Markus Richter, an accomplished expert in additive manufacturing simulation using Abaqus, hails from Germany. With a strong educational background, extensive experience, and deep expertise in simulation for additive manufacturing processes, Markus has established himself as a leading authority in the field of 3D printing simulations.

Education and Early Career:

Markus obtained his Bachelor’s degree in Mechanical Engineering from the Technical University of Munich, where he developed a passion for advanced manufacturing technologies. Intrigued by the potential of additive manufacturing, he pursued further education and completed a Master’s degree in Materials Science and Engineering, specializing in additive manufacturing processes.

Professional Accomplishments:

After completing his education, Markus joined a renowned engineering company in Stuttgart, where he focused on additive manufacturing simulations using Abaqus. His exceptional understanding of the intricate interactions between process parameters, material behavior, and part quality quickly gained recognition. Markus’s expertise allowed him to work on a wide range of projects, including aerospace components, medical devices, and automotive applications.

Expertise and Contributions:

Markus Richter’s expertise lies in the simulation and optimization of additive manufacturing processes using Abaqus. He has an in-depth understanding of the complex phenomena involved in 3D printing, including heat transfer, solidification, residual stress, and distortion. Markus specializes in accurately predicting the formation of defects, such as warpage, porosity, and microstructure variations, and optimizing process parameters to enhance part quality.

Using Abaqus, Markus has successfully simulated various additive manufacturing techniques, such as selective laser melting (SLM), fused deposition modeling (FDM), and stereolithography (SLA). He excels in modeling the behavior of different materials, including metals, polymers, and composites, during the additive manufacturing process. Markus’s expertise also extends to simulating post-processing operations, such as heat treatment and machining, to predict the final part performance accurately.

Markus actively stays updated with the latest advancements in additive manufacturing technologies and simulation methodologies. He collaborates with research institutions and industry experts to explore new materials, process innovations, and simulation techniques. Markus is known for his ability to provide actionable insights to optimize designs, reduce production costs, and improve the overall efficiency of additive manufacturing processes.

