1. What is welding?

Welding is a process used to join two or more materials, typically metals or thermoplastics, by causing coalescence through the application of heat, pressure, or both. In other words, Using heat to bond materials together is the main purpose of the crucial construction-related activity of welding. The most common type of welding involves melting the base materials, often with a filler material, to form a strong bond once the molten material cools and solidifies.

There are several different welding techniques, such as:

- Arc Welding: An electric arc is used to generate heat to melt the base material and filler.

- MIG (Metal Inert Gas) Welding: A form of arc welding that uses a continuous wire feed and an inert gas to protect the weld from contamination.

- TIG (Tungsten Inert Gas) Welding: Uses a non-consumable tungsten electrode and a separate filler rod.

- Stick Welding: A more manual form of arc welding, where the electrode rod is consumed to create the weld.

- Spot Welding: Uses pressure and heat from electrical current to join metals, commonly used in automotive manufacturing.

Welding is widely used in various industries such as construction, automotive, aerospace, and manufacturing due to its efficiency and the strong bonds it creates. Using heat to bond materials together is the main purpose of the crucial construction-related activity of welding.

2. Welding categorization

Generally, we have two methods for welding: Fusion welding and non-fusion welding.

Fusion welding uses heat to melt two or more materials to join them. This process may or may not need to use a filler material.

Non-fusion welding uses high pressure or, in some cases, heat to join materials. In this process, materials won’t melt, but they may be heated to an elevated temperature. Also, no filler is usually used in this process.

Fusion welding is done in three ways: Electron Beam welding (EBW). This method is based on the electron’s kinetic energy and is suitable for any material with any thickness. Laser Beam Welding (LBW). It uses a laser beam and is proper for narrow and deep welds. This method does not use any filler. Arc welding (AW). It is the most important and widely used method. It uses the electric arc to create enough heat to melt the parts and bond them. The arc welding can be done in seven ways according to the electrode used: Shielded metal arc welding (SMAW), Submerged arc welding, Flux-cored arc welding (FCAW or FCA), Carbon arc welding (CAW), Tungsten inert gas (TIG) welding, Gas metal arc welding (GMAW), Plasma arc welding (PAW).

The non-fusion welding is categorized into five methods. First, Friction stir welding (FSW). This method is a solid-state joining process. The heat will be generated by friction between a non-consumable rotating tool and the workpiece to create a softened region and bond the pieces. The second method is Explosive welding (EW). Like the FSW method, this one is also a solid-state welding process. It uses high energy rate deformation to join metal plates. The pressure caused by the explosion will bond the plates. The third method is Ultrasonic welding (UW). It is an industrial process that uses high-frequency ultrasonic acoustic vibrations to create a solid-state weld to join the workpieces being held together under pressure. The next method is Rolling welding. This one is used to connect metal sheets. In this method, we need to first clean the surface of two or more sheets. Then, pile the sheets together and pass them through the rolls until sufficient deformation occurs to weld the sheets. The fifth method is Resistance welding (RW), and it is the most widely used. This method uses heat caused by the application of electric current and mechanical pressure at the same time to form a great bond.

3. Welding simulation in Abaqus

Abaqus is a powerful tool for welding simulation, offering a wide range of features and options to simulate various types of welds. With its diverse thermal, mechanical, and coupled thermo-mechanical solvers, you can tailor the welding simulation to meet specific conditions and objectives. Additionally, by utilizing the DFLUX subroutine and the element birth-and-death functionality, Abaqus overcomes the typical limitations of such analyses, providing high accuracy. In this package, we have explained all the essential details surrounding this topic.

3.1. What does this package generally cover?

This training package fully covers the various possible methods for Abaqus welding simulation. Various methods in welding simulation include the Lagrangian method, The Eulerian method, ALE, and SPH methods.

In the Lagrangian method, nodes move exactly with material points, it is easy to track free surfaces and apply boundary conditions, and the mesh will become distorted with high strain gradients. In the Eulerian theory, nodes stay fixed while material flows through the mesh, it is more difficult to track free surfaces, and we have no mesh distortion because the mesh is fixed. The ALE is a combination of the two previous theories. In this method: the mesh motion is constrained to the material motion only where necessary (at free boundaries); otherwise, material motion and mesh motion are independent. The last method is smoothed-particle hydrodynamics (SPH). In this method, there are no elements, only a collection of nodes. This is one of the meshless (or mesh-free) methods in the ABAQUS.

