Introduction to Elastomeric Foam Simulation

Elastomeric foams are a type of foam material characterized by their elastic properties. In other words, they can undergo significant deformation and return to their original shape. They are typically made from polymers and have a high void volume fraction, making them lightweight and flexible. People often use these foams in applications requiring insulation, and impact absorption. The project focuses on (Elastomeric foam simulation) modeling the mechanical behavior of open-cell, isotropic elastomeric foams.

Numerical Simulation of Elastomeric Foams | Finite Element Analysis of Elastomers

Numerical simulations are crucial for studying foams. They allow researchers to model complex behaviors, such as simulating the large strain, time-dependent behavior of elastomeric foams, including their hyperelastic and viscoelastic properties. Moreover, simulations (Elastomeric Foam Simulation) enable evaluation of the foam’s performance under various loading conditions (compression, shear, tension) and combinations of invariants, which may be challenging to achieve experimentally. Generally, numerical methods help us to predict how the foam will respond to different strain rates and temperatures, although the current model assumes rate independence and isothermal conditions. Ultimately, insights gained from simulations can be used to enhance the design and formulation of elastomeric foams for specific applications. In conclusion, finite element analysis of elastomers are crucial for advancing the understanding and developing more accurate and comprehensive models for elastomeric foams.

Practical Applications

The applications of this project primarily lie within the field of materials science and engineering, focusing particularly on elastomeric foams. For instance, designers and developers can use the modeling framework to create new elastomeric foam materials. Such materials have tailored properties for specific applications. Furthermore, insights from the project can contribute to creating materials for impact protection, including automotive, sports equipment, and protective gear. The models can aid in designing biomedical devices that require materials with specific mechanical properties, such as prosthetics and cushioning materials. The aerospace and defense industries can also apply the research to develop lightweight, high-performance materials capable of withstanding various mechanical stresses. Finally, the findings can enhance the performance and durability of consumer products utilizing elastomeric foams, such as seating, and footwear. Overall, this project’s applications span multiple industries where the mechanical properties of elastomeric foams play a crucial role.

Apart from the mentioned cases, the project provides valuable information for implementing custom material behavior in FEA software such as Abaqus, which can be utilized in various engineering simulations and analyses.

