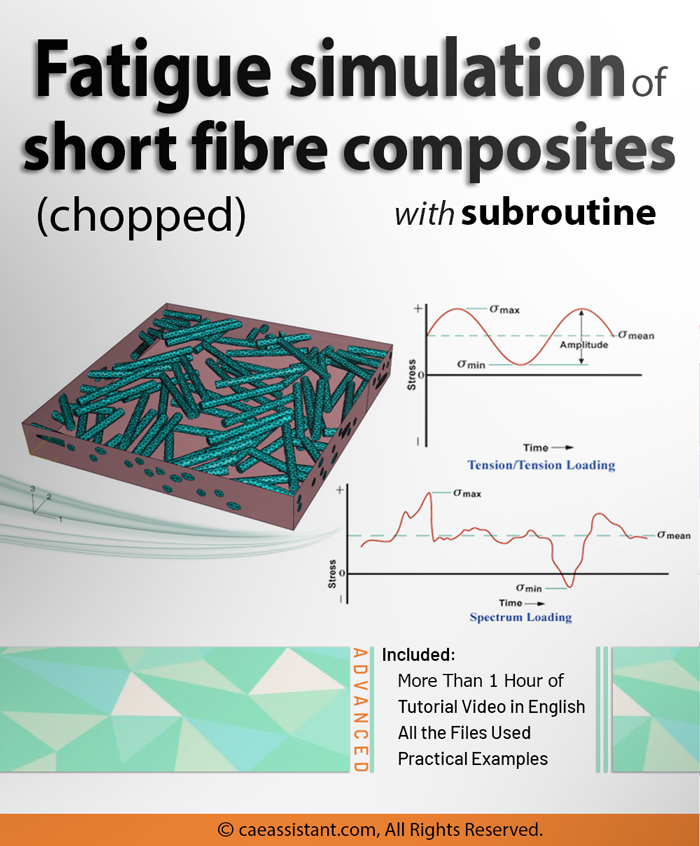

Fatigue short fiber composites simulation with Abaqus subroutine

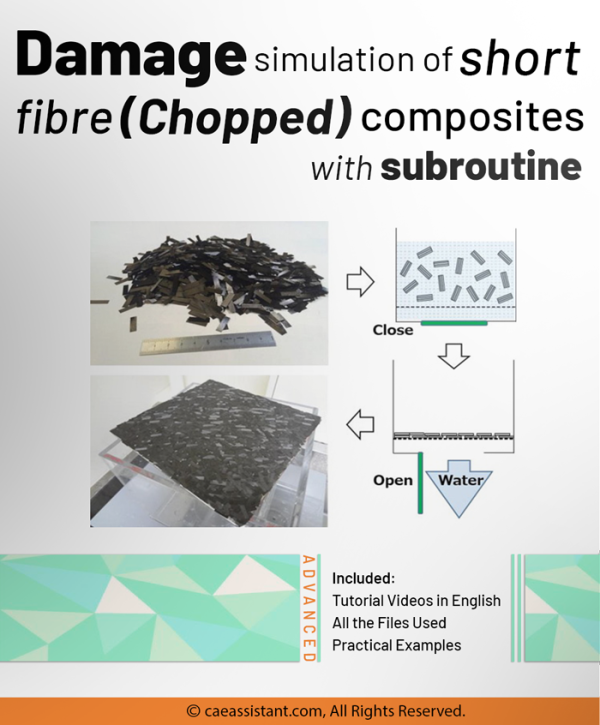

Thermoplastics containing short fiber reinforcements were first commercialized in the 1960s. The most common fiber types used in short-fiber thermoplastics are fiberglass and carbon fiber. The addition of short fibers to thermoplastic resins improves the performance of the composite for lightweight applications. In addition, short-fiber thermoplastic composites are easy and cheaper to produce than continuous-fiber composites. This trade-off between cost and performance allows staple fiber thermoplastics to be used in a myriad of applications. Fatigue short fiber composite or fatigue chopped composite is described in this tutorial.

Progressive cyclic damage evolution of short fiber reinforced PEEK composites presented significantly different patterns depending on applied stress level and on the presence of different reinforcement typologies. In order to reproduce the different fatigue damage kinetics and stages of progressive damage accumulation observed experimentally, a cyclic damage model was finally developed and implemented into a finite element code by which a satisfactory agreement between numerical prediction and experimental data at different stress levels for each examined material. Fatigue short fiber composite is a rare topic, and finding a good training resource would be hard.