In the process of welding, the base metal is melted, and generally, a filler material is added to create a pool of molten metal, which fuses the two components together. In creating a simulation model, there are two major issues when simulating the welding process to evaluate the structural behavior of a welded joint:

- The thermal and structural behavior of the model needs to be coupled with each other.

- Material needs to be added during the welding process. This also changes the boundaries and the location of the boundary conditions.

Here in this package, some techniques to overcome these issues in Abaqus welding problems are presented.

It would be useful to see Abaqus Documentation to understand how it would be hard to start an Abaqus simulation without any Abaqus tutorial.

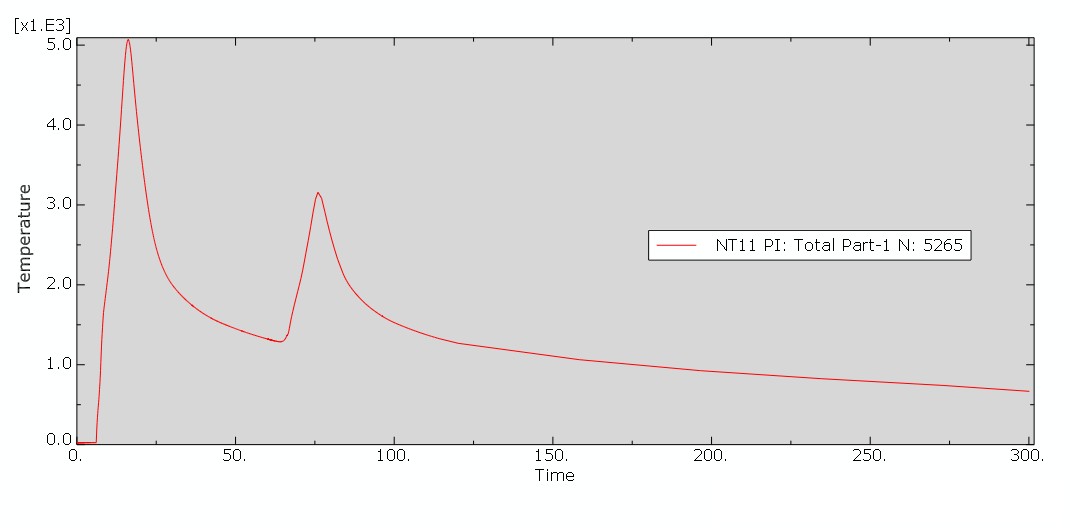

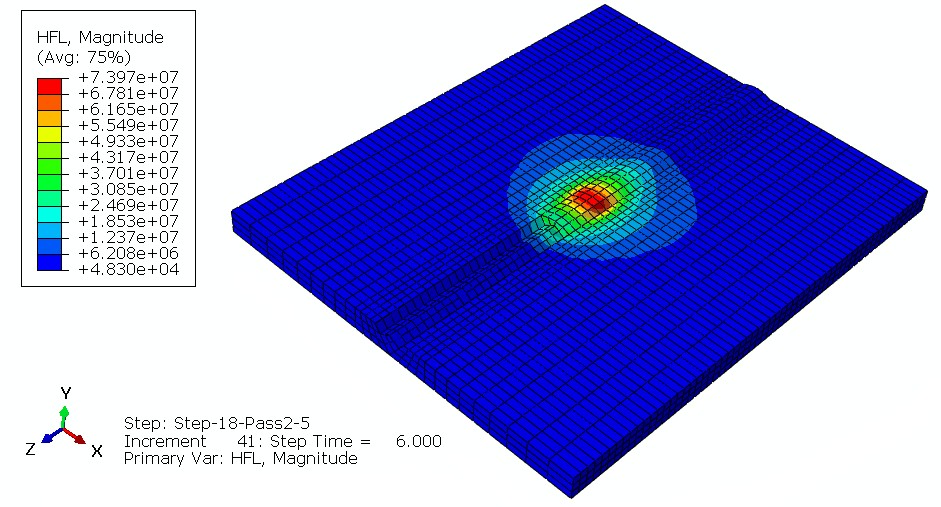

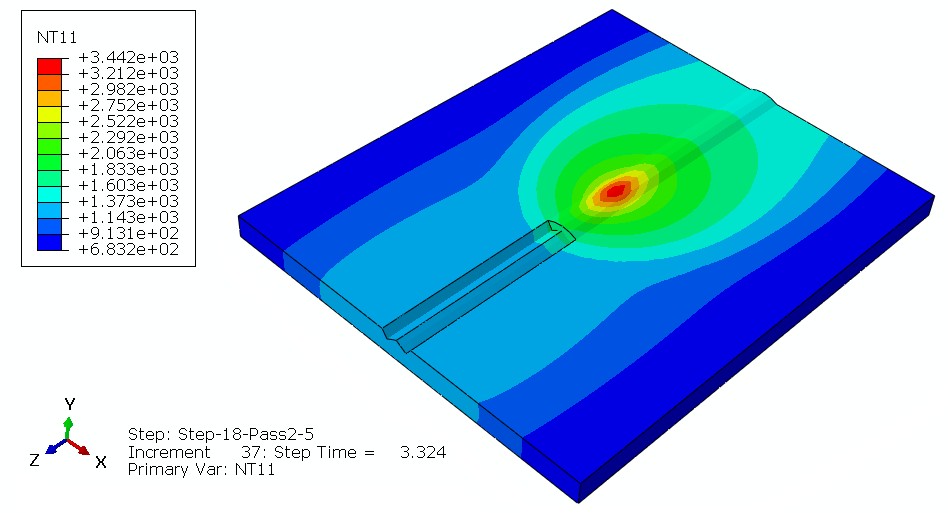

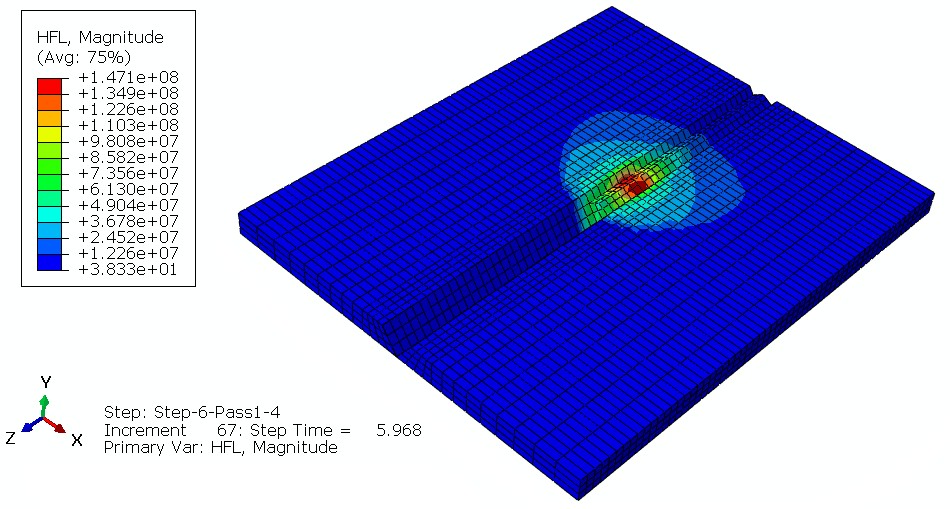

