Introduction to Composites & Stiffness Degradation Composites

Composite materials, particularly fiber-reinforced composites, have become fundamental in many high-performance applications due to their superior mechanical properties, including their exceptional strength-to-weight ratios. These materials, composed of two or more constituent materials, create a unique combination with characteristics distinct from the individual components. One critical factor in their performance is stiffness degradation composites, a key area of study to ensure these materials maintain their integrity over time. The most common types are those reinforced with fibers, such as carbon, glass, or aramid, embedded in a polymer matrix. This makes composites indispensable in industries like aerospace, automotive, and civil engineering.

However, despite their impressive properties, composites are not immune to damage. The complexity of their structure means that damage can occur in various forms and progress through different mechanisms, significantly impacting their structural integrity and performance. Understanding and predicting damage in composite materials is crucial for ensuring their safe and effective use in critical applications.

Damage Prediction in Composites

The Importance of Damage Prediction in Composites

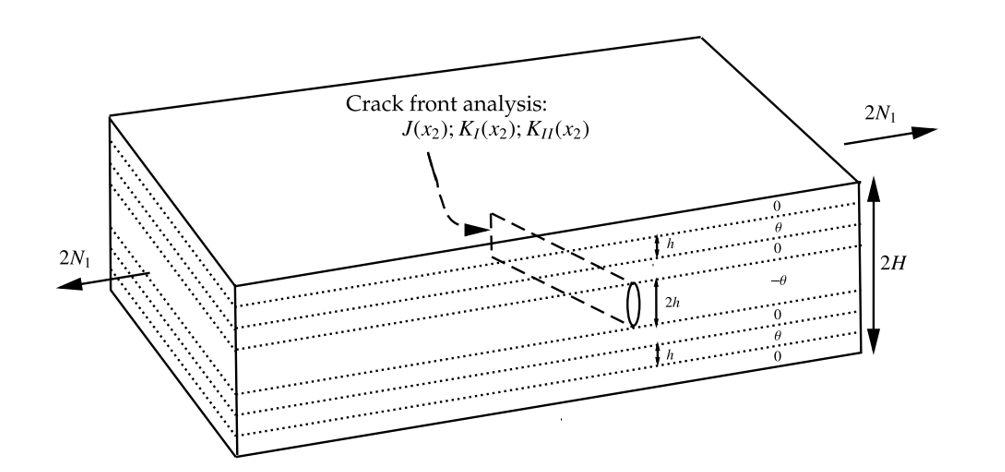

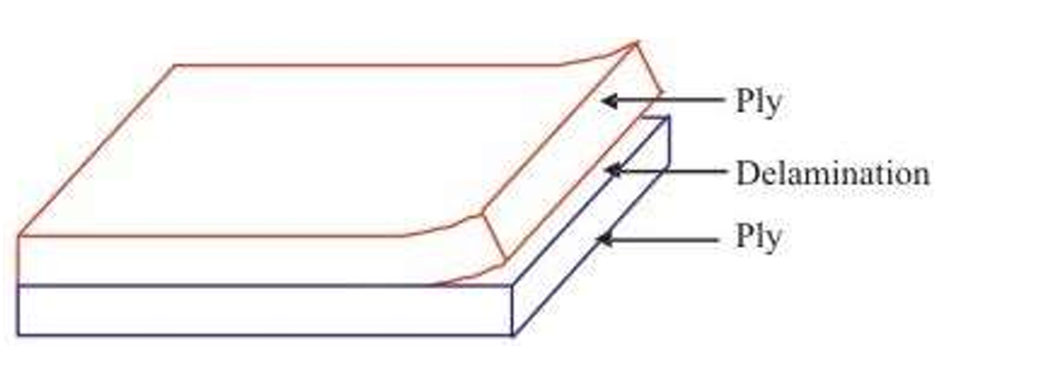

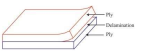

Damage in composites is a multifaceted problem due to the anisotropic nature of these materials. In other words, their properties differ depending on the direction of the load relative to the fiber orientation. Common damage mechanisms include tunnel cracking, fiber breakage, and delamination between layers. Each of these mechanisms can occur independently or in combination, making the prediction of damage progression challenging.

