Introduction to Tunnel Cracking Laminates

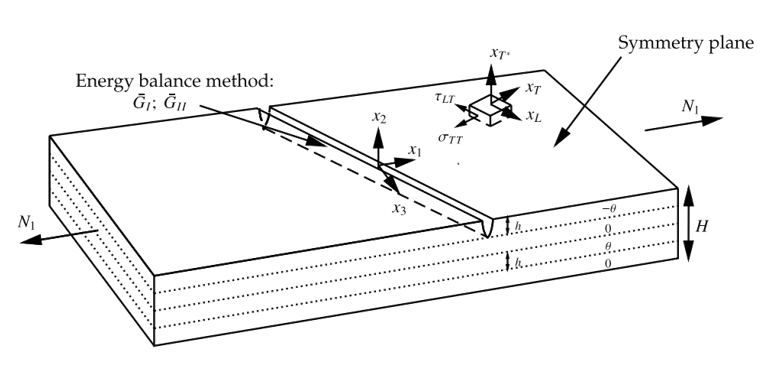

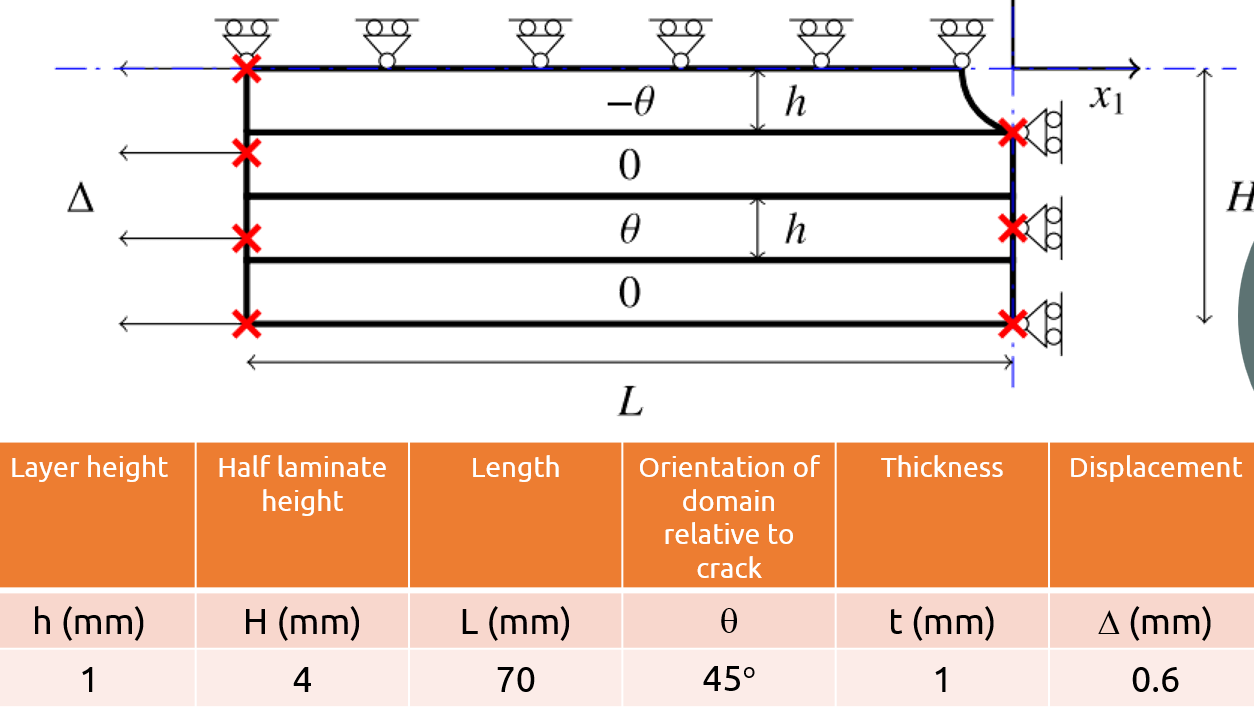

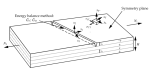

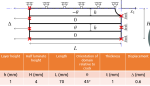

Off-axis oriented tunnel cracking laminates refers to the development of cracks at an angle relative to the fiber direction in composites. This phenomenon typically occurs in layered materials, such as laminates. In these materials, the fiber orientation significantly affects the mechanical behavior and failure modes. Investigating off-axis oriented tunnel cracking laminates involves examining how different factors influence the energy release rate and mode mix. For example, we can refer to ply thickness, crack spacing, and material properties. This project offers insights into the mechanics of crack growth in composite materials under various loading conditions. The analysis is conducted using Abaqus CAE. Moreover, it uses UEL and UMAT subroutines. Notice that, all modeling and Fortran subroutine files are provided for free.

