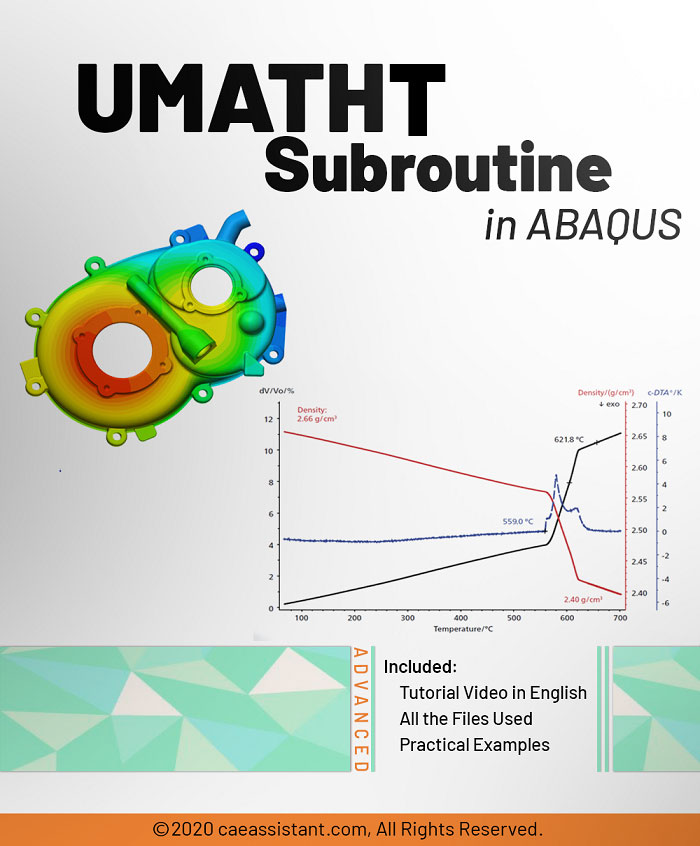

UMATHT Subroutine in ABAQUS

This subroutine is for defining a material’s thermal behavior and internal heat generation during a heat transfer analysis and is used in Abaqus Standard. This subroutine will be applied to all material calculation points (integration points) of elements. Also, you can use the UMATHT subroutine in conjunction with the USDFLD subroutine. This subroutine needs to define different variables, including internal thermal energy per unit mass, Variation of internal thermal energy per unit mass with respect to temperature, Heat flux vector, Variation of the heat flux vector concerning temperature, and variation of the heat flux vector for the spatial gradients of temperature.

This subroutine is one of the complicated subroutines recommended only for experts; with this package, however, you will learn how to work with the UMATHT subroutine like a piece of cake.

It would be helpful to see Abaqus Documentation to understand how it would be hard to start an Abaqus simulation without any Abaqus tutorial.

Reviews

Clear filtersThere are no reviews yet.