Introduction to Pultrusion | Pultrusion Abaqus

In Pultrusion, manufacturers use a continuous process to produce composite materials with a constant cross-sectional profile. The process involves pulling fibers, such as glass, carbon, or aramid, through a resin bath. This helps to impregnate them with a polymer resin. These impregnated fibers are then pulled through a heated die, curing and shaping the material into the desired profile. The result is a strong, lightweight composite material that manufacturers can use in various applications, such as construction, automotive, and aerospace industries. Therefore, it can be consluded that pultrusion is a type of composite curing method, the process of which differs from methods like oven curing.

Numerical simulation of Pultrusion | pultrusion crack simulation

The simulation of the Pultrusion process is important for several reasons. Firstly, simulations help in understanding the formation of potential defects, such as cracks, during the Pultrusion process. This is crucial for improving the quality of the final product. Moreover, by simulating the process, parameters such as pulling speed and die temperature can be optimized. This helps us to enhance the efficiency and quality of the pultruded profiles. For example, optimizing die temperature can improve the degree of cure in the Pultrusion process. Additionally, simulations can predict changes in material properties, such as the elastic modulus and strength of the polymerized resin. These are essential for ensuring that the final product meets the required standards. Furthermore, modeling and control of the Pultrusion process can be achieved through simulations. This allows for better management of the manufacturing process and ensures consistent product quality.

Overall, the simulation of Pultrusion processes such as pultrusion crack simulation is a valuable tool for improving the manufacturing process, enhancing product quality, and reducing costs.

Numerical simulations, while highly beneficial, come with several challenges. For example, developing accurate models that can capture the complex behavior of materials and processes, such as the mechanical behavior of composites or the kinetics of polymerization, can be very challenging. Moreover, high-fidelity simulations often require significant computational power and time, especially when dealing with large-scale or highly detailed models. The accuracy of a simulation heavily depends on the quality of the input data, such as material properties and boundary conditions. Therefore, inaccurate or incomplete data can lead to unreliable results. Additionally, setting appropriate boundary conditions, such as mechanical and thermal contact conditions, can be complex and significantly affect the simulation results. Finally, effectively using simulation tools often requires a high level of expertise in both the software and the underlying physical processes being modeled.

All of these factors highlight the need for accurate ways to capture Pultrusion, as we have provided in this package. Despite these challenges, numerical simulations remain a powerful tool for understanding and optimizing complex processes like Pultrusion. Also, we cover Pultrusion Abaqus modeling.

Theory and the formulation

The project employs several equations, formulations, and theories to describe the thermos-chemo-mechanical behavior of composites and to perform numerical simulations. For example, researchers use formulations related to the cure kinetics, gelation, and glass transition of epoxy resins to model the curing process of the composite materials. Moreover, the evolution of the bulk modulus of thermoset resins during crosslinking is studied to understand how the material properties change during the curing process. We implement these theories and formulations within the ABAQUS environment using various user subroutines to perform detailed numerical simulations and analyses.

Note that some of these models may have the same names as those introduced in our Intermediate and Advanced curing packages, but due to the differences in the process type and the materials being studied in this project compared to oven curing projects for prepregs, the equations and theories are different, and the required parameters also vary.