One of the most critical aspects of damage in composites is the degradation of stiffness due to tunnel cracking and delamination. Stiffness is directly related to the load-bearing capacity of a material. As damage accumulates, the material’s stiffness decreases. It can lead to potential failure if we do not detect and manage the damage in time. Accurate prediction of Stiffness Degradation Composites due to damage is therefore essential in the design, maintenance, and life-cycle management of composite structures.

An Overview of Damage Prediction Methods

Traditional methods of predicting damage in composites often require extensive experimental testing, which can be both time-consuming and expensive. As a result, there has been a significant shift towards the use of numerical methods, particularly finite element analysis (FEA), to simulate damage and predict its impact on the mechanical properties of composites.

Why Use Abaqus for Composite Damage Prediction?

Abaqus, a highly advanced FEA software, excels at modeling complex material behaviors, including those in composite materials. The software’s capability to incorporate detailed material models and simulate intricate damage mechanisms makes it a preferred choice for researchers and engineers working with composites.

The Role of Abaqus for Damage Prediction in this Package

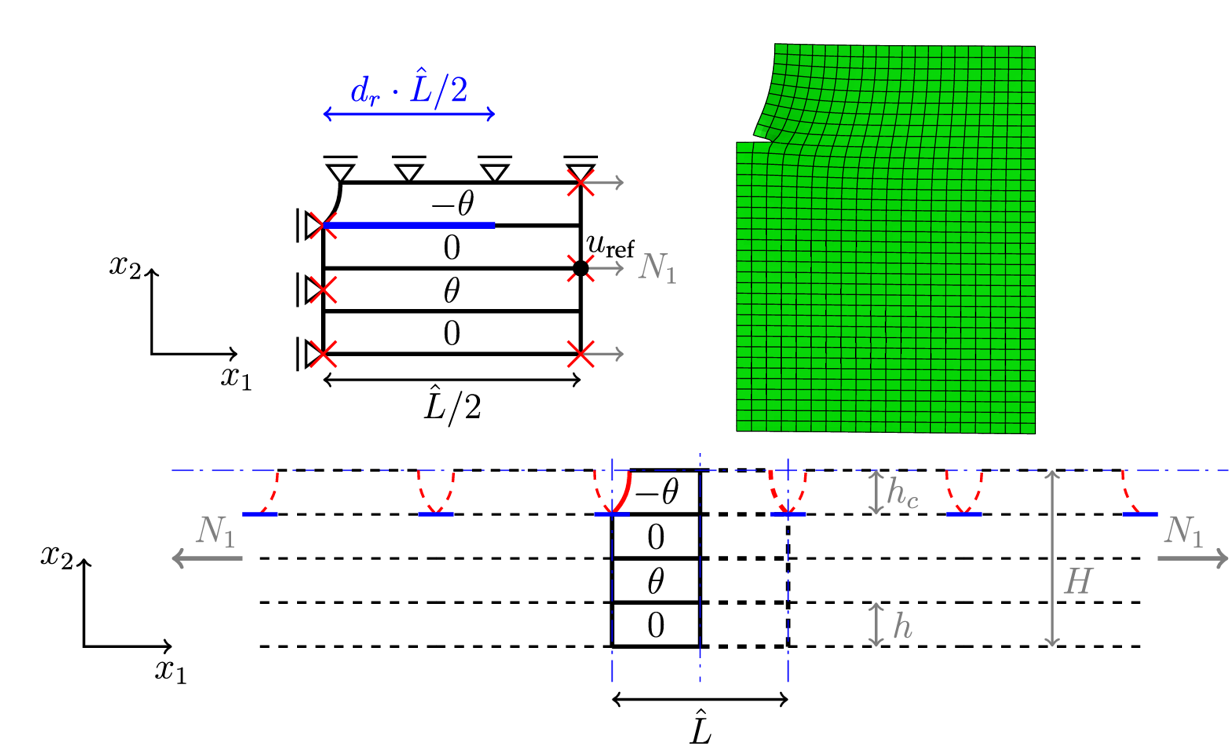

The research presented in the paper uses Abaqus to develop a novel finite element model. The model aimed at predicting Stiffness Degradation Composites laminates due to tunnel cracking and delamination. This model specifically focuses on laminates with arbitrarily oriented cracks. It addresses a gap in traditional modeling approaches that often assume cracks are perpendicular to the loading direction.

Key reasons for choosing Abaqus in this research

The key reasons for choosing Abaqus in this research include:

- Comprehensive Material Modeling: Abaqus allows for the implementation of complex material behavior models. They include anisotropic damage mechanics, which are essential for accurately simulating the behavior of fiber-reinforced composites.

