Lesson 1 & 2: Introduction to wood damage FEM

Wood is a natural material that provides structural support for trees and other plants. It has a wide range of applications, such as in construction, furniture making, and paper production. Despite its many applications, wood can suffer damage that may limit its uses. Insufficient strength in a wooden structure can lead to total failure, resulting in irreversible human and financial losses.

Early detection of damage is crucial for repairing and restoring sufficient stiffness in existing wooden structures. This also ensures the reliability of new structures. However, experimental methods for predicting wood damage require specific testing tools, which can be costly and challenging to use. To address these difficulties, numerical simulations using wood damage FEM offer a more cost-effective and less destructive alternative. We can adapt these simulations to a wide range of conditions and materials. Moreover, they are considered safe since they do not pose potential risks to humans. They also allow for comprehensive analysis of wood behavior, making them time-efficient and valuable.

Is numerical simulation of wood damage challenging?

Despite the benefits of numerical simulations compared to experimental methods, there are several issues and complexities associated with using such methods for predicting damage in wood structures. We will discuss these in detail in the following.

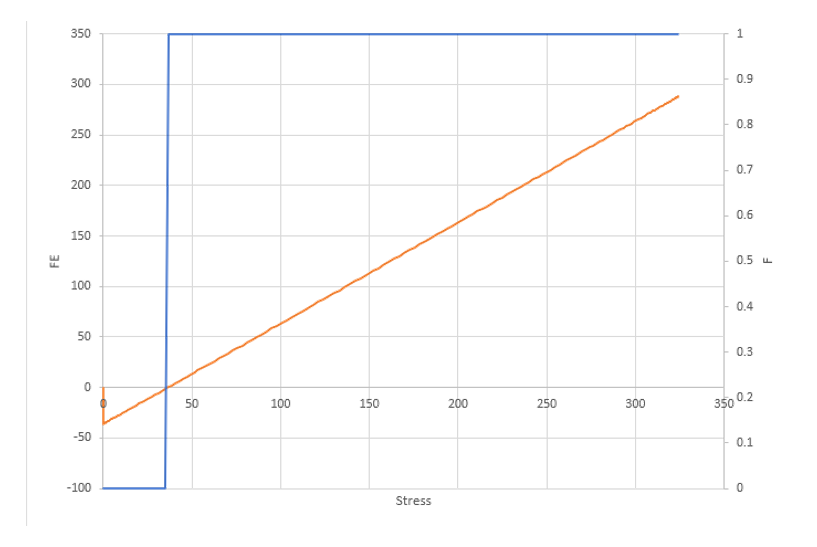

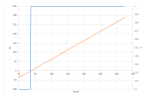

The accuracy of numerical models heavily depends on the input data. So, careful specification of the problem’s properties is essential to ensure accuracy. Moreover, wood exhibits complex behavior, showing different strengths in compression and tension. This complexity means that not all existing damage models are applicable to wood. On the other hand, wood demonstrates both brittle and ductile behaviors simultaneously, requiring advanced models that can accommodate both types of behavior.

Regarding the limitations related to continuum mechanics, models with softening can suffer from mesh dependency problems, which may lead to physically inadmissible solutions. Moreover, numerical models require different input parameters such as stiffness and strength values, which are typically derived from tests. Obtaining these parameters can be challenging due to the inherent variability in the mechanical properties of wood and the difficulties associated with testing and measurement.

All these factors make using numerical simulations challenging and require careful consideration and expertise to ensure reliable predictions. Consequently, we have limited numerical models that can accurately capture wood damage FEM.

Lesson 3: Numerical methods for damage prediction in wooden structures

We have three well-known numerical models for predicting wood damage, in literature, as:

