Introduction to Turbine Blade Creep Analysis

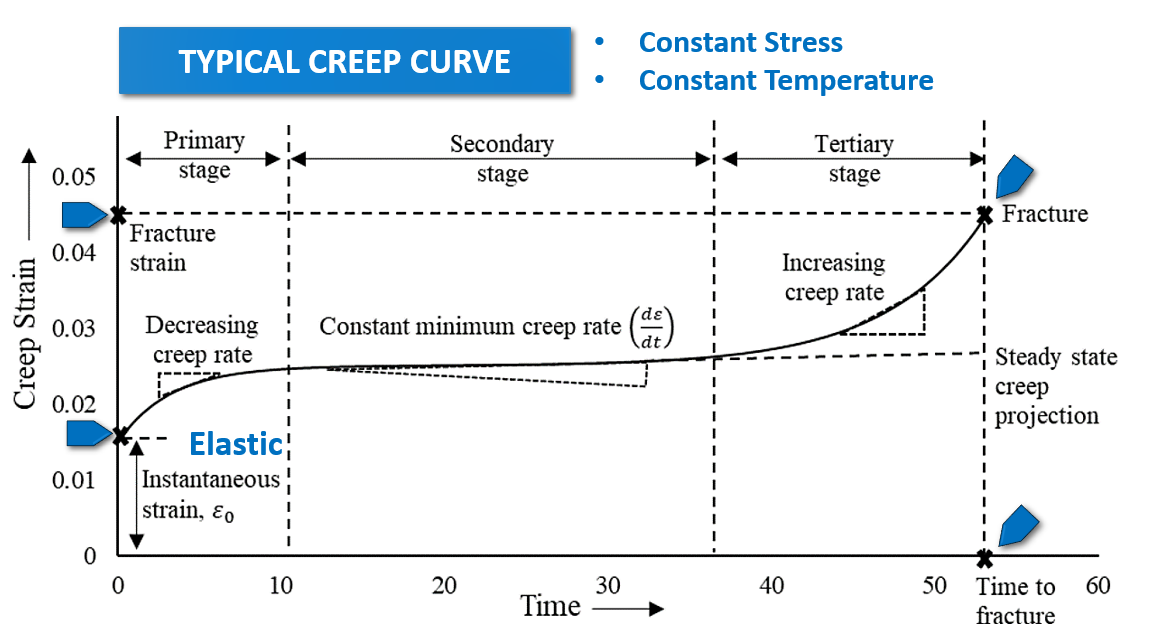

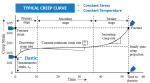

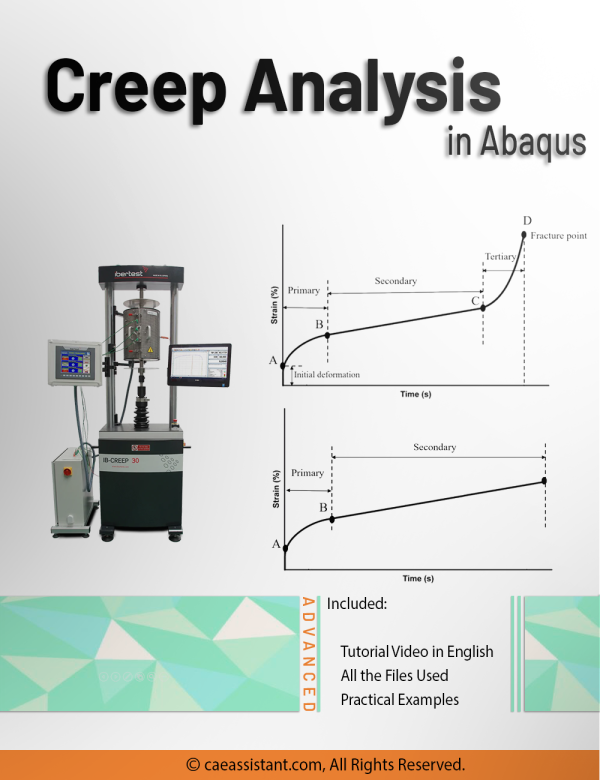

Creep is a time-dependent deformation of materials under constant stress, typically occurring at high temperatures. It is a critical factor in the life assessment and performance of materials, especially in applications like gas turbine components, pressure vessels, and high-temperature alloys. We have to use various constitutive models for creep analysis, to ensure the safety of engineering designs. So, it is a challenging task that requires great effort.