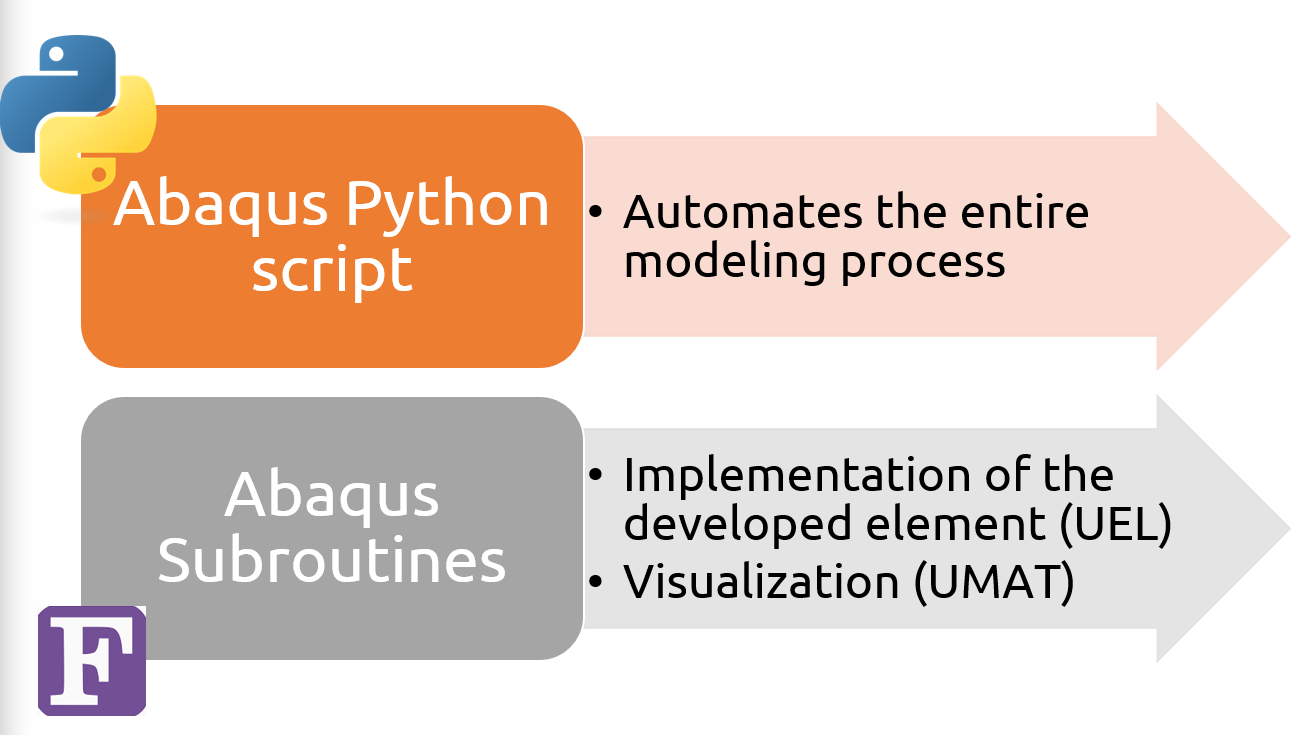

- Customizable User Subroutines: The ability to integrate custom Fortran subroutines and Python scripts within Abaqus enables the development of specialized models. Researchers tailor such models to meet specific research needs. This flexibility is crucial for simulating non-standard damage scenarios, such as the arbitrarily oriented cracks studied in this research.

- Robust Contact Modeling: Abaqus provides advanced contact modeling features, which are essential for simulating the interaction between crack surfaces. This is particularly important in the study of frictionless contact between crack faces, which significantly affects the Stiffness Degradation Composites.

Details of the Abaqus Model

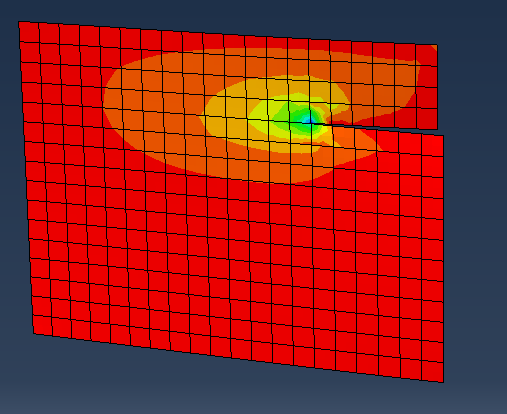

The Abaqus model developed in this research represents a significant advancement in the simulation of composite damage. It offers a novel approach to predicting Stiffness Degradation Composites laminates with cracks. Such cracks can occur at any orientation relative to the principal tensile