Simulation of Unidirectional Composite Damage in ABAQUS

€ 130.0

This package is about Unidirectional Composite Damage tutorial and applies various theories to initiate and progress damage in composite materials based on ABAQUS capabilities for different elements. As you know, according to the modeling done by the micro or macro method, the way of defining the Abaqus composite damage completely follows the separate method in ABAQUS. This training package is customized for Abaqus composite macro modeling. There are 5 different unidirectional composite examples to help you master unidirectional composite simulations and Abaqus composite laminate damage modeling. You can see the examples in the syllabus below.

| Expert | |

|---|---|

| Package Content |

.inps,video files, Fortran files (if available), Flowchart file (if available), Python files (if available), Pdf files (if available) |

| Tutorial video duration |

135 minutes |

| language |

English |

| Level | |

| Package Type | |

| Software version |

Applicable to all versions |

Frequently Bought Together

Introduction | Unidirectional Composite damage tutorial

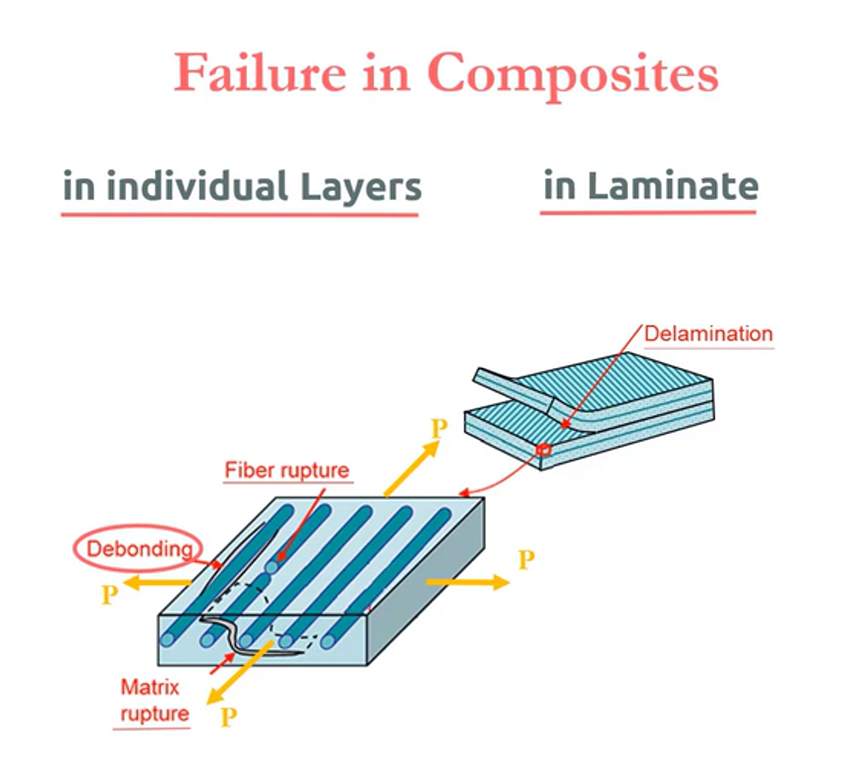

Unidirectional composites, with their fibers aligned in a single direction, offer exceptional strength and stiffness – perfect for lightweight, high-performance structures. However, their Achilles’ heel lies in their susceptibility to various damage mechanisms. These can include fiber breakage, matrix cracking, and delamination (separation of layers). The analysis and simulation of this damage, through a process called a unidirectional composite damage tutorial, is crucial for engineers. By understanding how and why these materials fail, we can optimize designs, predict lifespans, and ensure the safety and integrity of composite structures.

Unfortunately, mastering unidirectional composite damage analysis requires specialized knowledge and tools. Finding a professional tutorial that delves into the complexities of Abaqus software, the industry standard for finite element analysis, can be a challenge. This is where our comprehensive training program comes in. We offer a structured learning experience, guiding you through the intricacies of unidirectional composite damage simulation within the Abaqus framework.

Abaqus composite macro modeling

In this package, which focuses on how the modeling of composite materials is modeled by the macro method (Abaqus composite macro modeling) while introducing various theories to initiate and progress the damage of these materials and existing constraints based on software capabilities for different elements, teach users to simulate their models in ABAQUS.

5 Unidirectional composite examples

Unidirectional composite examples serve as valuable tools for understanding and predicting real-world scenarios. Through these examples, engineers can explore how factors like fiber orientation, matrix properties, and loading conditions influence damage initiation and progression. This allows for the optimization of composite structures, ensuring they can withstand the demands placed upon them.

In this training package we offer 5 professional examples which you can see them in the following.