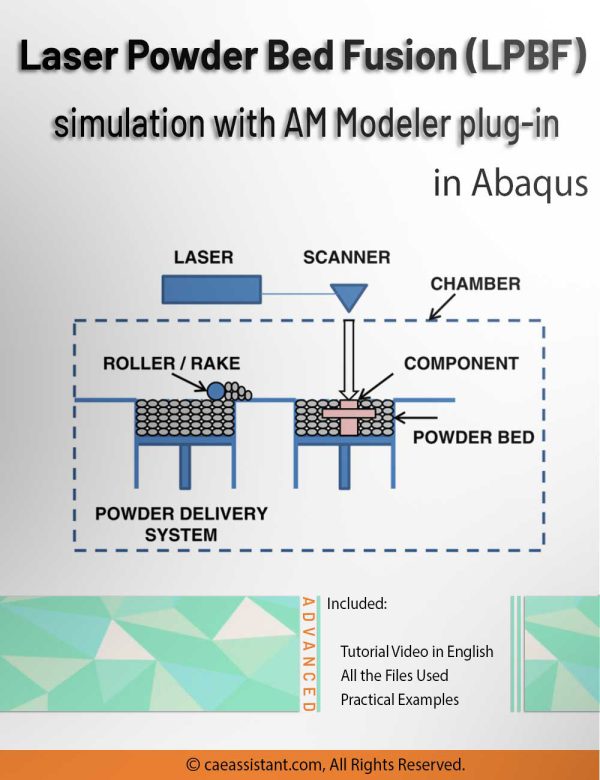

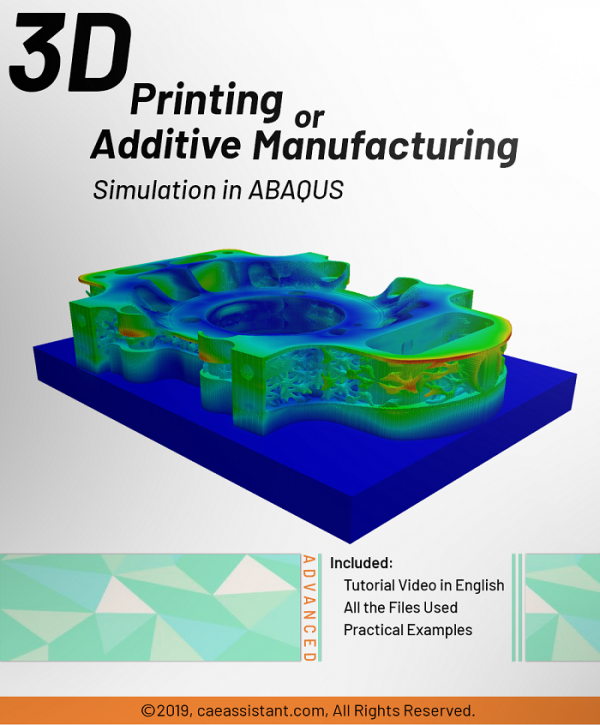

3D printing simulation with Laser Powder Bed Fusion (LPBF) method in Abaqus

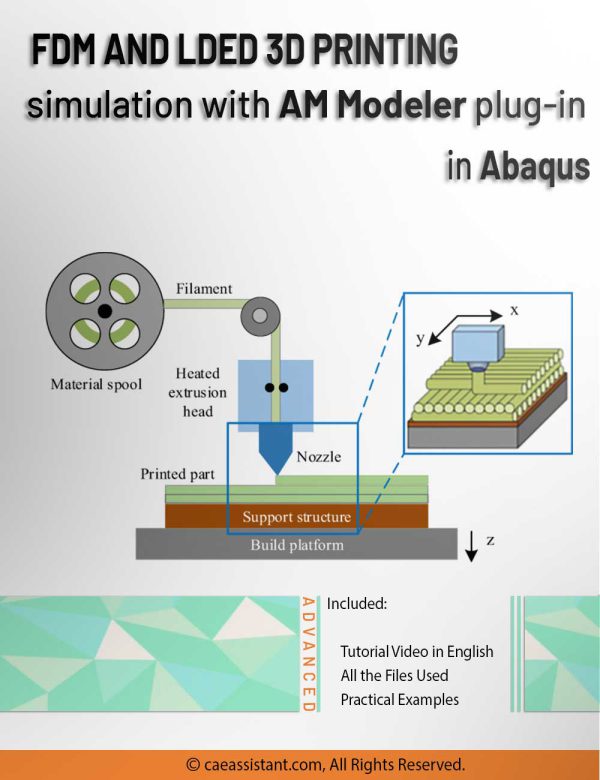

3D printing simulation with Fused Deposition Modeling (FDM) in Abaqus

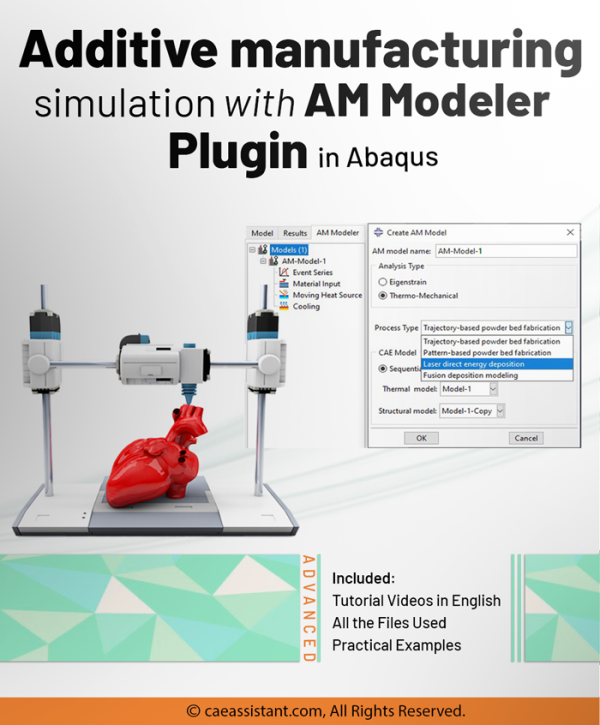

Additive manufacturing simulation with Abaqus AM modeler plugin

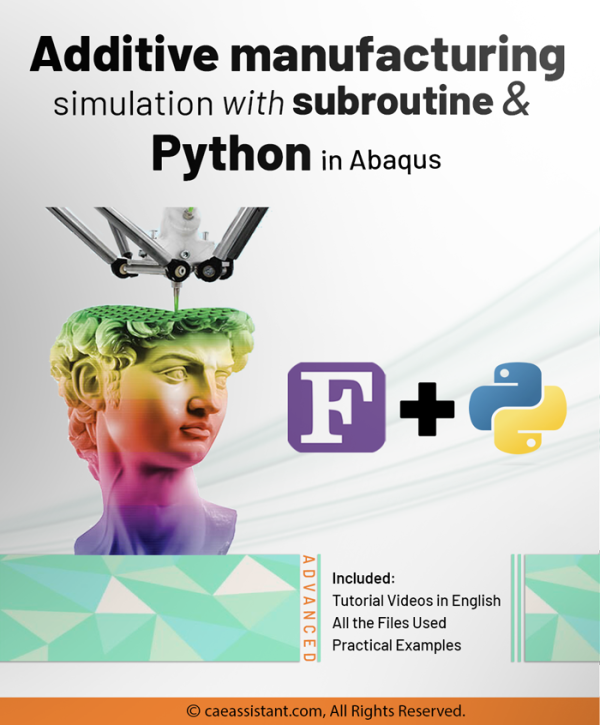

Additive manufacturing simulation with Abaqus subroutine & python | 3D printing Python

Additive Manufacturing or 3D Printing Abaqus simulation