The Importance of Analyzing Tunnel Cracks

Tunnel cracks commonly appear in composite materials, especially in layered laminates (Tunnel Cracking laminates). Areas with high-stress concentrations frequently have these cracks. For example, they may form near existing cracks or regions under multiaxial loading conditions. Factors like ply thickness, crack spacing, and fiber orientation in the laminate can impact the formation of tunnel cracks.

If tunnel cracks continue to grow, they can substantially weaken the structural integrity of the composite material. This crack propagation changes the stress distribution within the tunnel cracking laminates, potentially causing more cracks or failure. As the cracks extend, they might also shield the stress field in adjacent areas. This impacts the energy release rate and mode mix, and affects the chances of new cracks forming. Consequently, the overall performance and durability of the composite structure may be compromised. Therefore, it is essential to monitor and analyze crack growth in these materials. Investigating these cracks provides valuable insights into the failure mechanisms of composite structures.

The Role of Numerical Simulations in Analyzing Tunnel Cracking laminates

Benefits of the Numerical Simulation of Tunnel Cracks

Numerical simulations are powerful tools for analyzing tunnel cracks. They offer detailed insights into the behavior of cracks within composite materials. These simulations allow for the prediction of crack growth under various loading conditions, aiding in the identification of failure points. Additionally, they enable comprehensive parameter studies to evaluate how different factors affect tunnel cracking laminates behavior. For example, we can refer to ply thickness and crack spacing. Simulations can quantify the energy release rate and mode mix associated with crack growth. These are crucial for understanding the mechanics of crack propagation.

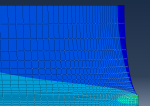

From another angle, numerical methods can reveal the stress and strain fields around cracks. So, they aid in the identification of high-stress concentration areas. Additionally, employing a 2D finite element model instead of a 3D one can greatly reduce computational time, enabling more extensive analyses than traditional methods allow. Furthermore, finite element models can incorporate various complexities, such as randomness in microstructure, which is crucial for realistic modeling of composite materials.

Complexities in the Numerical Simulation of Tunnel Cracks

Despite their advantages, numerical simulations for analyzing tunnel cracking laminates have limitations. For instance, these models might not accurately depict scenarios with edge effects, where crack behavior can differ significantly from that in the bulk material. Additionally, models may face challenges with cracks oriented in multiple directions, as the assumptions made in the simulations might not apply in such cases. Moreover, the methods rely on a steady-state condition, and if this condition is not met, the results may not be reliable.

From a computational cost standpoint, although newer models have become more efficient, full 3D models can still be computationally intensive, particularly for complex geometries or high aspect ratios. Conversely, some models might incorporate simplifications that could neglect important physical behaviors, such as the non-rigorous distinction between Mode I and Mode II.

Using Abaqus for the Numerical Simulation of Tunnel Cracking laminates

Abaqus significantly addresses many limitations of numerical simulations for tunnel cracks in composite materials. It enables the use of user-defined elements (UEL). We can customize it to more accurately represent material behavior and crack propagation. Additionally, Abaqus supports automation via Python scripts, streamlining model creation, input file modification, and post-processing, thereby facilitating systematic parametric studies. The software also offers a variety of advanced material models, including those that account for complex behaviors such as non-linearities and anisotropy, which are essential for accurately modeling composite materials.

In conclusion, the software features efficient computational algorithms that can greatly reduce computational time, enabling more extensive analyses and the handling of larger models. It also provides robust post-processing capabilities, allowing for detailed analysis of stress and strain fields to identify critical areas around cracks.

Is Using Abaqus for Tunnel Cracking Analysis Challenging?

While Abaqus is a powerful tool for analyzing tunnel cracking laminates, it does have some limitations. For instance, despite its efficiency, Abaqus can still demand substantial computational resources for complex models, especially in 3D simulations or large-scale problems. Additionally, accurately representing material properties and geometries can complicate the modeling process, and any simplifications may result in less accurate outcomes.