direction. This capability is particularly valuable for applications where complex loading scenarios make it difficult to control or predict the direction of damage.

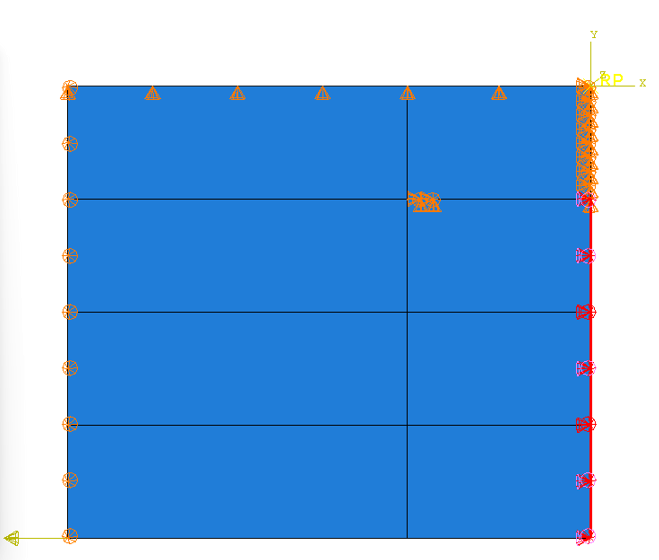

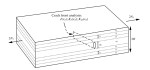

To implement the introduced model in Abaqus, the authors have used UEL and UMAT subroutines and written a DISP subroutine to apply the load to the composite. They have provided all modeling details and steps in a Python script. Simply download the files, open Abaqus, and run the provided script. The model will be created, and the job will start analyzing automatically.

Modeling Arbitrary Crack Orientation

Traditional composite damage models often assume that cracks align perpendicular to the loading direction. This simplifies the analysis but limits the model’s applicability to real-world scenarios. The model developed in this research overcomes this limitation. This flexibility enables the model to simulate a broader range of damage scenarios. This makes it more applicable to actual composite structures used in practice.