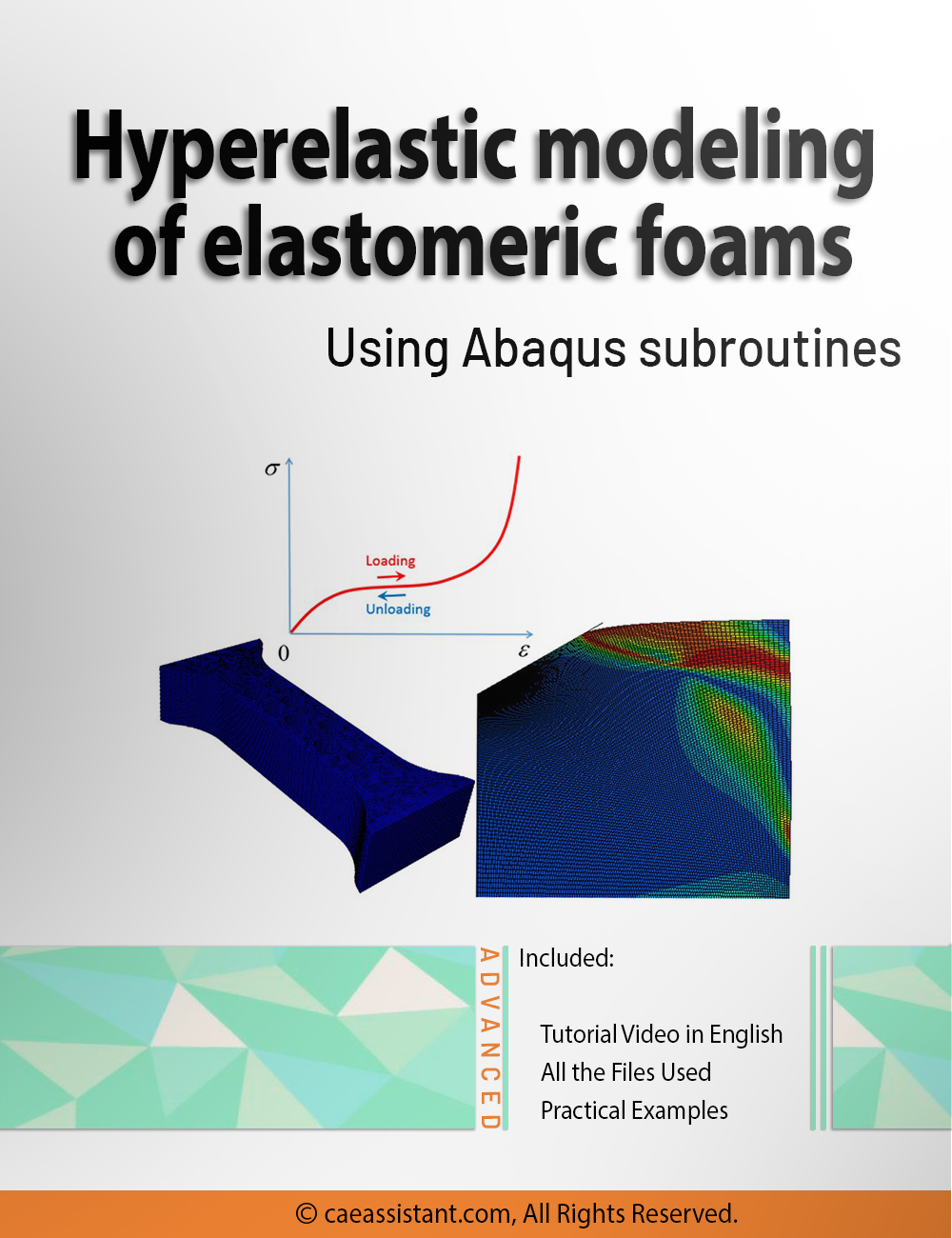

Theory and the formulation

The modeling in this project involves several theories and formulations. For example, it proposes a hyperelastic constitutive model based on invariants of the logarithmic, Hencky strain. This involves understanding and applying hyperelastic material theories to capture the nonlinear stress-strain behavior of elastomeric foams. Moreover, the model is designed to handle finite deformations, which are common in elastomeric materials. This requires formulations that can accurately describe large strains. Moreover, the model involves a systematic path for material parameter estimation from simple compression/tension data, which requires understanding how to extract and fit material parameters from experimental data. All these theories and formulations make the numerical simulation of elastomeric foams, challenging.

What We Expect From this Package?

Learners can gain several insights and benefits. For instance, they will gain an understanding of elastomeric foam modeling. The project provides a comprehensive framework for modeling elastomeric foams, including hyperelasticity, finite deformation theory, and viscoelasticity frameworks. Moreover, they will learn about the finite element simulations used to validate the proposed models. For example, we can refer to the specific steps and boundary conditions applied in Abaqus. Furthermore, they can utilize this knowledge for potential future work, such as extending the modeling framework to incorporate strain-rate and temperature sensitivity and addressing microstructural defects in very low-density foams. Finally, they will have access to practical resources such as the implementation of user-material subroutines and sample input files. It can be valuable for researchers and engineers working in this field. Overall, the project equips readers with both theoretical knowledge and practical tools to advance their understanding and application of elastomeric foam modeling.

Workshop

Abaqus plays a crucial role in this project by serving as the platform for implementing the constitutive model. The phenomenological, isotropic, finite-deformation, hyperelastic constitutive model based on invariants of the logarithmic, Hencky strain was implemented in Abaqus. To do so, we have used the Abaqus user-material subroutine (UMAT). UMAT is a custom-defined material model that allows users to implement their own constitutive models in Abaqus. This subroutine enables the researchers to implement specific material behavior that is not available in the standard Abaqus material library (Elastomeric Foam Simulation).

Reviews

Clear filtersThere are no reviews yet.