- The Hashin model

- The Sandhaas model

- The Balsa model

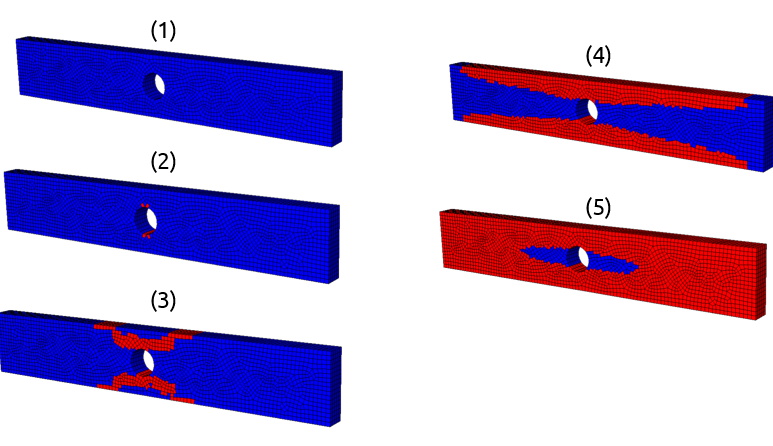

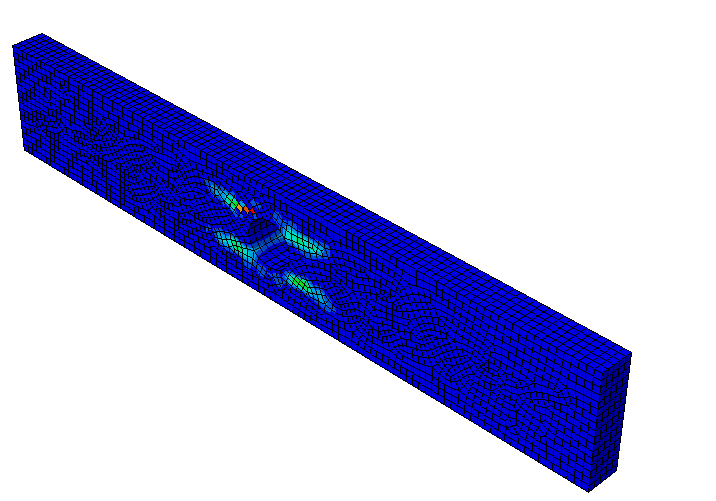

These models are recognized for their accuracy in predicting whether a failure has occurred at a material point. Additionally, we can extend them to evaluate damage propagation and stiffness reduction in wood due to failure. These capabilities make them integral to wood damage FEM. We review them in more detail in the following sections.