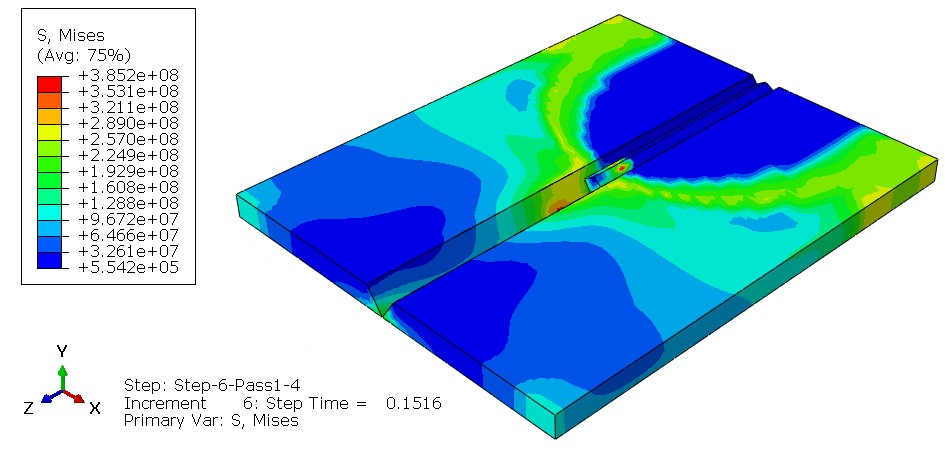

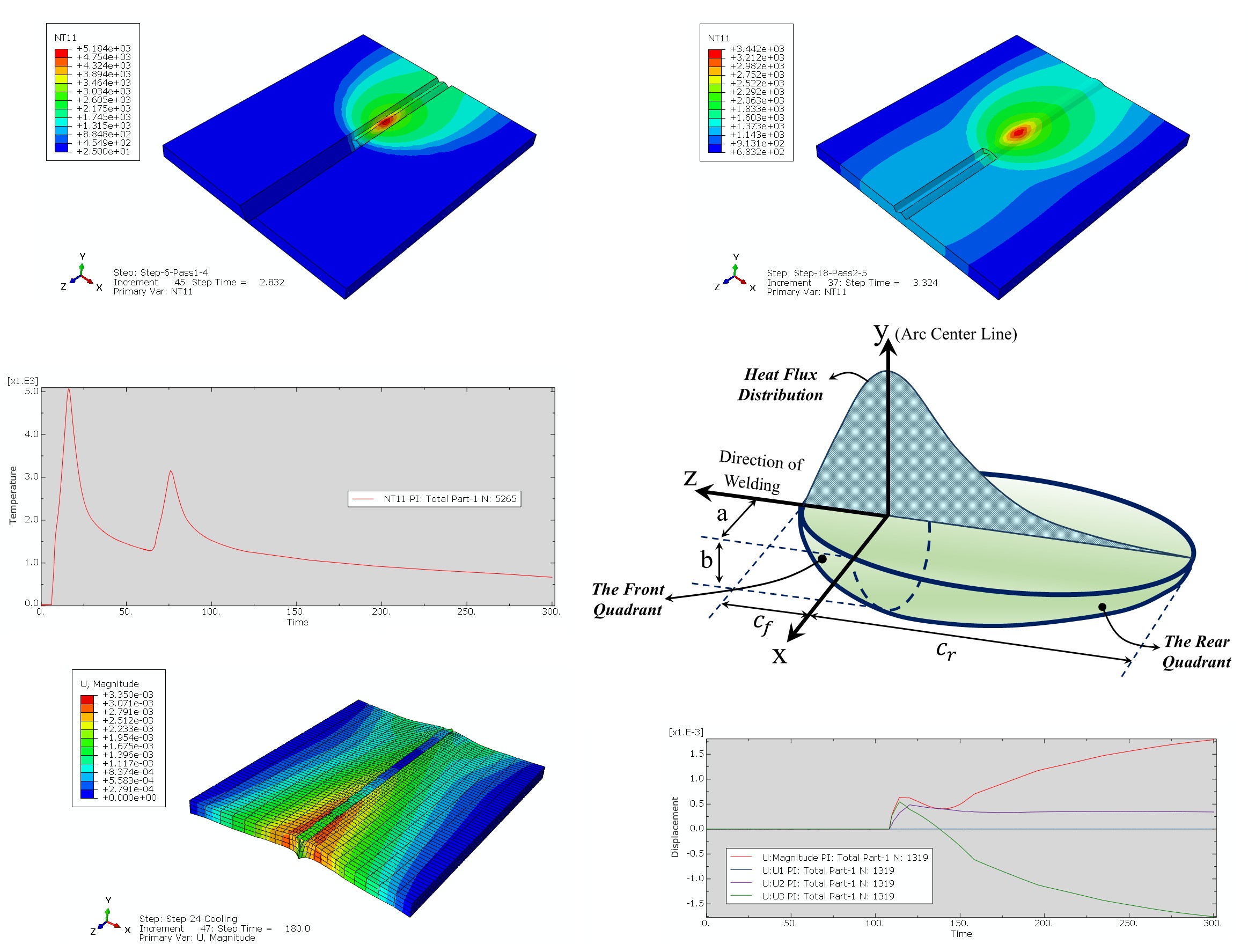

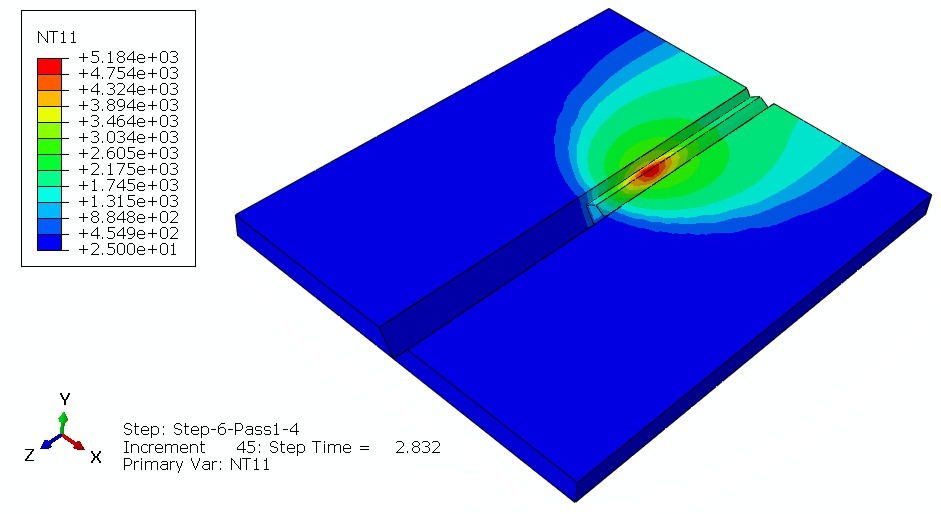

3.2. Two-pass and Multi-pass gas metal arc welding simulation

As one of the contributions of this package, how to define the heat flux, in order to model two-pass gas metal arc welding (GAMW), is taught in detail. This heat flux created by the electric arc is transferred to the welded parts and leads to a significant increase in temperature. The implementation of the heat flux in the welding model is done with DFLUX subroutine for Abaqus/Standard solver (implicit method). In user subroutine DFLUX, the nonuniform distributed flux can be defined as a function of temperature, time, integration point number, element number, etc. In the welding simulation model of this tutorial, the death and birth of elements technique (deactivating and activating elements) has been used to increase the accuracy of predicting results.