Incorporating Frictionless Contact Between Crack Surfaces

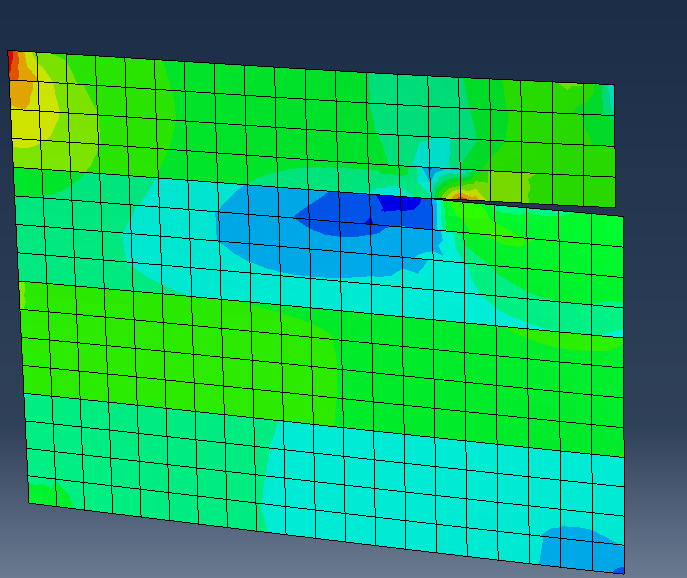

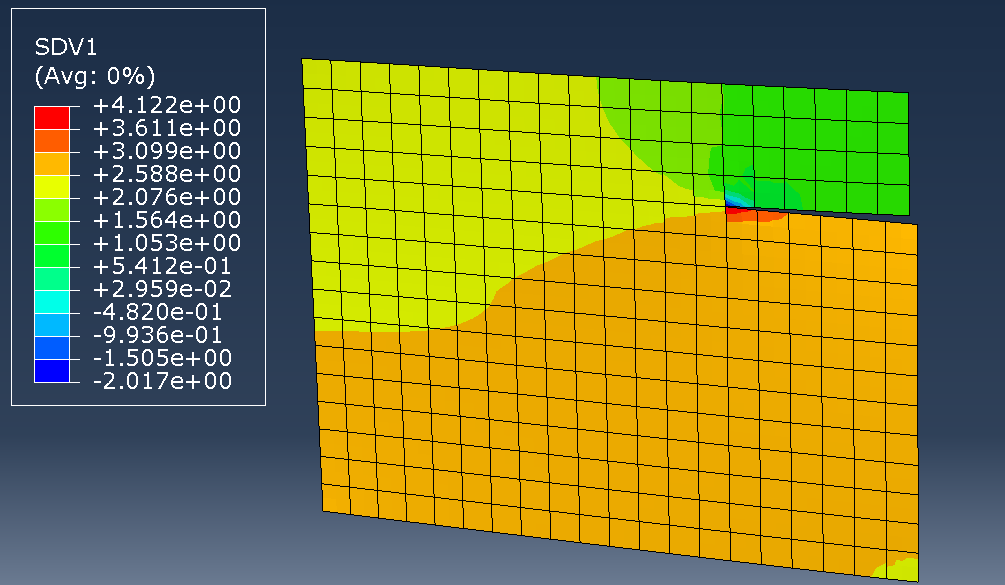

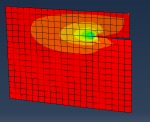

The model also incorporates the effect of frictionless contact between crack surfaces. It refers to a feature that is particularly relevant for predicting Stiffness Degradation Composites carbon fiber. The research found that in laminates with off-axis cracks below 40°, the frictionless contact between crack surfaces significantly influences the Stiffness Degradation Composites. By including this effect in the model, the researchers can provide more accurate predictions of stiffness loss. It is more valuable in cases where traditional models might underestimate the impact of crack surface interaction.