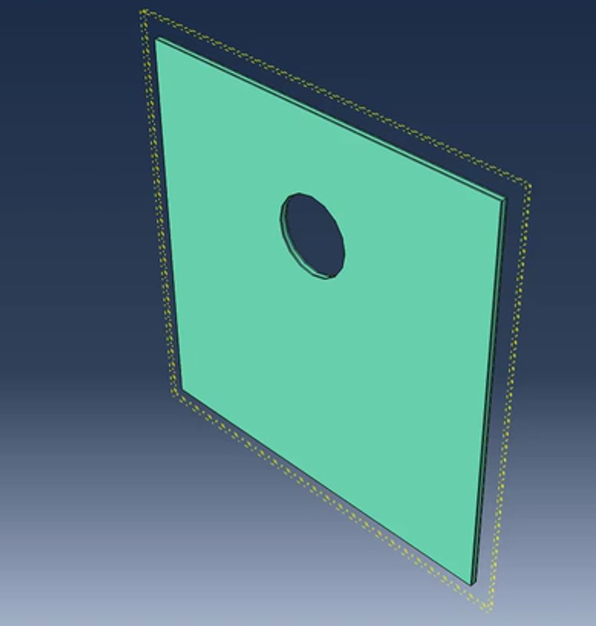

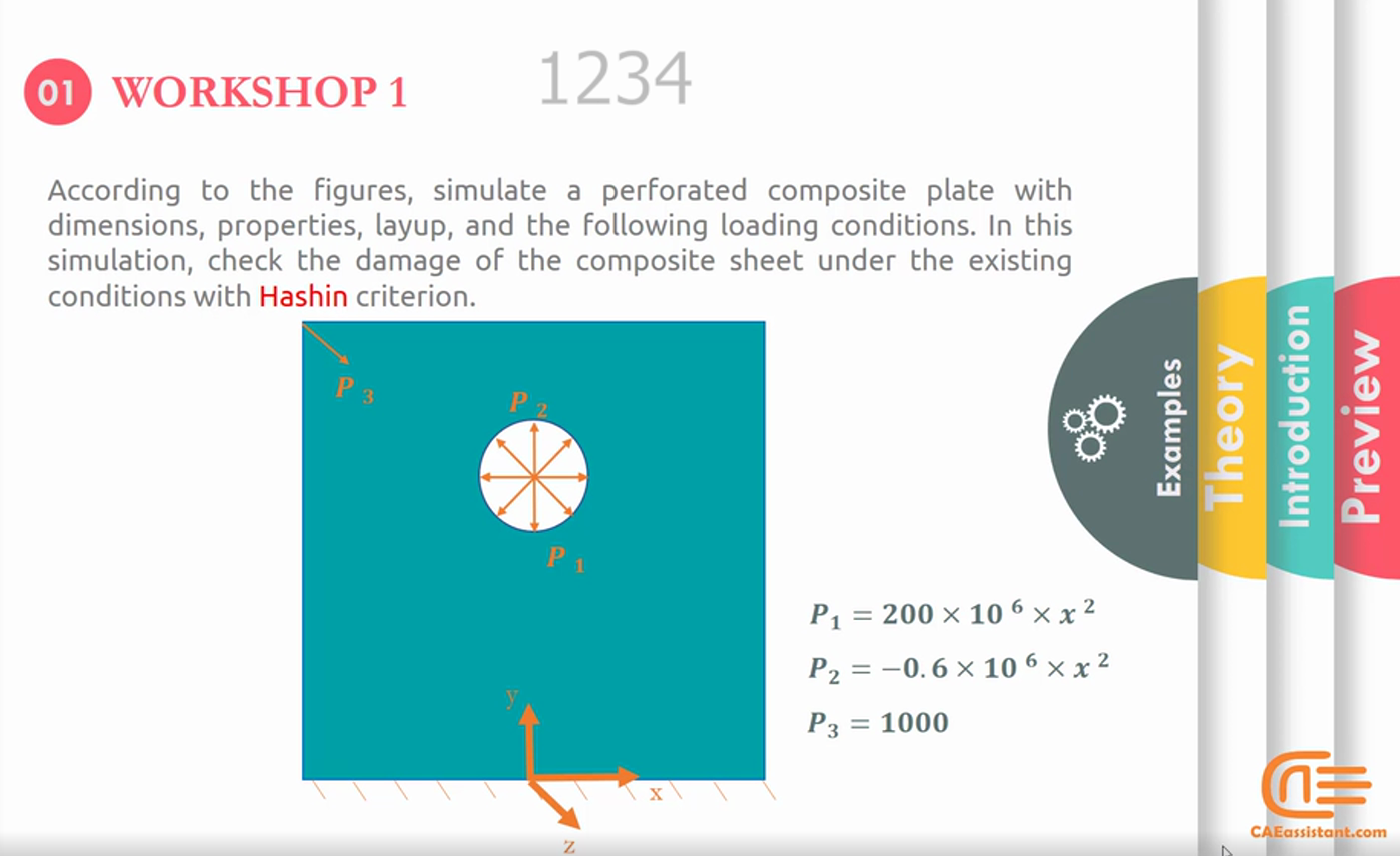

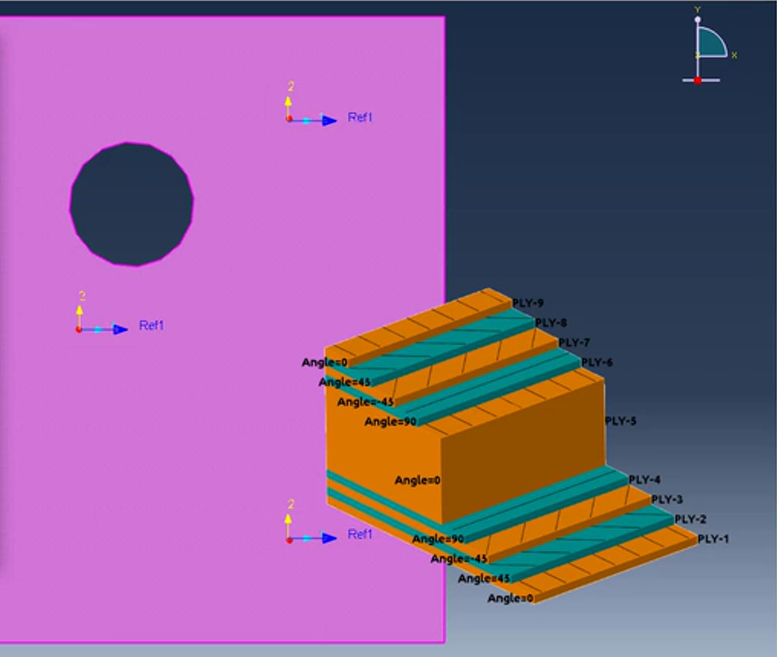

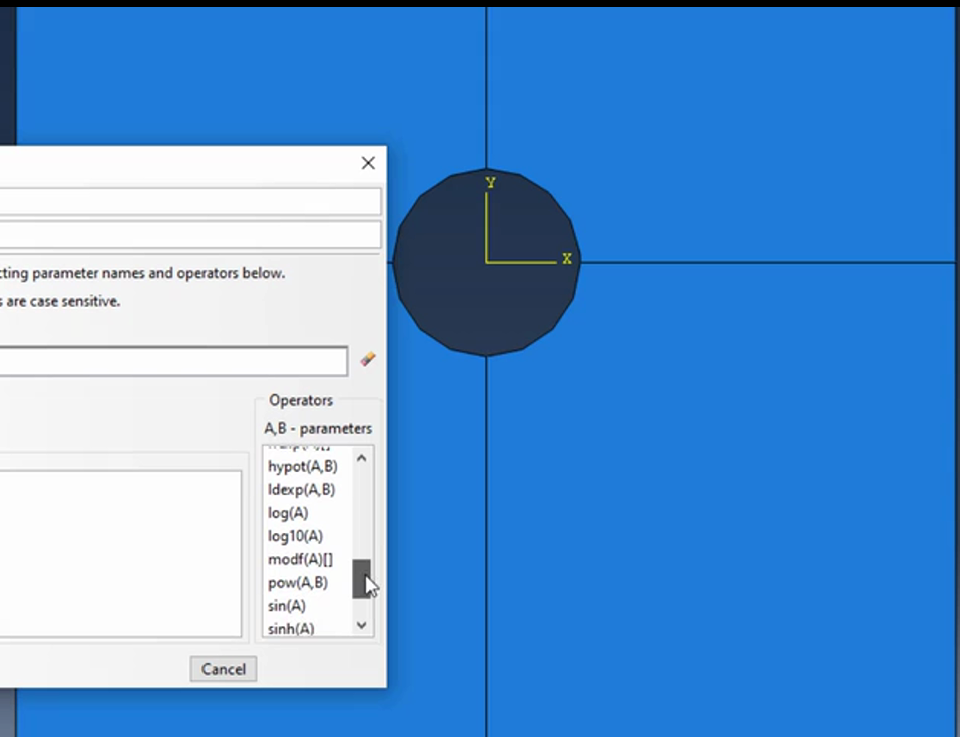

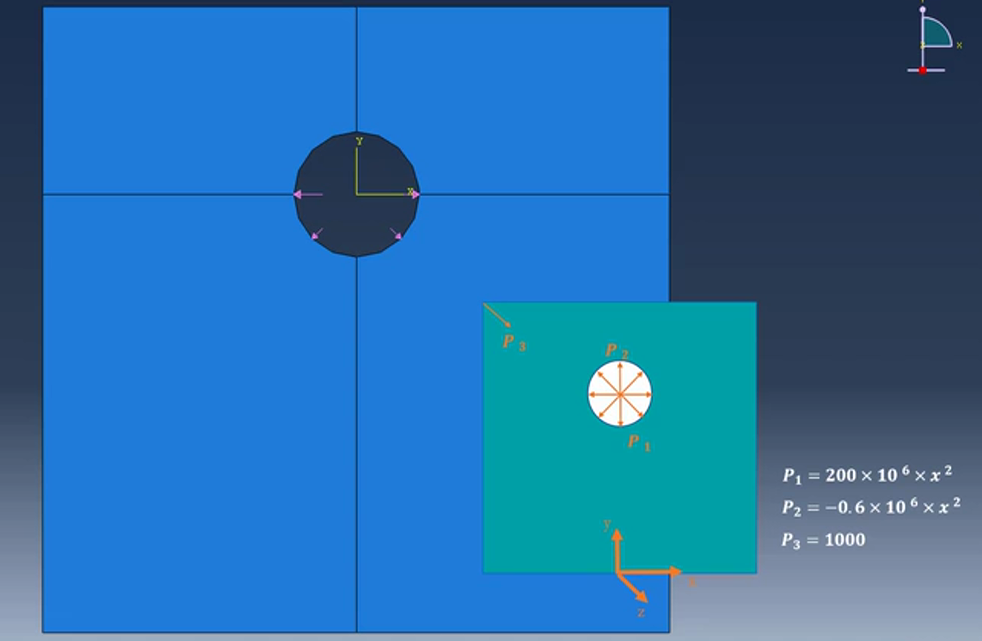

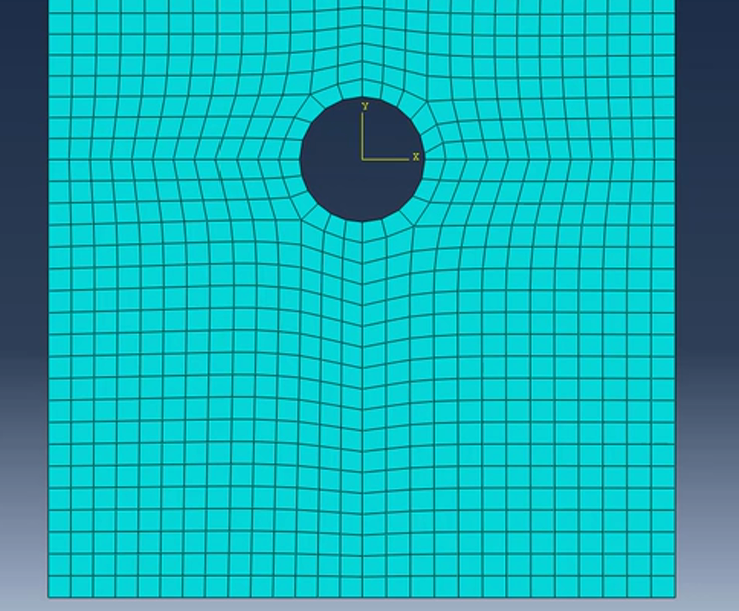

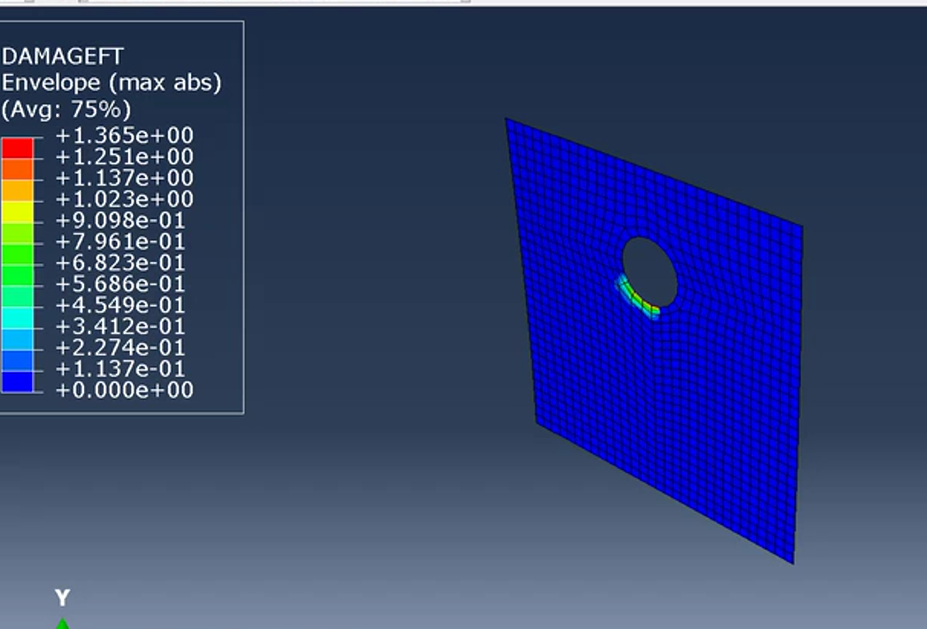

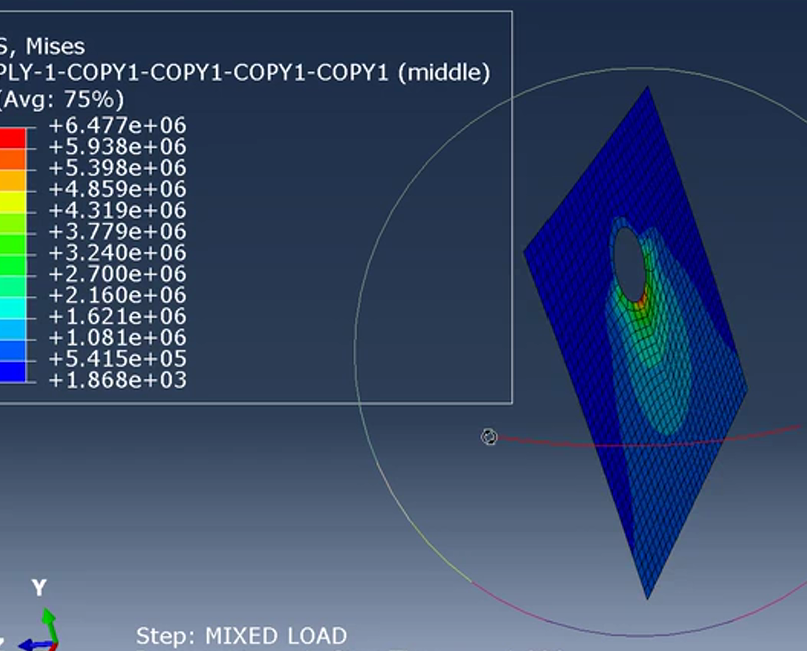

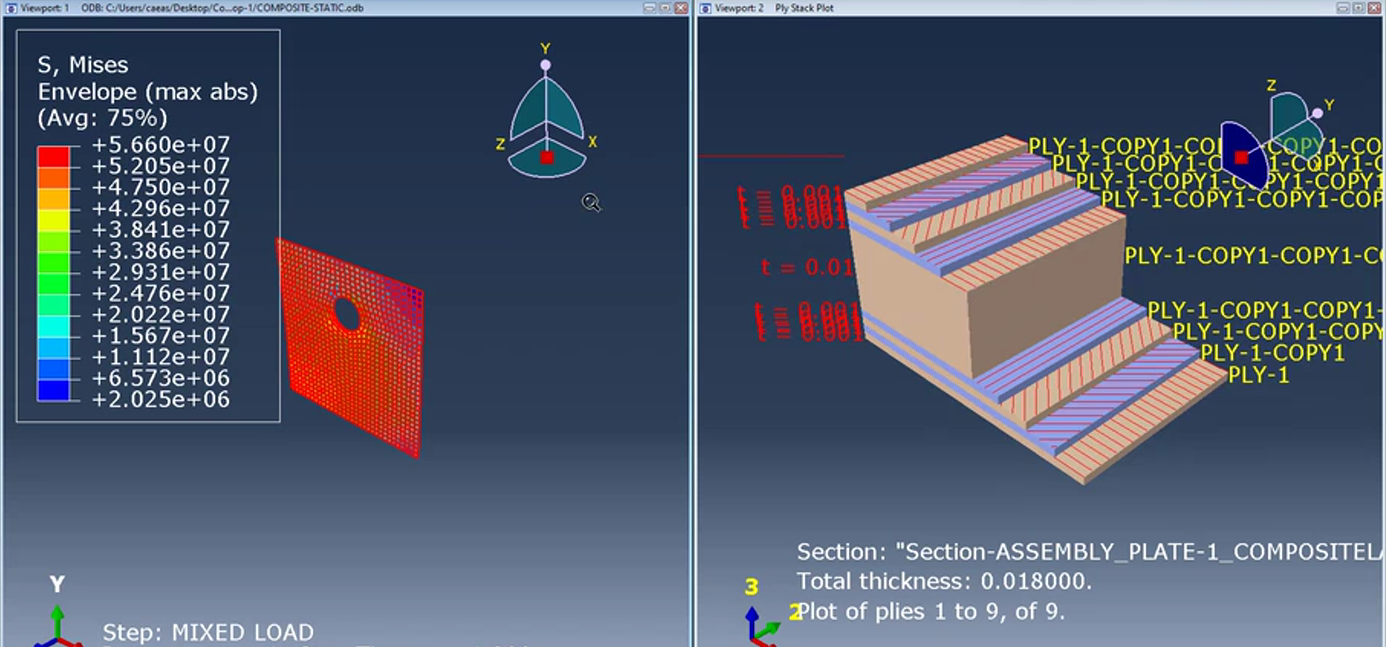

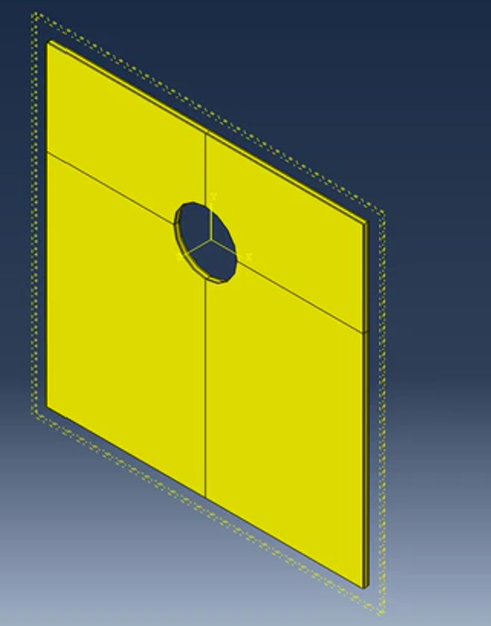

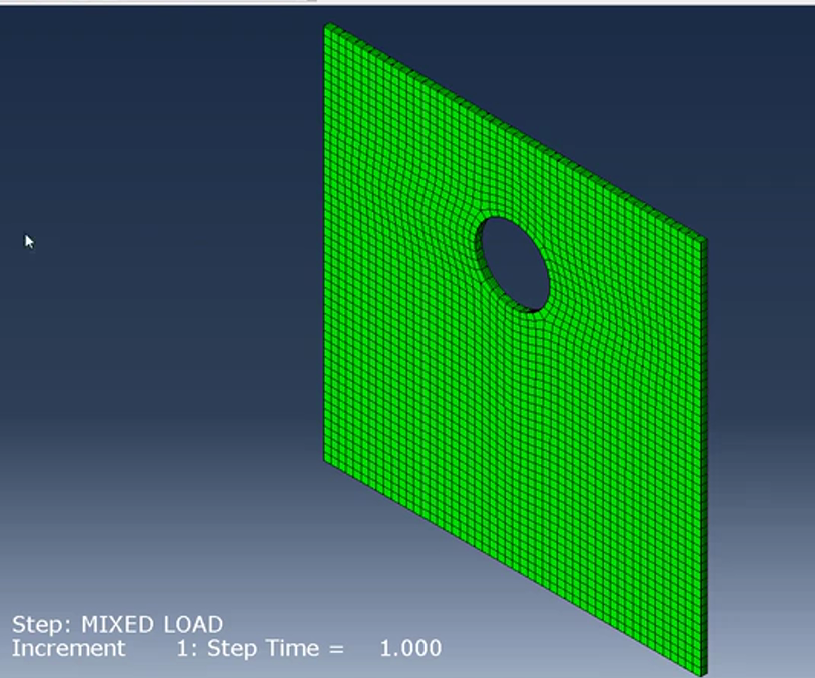

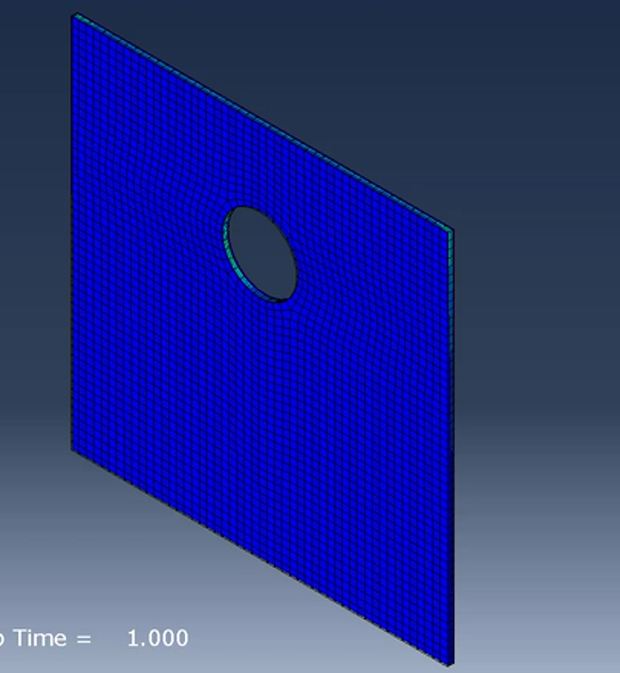

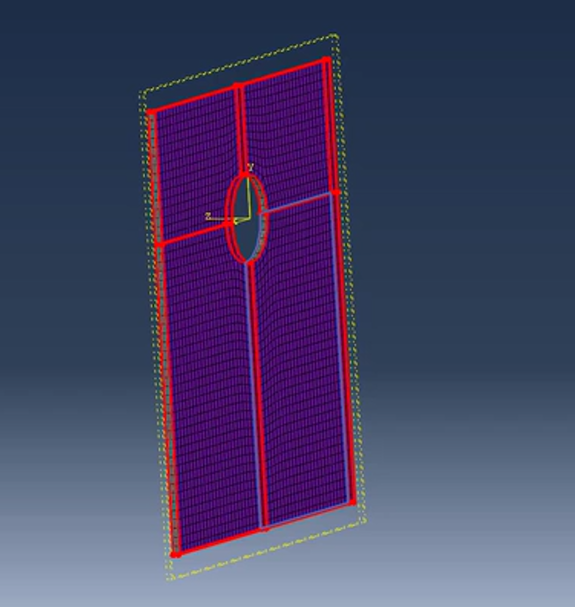

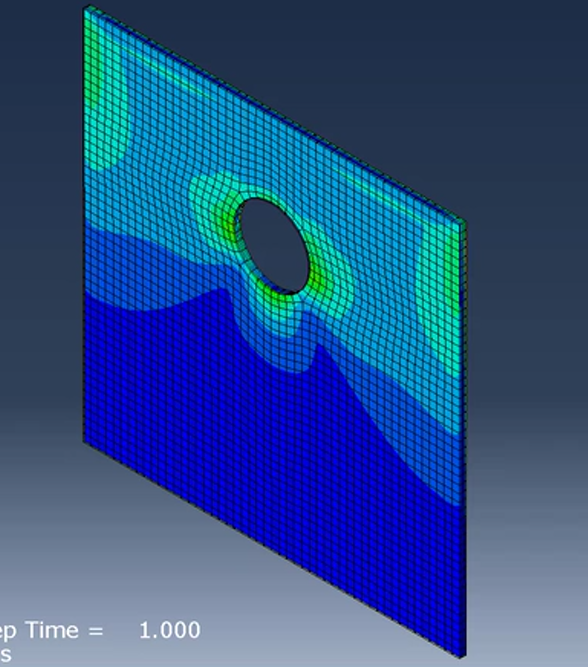

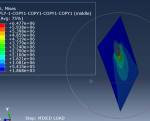

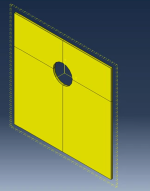

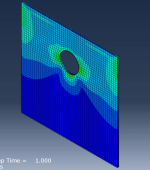