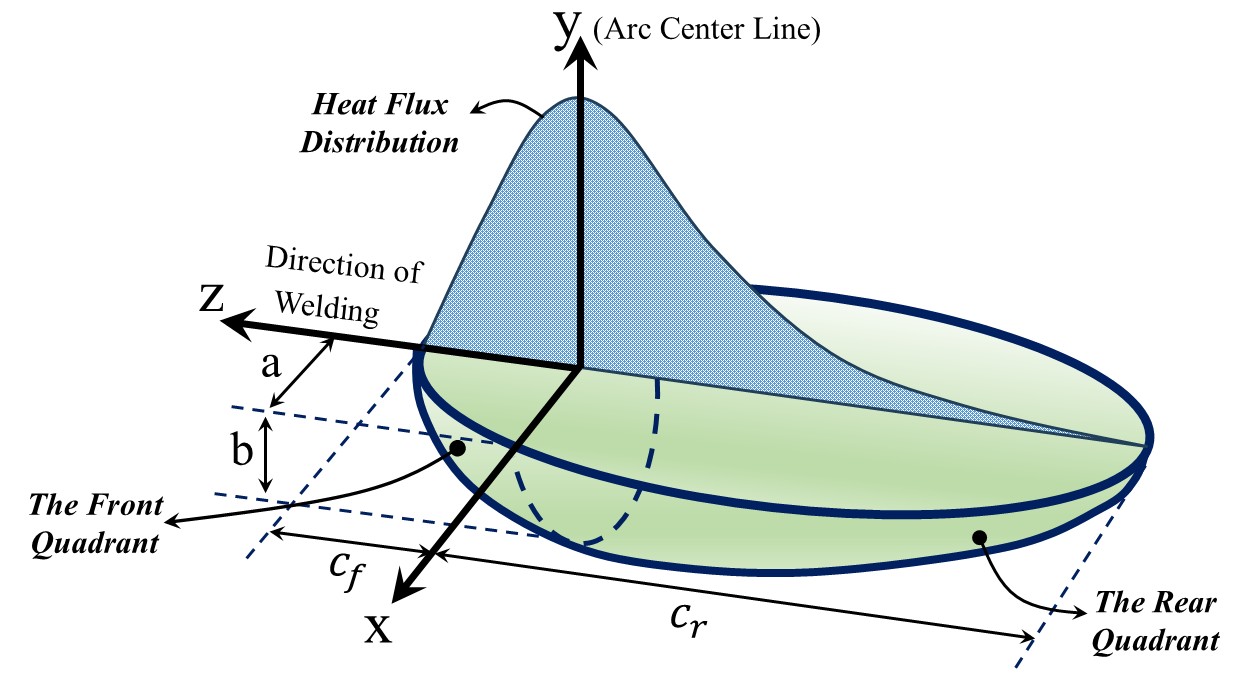

During a welding process, there are many physical processes that interact with each other to generate the heat flux and thus the final resulting temperature field in the parts to be welded. Over time, various heat source models were presented and developed to predict heat flux in different types of welding. Each of these models had advantages and disadvantages and was gradually generalized and improved. In this tutorial, the Goldak’s double ellipsoid heat source model is used to simulate the heat flux in GMAW process using the DFLUX subroutine.

4. Workshops

To enhance your learning, we have prepared six workshops for you in this project, the details of which are provided below.

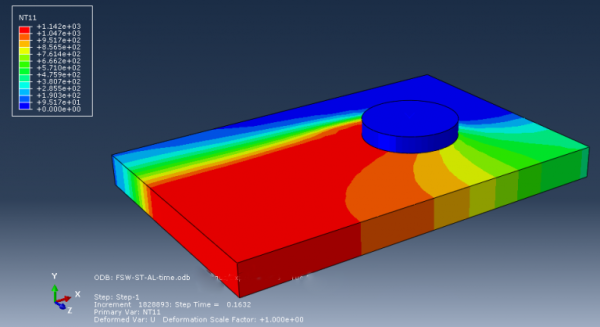

4.1. Workshop 1: FSW Simulation with Eulerian Elements

In the first workshop, we demonstrated the simulation of Friction Stir Welding (FSW) in Abaqus using Eulerian elements. In Eulerian modeling, the nodes remain stationary while the material flows through the mesh, making it more challenging to track free surfaces. However, this approach eliminates mesh distortion since the mesh itself remains fixed. FSW is a solid-state joining process in which heat is generated by friction between a non-consumable rotating tool and the workpiece, creating a softened region that facilitates bonding of the pieces.

4.2. Workshop 2: Explosive welding simulation

In the second workshop, we simulated Explosive Welding, a solid-state welding process that relies on high-energy rate deformation to join metal plates. The explosion generates intense pressure, which causes the plates to bond together.

4.3. Workshop 3: Simulation of FSW with SPH method

In the third workshop, we employed Smoothed-Particle Hydrodynamics (SPH) for simulating Friction Stir Welding. In this approach, there are no elements, only a set of nodes, making it one of the meshless methods available in ABAQUS.

