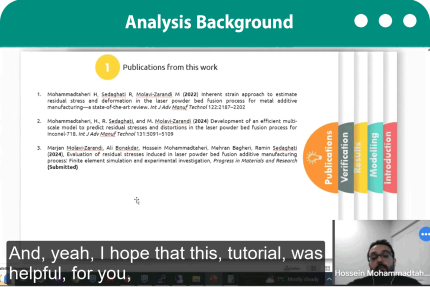

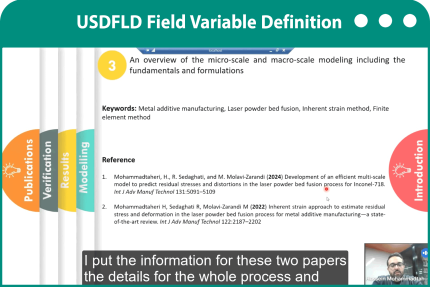

This product is the result of a doctoral thesis—years of dedicated research distilled into an advanced, cutting-edge resource. It covers unique topics that have no comparable alternatives. Additionally, its specialized nature means it is not intended for general, entry-level use, where lower prices might be more common.

Now, consider this: if your own years of expertise and research were turned into a product, at what price would you be willing to sell it?

In fact, with this payment, you are saving yourself hours of time spent searching for credible articles and simulating coding, watching hours of pointless videos on YouTube, and trial and error in software to achieve similar results. The value of those hours is certainly far greater than this amount.

You may find competitors offering similar products at lower prices. However, many of our customers come to us after trying those options, realizing they received incomplete, low-quality content, unverified, inaccurate or sometimes wrong that didn’t truly help them.