Workshop 1: Static analysis of damage initiation and progressive damage based on HASHIN failure criterion in holed composite plate under non-uniform loading (shell element)

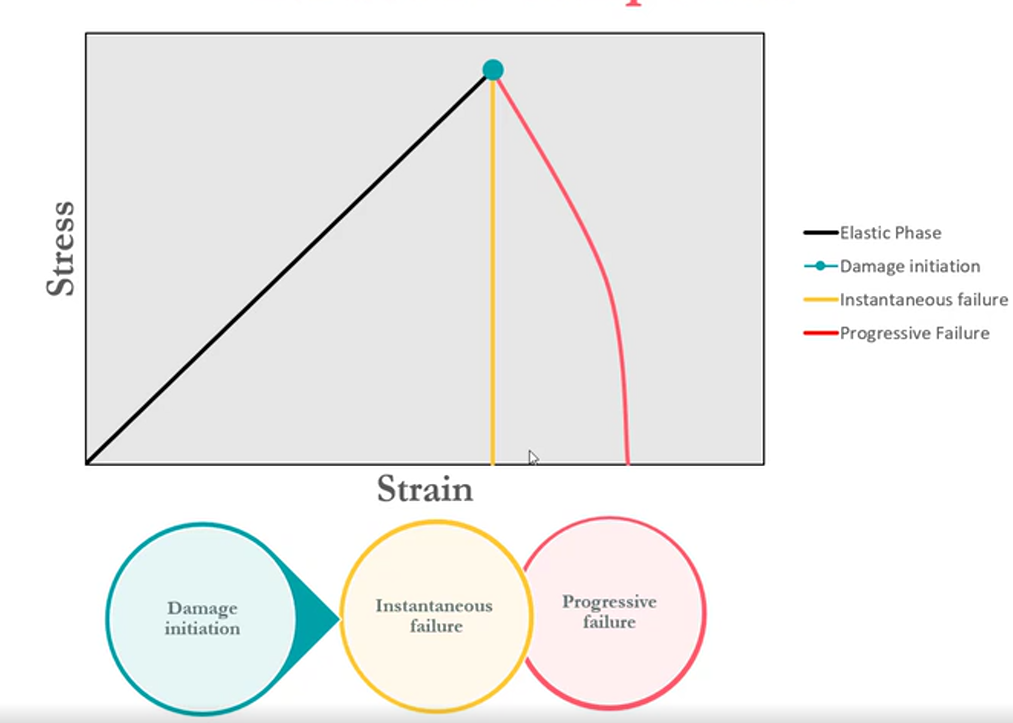

In this unidirectional composite damage tutorial, a multilayer composite plate with different orientations with holes with a shell element is placed under the tensile load as a nonlinear function inside the hole. In this simulation, the damage initiation is based on Hashin’s Physics-based phenomenon criterion and progressive damage is gradual on the basis of energy. In the HASHIN criterion failure in fiber and matrix is investigated separately in compression and tension. So, the user knows in which mode failure occurs and can reinforce his composite.