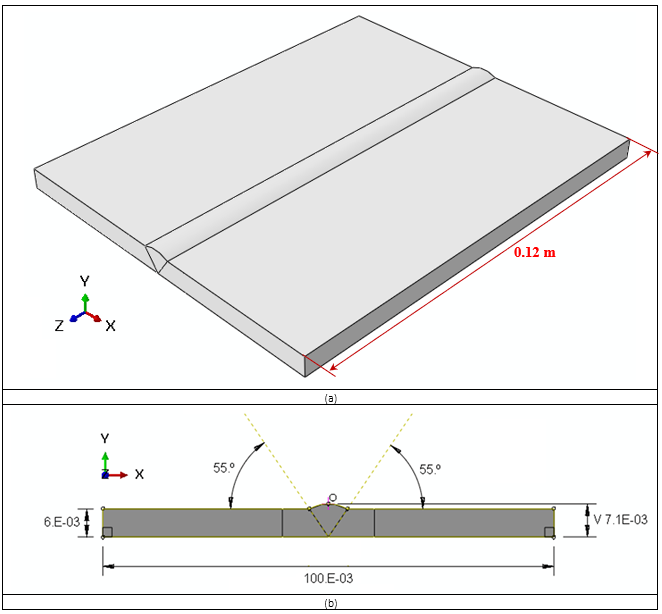

4.4. Workshop 4: Butt welding with death and birth of an element method

In the fourth workshop, we simulated butt welding using the birth and death of elements. Butt welding is a process where two workpieces are joined by aligning their edges (or “butts”) together, typically in a straight line. Heat and pressure, generated by sources like an electric arc, laser, or other methods, are applied to the surfaces to create the weld. This technique is commonly used when the pieces being welded have the same thickness and are aligned edge-to-edge, often for joining pipes, plates, or sheets. The objective is to achieve a strong, continuous bond without the need for filler material.

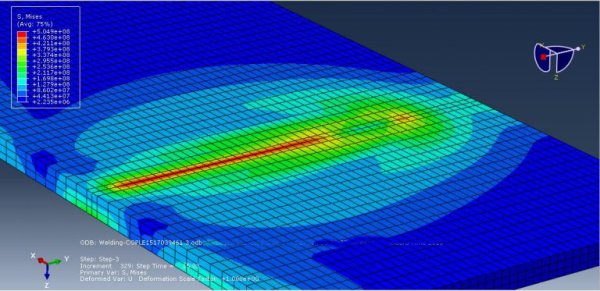

4.5. Workshop 5: Simulation of Arc welding between two tube with DFLUX subroutine (Thermomechanical Analysis)

In the fifth workshop, we utilized the DFLUX subroutine in Abaqus to simulate Arc welding between two tubes. DFLUX enables the creation of user-defined fluxes to apply custom load distributions during the simulation.

Figure 1: The schematic design of the welding specimen

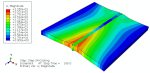

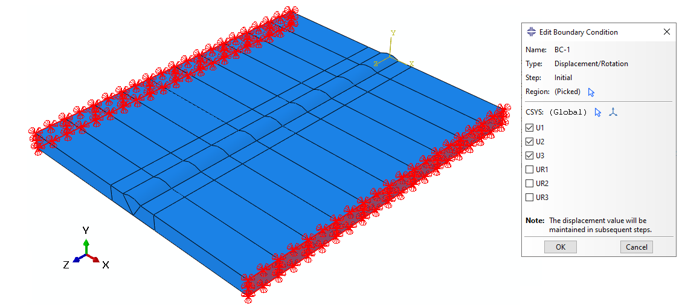

Figure 1: The schematic design of the welding specimen Figure 2: The displacement boundary conditions

