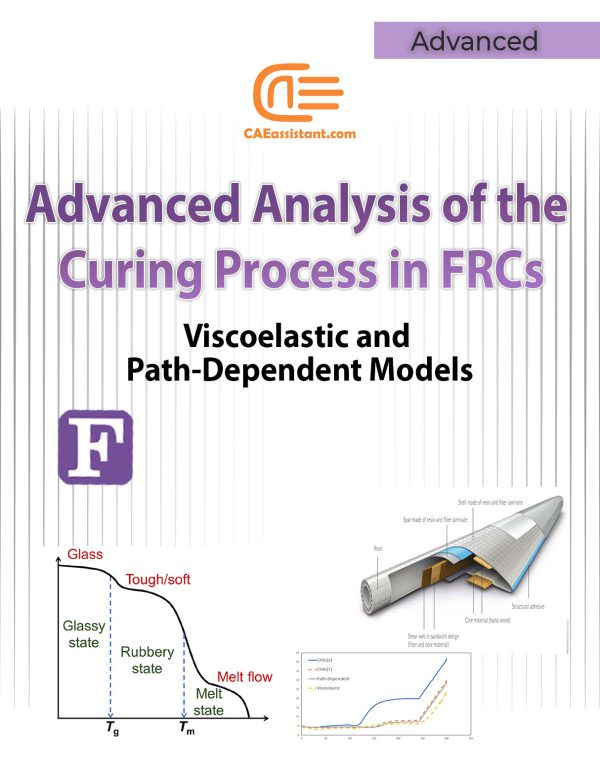

Lesson 1: Simulation of the Curing Process in Fiber-Reinforced Composites

What are fiber-reinforced composites (FRCs)?

A fiber-reinforced composite (FRC) is a specimen composed of at least two different components: fibers and a matrix. Fibers provide the composite’s primary load-bearing capability due to their superior strength and stiffness. The matrix, which cohesively bonds the fibers, plays a crucial role in load transfer between fibers, protecting them from damage, and contributing to the composite’s overall structural uniformity. This combination results in a material that exhibits properties superior to those of either component alone.

Fiber-reinforced composites (FRCs) are well-known for their lightweight nature, strength, durability, and adaptability. Such properties make them valuable across a diverse range of industries, including aerospace, automotive, construction, sports equipment, and beyond. They are extensively employed in applications where a combination of strength, stiffness, and low weight is essential. Due to their remarkable properties, FRCs have become one of the most promising materials of this century.

FRCs can be classified into different groups based on their constituent materials. Common matrix types include polymers, metals, or ceramics, with a specific focus on polymers in this package. Furthermore, composites vary depending on their fiber materials, often involving glass, carbon, and aramid. They can take various forms, such as single-layer or multilayer, and exhibit either unidirectional or multidirectional properties, based on their intended applications. This wide range of compositions leads to diverse behaviors and applications across various fields.

How FRCs are made?

Regardless of their types, today, composites are often manufactured using two methods: Resin Transfer Molding (RTM) and Prepreg. Each method has its own set of advantages. RTM involves injecting resin into a mold that contains dry reinforcing fibers. The resin is injected under pressure to remove air and saturate the fibers. The mold will be heated to enable resin curing.

On the other hand, Prepreg involves reinforcing fibers (such as carbon, glass, or aramid) that already contain a resin matrix, typically epoxy, in a controlled environment. The resin is partially cured, but not fully hardened. During the manufacturing process, these prepreg sheets are placed into molds and undergo further curing under heat and pressure to achieve the final product. This method ensures precise control over resin content and results in uniformity in the final composite, producing high-quality parts with excellent mechanical properties.

While both methods involve the use of resin and fiber reinforcement, the main difference lies in how the resin is applied. In both methods, the composite is subjected to pressure and temperature cycles to convert the resin from liquid to solid. This process, known as curing, is crucial for all applications and requires precision.

