address many of the challenges associated with numerical simulation of concrete-steel bolted shear connection. It provides a powerful tool for engineers to design and analyze concrete-steel bolted shear connection. However, it also has its challenges, which we will discuss below.

The challenges of using ABAQUS For the Analysis of BSC:

The finite element (FE) analysis of bolting steel to concrete in ABAQUS requires modeling several components. These include concrete slabs, steel beams, bolts, steel washers, and steel reinforcement. Additionally, both geometric and material nonlinearities must be considered for these problems. This is a challenging task, but we have simplified it for you in this package. To provide more detail, we have highlighted the main key points of ABAQUS modeling in the following section.

Key pints of concrete-steel bolted shear connection Abaqus simulation

In this section, we will discuss the details of analyzing the BSC. This includes material properties, boundary conditions, loads, and interactions, among other factors. It helps you to gain a deep understanding regarding concrete-steel bolted shear connection Abaqus simulation.

Material and Geometric Non-linearities

To capture accurate results for the behavior of concrete-steel bolted shear connections, one must properly model material and geometric nonlinearities. For example, we need to use a plastic material model in ABAQUS to simulate the behavior of steel materials. To do this, we obtain the material characteristics of all steel components based on standard uniaxial tensile tests. These characteristics include modulus of elasticity, yield strength, ultimate strain, and strength. We use an idealized piecewise linear representation of these tensile tests in the finite element (FE) model. Ductile damage model is used to represent the actual behavior of the bolt for concrete-steel bolted shear connection abaqus simulation. This approach allows us to accurately simulate the properties of steel materials in a simplified manner.

For concrete, we use a well-known model to simulate compression, which includes both an elastic range and a nonlinear portion. Additionally, we fully account for its tensile nonlinear behavior, which many papers often neglect. To incorporate these features in ABAQUS, we use the Concrete Damage Plasticity (CDP) model.

To account for geometric nonlinearities, we use the static general solver in ABAQUS with the NLGEOM option selected. This approach allows us to perform displacement-controlled nonlinear analysis. By considering these nonlinearities, the FE model can accurately predict the behavior of composite connections under different loading conditions.

Boundary Conditions For the Analysis of Bolting Steel to Concrete:

We have applied appropriate boundary conditions to the model to restrain its motion and accurately simulate the push-out test specimens. For example, we have restricted some nodes of the precast concrete from translating in the X, Y, and Z directions. Additionally, we have restrained some nodes of the steel beam in the Y direction. We also have prevented them from rotating around X and Z directions for the analysis of bolting steel to concrete.

Element definition For the Analysis of Bolting Steel to Concrete:

We have defined different element types for various components for the analysis of BSC. For example, we used 3D eight-node elements (C3D8R) for concrete slabs and structural steel beams. Additionally, the model includes 3D twenty-node quadratic brick elements (C3D20R) for bolt shear connectors. We also used two-node linear 3D truss elements (T3D2) for steel reinforcement. To reduce computational efforts and time while obtaining reasonable results, we defined a coarse mesh for the overall member. However, a fine mesh is necessary for the bolt shear connectors and the region around them to achieve accurate results.

Interactions For the Analysis of BSC:

Properly defining the interaction and constraint conditions is crucial for accurate modeling of bolting steel to concrete. We have addressed several interaction challenges in the ABAQUS model. Here are some key points regarding the interaction techniques we have used:

We have used surface-to-surface contact interaction to define the contact between various components. These components include the bolt head, steel washer, bolt nut, and steel beam, among others. For the tangential behavior between these surfaces, we have used the PENALTY option. Additionally, we defined a hard contact property in the direction normal to interface plane to analyze concrete-steel bolted shear connections.

We employed the embedded feature in ABAQUS to model the contact interaction between the steel reinforcement and the concrete part. In this method, we assumed the reinforcing bars embedded into the concrete slab and ignored slip between the components.