Pultrusion Abaqus modeling

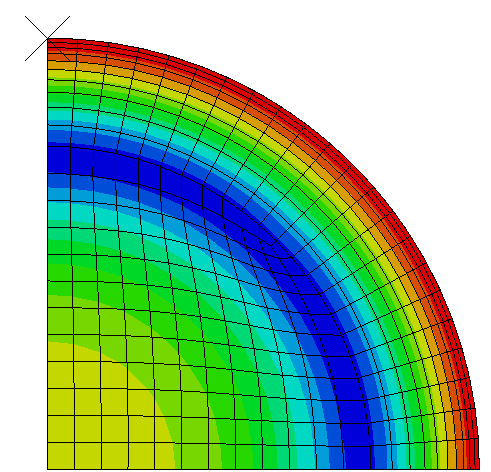

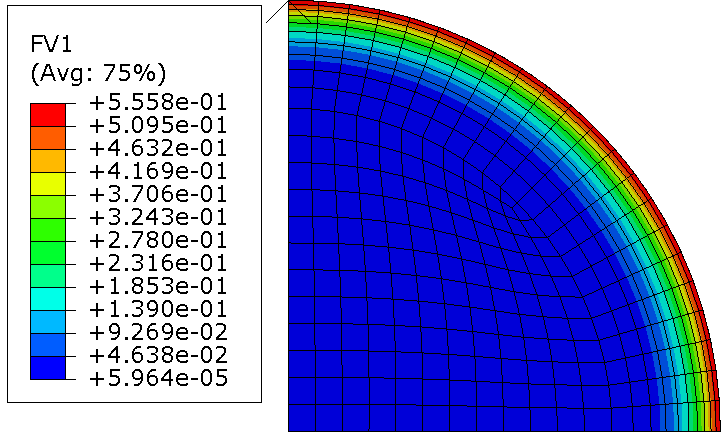

ABAQUS plays a crucial role in the numerical simulation of the mechanical behavior of composites in today’s world. So, we have used it to model the Pultrusion process in this project (Pultrusion Abaqus modeling). To do so, we have used the incremental linear elastic approach within ABAQUS. It enables us to calculate displacements and stresses. To accelerate computations, we will consider a 2D setting for problems related to thermal conductivity, degree of polymerization distribution, and stress-strain state calculations. Symmetrical boundary conditions and mechanical contact boundary conditions are set within ABAQUS to simulate interactions with the rigid surface and thermal contact with ambient air.

The Abaqus model includes multiple steps. In the first step, a die is attached to the specimen and begins heating. The heat is applied to the die via convection using the Film subroutine in Abaqus. In the next step, the die is removed. In the third step, we analyze the specimen’s behavior after the die is removed to predict deformation and residual stresses.

Code description

Abaqus is a powerful tool for the simulation of Pultrusion Abaqus. However, it has limitations in the models for describing the mechanical behavior of composites and the stress-strain state calculations. To address this, we have used several user subroutines including UMAT, FILM, USDFLD, HETVAL, UEXPAN, and UEXTERNALDB to perform the simulation in this project.

The UMAT subroutine allows us to define the stiffness and material properties of the specimen during curing, as a function of temperature and the degree of cure. The Film subroutine enables the assignment of heat convection to the die in the analysis. HETVAL helps account for heat generation due to chemical reactions in the model. UEXPAN accounts for thermal expansion and chemical shrinkage. Finally, UEXTERNADB helps write data to files. By using these subroutines, we can accurately model the thermo-chemo-mechanical behavior of composites during the pultrusion process (Pultrusion Abaqus modeling), including the modeling of the die and its removal. We have provided a step-by-step guide on writing each subroutine to create a valuable learning experience for you.

What makes this project different from the training packages for curing prepregs in an oven?

Despite the general similarities in composite curing methods that we have explained, what differentiates this package from our Intermediate and Advanced curing packages is, first, that the equations used here are different from those provided for curing prepregs in oven due to differences in the process type and material. Secondly, we have modeled the die, applied heat to it, and transferred the heat from the die to the composite, in the current package. Afterward, we opened the die, which reflects what actually happens in the pultrusion process. Finally, we examined the composite’s behavior after the die is removed. However, in the case of trainings for composite curing in an oven, without considering the mold, only the temperature is directly applied to the specimen.

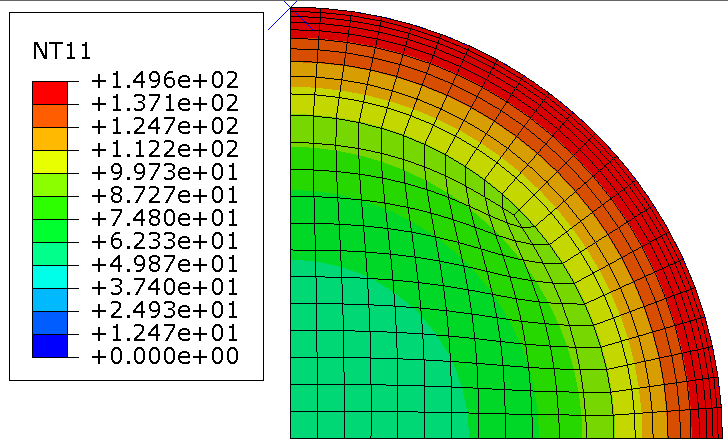

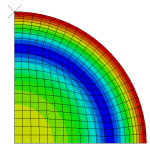

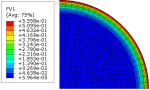

Results

The study monitors several components within the result. For instance, temperatures in different sections are monitored to ensure proper curing and quality of the profiles. We monitor the degree of polymerization (Curing) to ensure that the material properties meet the required standards. Moreover, transverse stress and residual stress fields are monitored to understand their impact on overall material integrity. Finally, changes in the elastic modulus and strength of the polymerized resin are monitored through mechanical tensile testing. These components are critical for ensuring the quality and reliability of the manufactured composite profiles and for optimizing the Pultrusion process.

What do we expect from this tutorial?

From this project, the learner can gain several insights. For example, understanding how phase transitions and mechanical stresses affect the changes in the elastic modulus and strength of polymerized resin. And the process of applying heat to a die in Abaqus, using the film subroutine, and removing the die to capture the response of composite. Finally, practical information on how to implement these findings in a real-world manufacturing setting to enhance the quality and efficiency of composite material production. Overall, the reader gains a comprehensive understanding of the factors influencing the quality of pultruded composite profiles and methods to optimize the manufacturing process for improved outcomes.

Reviews

Clear filtersThere are no reviews yet.