Creep in components, like gas turbine blades (turbine blade creep), which operate under high temperatures and stresses for extended periods, is a critical subject in engineering fields. Therefore, we have covered it in this project, which will help you in the following ways:

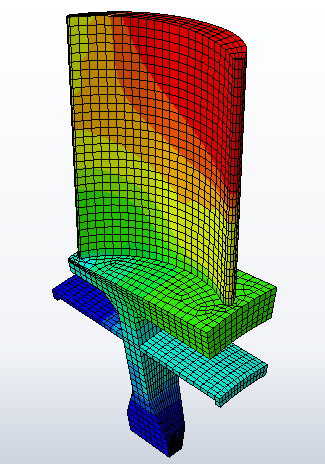

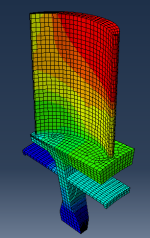

- Improving Design: By observing high creep areas, the design of components can be optimized for better creep life.

- Ensuring Reliability: Accurate creep prediction ensures that components can withstand the operational stresses without premature failure (Creep failure in turbine blades).

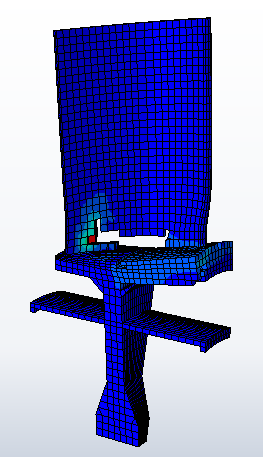

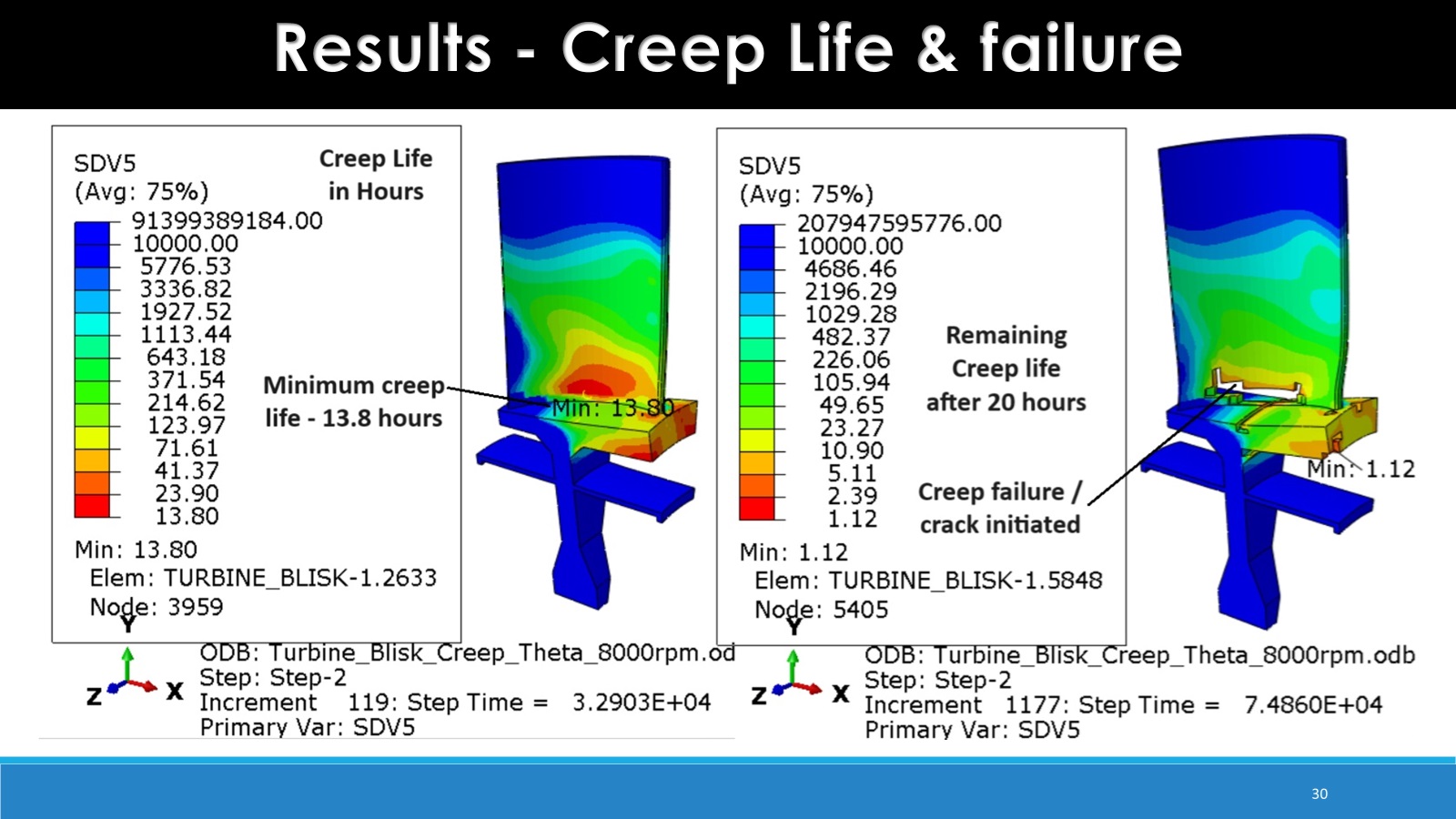

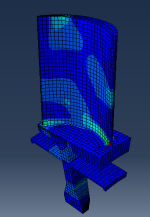

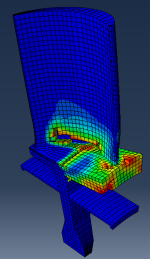

- Visualizing Damage: Creep analysis allows for the visualization of critical regions, crack initiation, and propagation. Such a visualization is crucial for maintenance and safety.

- Studying Effects: It allows for the study of the effects of thermal barrier coatings, creep-fatigue interaction, and other factors. Where such factors can influence the performance of the components.

Overall, understanding creep helps in designing more durable and efficient components, leading to better performance and safety. Numerical simulations of creep are a way to gain these benefits. Therefore, we have used them in this project. They offer several advantages over other methods, such as experimental tests, as follows:

- Comprehensive Modeling: Numerical simulations can provide a detailed understanding of the material behavior over time.

- Visualization of Internal State Variables: Simulations allow for the visualization of internal state variables. Such variables may include hardening, softening, and damage. These are crucial for understanding the material’s response to stress and temperature.

- Prediction of Critical Parameters: Numerical methods can predict critical parameters like creep fracture strain, time to creep fracture, and the onset of cracking, which are essential for assessing the life and safety of components.

- Identification of Critical Regions: Simulations can identify critical regions where creep is most likely to occur. This helps in targeted inspections and maintenance.

- Reliable Results Under Various Conditions: Numerical simulations provide reliable results at both interpolated and extrapolated stress conditions. This makes them general for different operational scenarios.