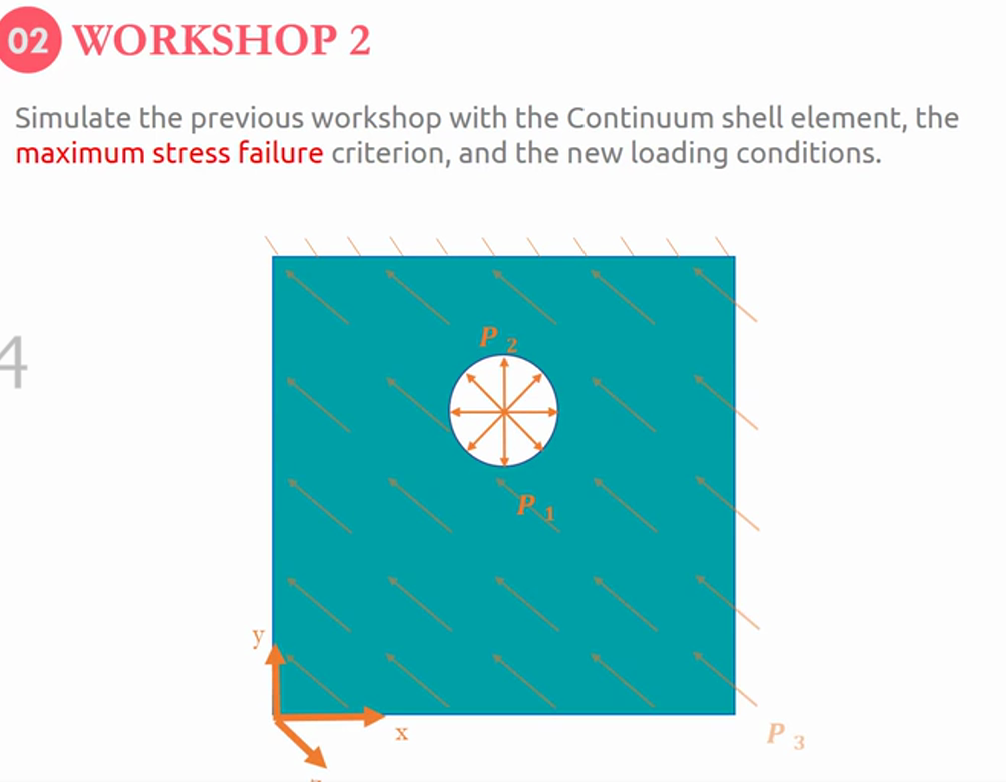

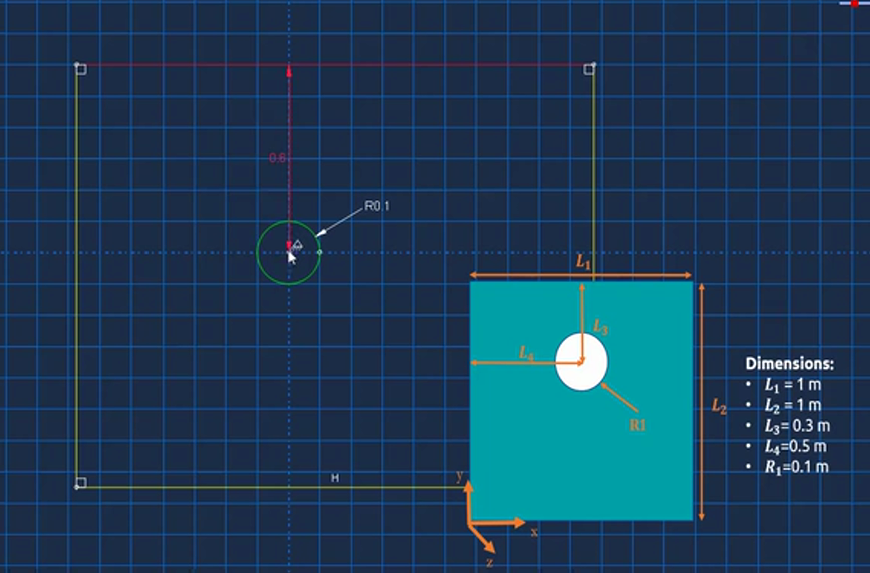

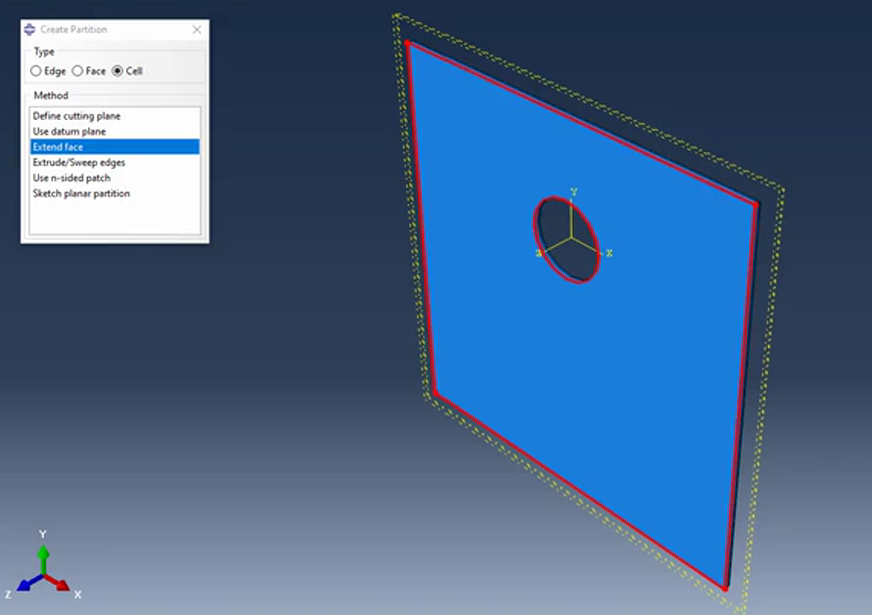

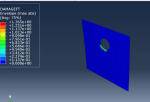

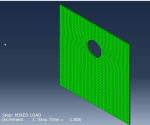

Workshop 2: Static analysis of stress based damage initiation criterion on holed composite plate under complex non-uniform loading (continuum shell element)

In this unidirectional composite damage tutorial, simulation of the composite material damage is performed based on non-physical phenomenon criteria such as Tsai-Hill and Tsai-Wu on a multilayered plate with a continuum element. Note that the simulation method and the necessary points for modeling are completely different from the previous workshop. In this workshop, one of the elementary methods of Abaqus composite damage modeling is investigated.

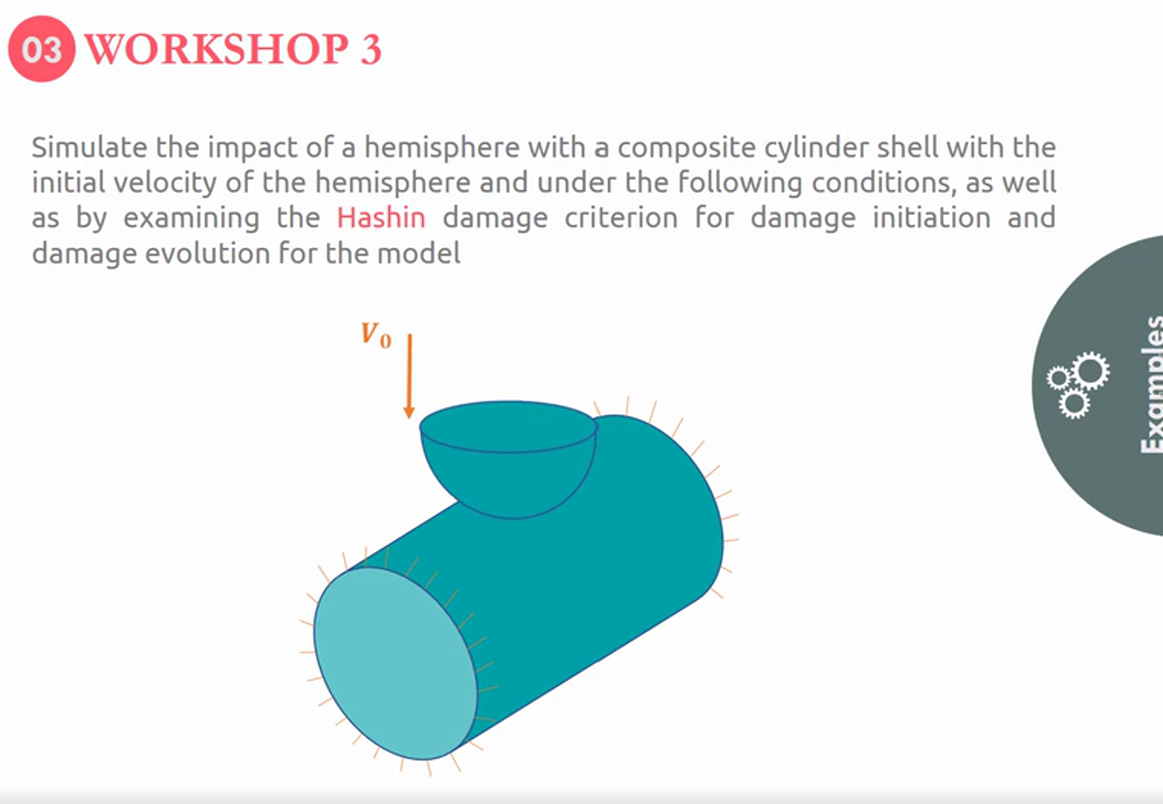

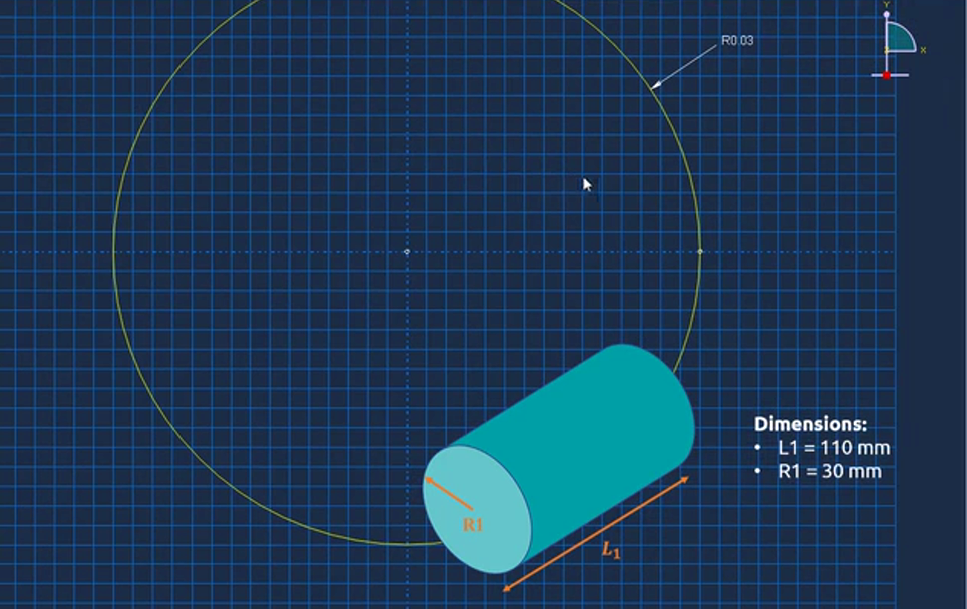

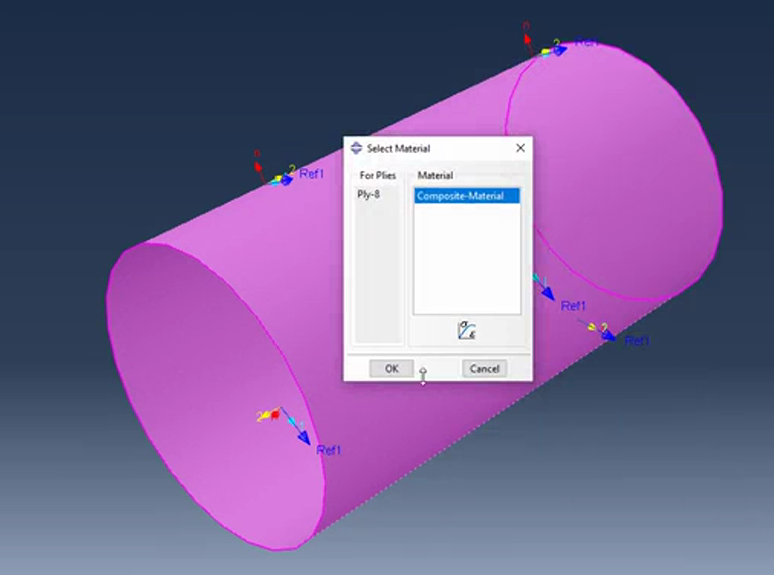

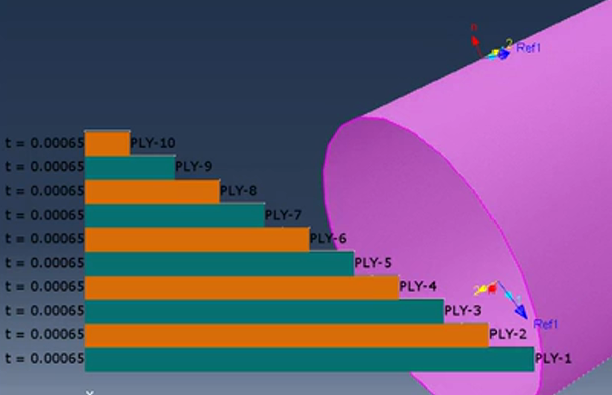

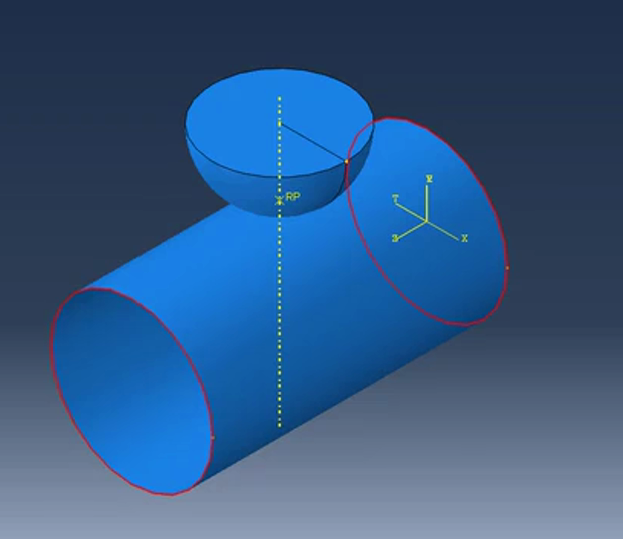

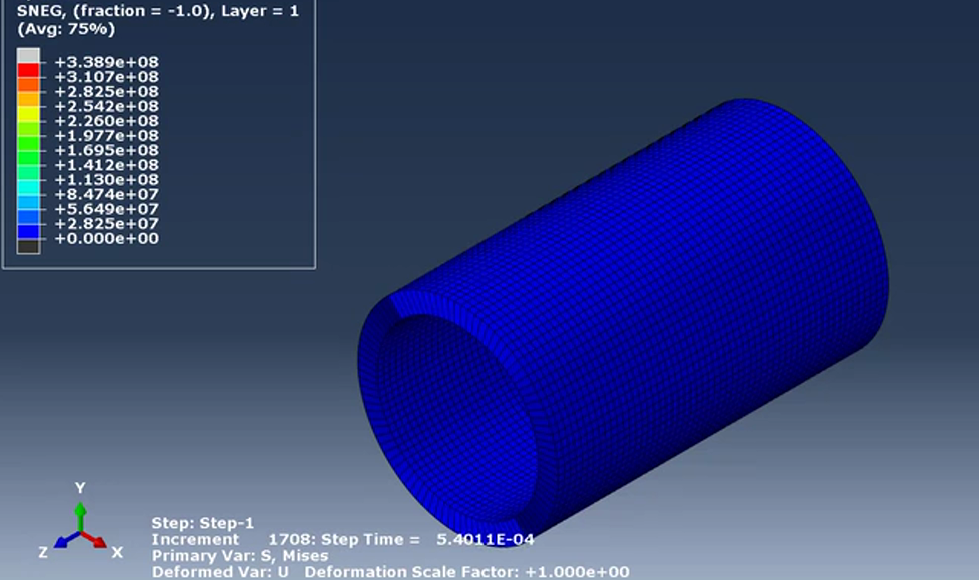

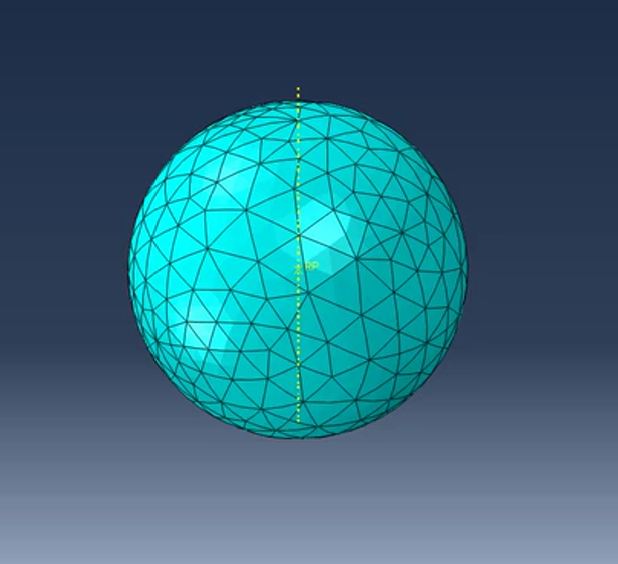

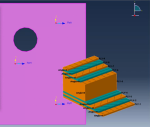

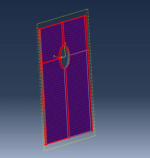

Workshop 3: Abaqus composite laminate damage modeling | damage initiation and progressive damage based on criteria in the impact of a bullet on a laminate composite cylinder shell (shell element)