From another angle, Abaqus can model cracks, but accurately capturing complex crack propagation behaviors can be challenging, particularly when dealing with multiple interacting cracks or non-linear material responses. Additionally, the accuracy of the results heavily depends on the quality of the input data, such as material properties and loading conditions. Inaccurate input can result in misleading outcomes. Consequently, effective use of Abaqus often requires advanced expertise in both the software and the underlying mechanics of materials. It can be a barrier for some users.

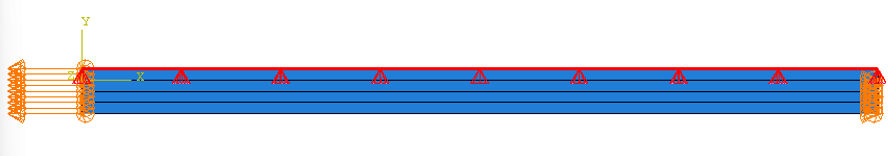

Using Abaqus for Tunnel Cracking Simulation in This Project

The project offers valuable insights and methodologies for using Abaqus to simulate tunnel cracks in composite materials. It involves implementing a novel 2D model in Abaqus, using a Python script to automate processes, and highlighting the benefits of the computational methods used. This information can help users effectively utilize Abaqus for their simulations, especially in analyzing energy release rates and crack profiles.

Using a Python Script to Generate the Abaqus Model

The Python script is essential for automating the entire process of simulating tunnel cracks in Abaqus. It handles several key tasks, including creating the geometry, defining model properties, and setting load and displacement boundary conditions. The script generates the input file for Abaqus and automatically modifies it to incorporate the user element subroutine (UEL). This input file is then submitted for solving within Abaqus. After solving, the script proceeds with post-processing to calculate the crack profile and the energy release rate. Overall, the Python script streamlines the workflow, making it more efficient for users to conduct systematic parametric studies and analyze results.

Using Abaqus Subroutines

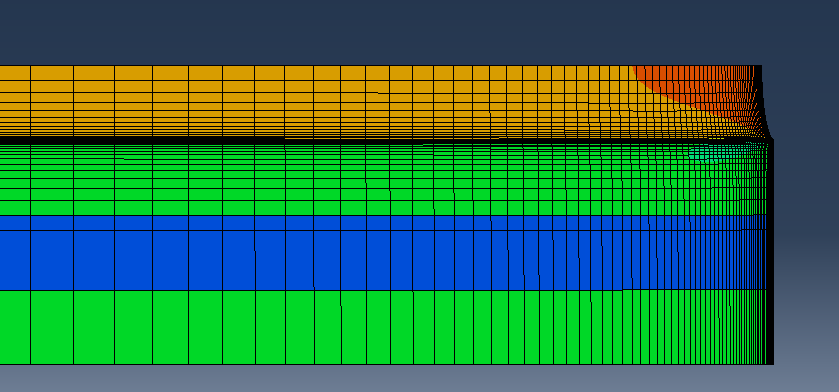

The project utilizes Fortran subroutines for Abaqus, specifically the user element subroutine (UEL) and the user material subroutine (UMAT). The UEL subroutine is invoked by each element and requires the definition of the stiffness matrix and the residual vector. The UMAT subroutine is employed to transfer stresses and strains via a Fortran common block from the UEL subroutine.

The user element subroutine (UEL) is crucial in Abaqus, allowing users to define custom elements for their simulations. This enables the implementation of tailored element behaviors not available in the standard Abaqus library. With this subroutine, users can specify element behavior to meet their specific requirements.

In this context, the user material subroutine (UMAT) is employed to define custom material behavior for Abaqus simulations. It transfers stresses and strains via a Fortran common block from the user element subroutine (UEL), allowing user-defined material properties to integrate with the element behavior. A zero stiffness constitutive model is used, resulting in a zero stiffness matrix to ensure the material subroutine does not alter any values of the UEL subroutine. The UMAT stores stresses and strains as state variables, instead of using the built-in variables, enabling a more flexible representation of material behavior. This subroutine facilitates the visualization of stress and strain fields while allowing custom material models in the analysis.