The Sandhaas model

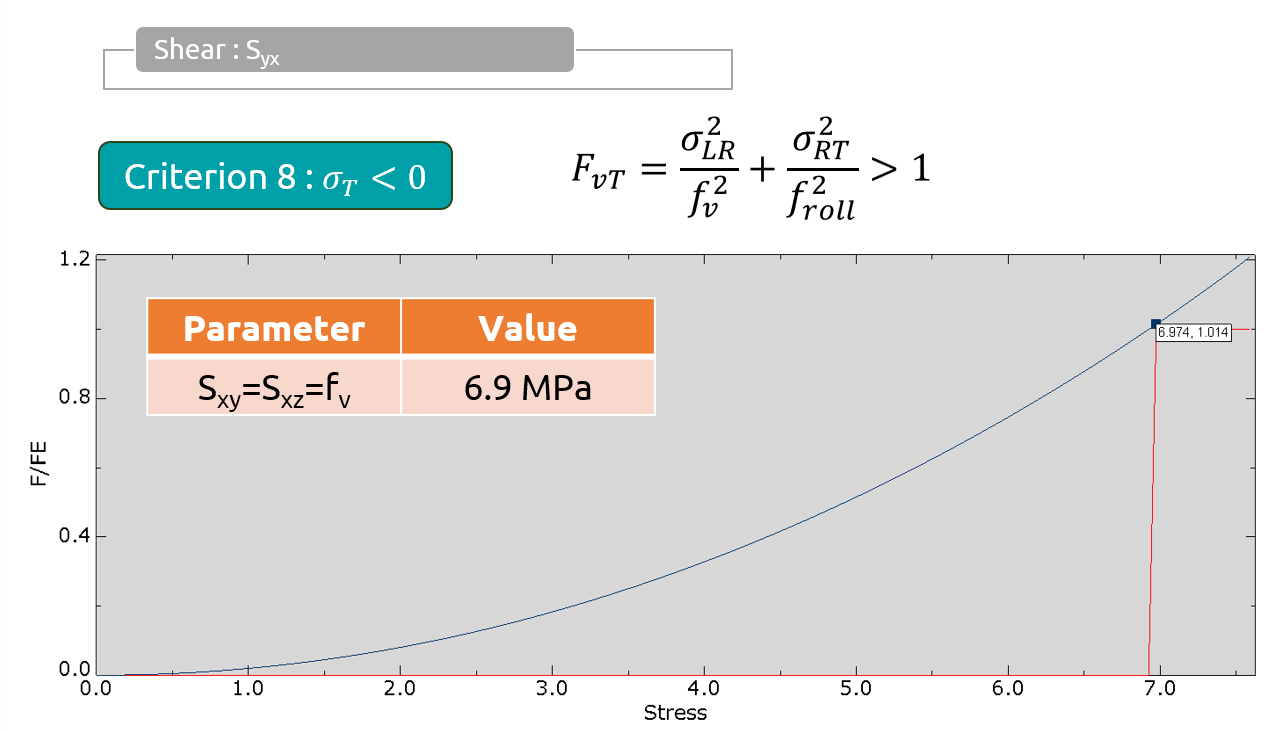

The Sandhaas model is a well-known numerical model primarily used to predict failure initiation and propagation in wood. It is primarily developed to predict whether a failure has occurred at a material point. To do so, it requires material strength parameters as input data to check for failure. For example, this includes tensile and compressive strengths parallel and perpendicular to the grain.

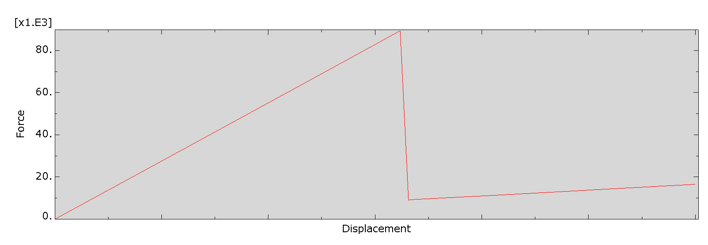

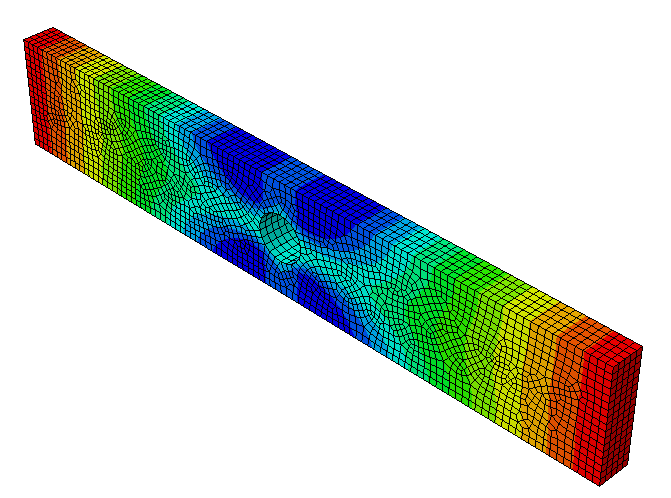

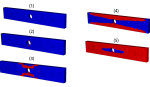

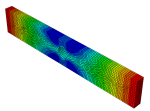

The Sandhaas model considers 8 failure states to determine whether the wood has failed. Failure occurs when a combination of stress components exceeds the material’s strength. Moreover, the model is often used in conjunction with a Continuum Damage Mechanics (CDM) model to assign damage to the failed material and degrade its stiffness, thereby capturing the real behavior of a failed material. The damage model frequently used with the Sandhaas criterion is a nonlinear elastic model that introduces nonlinearity by modifying the stiffness matrix during the solution. However, the model is simplified by neglecting plastic deformations during unloading.

In conclusion, the Sandhaas model is popular among researchers and practitioners for its useful features and is often used to predict failure initiation without considering damage and stiffness reduction due to the propagation of failure. Many practitioners combine it with a CDM model to capture stiffness degradation and damage propagation in the material.

The Hashin model

Hashin is another numerical model we use to predict failure in wood. The Hashin model defines failure modes with two main rules:

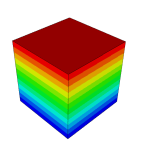

- Transversely Isotropic Behavior: The model considers the wood as transversely isotropic, meaning its properties are the same in both directions perpendicular to the grain.

- Shear Stress Effects: Shear stress can reduce wood’s resistance to compression or tension.

Based on these rules, the model considers four modes of failure. A value of 1 indicates that failure has occurred, while 0 indicates that the point has not failed. We can also extend the model to reduce stiffness parameters and predict damage propagation in the material.

The Balsa model

The Balsa model refers to a specific numerical model used to predict damage in Balsa wood. Balsa wood has many industrial applications, including thermal insulation for refrigerated ships, flotation aids in lifeboats, lightweight core material for sandwich panels, and packaging applications.