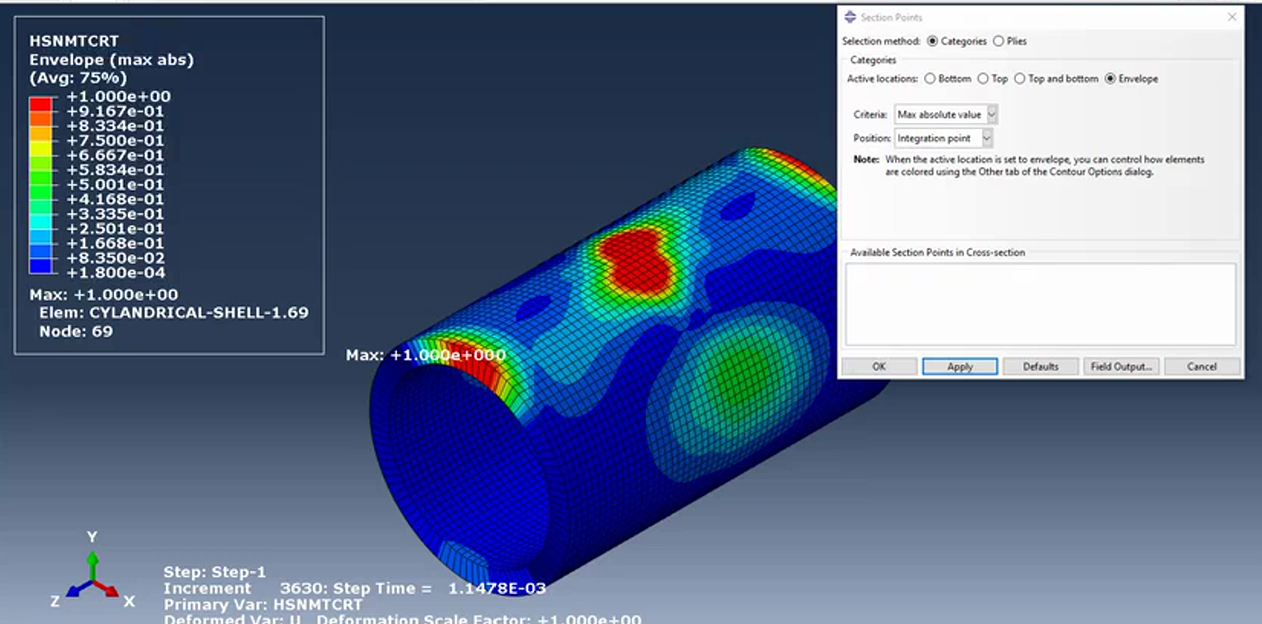

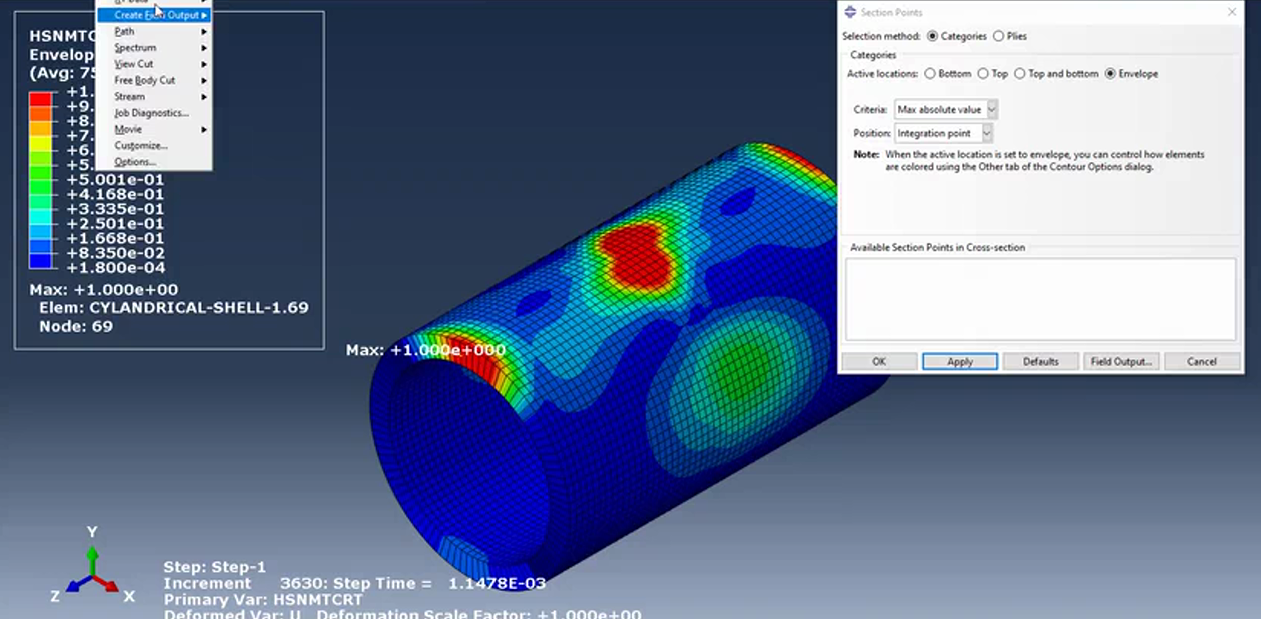

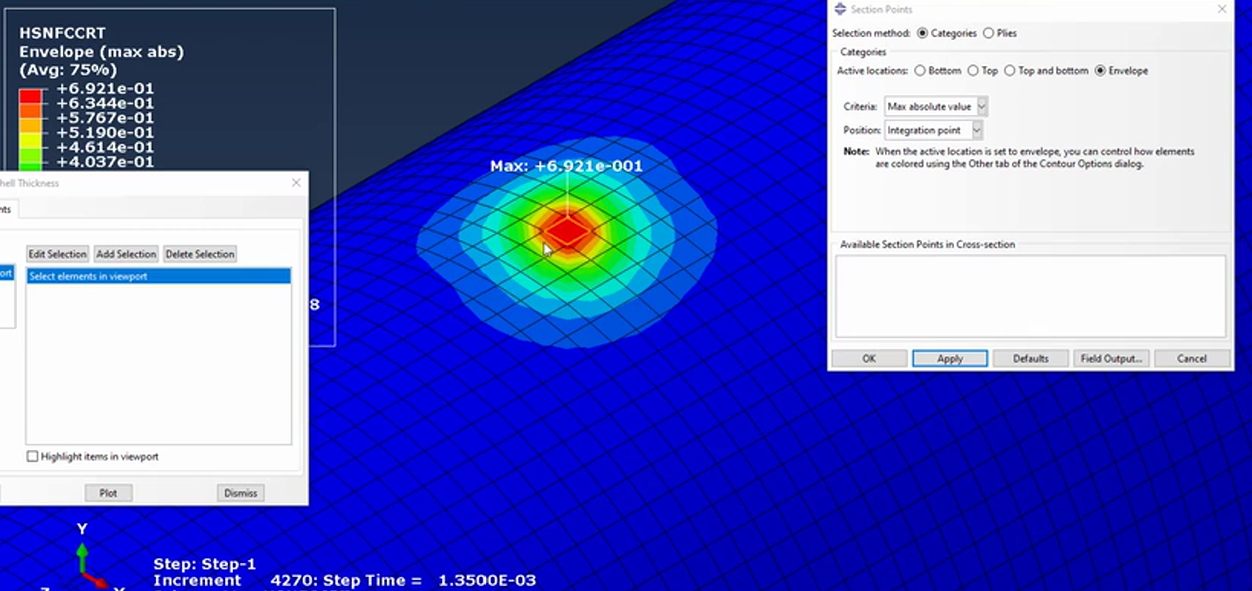

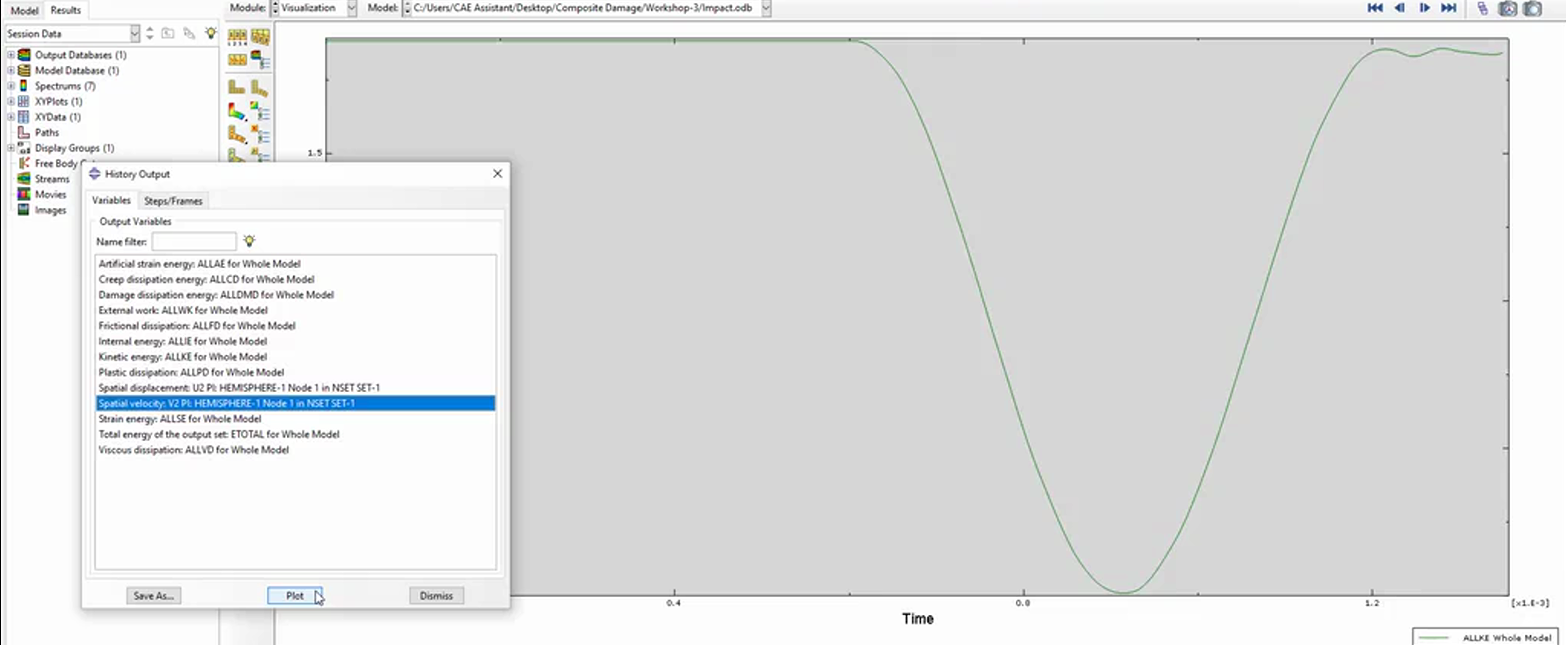

In this Abaqus composite laminate damage modeling, a composite cylinder is hit by a hemisphere. In this dynamic analysis, the composite material damage for initiation and progression is investigated using the Hashin criterion.

