Introduction | An Overview of Fiber Reinforced Composites

Engineers integrate fibers systematically into the concrete matrix to create Fiber Reinforced Concrete (FRC). The primary advantage of incorporating fibers is the mitigation of concrete’s inherent brittleness. So they can transform it into a more ductile material. The fibers prevent cracks from propagating and thereby improve the overall durability and longevity of the structure. This characteristic makes FRC particularly suitable for structures subjected to dynamic loads, heavy traffic, or environments. Considering all these benefits, accurate modeling and analysis of FRC beams require sufficient experience and are necessary for attaining the desired performance.

Applications of Fiber Reinforced Concrete Specimens

Engineers widely recognize Fiber Reinforced Concrete for its superior performance in structural applications. Today, FRCs are commonly used in the construction of industrial floors and pavements. Moreover, the high durability and crack resistance of FRC make it suitable for areas subjected to heavy traffic. FRCs can also improve impact resistance of bridge decks and tunnels. In these cases, the material must endure harsh environmental conditions and repeated load cycles. Finally, in regions prone to seismic activity, the enhanced ductility of FRC provides additional safety margins.

Analyzing the Flexural Behavior in FRC

The flexural behavior of concrete is a critical aspect of structural design. It is very important in elements such as beams and slabs, where bending is a primary mode of stress. For FRC, the fibers introduce additional complexity to the material’s response under flexural load. Flexural strength and rigidity are key indicators of a material’s ability to resist deformation and failure. This makes them essential parameters in the design and analysis of concrete structures. Accurately analyzing flexural behavior is essential for predicting the performance of FRC structures under real-world conditions.

Challenges in Analyzing Flexural Behavior

Analyzing the flexural behavior of FRC beams poses significant The challenges lie in developing models that can accurately replicate the complex interaction between fibers and the concrete matrix. Moreover, the transition from uncracked to fully cracked sections in FRC beams is particularly challenging to model. Abaqus is a powerful tool that addresses many limitations related to the numerical simulations. Accordingly, we have used it in this project to analyze FRC beams.

Using Abaqus For the Analysis of FRC Specimens

Abaqus provides a powerful platform for simulating complex physical phenomena. When applied to concrete specimens, it proves invaluable in capturing the complex behavior of the material. The software offers a variety of constitutive models, such as concrete damaged plasticity, to accurately represent concrete’s nonlinear stress-strain response. It enables the modeling of reinforced concrete structures by incorporating reinforcement elements. Through careful calibration and validation, ABAQUS can provide valuable insights into the structural performance of concrete components, aiding in design, optimization, and failure prediction.

Details of Abaqus Model Used In This Package

Material Models

In this package, the Concrete Damage Plasticity (CDP) model is used to represent the nonlinear behavior in FRC beams. The model considers both nonlinear tensile and compressive behaviors. For compressive stresses, damage parameters are also defined. However, tensile damage is not considered in this model For the reinforcement bars embedded in the concrete, a plastic behavior model without hardening is defined. This approach captures the nonlinear behavior of steel rebars accurately while maintaining simplicity. We have analyzed different specimens with varying fiber ratios, all of which are experimentally investigated in the following paper. However, for simplification, we considered a homogeneous model for the concrete and steel rebar behavior altogether.

Step Definition

To solve the problem in Abaqus, two well-known solvers are available: the general static and explicit. Explicit solvers have fewer restrictions when solving such nonlinear problems. On the other hand, the static solver provides more reliable results, although it may encounter convergence issues. In this case, we chose the static solver to ensure more reliable results.

Defining the Interactions

Since the fiber-reinforced concrete specimen is assumed to be homogeneous, there is no need to define any interaction between the concrete and steel fibers. However, the interaction between the steel rebars and concrete must be defined. To achieve this, we used the embedded interaction type in Abaqus CAE.