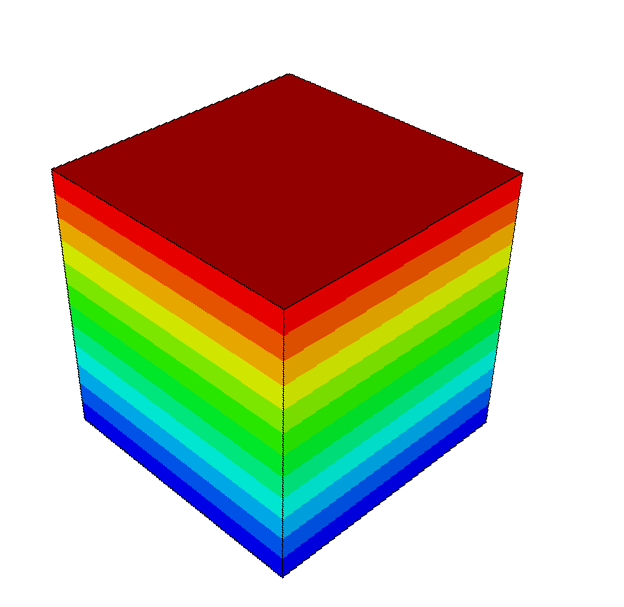

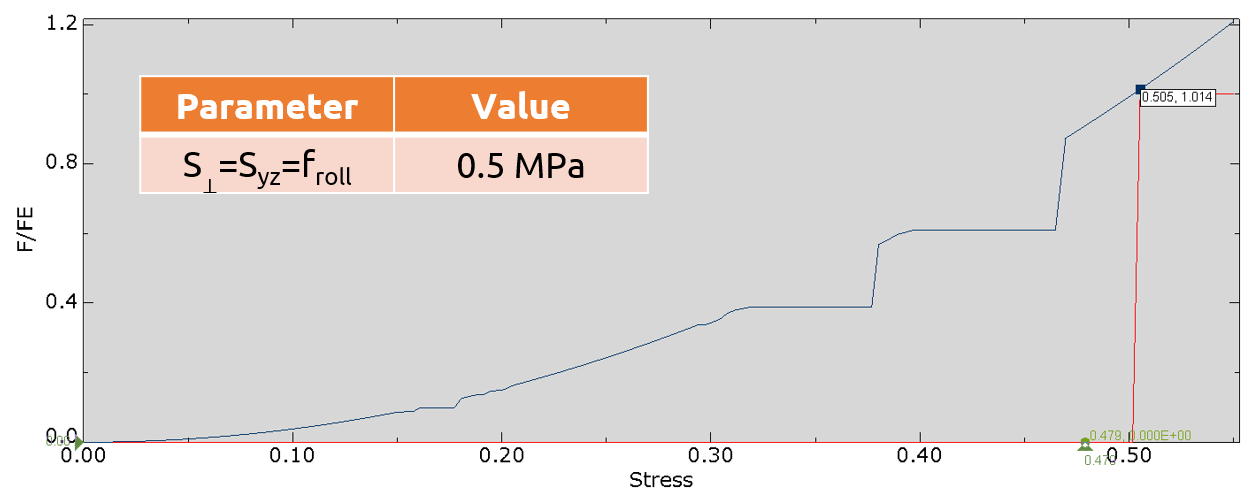

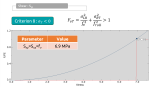

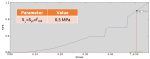

The model assumes that wood is transversely isotropic, meaning its properties are the same in both directions perpendicular to the grain. Moreover, it uses a simple failure criterion, compared to the Hashin and Sandhaas models. In this model, failure occurs when the equivalent stress exceeds the equivalent yield strength. Accordingly, we must calculate the equivalent stress using a specific equation that involves the stress components related to different axes.

Lesson 4: Implementation of the wood damage Abaqus

Abaqus is a powerful tool that plays a crucial role in predicting damage in wooden structures. It provides a platform for implementing advanced numerical models. The software supports numerical simulations, which are cost-effective and less destructive methods for damage prediction compared to experimental techniques. These simulations can predict whether a failure has occurred at a material point and evaluate damage propagation and stiffness reduction. Additionally, Abaqus offers tools to handle the complex behavior of wood, including its varying strengths in compression and tension, as well as its simultaneous brittle and ductile behaviors. This capability allows for the use of advanced models that accommodate these behaviors, making wood damage Abaqus simulations highly effective.

To perform such simulations, the VUSDFLD subroutine in Abaqus can be used. This subroutine allows for the definition of field and state variables, which can then be incorporated into the Abaqus simulation. Note that VUSDFLD is designed for use with explicit steps in Abaqus. For general static steps, we can use the USDFLD subroutine instead.

Reviews

Clear filtersThere are no reviews yet.