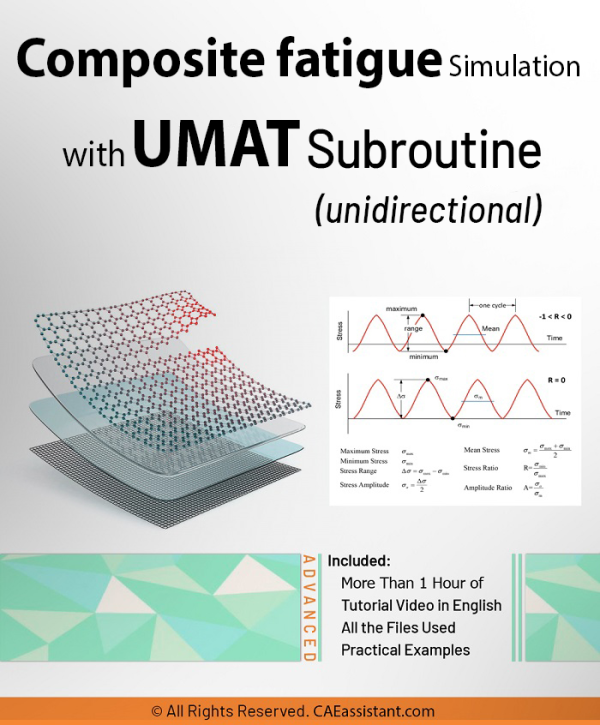

This training package is based on “Fatigue behavior and cyclic damage of peek short fiber reinforced composites” article. The subroutine has been implemented based on the mentioned article. However, this article has used the USDFLD subroutine, but we use the UMAT subroutine, which is more accurate than USDFLD since the material strength and properties reduction is smooth. If you are working on a dynamic problem and need to use the explicit solver, you can order the VUMAT subroutine version of this package. Fatigue short fiber composite or fatigue chopped composite is fully described and you can boost your modeling by watching this useful package.

Lesson 1: Fatigue and Fiber-reinforced composites

In this lesson, we provide explanations about fatigue and its types, as well as short fiber composites.

What is the fatigue?

In mechanical engineering, fatigue is a phenomenon that occurs in materials when they undergo repeated or fluctuating stresses. These stresses may be below the material’s ultimate strength or even below its yield limit. Fatigue failure is characterized by the initiation and propagation of cracks within the material, eventually leading to structural failure. Fatigue is particularly important because it is responsible for a significant percentage of mechanical failures in various applications, such as automotive, aerospace, and structural engineering. Unlike other failure modes, fatigue failure often occurs without prior warning or visible signs, making it challenging to predict and prevent.

The process of fatigue involves several stages. It begins with the initiation of microscopic cracks, which are typically caused by the repetitive stress cycles. These cracks then propagate and grow under subsequent stress cycles until they reach a critical size, leading to sudden failure.

Factors influencing fatigue life include the applied stress range, stress concentration, material properties, surface conditions, temperature, and environmental factors. Engineers employ various techniques to mitigate fatigue, such as improving material selection, optimizing design, incorporating stress-relief features, and implementing regular inspections and maintenance to detect and address potential fatigue-related issues. Among the factors affecting crack initiation and growth, the “Mean stress” has a special importance. To study this parameter, it is better to first know the types of loading that lead to fatigue:

- The first case of loading is tensile and compressive, such that the amount of tensile and compressive loads are equal.

- The second case is also a combination of tensile and compressive stresses. But in this case, the amount of stresses are not equal and the tensile stress is greater than the compressive stress.

- …

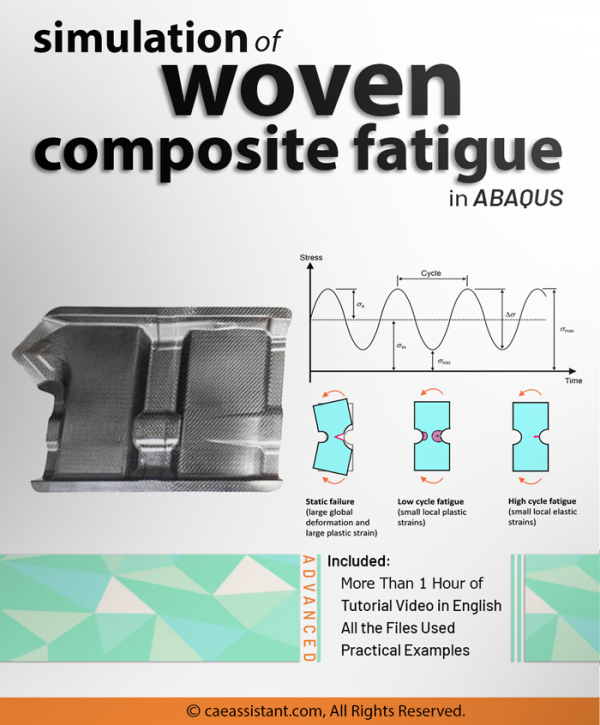

Another issue that is important in fatigue analysis is the number of cycles that the specimen is subjected to. Generally, loading can be divided into two categories in terms of cycle number; The first category is high-cycle fatigue. High-cycle fatigue is a type of fatigue that occurs due to alternating stresses in the elastic range. Fatigue cracks start after long periods of use, such as hundreds of thousands or millions of cycles.