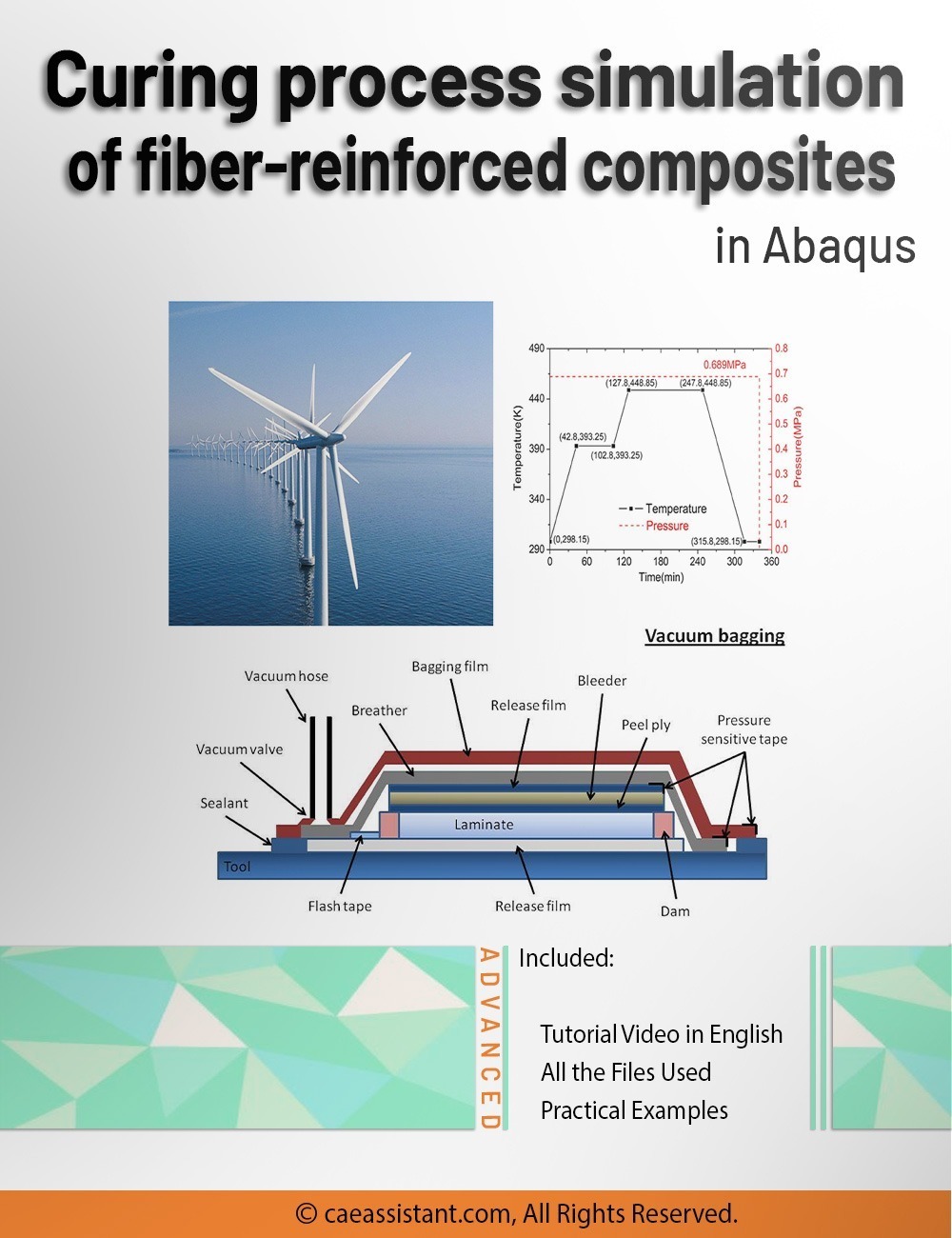

Two main methods are often used to apply heat and pressure to composite materials for curing: Oven heating and Autoclave curing. The Autoclave method is modern and more precise, but it is also more expensive. Whether using an oven or an autoclave, the curing protocol should be designed carefully to maintain the performance and quality of the composite, as well as to improve its surface finish. Therefore, the curing process is crucial in the production of FRCs.