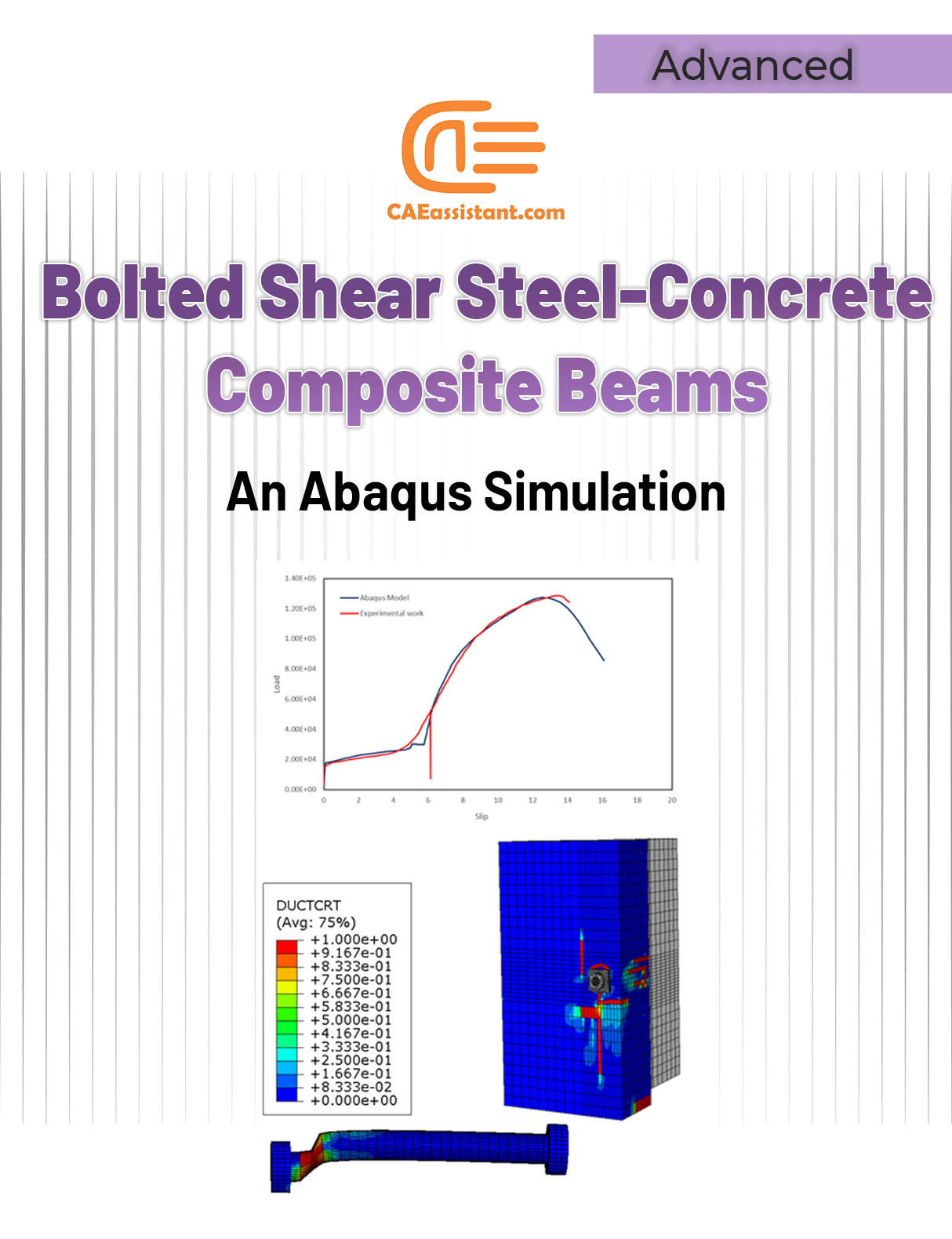

Verification and Results for Steel Concrete Bolts

We have verified the Abaqus finite element model for concrete-steel bolted shear connections against experimental results for steel concrete bolts.

In the following, we present some key points regarding this verification:

First, we compared calculated load-slip curves for the concrete-steel bolted shear connections from the FE model with the experimental results. The FE model’s load-slip curves aligned well with the experimental curves. Additionally, the FE model successfully predicted the ultimate shear resistances of shear connections using precast slabs and shear connectors. These results validate the FE model against experimental data for bolting steel to concrete. This demonstrates its capability to accurately and efficiently predict the behavior of the structural components under study.