The second category is low-cycle fatigue. The Low-cycle fatigue occurs when the load cycles are large enough to cause plastic deformation in the materials. The number of failure cycles is usually less than 10,000 and the failure mode is usually ductile fracture.

And one last issue is the fatigue life. Fatigue life is an expression of the number of stress cycles that the test body undergoes before it fails. Understanding and managing fatigue is crucial in engineering design and maintenance to ensure the reliability, safety, and longevity of structures, components, and machinery subjected to cyclic loading and operational conditions.

What are fiber-reinforced composites?

Fiber-reinforced composites are composite materials consisting of a matrix (typically a polymer) reinforced with fibers. These fibers, which can be made of materials like carbon, glass, or aramid, provide enhanced mechanical properties to the composite, such as increased strength, stiffness, and durability. The fibers are usually continuous and oriented in a specific direction to optimize the material’s performance in a particular application. Fiber-reinforced composites are widely used in industries such as aerospace, automotive, and construction due to their high strength-to-weight ratio and excellent resistance to corrosion and fatigue.

On the other hand, short (chopped) fiber composites are a type of fiber-reinforced composite where the reinforcing fibers are relatively short in length. Unlike continuous fibers found in traditional fiber-reinforced composites, short fibers are typically a few millimeters to a few centimeters long. These fibers are randomly or semi-randomly dispersed within the matrix during the composite manufacturing process. Short fiber composites offer improved mechanical properties compared to the unreinforced matrix material, but to a lesser extent compared to continuous fiber composites. They are used in applications that require cost-effectiveness and moderate performance, such as automotive components, consumer products, and packaging materials. The random fiber distribution in short fiber composites provides isotropic strength characteristics, making them suitable for applications where multidirectional loading is present.

Lesson 2: What are short fiber composite fatigue damage model?

In this lesson, we examine failure models of short fiber composites, including the Nouri and Avanzini models.

What is Nouri fatigue damage model?

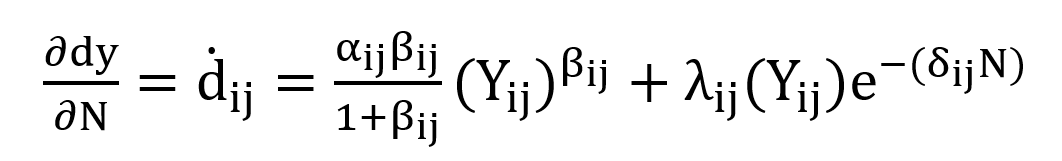

This model is applicable for composites with orthotropic behavior. In Nouri’s model, the damage growth rate per cycle is calculated from equation bellow:

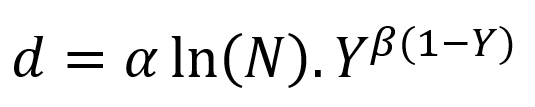

What is Avanzini fatigue damage model?

This is the Nouri’s model with just some modifications. With these changes, the model proposed by Nouri was transformed into a new model with one damage variable. These changes will help reduce the calculations. This model has considered the fiber distribution in the matrix to be homogeneous and random. It has assumed the material behavior to be isotropic.

The equation below, shows the damage variable of Avanzini’s model:

More info about these equations and their parameters are available in the package.

Lesson 3: How to model composite material behavior?

In this lesson, brief explanations about the UMAT subroutine are given, and the UMAT subroutine flowchart is explained. Next, the UMAT subroutine is analyzed line by line.

The reference article, “Fatigue behavior and cyclic damage of peek short fiber reinforced composites”, has implemented the USDFLD subroutine, but we use the UMAT subroutine, which is more accurate than USDFLD since the material strength and properties reduction is smooth.