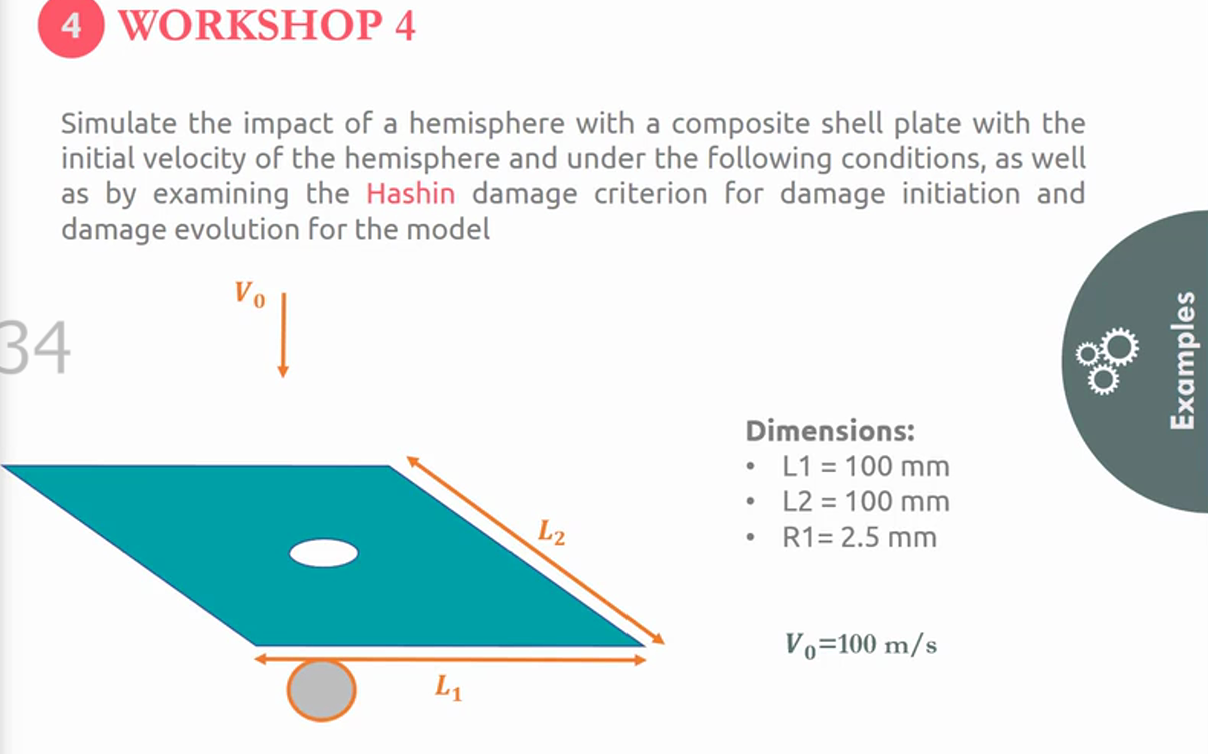

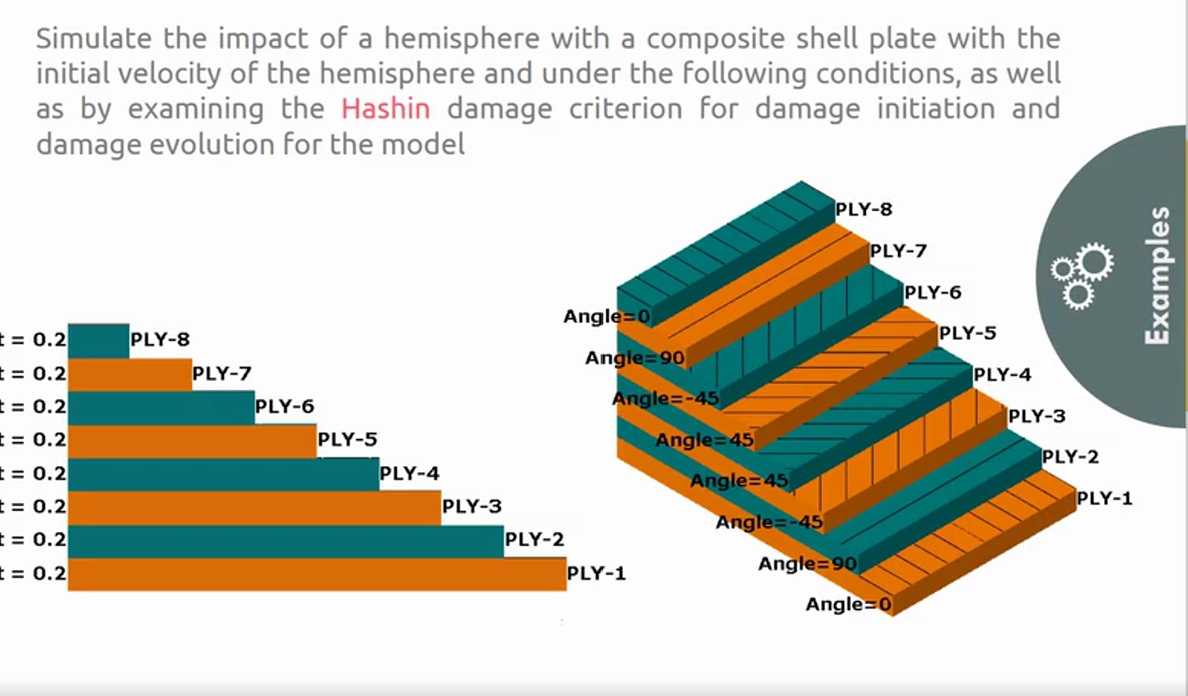

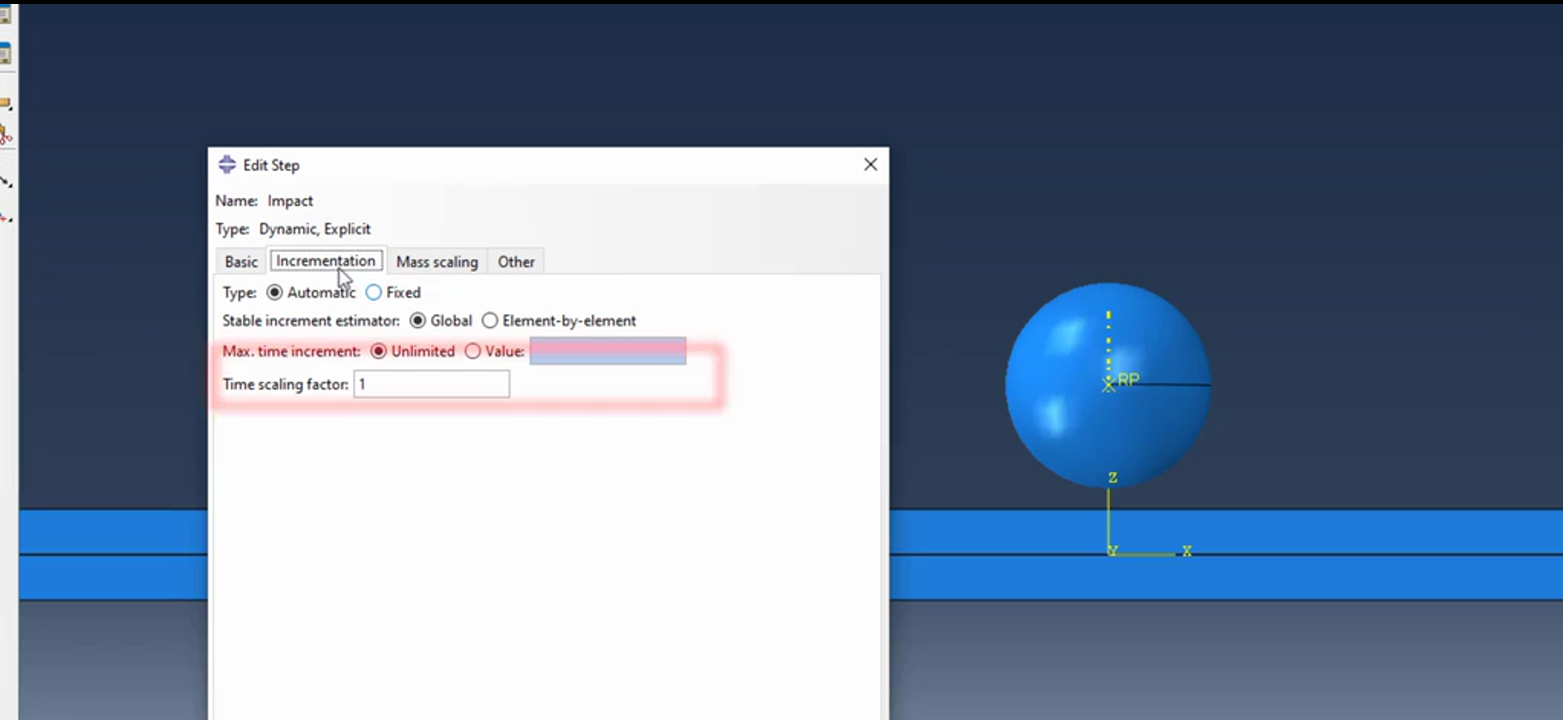

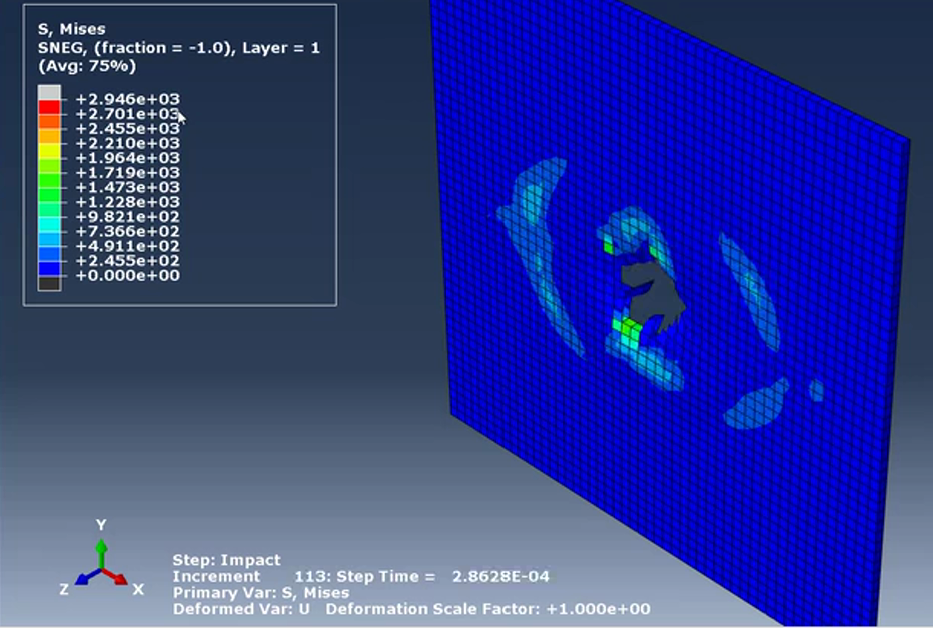

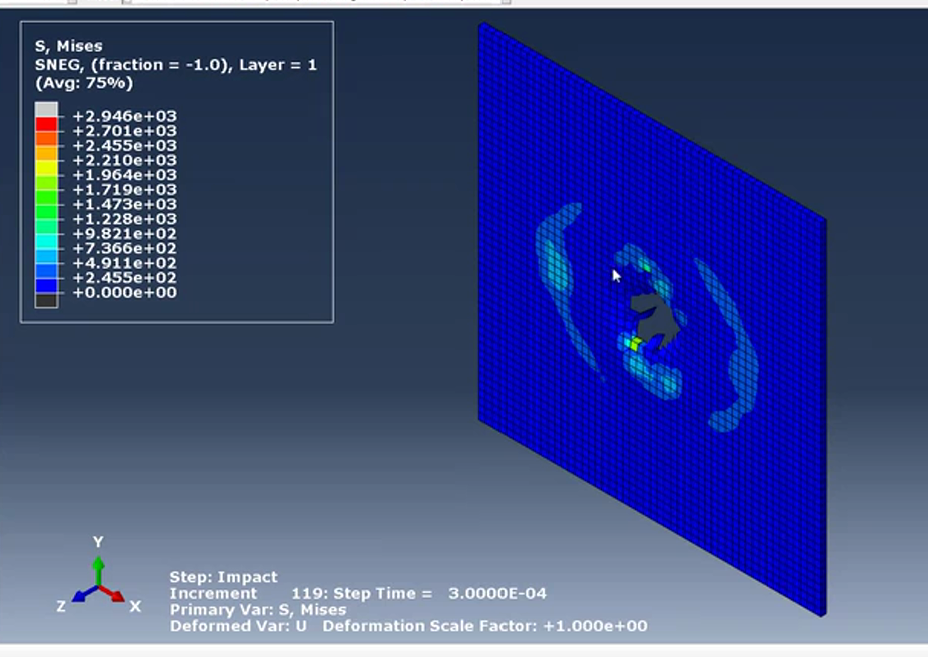

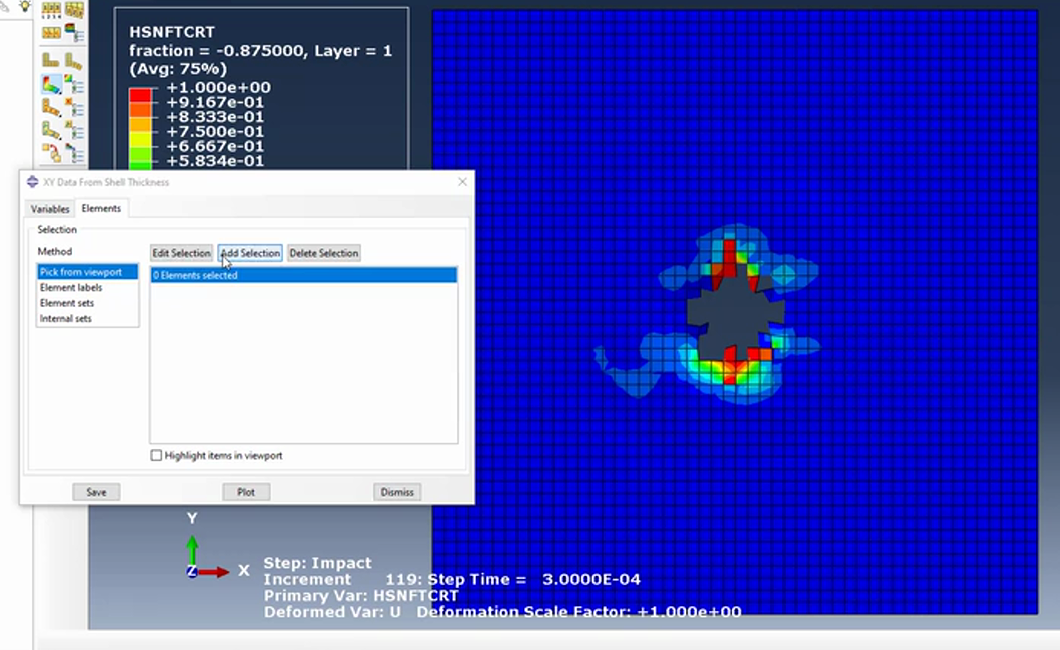

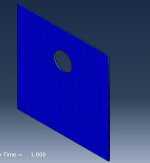

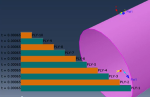

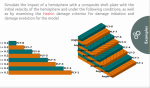

Workshop 4: High-speed Impact analysis on multi-layered composite plate based on HASHIN failure criterion (damage initiation and progressive damage/ Physical based criterion/ shell element))

High-speed impact simulation is one of the most widely used applications in industry today. In this simulation, a composite multilayer sheet is impacted, and the amount of energy absorbed by the sheet is calculated. The damage criterion of the composite is HASHIN criterion for failure initiation and the energy criterion for progressive failure.

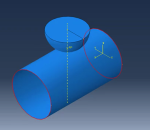

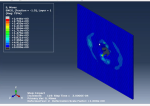

Workshop 5: Impact analysis on composite plate with continuum shell element (damage initiation and progressive damage)

In the last workshop, the damage in composite materials along with the adhesive damage is examined. This time, the impact is made on a composite plate with continuum elements, which is glued between its layers. After the bullet hits the composite plate, the composite damage and the effect of lamination are both visible at the same time.

It would be useful to see Abaqus Documentation to understand how it would be hard to start an Abaqus simulation without any Abaqus tutorial. Also, there is an article about this niche, which you can learn more “Unidirectional composite damage“.

In comparison to metals, composites’ damage mechanisms are less well known. Composite materials and structures are susceptible to defects, whether they appear during material processing, component fabrication, or in-service use. Understanding how the damage or defect affects the structural integrity of the composite component is crucial to determining how critical the defect is. If we can somehow determine these damages and tend to them in time, the maintenance cost would be severely decreased. Also, our design will be better and well-optimized.

Read More: Introduction to Finite Element Method | Finite Element Analysis