With all these benefits, the numerical models are still challenging and need more development. For example, we can refer to the limitation of existing material models in commercial software as one of the most important issues. To address this, we will develop Fortran user subroutines for Abaqus CAE. It helps you model creep in Abaqus in an accurate manner.

The aim of the turbine blade creep project

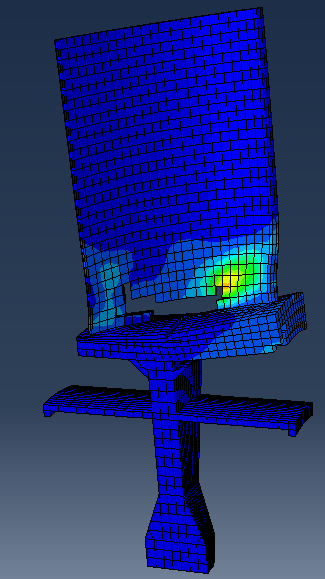

The goal of the project is to develop user subroutines for creep analysis that can accurately model all stages of creep. To do so, we have provided a Fortran-based Abaqus user subroutine that uses the Theta projection method to predict turbine blade creep behavior accurately. These subroutines aim to improve the prediction of creep behavior and provide better visualization of internal state variables, ultimately addressing the limitations of existing CAE tools. For validation, we have checked the subroutines with various test cases and compared the results with reference data to ensure accuracy.

Applications

Creep modeling of components subjected to high temperature and stress conditions could lead to more reliable creep life predictions and identification of regions with high creep. That is to say, this represents one of the most direct applications of this project. The creep modeling methodology explained in this project can be useful for predicting the creep life of gas turbine blades (turbine blade creep), automotive components, pressure vessels, hot piping, nuclear reactor structures, and even polymers. In conclusion, the ultimate goal of the project is to provide a more comprehensive and accurate tool for creep analysis, addressing the limitations of standard models in commercial software. Therefore, one may apply it to a wide range of other mechanical applications. In short, you can gain several insights from this project:

- Understanding of Creep Modeling: Detailed knowledge about modeling all stages of creep analysis.

- Custom Subroutine Development: Insights into the development and validation of a new user subroutine for creep analysis, which can be used in Abaqus CAE.

- Understanding the Advantages Over Existing Models: Understanding the advantages of the proposed method over existing built-in creep models in CAE tools, including the ability to model all stages of creep and visualize critical regions of creep.

- Become ready for Future Work: Potential extensions of the project include analyzing the effect of pre-strain, initial damage, thermal barrier coatings, and creep-fatigue interaction on the remaining useful life of gas turbine blades.