Results

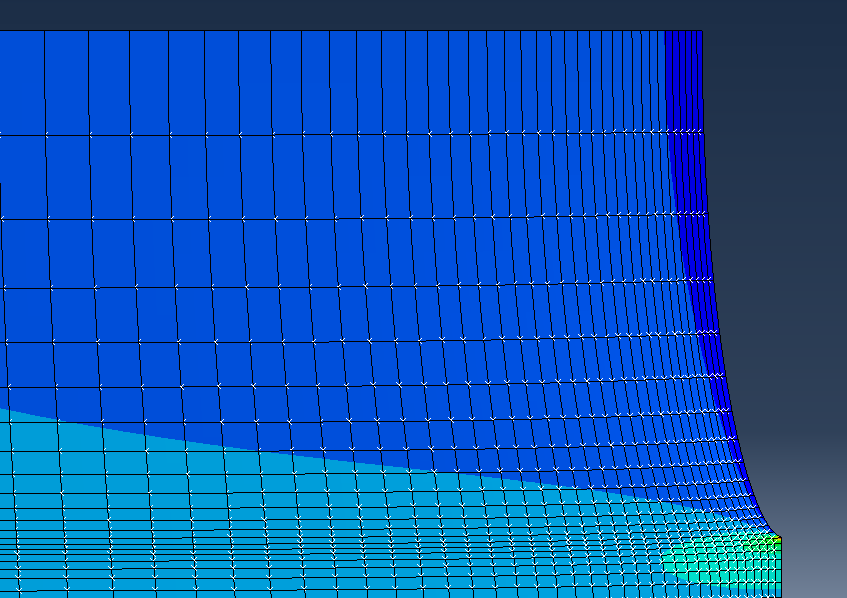

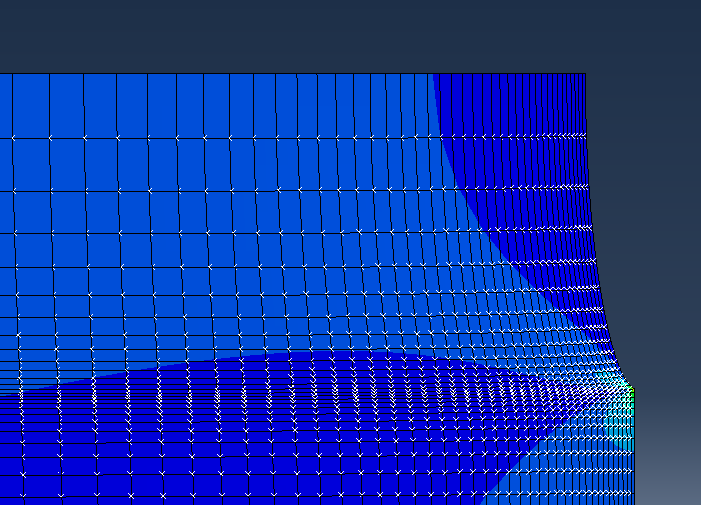

The project allows you to extract and explore several key results, including:

- Out-of-Plane Displacement and Strain

- Comparison of 2D and 3D Models

- Crack Opening Displacement and Energy Release Rate

- Computational Efficiency achieved with the novel 2D off-axis element compared to the 3D model

Verification

The project results are verified by directly validating the novel 2D formulation against the full 3D model. The material systems analyzed were also considered by other researchers in 3D, allowing for comparison. This validation is conducted for several cases, ensuring the reliability of the findings.

Who Benefits from This Project

The project can benefit a variety of stakeholders, including:

- Researchers: Those studying composite materials and their behavior under different loading conditions can gain valuable insights from the findings.

- Engineers: Professionals in structural engineering, materials science, and mechanical engineering can apply the methodologies and results to improve their designs and analyses.

- Academics: Educators and students in engineering and materials science programs can use the project as a resource for learning and teaching advanced material modeling and analysis techniques.

- Industry Practitioners: Companies involved in manufacturing or utilizing composite materials can leverage the research to enhance product performance and reliability.

Declaration and citation

The project is used for the analysis of off-axis oriented tunnel cracking laminates as detailed in the paper titled “A special finite element method applied to off-axis tunnel cracking laminates”. The paper provides all the necessary information regarding the theory and formulation, modeling procedure, writing Abaqus script, and subroutines. They are written in a simplified, comprehensive manner, allowing engineers to easily access all the required details. We only will provide you with the Abaqus files, including .inp, Python script, and Fortran subroutines, for free. You can read the paper on the publisher’s website for free. It is published as an open-access paper, making it available to everyone without any cost.

Tapobrata –

Contents are very helpful specially for beginers.

a.sascha.golod –

I can’t find any exe file to watch the explanation. The Abaqus files are looking good.

Viet Dung Luong –

Excellent

Viet Dung Luong –

Great

Mostapha Tarfaoui –

Great