It’s true that the composite structures have sufficient strength and stiffness but like other structures, they may get damaged during the service. The damages could be caused by impact, low resistance to the service environment, overloading, Staff carelessness, etc.

In-service damages include:

- Impact damage

- Fatigue

- Cracks

- Delamination

- Fiber fracturing

- …

Service flaws in composite structures are typically caused by impact damages. Delamination is the most frequent impact-related damage. Delamination occurs when layers in a laminated composite are split, creating a mica-like structure with a considerable loss in mechanical properties. Delamination is the separation of the laminate at the boundary between two layers as a result of shock, impact, or repeated cyclic pressures. Individual fibers can pull away from the matrix, for instance.

It is the engineer’s duty to analyze the structures and determine the defects and damages so that the structure can keep working properly and lower the cost of maintenance. With the help of Computer-aided engineering (CAE) and finite element method (FEM), you would be able to do this task in the best way possible.

We are here at the CAE Assistant to explain some about composite material damage and introduce some FEM tools to simulate these damages correctly. Also, we will help you out learn how to simulate and analyze your model and structure. With our high-quality education, you can learn how to work with the Abaqus and analyze composite structures. I recommend you read the topics of this training package on the right side of this page and if you have more questions about this package and its content and quality, ask on the live chat on the left side of this page.

Read More: Abaqus composite material

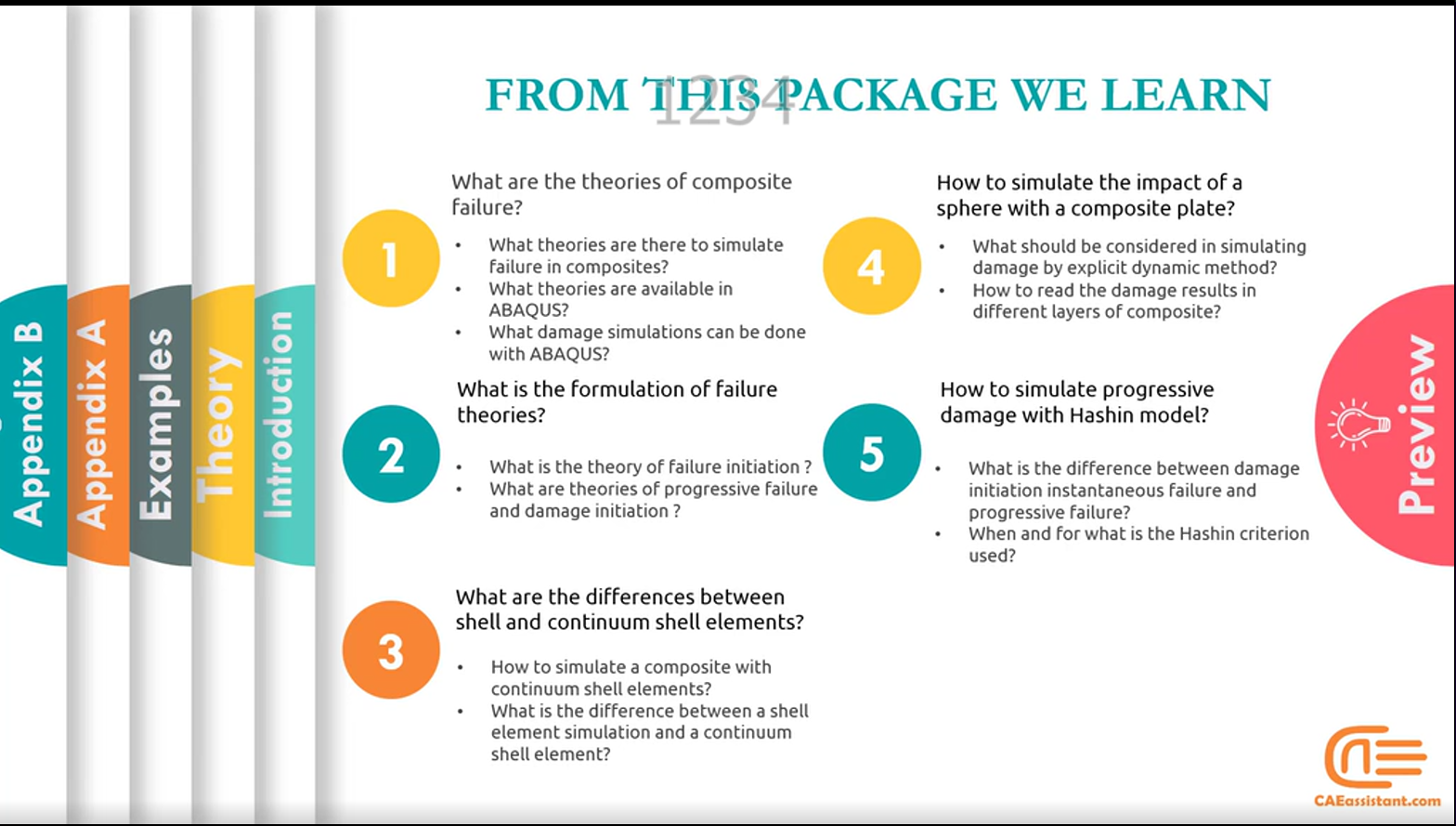

- What do we learn from this package?

- Teaching plan and Prerequisites and Next steps

- Package specification

You can watch demo here.

- What is the definition of damage and its applications?

- What is the difference between microscopic and macroscopic damage in composite materials?

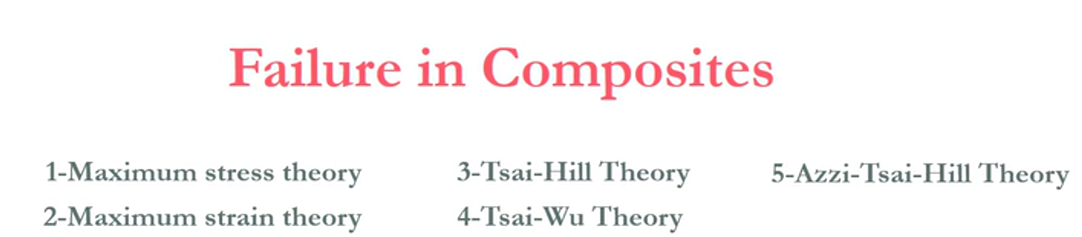

- What is the various theories to simulate initiation damage in composite material structures?

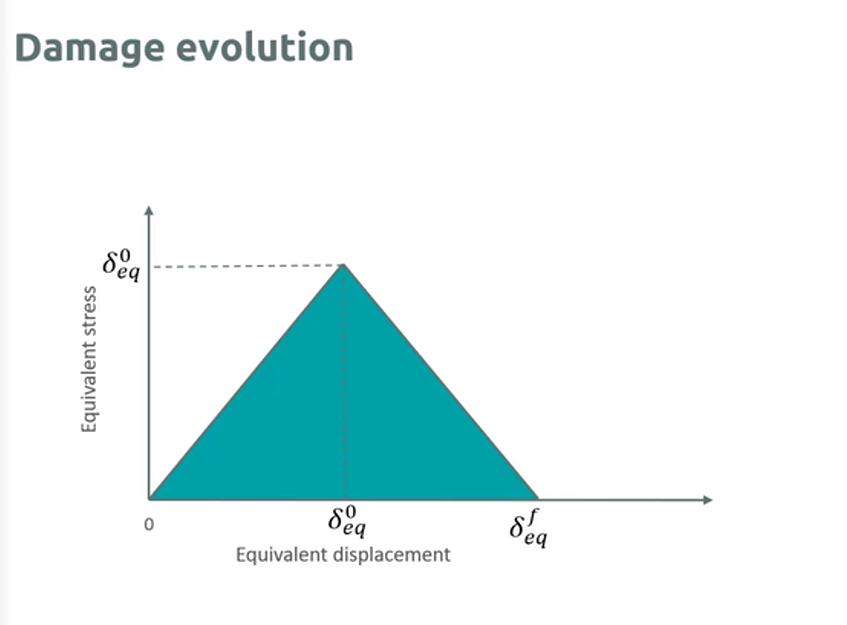

- What is the available theory to simulate progressive damage of composite material structures?