Creep Failure in Turbine Blade Modeling

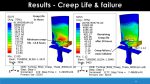

In this project, we have used the Theta projection method for Turbine Blade Creep prediction in Abaqus. The method involves using Theta coefficients, which are obtained through robust curve fitting methods, for creep prediction. The reliability of Theta values can be visually checked by plotting them against stress (σ) and temperature (T) to ensure a logical relationship. That is to say, to make it easier to understand, all the formulations for the Theta projection method are included.

Code description

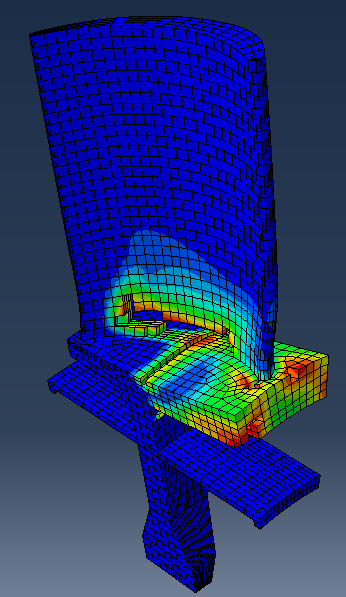

Both the USDFLD and CREEP Abaqus user subroutines were developed and used in this project. We have tested them for a variety of cases, to validate the results. Certainly, the results of creep analysis using the subroutines were compared with experimental data. This ensures that the subroutines can predict turbine blade creep with reasonable accuracy.

Results of Theta Protection Creep Model

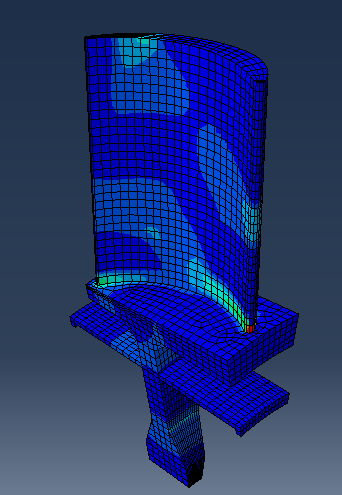

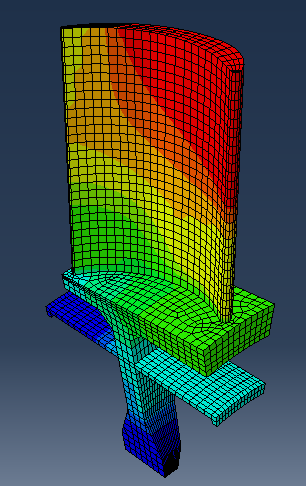

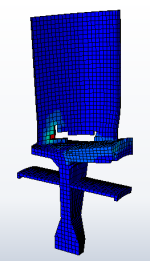

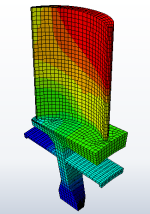

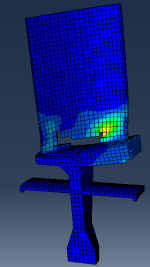

The project primarily focuses on extracting the creep life in hours, hardening state & accumulated damage (Creep failure in turbine blades) of the component modeled through internal calculations of Theta values, stress components, strain components, and the thermal field that happens in the subroutines. However, it is straightforward to activate any desired output component in Abaqus yourself to extract the desired results for your project. The validation in the project is done through several methods, including comparing the results with experimental data.

Zebedee –

I was struggling to model creep in Abaqus, but this tutorial and sample code have been a game-changer. The Theta Projection method is now demystified, and I’m able to simulate creep behavior in gas turbine blades with confidence. Will this approach be applicable to other materials and applications as well?

Emily –

This package on creep modeling in gas turbine components is really comprehensive and complete. From the theoretical principles to the practical implementation in Abaqus, everything is well explained. I was able to obtain accurate and reliable results. Is it possible to provide interactive training for this method?

Theophilus –

I used this package for my gas turbine design project and got very good results. The ability to accurately predict the primary, secondary, and tertiary creep stages helped me improve the design. Is there a possibility of updating this model for use in newer versions of Abaqus?

Ezekiel –

As a gas turbine design engineer, I used this package and obtained very good results. The ability to accurately model the different stages of creep, especially the third stage, really helped me to perform a better optimization of the design. Is there a possibility of future updates to this package?

Winifred –

Using this package and the provided application code for creep modeling in Abaqus was really helpful. I gained a lot of confidence that my analysis results are accurate and reliable. Is it possible to provide additional training for working with this method?

Catriona –

This package fully covers the issue of creep modeling in gas turbine components. From the theoretical principles to the practical code for Abaqus, everything is well presented. I can use this method in my future projects and obtain more accurate results. Is it possible to provide more examples of the application of this method?