Simulating the curing process in FRCs

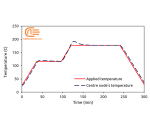

Time and temperature are two critical factors influencing the curing quality of fiber-reinforced composites. High-quality composites often require several hours of curing at an optimal temperature to meet industry standards. However, this extended curing duration can slow down production speed and reduce efficiency. Consequently, many producers opt for shorter curing times at higher temperatures to increase production output. However, this approach may lead to the creation of residual stress in the composite and affect its quality. Hence, optimizing the curing process becomes essential to strike a balance between quality and time. Numerical simulation is a cost-effective method that can be used to achieve this optimization.

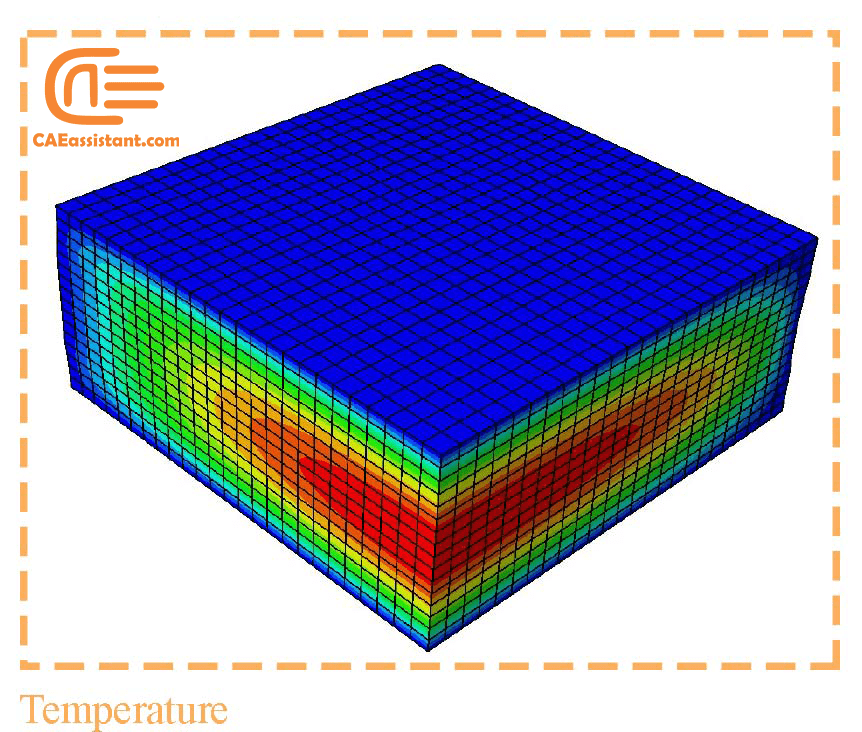

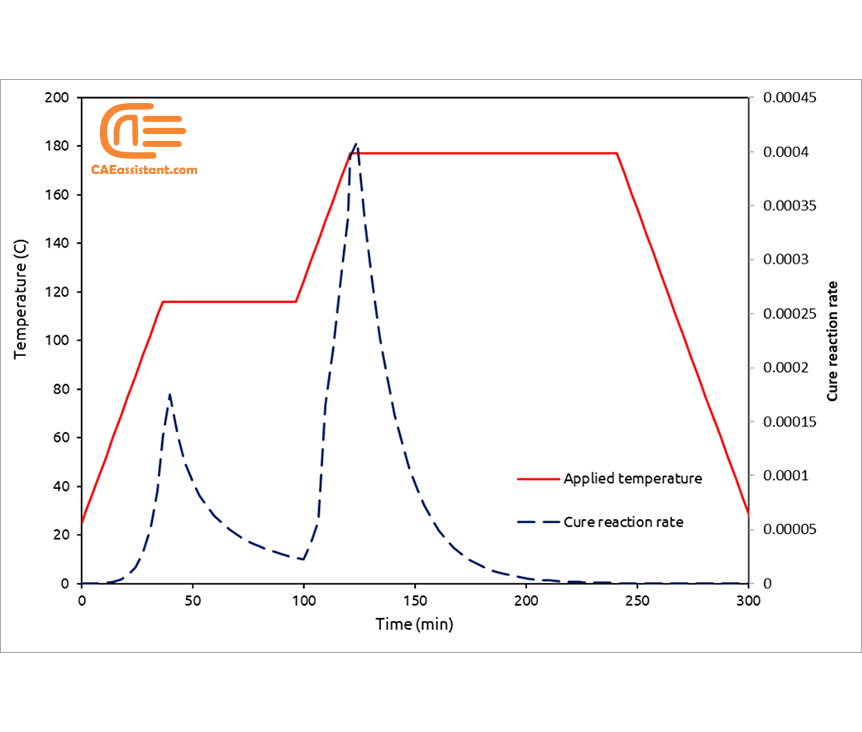

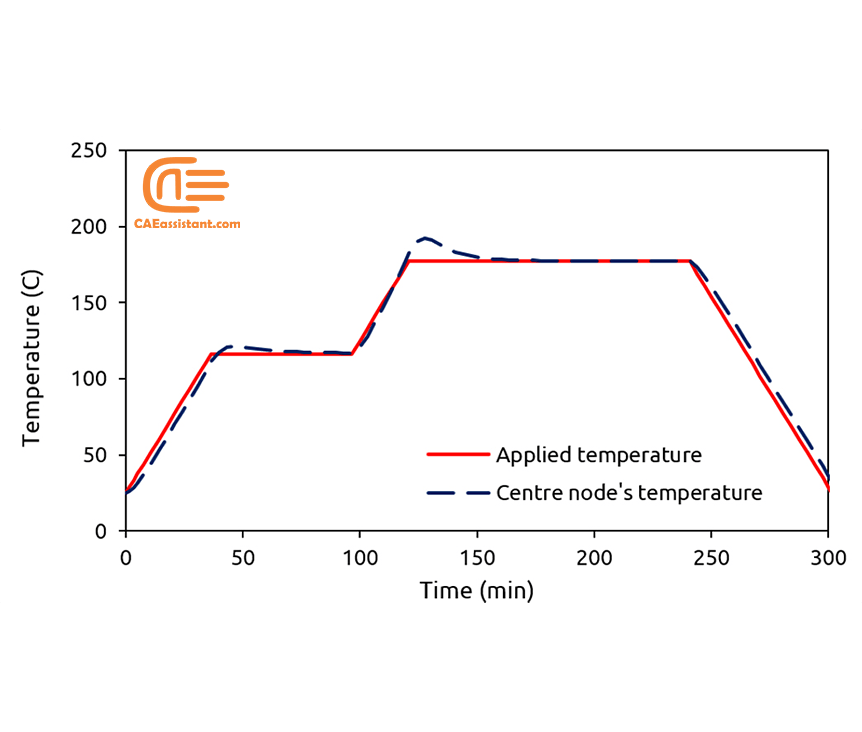

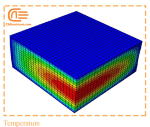

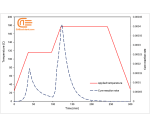

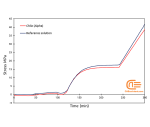

When dealing with curing simulation, the degree of cure is a key parameter. It determines the extent to which the material is cured. The degree of cure is a function of heat distribution within the material. The challenge arises from the presence of two heat sources in a composite: external heat and internal heat generated by chemical reactions in the matrix. The internal heat is typically a function of the degree of cure; therefore, a thermo-chemical model is necessary to study such behavior.

A thermo-chemical model should include a heat transfer equation and a cure kinetic equation to accurately describe the curing process. Within the cure kinetic equation, the rate of curing determines the heat flux, and this rate varies based on the specific composite type. This complicates the calculation of internal heat generated during the curing process for different composites.