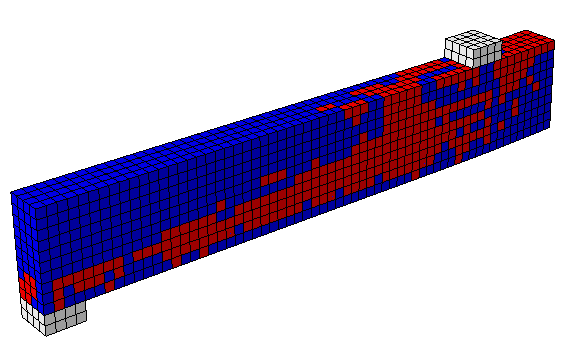

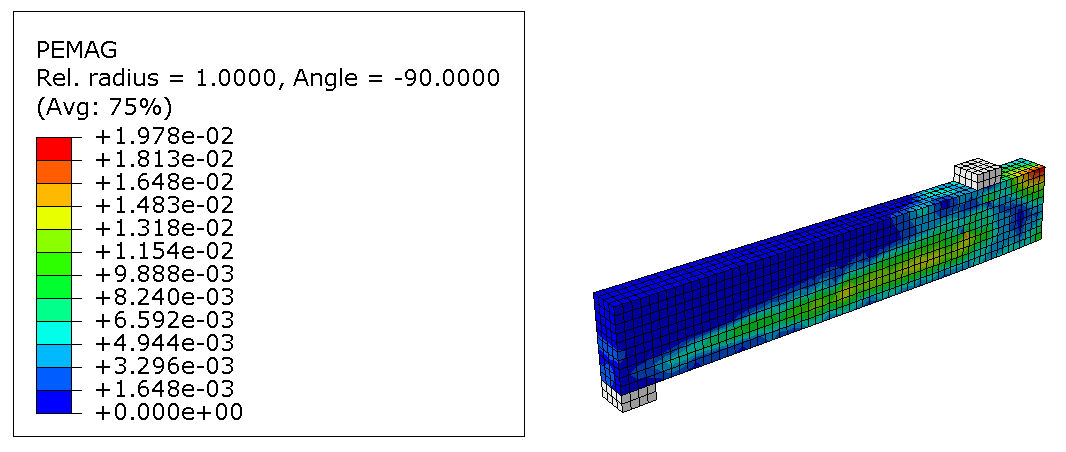

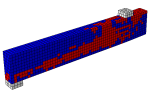

An overview of the models

The provided Abaqus models allow you to Analyze FRC beams in 3D space, providing a comprehensive picture of the beam’s performance under load. By using these models, engineers and researchers can conduct detailed analyses of FRC beams without the need for extensive physical testing. The simulations offer accurate predictions of beam behavior, facilitating the optimization of designs and ensuring that structures meet required performance criteria.

Results

The key results that you can extract from the modeling files are:

- Effect of Fiber Content: The inclusion of steel fibers in the concrete matrix significantly enhances the flexural strength and rigidity of the beams. This result highlights the importance of fiber content in determining the overall performance of FRC beams.

- Impact of Concrete Compressive Strength: Higher concrete compressive strength leads to an increase in the flexural rigidity of the beams. Accordingly, the addition of fibers helps to mitigate the brittleness typically associated with these materials, resulting in improved structural performance.

- Influence of Tensile Reinforcement Ratio: The tensile reinforcement ratio plays a crucial role in the flexural behavior of FRC beams. The models show that as the reinforcement ratio increases, the beam’s load-carrying capacity and stiffness also increase.

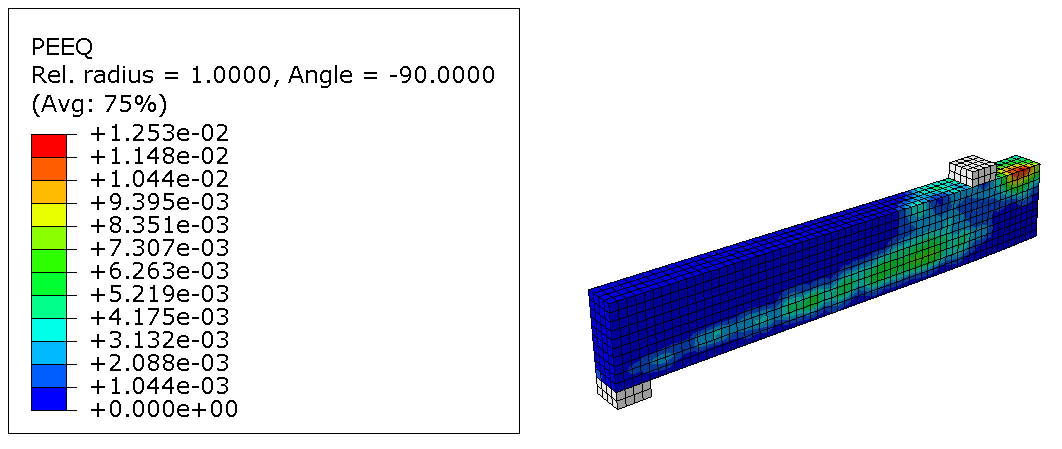

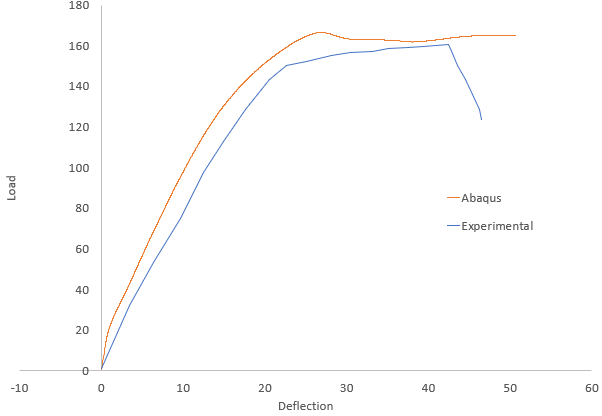

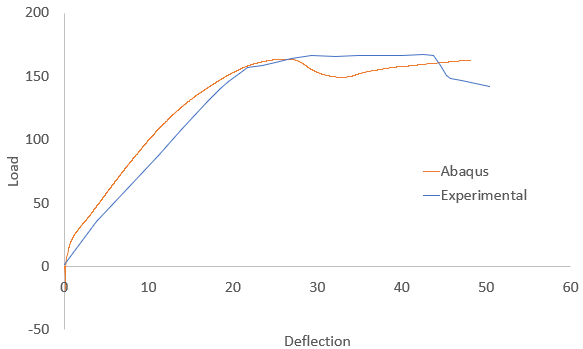

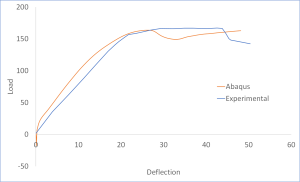

The question that arises is how you can be sure of the models. Don’t worry, we’ve checked them. To do so, we extracted the load-deflection curves and compared them with the experimental results provided in the following paper. The comparison for one of the models is shown in Figure 1.

Figure 1 Validation of the Load-Deflection curve

These results are invaluable for engineers and researchers working on the design and analysis of FRC structures. The ability to accurately predict the performance of FRC beams under various conditions allows for more efficient and reliable design processes. Ultimately, It leads to safer and more durable structures.

Reviews

Clear filtersThere are no reviews yet.