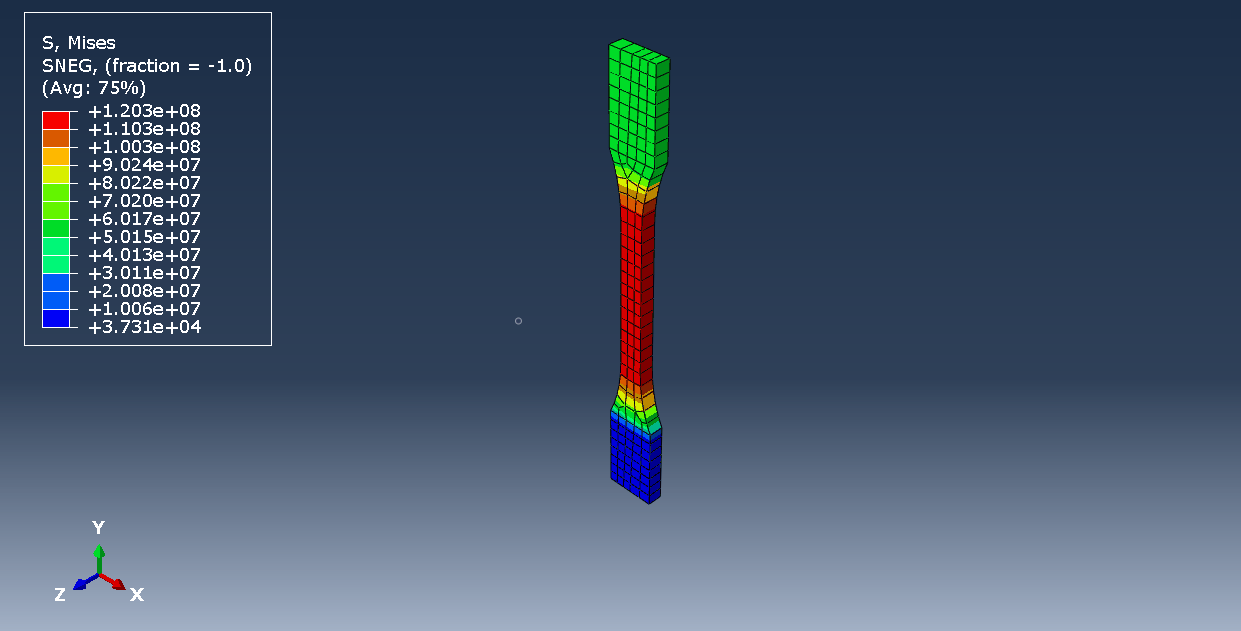

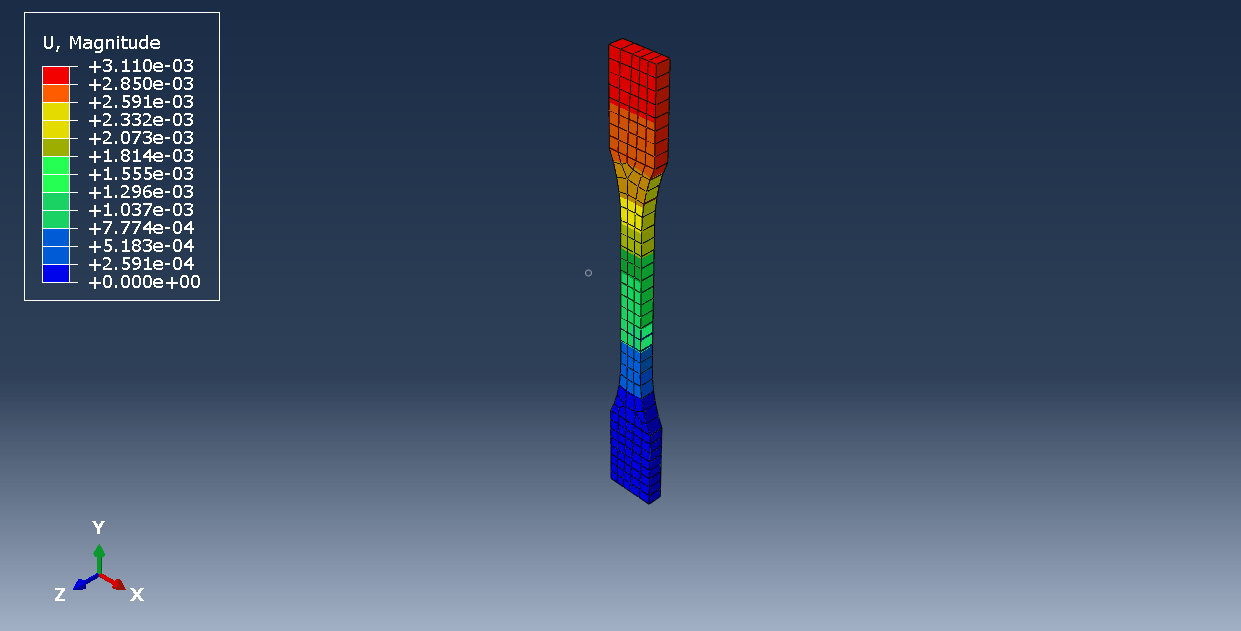

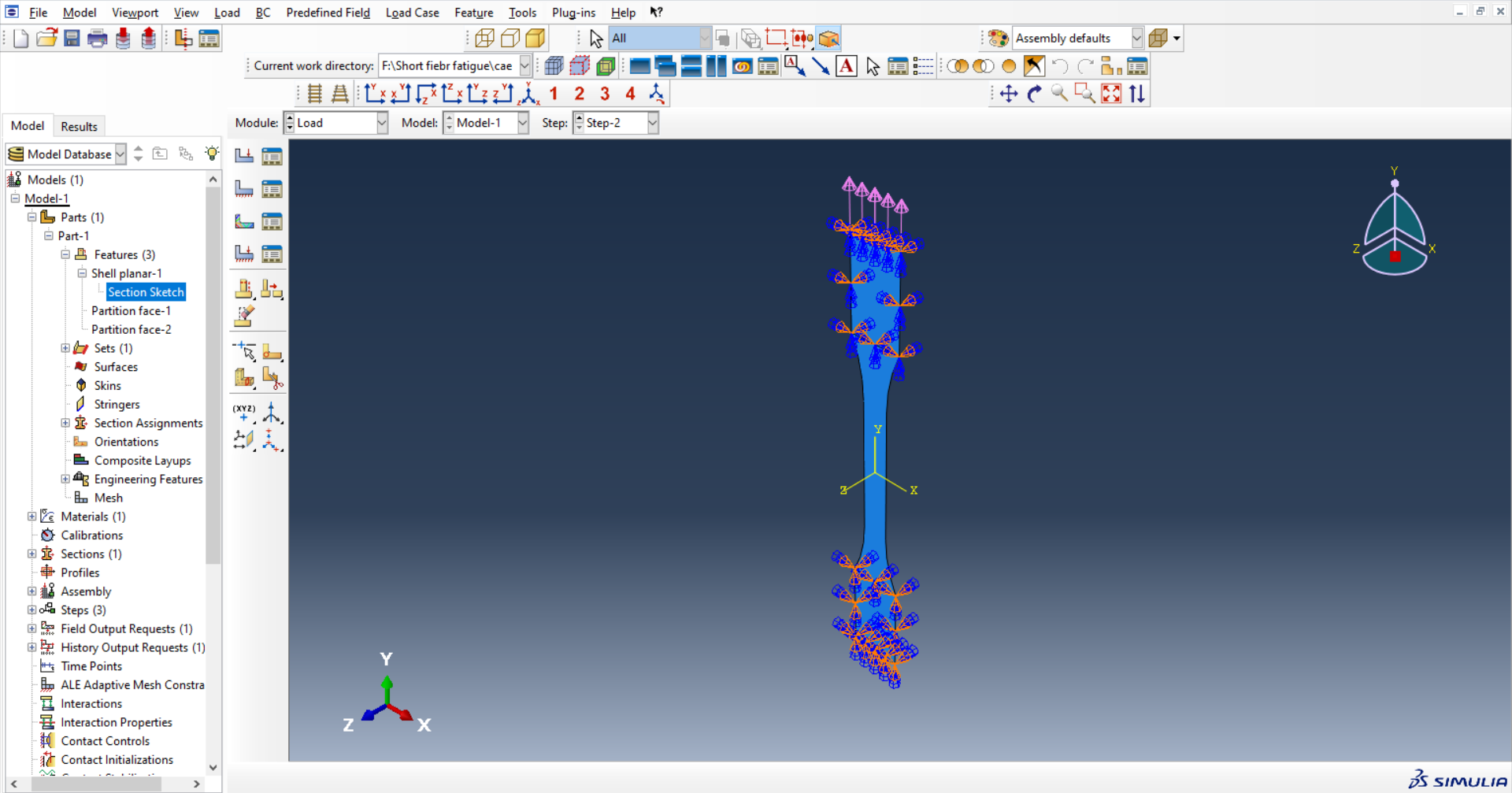

Workshop: Fatigue modeling on a standard tensile test specimen

In this workshop, a standard tensile test specimen is modeled. One side of the sample is completely fixed, and a uniaxial load of 60 MPa is applied on the other side of the sample. The material is modeled using the UMAT subroutine. You can gain more details on the tutorial video.

Read more: Short Fiber Composite Fatigue Analysis

Reviews

Clear filtersThere are no reviews yet.