How simulation is conducted in this lesson

The thermo-chemical model can vary based on the composite properties and is not universally standardized. Consequently, reviewing all of the models in a single package is not feasible. However, in this package, we have chosen a highly applicable composite type: AS4/3501–6 multidirectional carbon/epoxy prepreg for simulation. We will explain the thermo-chemical model specifically developed for simulating the behavior of this type of material. The model will be utilized to simulate the curing process and derive parameters such as the degree of cure and the temperature field in the composite. Due to the limitations of Abaqus alone to handle such a complex behavior, we must utilize Abaqus subroutines for the simulation.

Required subroutines in this lesson

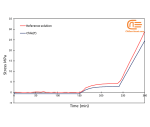

In this lesson, we utilized the HETVAL subroutine to calculate the heat flux resulting from chemical reactions. Additionally, the DISP subroutine is used to apply the temperature cycle. By utilizing these subroutines, we can effectively simulate such a complex problem within Abaqus without significant limitations. So, by learning this lesson, you will also gain valuable insights into writing such subroutines.

Lesson 2: Thermo-Chemo-Mechanical Simulation of Curing Process in Fiber-Reinforced Composites

Thermo-chemo-mechanical simulation of curing process

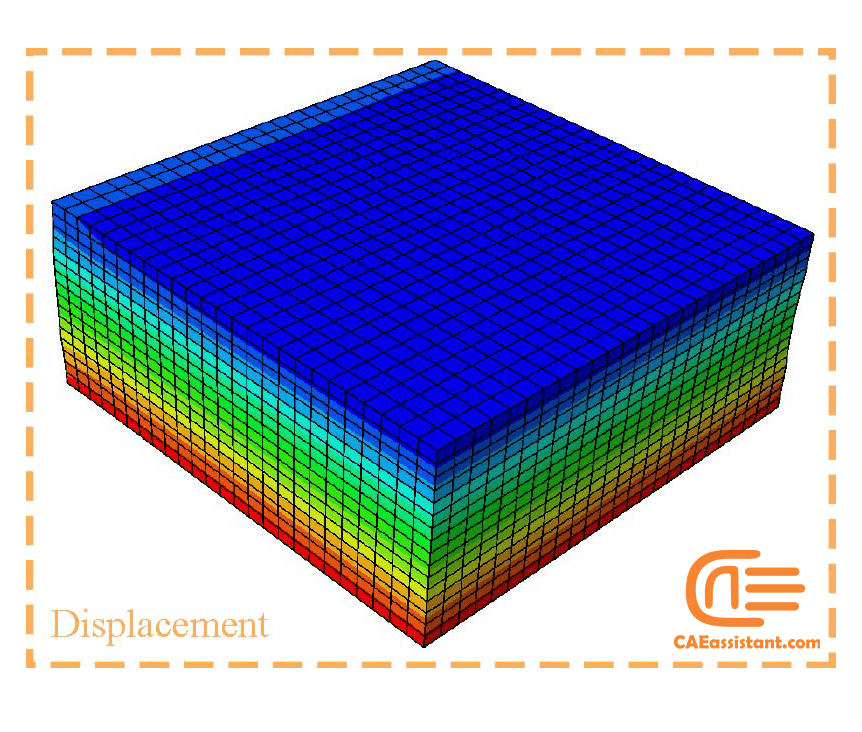

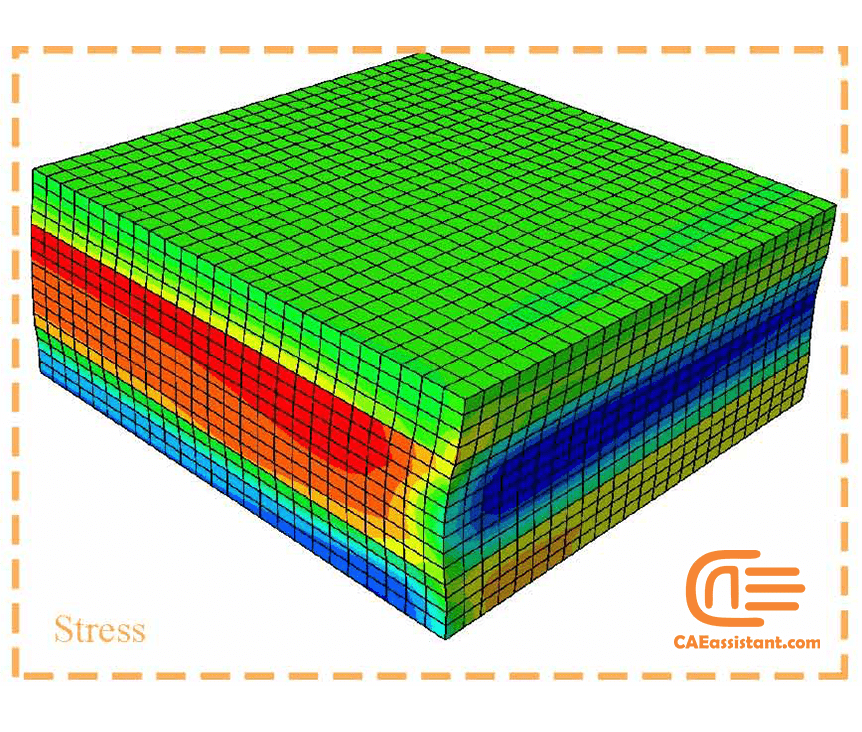

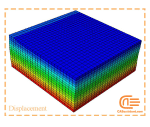

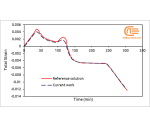

Throughout the curing process of fiber-reinforced composites (FRCs), the presence of non-mechanical strains and residual stresses within the laminate layers significantly influences the quality of the product. Therefore, it is crucial to consider these factors during composite production. However, the challenge lies in the dependence of strain and stress on both temperature and the degree of cure. Consequently, analyzing strain and stress in composites during curing requires a coupled model, commonly referred to as a thermo-chemo-mechanical model, as discussed in this lesson.