Who will benefit from this project for designing steel concrete bolts?

Structural Engineers: They can use the findings and methodologies to design and analyze steel concrete bolts more accurately. Thereby, they can ensure safety and efficiency in construction projects when bolting steel to concrete.

Researchers in structural engineering can use the verified FE model to further analyze bolting steel to concrete. This allows them to explore new materials and design techniques.

Construction professionals: Contractors and construction managers can benefit from an improved understanding of BSC. This leads to better construction practices and has the potential to reduce costs and construction time for steel concrete bolts.

Software Developers: Developers working on simulation software like ABAQUS can use these insights to enhance the software’s capabilities. It helps them to improve the user experience for the design of steel concrete bolts.

Students: Engineering students can use the project as a case study in advanced modeling techniques for bolting steel to concrete. It helps them understand the practical applications of their theoretical knowledge and design steel concrete bolts.

Organizations: Organizations responsible for setting construction standards can use the research to update their guidelines for bolting steel to concrete. This ensures that new structures meet safety and performance criteria.

By addressing the challenges, this project helps these groups achieve greater reliability for bolting steel to concrete. If you want to model BSCand verify results with experiments in following references, this project helps. It can be particularly beneficial for your work. You will learn the essential specifics to keep in mind when performing such simulations for steel concrete bolts.

The reference that this tutorial helps you with modeling their examples | With Specific Focuse on Bolting Steel to Concrete

- Ataei, Abdolreza, and Mehran Zeynalian. “A study on structural performance of deconstructable bolted shear connectors in composite beams.” Structures. Vol. 29. Elsevier, 2021.

- Liu, Xinpei, et al. “Finite element modelling of steel–concrete composite beams with high-strength friction-grip bolt shear connectors.” Finite Elements in Analysis and Design108 (2016): 54-65.

- Fahmy, Ahmed Shamel, Sherine Mostafa Swelem, and Mohamed Kamal Abdelaziz. “Behavior of high-strength demountable bolted shear connectors in steel-concrete girders with prefabricated slabs.” Alexandria Engineering Journal70 (2023): 247-260.

- Hosseinpour, Mahmoud, et al. “Push-out tests on bolted shear connectors in composite cold-formed steel beams.” Thin-Walled Structures164 (2021): 107831.

- Ataei, Abdolreza, and Seyed Ali Mahmoudy. “Modeling of innovative bolted shear connectors in demountable cold-formed steel-concrete composite beams: Validation of finite element model and parametric study.” Journal of Building Engineering(2024): 110076.

- Ataei, Abdolreza. “Modelling of demountable steel-concrete composite connections: Validation of finite element model and parametric study.” Journal of Constructional Steel Research198 (2022): 107585.

- Zhang, Yujie, et al. “Experimental study on shear behavior of high strength bolt connection in prefabricated steel-concrete composite beam.” Composites Part B: Engineering159 (2019): 481-489.

Summery and Conclusion

In conclusion, careful design of bolting steel to concrete is essential for enhancing the safety, and performance of structures. Traditional welded connections pose significant challenges for disassembly and reuse, whereas bolting steel to concrete offers a more sustainable alternative. It is due to due to their ease of disassembly and superior fatigue resistance.

Bolting steel to concrete is a common method to achieve stable structures. While experimental methods provide valuable insights into concrete-steel bolted shear connections, numerical simulations are crucial for addressing the complexities involved. By combining both experimental and numerical approaches, engineers can develop reliable and efficient designs for steel concrete bolts. So, they can ensure the longevity and functionality of bolted connections in various structural applications. This integrated approach not only advances engineering practices but also supports the development of more sustainable and cost-effective construction methods. Abaqus is one of the powerful tools that enables us to simulate the behavior of bolted connections. It offers many features, such as defining material and geometrical nonlinearities and applying preload for bolts. However, defining these components in Abaqus can be a challenging task. In this project, we have addressed this issue with a step-by-step guide.

Reviews

Clear filtersThere are no reviews yet.