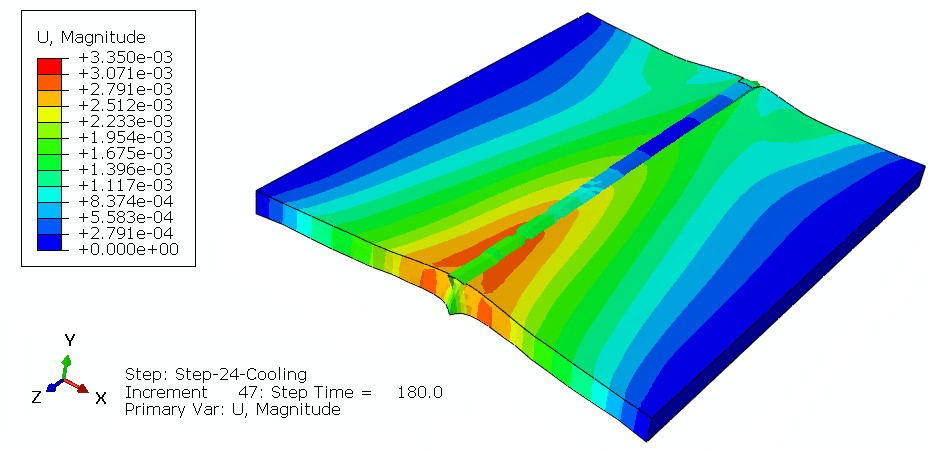

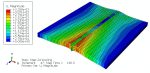

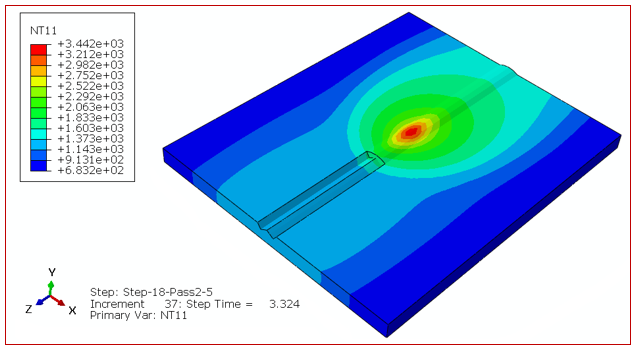

Figure 2: The displacement boundary conditions Figure 3: The nodal temperature distribution field

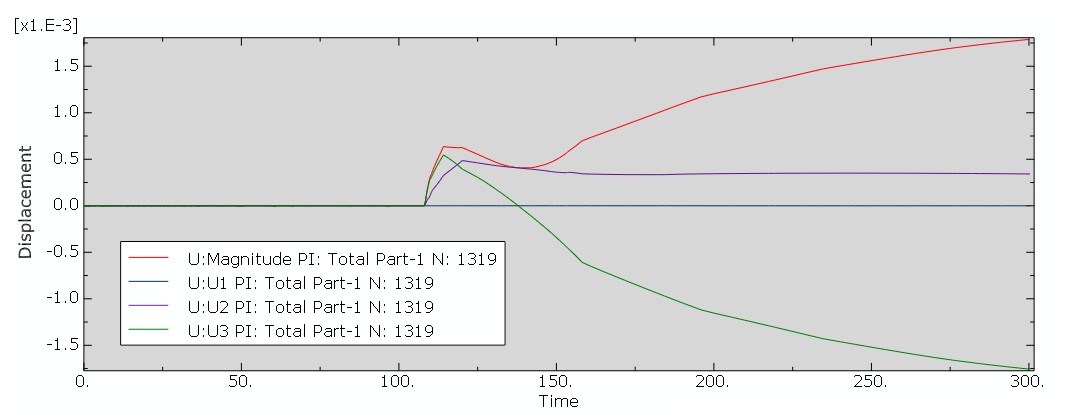

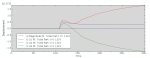

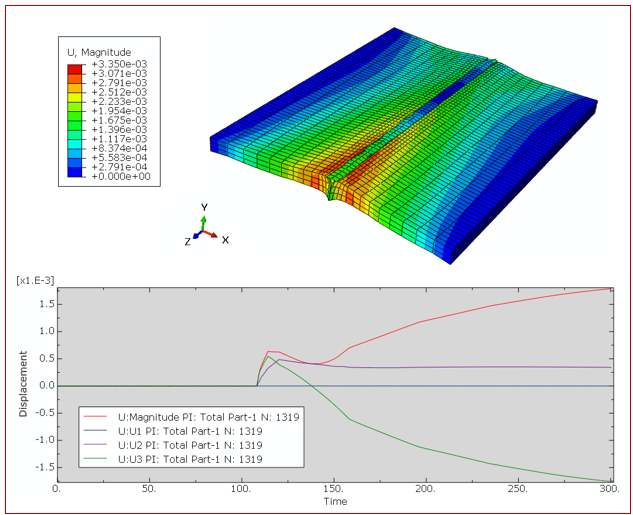

Figure 3: The nodal temperature distribution field Figure 4: Displacement-time diagram (U-t)

Figure 4: Displacement-time diagram (U-t)

Aleron Blanchet –

Based on the description it seems to be a useful and complete tutorial… I am waiting for your publish date.

Experts Of CAE Assistant Group –

It was available two weeks ago!

Karan –

The quality of the instructional videos in this package was very good, and I was able to easily follow the different simulation steps.