Strain evaluation in FRCs during curing

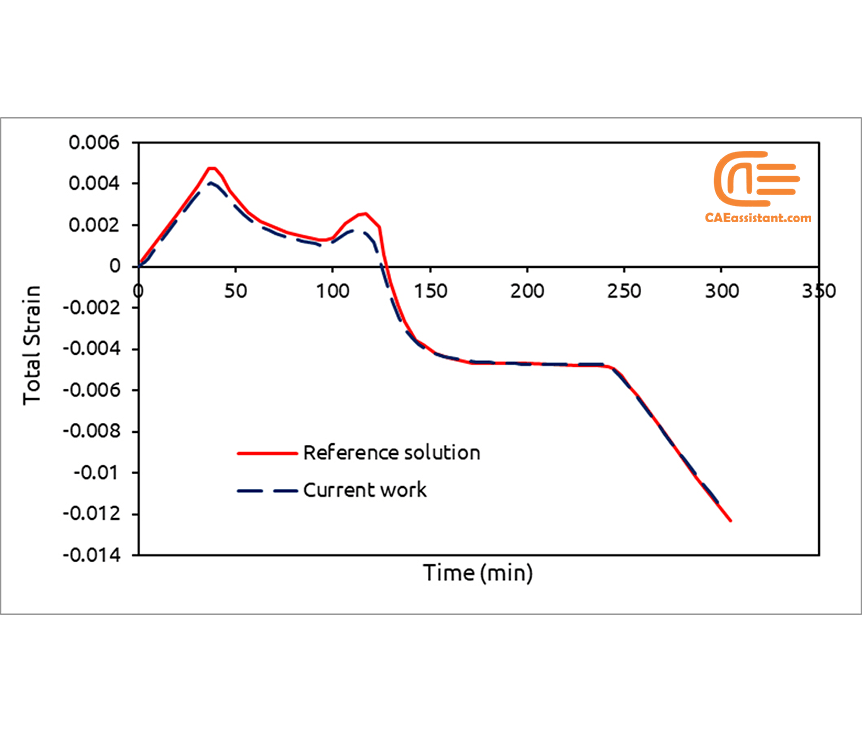

The total strain generated in a composite during curing is the summation of mechanical and non-mechanical components, where the non-mechanical strains arise from thermal expansion and chemical shrinkage. Therefore, we have to consider all these components in numerical simulations. The primary challenge in evaluating strain in composites lies in the consideration of non-mechanical strains. This is because the chemical expansion, resulting from the release of gases and solvents during curing, is a function of the degree of cure. Additionally, thermal expansion depends on both the applied temperature and the temperature released during curing. Furthermore, the thermal expansion coefficients vary between the matrix and fiber and also in different directions. All of these factors complicate the computation of non-mechanical strains in composites. To address all the strain components in the current lesson, we have utilized multiple Abaqus subroutines together.