- What is the elements limitations to simulate progressive damage of composite material structures?

- Which ways are available to add criterion to simulate composite damage?

- How to use composite damage results as an initiation condition of other simulation?

- Defining Elastic property by engineering constant selection

- Defining failure criterion parameters for HASHIN

- Setting in field output to get required results

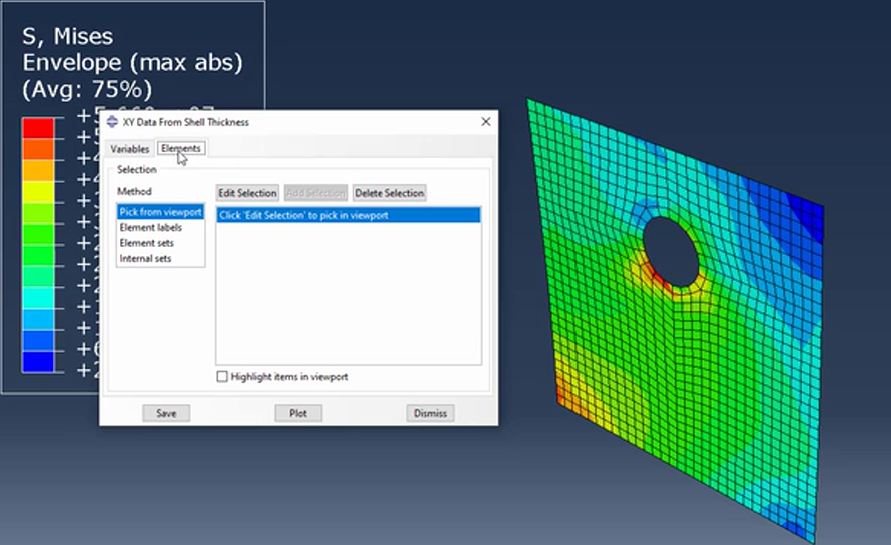

- View results in layers for fiber and matrix separately

- Problem Description

- Defining Elastic property by lamina selection

- Defining failure criterion parameters for Maximum stress, Tsai-Wu, Azzi-Tsai-Hill criterion

- Setting in field output to get required results in layers

- Setting shell element (different DOF)

- View results in per layer

- Defining failure criterion parameters for Maximum strain

- Setting in field output to get required results in layers

- View results in per layer

- Problem Description

- Defining Elastic property by orthotropic selection

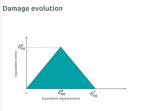

- Defining damage initiation (HASHIN) and damage evolution (Energy) parameters

- Setting in field output to get required results and element removal

- View results in layers for fiber and matrix separately

- Problem Description

- Defining Elastic property by orthotropic selection

- Defining damage initiation (HASHIN) and damage evolution (Energy) parameters

- Setting in field output to get required results and element removal

- View results in layers for fiber and matrix separately

Users ask these questions

In social media, users asked questions regarding Composite simulation. We answered some of them, which you can see below:

I. Composite laminate analysis

Q: Hello ResearchGate Community,

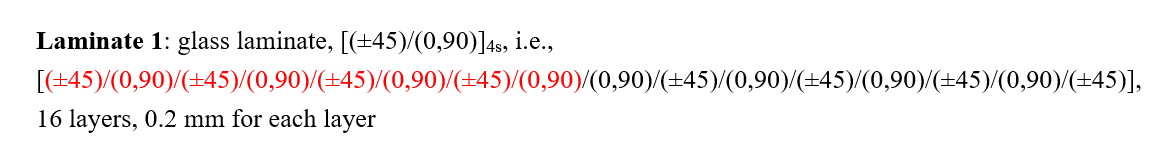

I am working on composite laminate analysis. Need to do a numerical analysis and the stacking sequence is given by the supervisor in the attached photo.

– If there is a + and – sign together (as in the case for 45 degree), then what to do?

– What to do during (0,90)?

– How the symmetry will work here?

I have some options (options given below), but not sure and don’t have a clear explanation. Can anyone please help me and confirm it?

(1) 45/0/90/45/45/90/0/45/45/0/90/45/45/90/0/45

(2) 45/0/0/45/45/0/0/45/45/0/0/45/45/0/0/45

(3) 45/0/45/0/45/0/45/0/45/0/45/0/45/0/45/0

I thought to use only +45, so I have come up with these 3 options, but not sure~

Thank you a bunch in advance for your effort and time 🙂

A: Greetings,

First, you need to determine the direction of the plies, I mean, in which direction the plies must stack. Second, you can toggle on the symmetric option in the composite layup edit window from the plies tab. If you need some examples with a complete tutorial, check the link below:

Simulation of Unidirectional Composite Damage in ABAQUS

Best regards.

II. Composite damage (CFRP)

Q: I’ve been trying to simulate a tensile test of CFRP in Abaqus, and I’ve set the displacement in Load case(step1) to 5mm with a concentrated load of 10000N, but the specimen doesn’t break and the displacement keeps increasing ( 15-20-25mm etc). So, could someone maybe assist me in resolving this problem so that I can see the material damage after a 5mm displacement? Thanks.

A: Greetings,

If by CFRP you meant Carbon fiber-reinforced polymers, to see the damage and the breaking, you need to define the Hashin Damage in the Property module. if you don’t know how to use it, well, google it, or you can refer to the link below:

Simulation of Unidirectional Composite Damage in ABAQUS

there, you will learn the damage in composites with different examples.

Best luck.

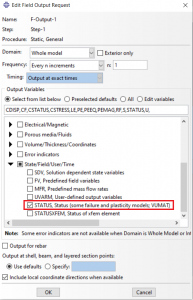

III. Element deletion in Abaqus

Q: When material damage reaches a particular level, it degrades and fails in the finite element of continuum damage mechanics. So, how do you simulate material failure in ABAQUS using node-release?

A: Hi,

If by node release you mean element deletion, you must first define a damage criterion and damage evolution in the Property module; then, select the STATUS variable from the Field output (see attached figure). If the stress reaches the damage criterion, the element and its nodes will be deleted.

If you need to know more, refer to the following link.

If your model is composite:

All the package includes Quality assurance of training packages. According to this guarantee, you will be given another package if you are not satisfied with the training, or your money is returned. Get more information in terms and conditions of the CAE Assistant.

All packages include lifelong support, 24/7 support, and updates will always be sent to you when the package is updated with a one-time purchase. Get more information in terms and conditions of the CAE Assistant.

Notice: If you have any question or problem you can contact us.

Ways to contact us: WhatsApp/Online Support/[email protected]/ contact form.

Projects: Need help with your project? You can get free consultation from us here.

- Online payment: with MasterCard, VisaCard and etc.

- Offline payment: In this payment method, you should pay via PayPal and send your payment receipt as an attached file in the offline payment form.

- via download link After purchase, a download link will be sent to you a zip file included training videos, documents and software files.

- Send us your machine ID

To access tutorial video run the .exe file on your personal pc and send the generated code to [email protected] and wait for your personal code, which is usable only for that pc, up to 24 hours from CAE Assistant support.

Here you can see the purchase process of packages: Track Order

13 reviews for Simulation of Unidirectional Composite Damage in ABAQUS

Clear filtersYou must be logged in to post a review.

You may also like…

Simulation of composite Puck damage in 3d continuum element in Abaqus (UMAT-USDFLD-VUMAT)

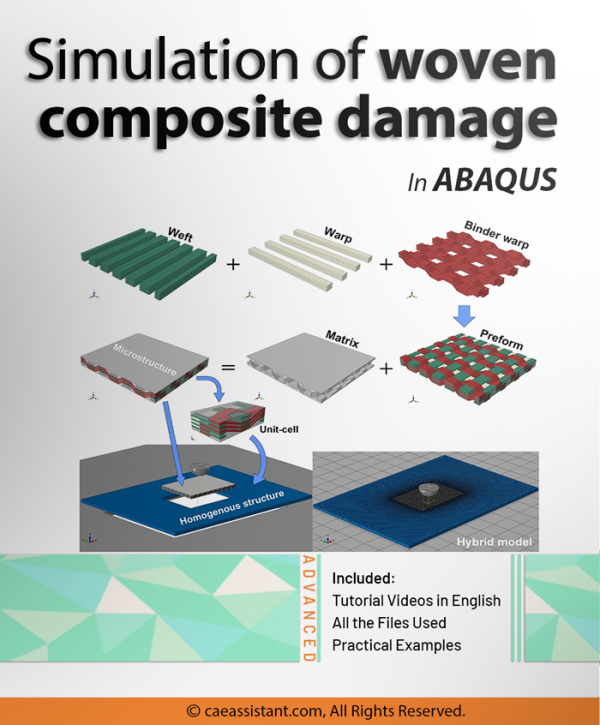

Simulation of woven composites damage in Abaqus

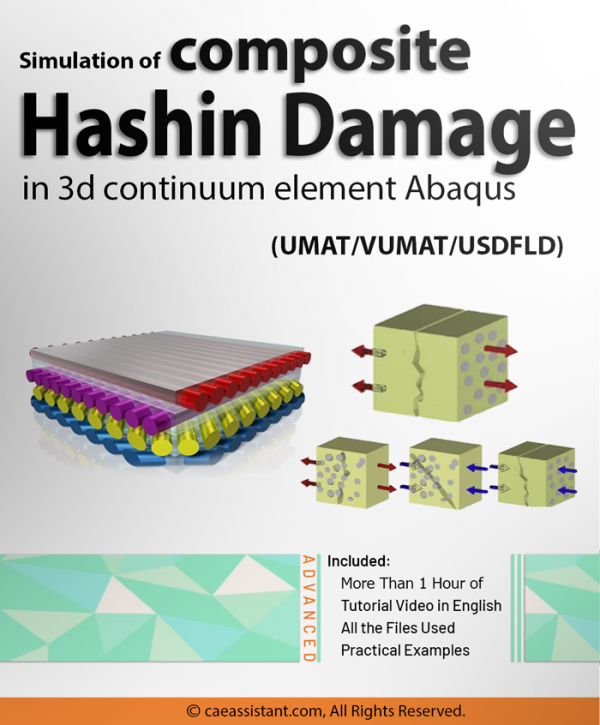

Simulation of composite Hashin damage in 3d continuum element in Abaqus (UMAT-VUMAT-USDFLD)

3D continuum Abaqus HASHIN progressive Damage for composite materials (VUMAT Subroutine)

The Hashin failure criteria is a set of failure criteria developed specifically for composite materials. It predicts different failure modes in composites based on the stresses experienced by their constituents (fiber and matrix). The criteria are widely used in engineering and computational models to assess composite material performance under mechanical loading. The criteria, while highly efficient and widely used, pose challenges when implemented in numerical simulations. Abaqus has emerged as a powerful tool to address these challenges, enabling the prediction of damage initiation and its progression (via stiffness reduction) based on the Hashin criteria. However, a key limitation of Abaqus is its applicability being restricted to 2D plane stress elements. To overcome this limitation, we developed a VUMAT subroutine in this project. This custom subroutine extends the capabilities of Abaqus, allowing for the simulation of damage initiation and propagation in 3D problems in accordance with the Hashin criteria. It should be mentioned that this subroutine includes gradual progressive damage based on the energy method. This complex subroutine could be used for static and dynamic problems.

A notable point is that in one of our other packages, we also provide training on using Abaqus subroutines to analyze the Hashin criterion. However, in that package, damage occurs instantaneously. In the current package, we have modeled the progressive Damage, which is more complex but could be more beneficial for solving your specific problems.

aiko watanabe –

This is excellent. Need to watch the segments several times with the package in front of you to fully benefit from the videos. It also has a professional narrations.

nickul-7543 –

Hi, I want to do progressive damage in symmetric composite sheet. Does this package help me in this matter? What is your suggestion for this issue?

thanks for your help

felix –

Hello, according to the title of the package, this training is in the field of macro. I need to investigate composites in the field of micromechanics. Does this package help me?

alex-mv –

should I know how it work with FEM software? Does this package is good enough for industries?

salleh –

Thank you for the complete description. According to these explanations, I will definitely buy this package.

Cristina –

I am very satisfied with the training package. The workshops were well-organized and the complex analyses were clearly explained. The various exercises were very helpful.