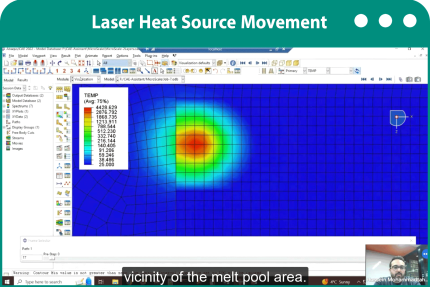

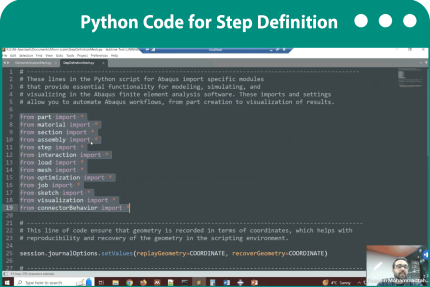

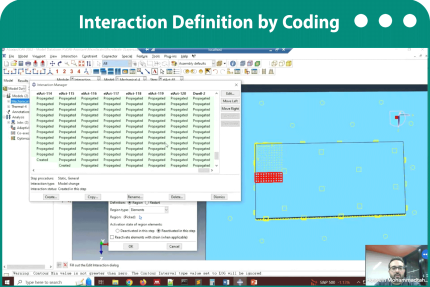

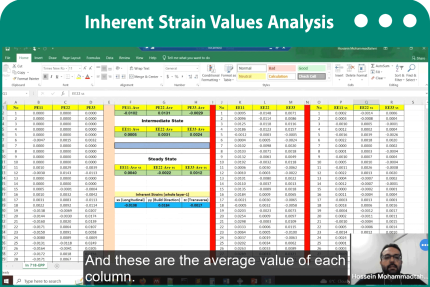

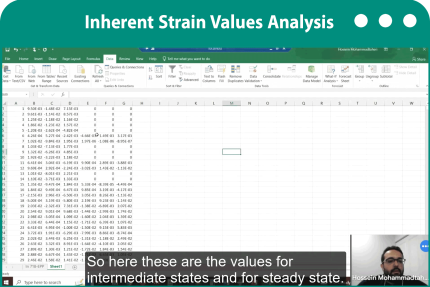

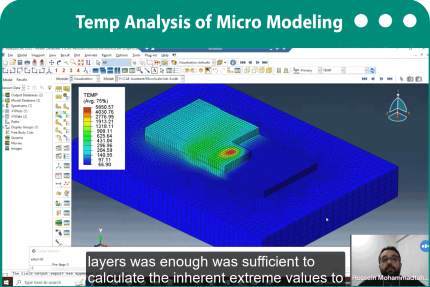

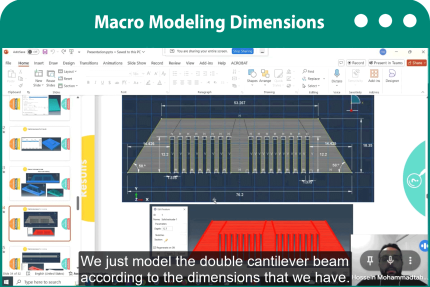

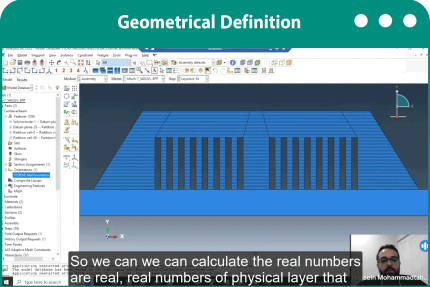

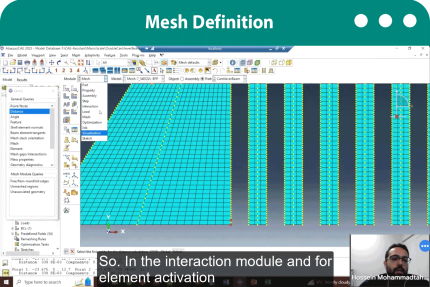

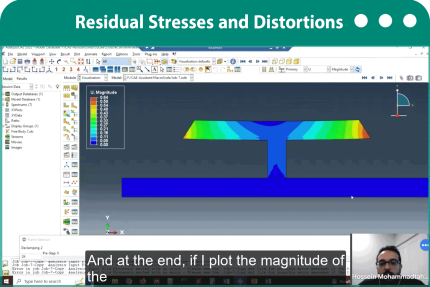

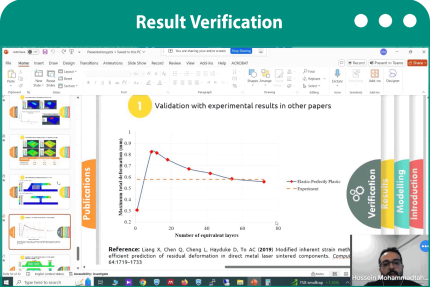

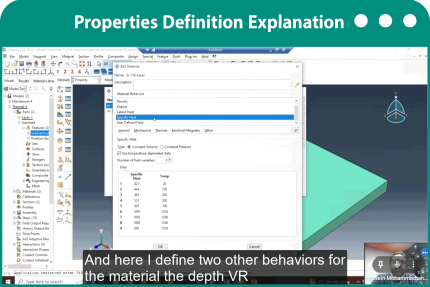

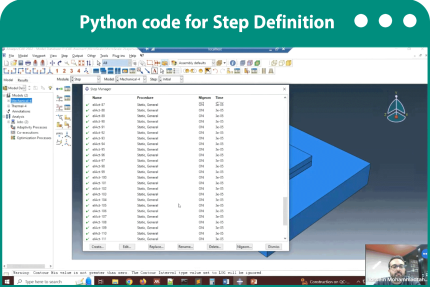

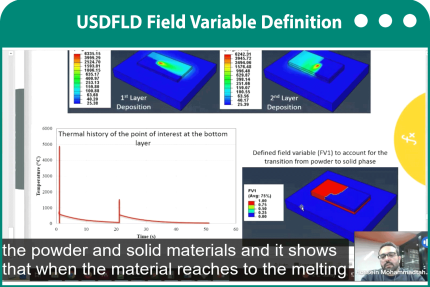

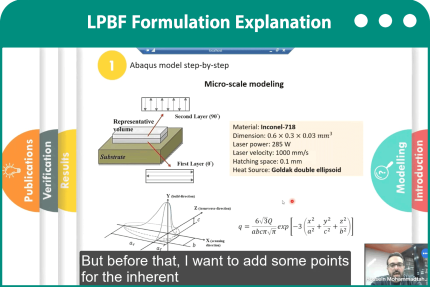

What sets our tutorials apart is the depth of knowledge, step-by-step simulations, and carefully structured theoretical explanations. Every detail is meticulously crafted using the highest-quality materials to ensure a superior learning experience.