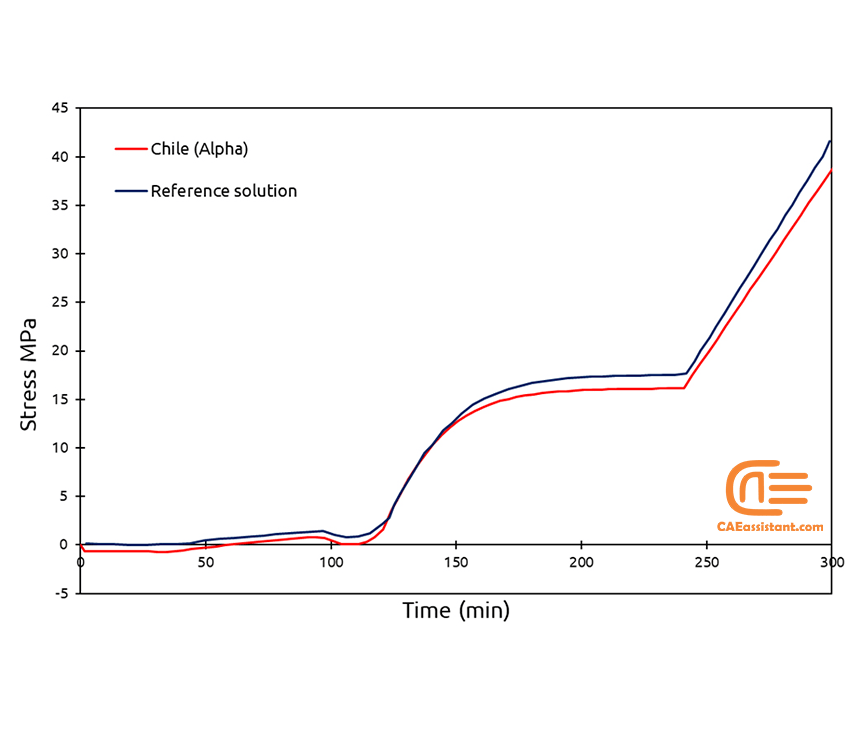

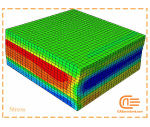

Evaluation of stress components during the curing process

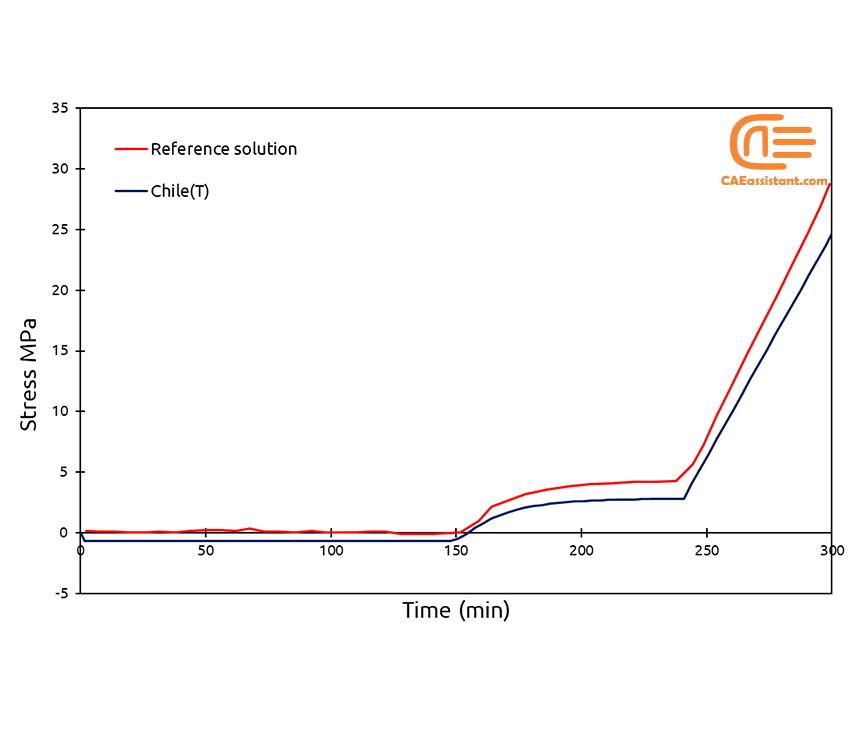

The calculation of stress within the composite layers during curing is not a simple task. This is because the resin’s modulus of elasticity depends on the degree of cure and the applied temperature. Viscoelastic models are developed based on the degree of cure and temperature field to evaluate stress within the composites. However, these models are very complex. To simplify this matter, linear elastic models are developed. They can consider the variation in the resin’s modulus of elasticity over time with less accuracy compared to the viscoelastic models but in a simpler way. In this lesson, we will guide you through using two different linear elastic models to evaluate the resin’s modulus of elasticity and the stress within the laminate layers.

Required subroutines for this lesson

We have mentioned that a thermo-chemo-mechanical model is used in this lesson to calculate the degree of cure, released temperature, strain, and stress altogether during the curing process. However, the consideration of multiple complex models that depend on each other is not a simple task. Therefore, we have to employ various subroutines in Abaqus CAE, including USDFLD, UMAT, HETVAL, DISP, and UEXPAN. By utilizing these subroutines, we can effectively simulate such complex problems within Abaqus. Learning this lesson will provide you with valuable insights into writing all these subroutines.

How simulation is conducted in this lesson

In this lesson, we utilized the DISP subroutine to apply the curing temperature cycle to the composite. The USDFLD subroutine was employed to evaluate the degree of cure and cure reaction rate during the solution. It stores these values in user-defined state variables to be utilized by other subroutines. The UEXPAN subroutine uses the degree of cure and temperature to calculate the