Efficient Computational Approach

One of the key strengths of the model is its computational efficiency. Despite the complexity of the damage mechanisms it simulates, the model is designed to run efficiently on standard computational resources. This efficiency is achieved through the use of a 2D finite element approach. It reduces the computational cost compared to full 3D models without sacrificing accuracy. This makes the model particularly useful for conducting large-scale parametric studies or for exploring the behavior of composite laminates under different loading conditions.

Extracted Results and Their Implications

The Abaqus model developed in this research provides detailed predictions of Stiffness Degradation Composites laminates due to damage. It is used for the solution of problems in the following paper.

So, the key results extracted from the model and included in the paper that are relevant to this project are as follows:

- Axial and Transverse Stiffness Degradation: The model predicts how stiffness degrades in both the axial (parallel to the fibers) and transverse (perpendicular to the fibers) directions as cracks form and propagate within the laminate. This information is crucial for assessing the load-bearing capacity of the composite and for determining the point at which the material may no longer be considered safe for use.

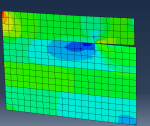

- Damage Progression Monitoring: The model tracks the progression of damage, from the initial formation of tunneling cracks to the onset of delamination and eventual fiber breakage. This capability is particularly valuable for applications where it is important to understand not just the current state of the material, but also how it is likely to degrade over time.

- Impact of Crack Orientation on Stiffness: The research demonstrates that the orientation of cracks relative to the tensile direction has a significant impact on the rate of stiffness degradation composites. Cracks oriented at angles other than 90° to the loading direction cause a different stiffness reduction pattern, which must be accounted for in the design and analysis of composite structures.

Applications and Benefits for Potential Users

This Abaqus model and the associated modeling files are valuable tools for a wide range of professionals. Such professionals may be involved in the design, analysis, and maintenance of composite structures. The potential users and applications of this product include:

Aerospace Engineers: Aerospace engineers who work on the design of lightweight and durable aircraft structures will benefit from this model. This is due to the model’s ability to predict damage in composite materials. The model’s accuracy in predicting stiffness degradation is particularly important for ensuring the safety and longevity of critical components. For example, we can refer to wings, fuselages, and other load-bearing structures.

Automotive Engineers: In the automotive industry, where the use of composites is increasing due to the demand for lighter and more fuel-efficient vehicles, this model provides an essential tool for predicting the performance of composite components under various loading conditions. Engineers can use the model to optimize the design of composite parts, ensuring that they can withstand the stresses encountered during vehicle operation.

Structural Analysts: Structural analysts responsible for assessing the integrity of composite structures in buildings, bridges, and other civil engineering applications can use this model to predict how damage will affect the long-term performance of these materials. The ability to simulate different damage scenarios allows analysts to make informed decisions about maintenance and repair strategies.

Researchers in Material Science: For researchers developing new composite materials or studying the effects of different loading conditions on existing materials, this model provides a powerful tool for exploring the behavior of composites at a fundamental level. The ability to simulate arbitrarily oriented cracks and their impact on stiffness degradation composites is particularly valuable for advancing the understanding of composite damage mechanics.

Declaration and citation

The project is used for the analysis of Stiffness Degradation Composites in the paper titled ”An efficient stiffness degradation model for layered composites with arbitrarily oriented tunneling and delamination cracks”. The paper contains comprehensive details on the theory, formulation, and modeling process. We will offer the Abaqus files, including .inp files, Python scripts, and Fortran subroutines, at no cost. The paper is available for free on the publisher’s website as an open-access document, so that you can read it without any charge

Viet Dung Luong –

Great

Mostapha Tarfaoui –

Great

[email protected] –

Hello Mr Herrmann;

How can i download the files? I am not able to find the files!

Best regards

Experts Of CAE Assistant Group –

You can find it in your dashboard from download section

Rafil Laftah –

Good