Ultimately, those who truly understand the value of this product recognize that its price is not just reasonable—it’s a worthwhile investment.

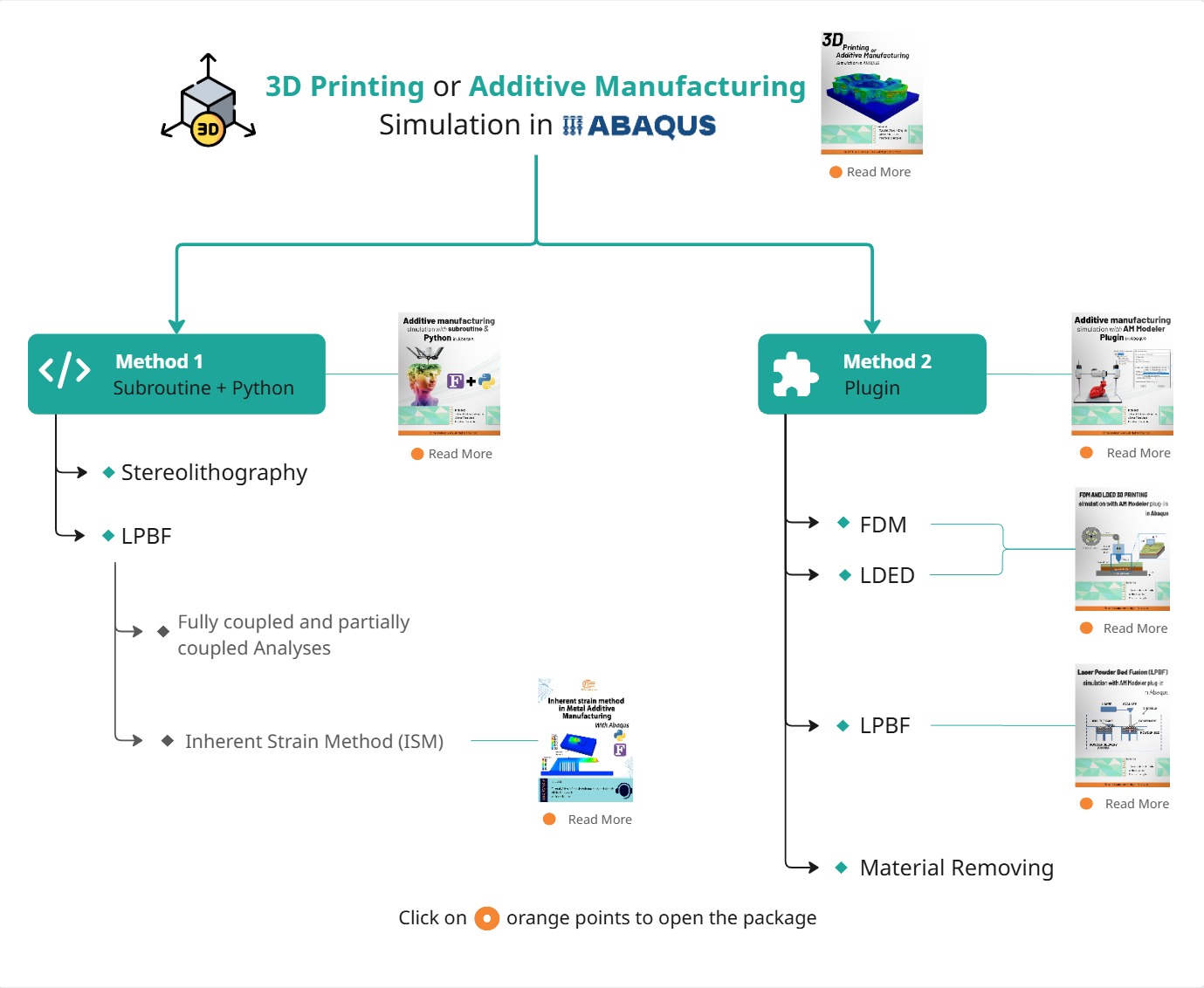

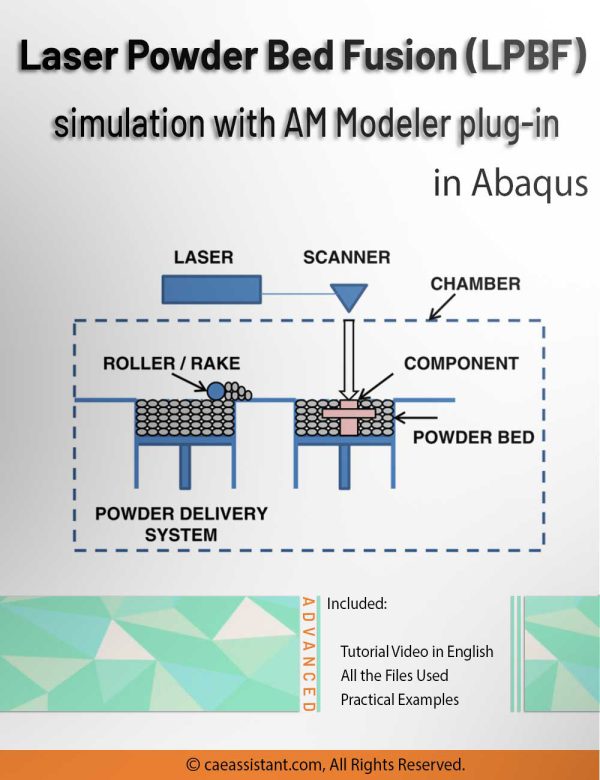

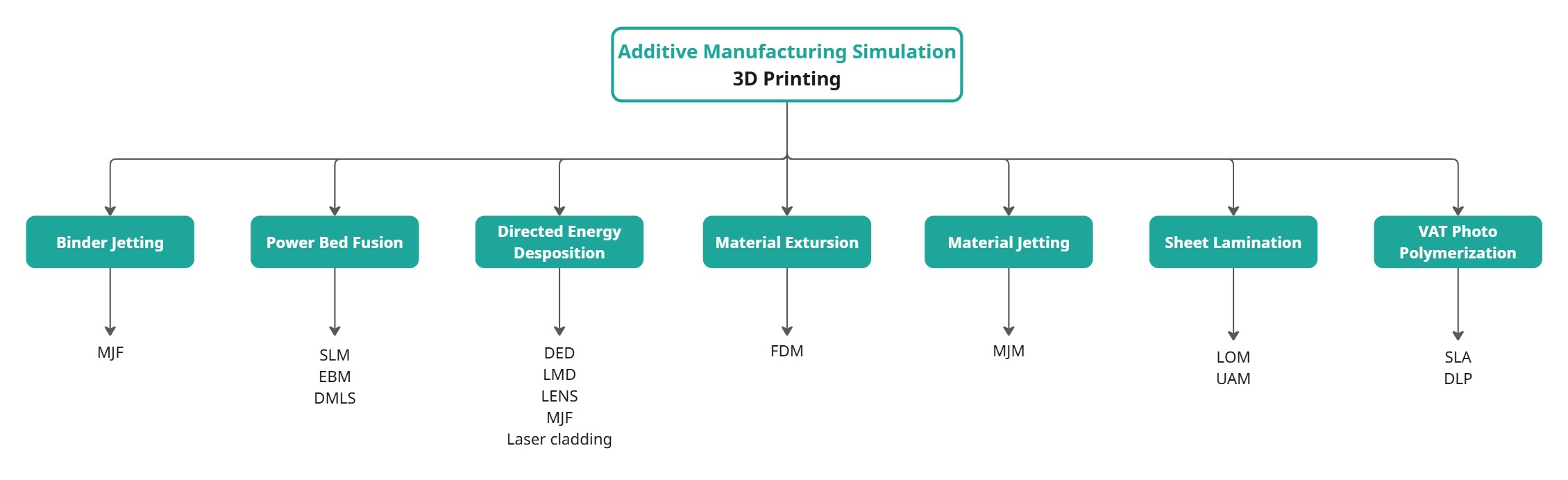

You can discuss your problem with our experts, who will review it based on the methodologies mentioned in the diagram above and introduce the best option to fit your needs.

You can discuss your problem with our experts, who will review it based on the methodologies mentioned in the diagram above and introduce the best option to fit your needs.

Reviews

Clear filtersThere are no reviews yet.