chemical shrinkage and thermal expansion strains. The UMAT subroutine computes the composite stiffness based on the degree of cure and temperature and calculates the stress within the laminate layers. Finally, the HETVAL subroutine uses the calculated degree of cure to evaluate the internal heat generated during the curing process. Now, you can see that such a complex problem can be solved by using multiple Abaqus subroutines together.

Tynchtyk –

The curing process simulation package has effectively addressed our needs and provided valuable insights into our production processes. We are keen to further develop our expertise with the tool. Are there additional educational resources, such as tutorials or case studies, available to help us advance our understanding and use of the package’s specialized features?

Deepika –

In the context of modeling the curing process in Abaqus, how can the influence of various microstructures of fiber-reinforced composite materials be considered in the simulation results?

Experts Of CAE Assistant Group –

You can consider it as defect in the model

Aurpon Shams –

Nice product. All the details are in there

Experts Of CAE Assistant Group –

Thanks for your nice review

Talant –

This simulation tool has been crucial in reducing curing-related problems and optimizing our product quality. We are interested in customizing the simulation settings to better fit our specific production conditions.

Janyl –

We have been impressed with the performance and reliability of the curing process simulation package. It has made a notable difference in our production quality.

Nazar –

Our experience with the curing process simulation package has been very positive, especially with regard to the accuracy of the simulation results. We are interested in exploring the advanced features of the package but are unsure if any special configurations or settings are needed. Could you provide details on how to configure the tool for optimal use of its advanced features?