Introduction to Tread wear

Tread wear typically refers to the gradual erosion or reduction in the thickness of the tread on a tire. The tread is the patterned rubber on the outer surface of the tire that makes contact with the road. It serves several important functions, including providing traction, improving handling, and aiding in the dispersion of water on wet roads.

As a tire rolls along the road, it experiences friction, which can lead to wear on the tread. Over time, this wear can result in a reduction of tread depth. Tread wear is a natural and expected part of a tire’s lifecycle, but it’s important to monitor it to ensure that the tire remains safe and effective.

Tire manufacturers often design tires with tread wear indicators (also known as wear bars) that become visible when the tread depth reaches a certain level. This serves as a visual signal that the tire may need replacement soon. Adequate tread depth is crucial for maintaining traction, especially in wet or slippery conditions. Insufficient tread depth can lead to reduced grip, longer stopping distances, and an increased risk of hydroplaning on wet roads. Therefore, regularly checking and replacing tires with significant tread wear is essential for vehicle safety and performance.

Tread wear simulation is an essential aspect of tire testing and development in the automotive industry. Here are several reasons why it is important:

Safety: Adequate tread depth is crucial for maintaining traction on the road, especially in adverse weather conditions. Tread wear simulation helps manufacturers understand how tires wear over time, allowing them to design and produce safer tires that provide consistent performance throughout their lifespan.

Performance: Tires play a significant role in a vehicle’s overall performance, including handling, braking, and fuel efficiency. Tread wear simulation helps manufacturers optimize tire designs for better performance, ensuring that the tire characteristics remain consistent over time.

Regulatory Compliance: Various countries and regions have regulations regarding minimum tread depth for tires. Tread wear simulation allows manufacturers to ensure that their tires meet these regulatory requirements.

Durability: Understanding how tires wear under different conditions helps manufacturers improve the durability and lifespan of their products. This is crucial for customer satisfaction and reducing the frequency of tire replacements.

Cost Efficiency: Tread wear simulation allows manufacturers to identify design improvements that can enhance a tire’s wear resistance. This can result in longer-lasting tires, potentially reducing the frequency of replacements for consumers and contributing to overall cost efficiency.

Environmental Impact: Tires that wear more slowly and evenly may have a reduced environmental impact. By optimizing tread wear characteristics, manufacturers can contribute to sustainability efforts by extending the lifespan of tires and reducing waste.

Consumer Confidence: Through rigorous tread wear simulation and testing, manufacturers can provide consumers with more accurate information about the expected lifespan and performance of their tires. This transparency can enhance consumer confidence in the product.

In summary, tread wear simulation is a critical component of tire development, ensuring that tires meet safety standards, provide optimal performance, and are durable over their intended lifespan. It helps manufacturers create products that align with regulatory requirements, customer expectations, and industry standards.

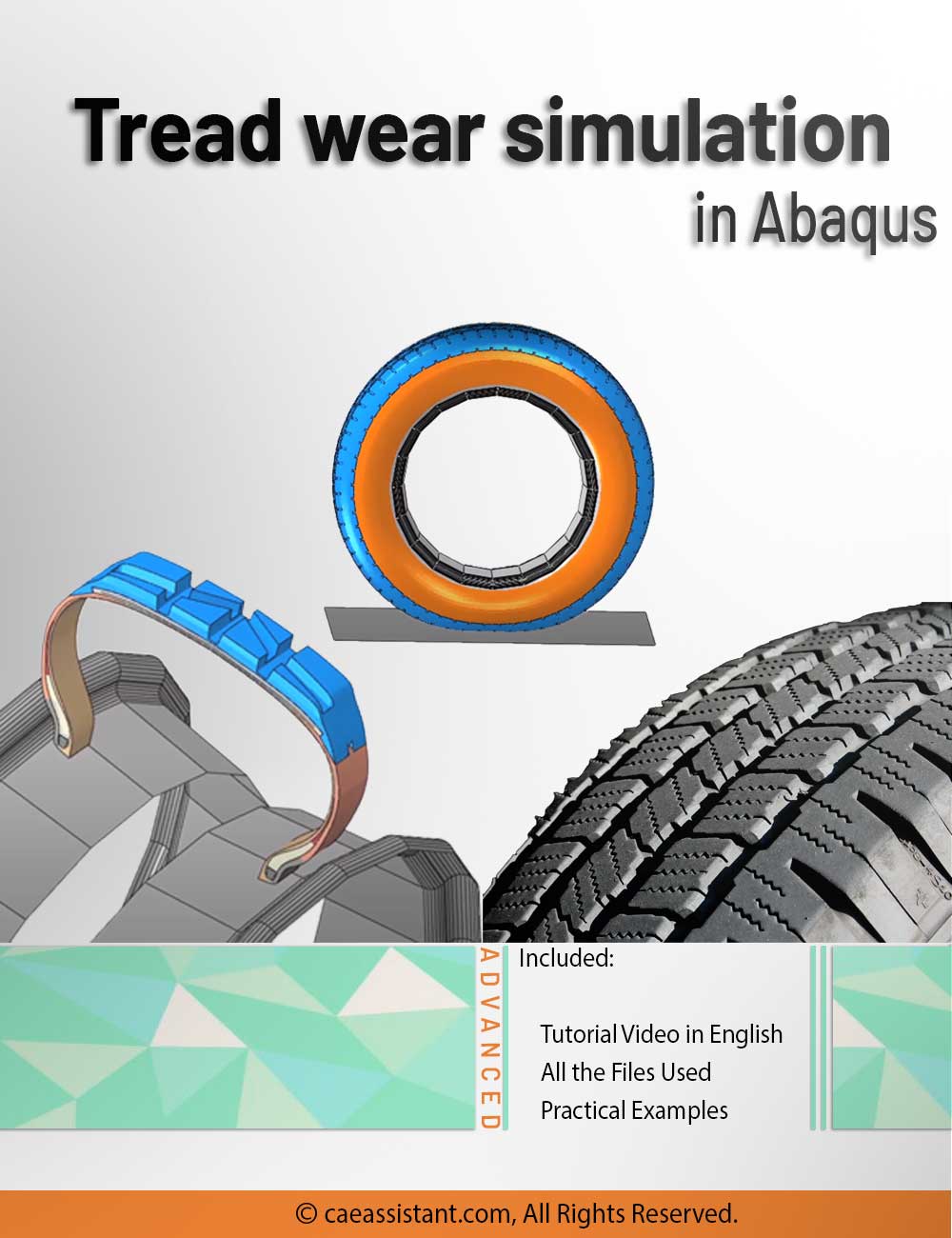

In this training package, you will learn how to model tread wear in Abaqus using UMESHMOTION subroutine.

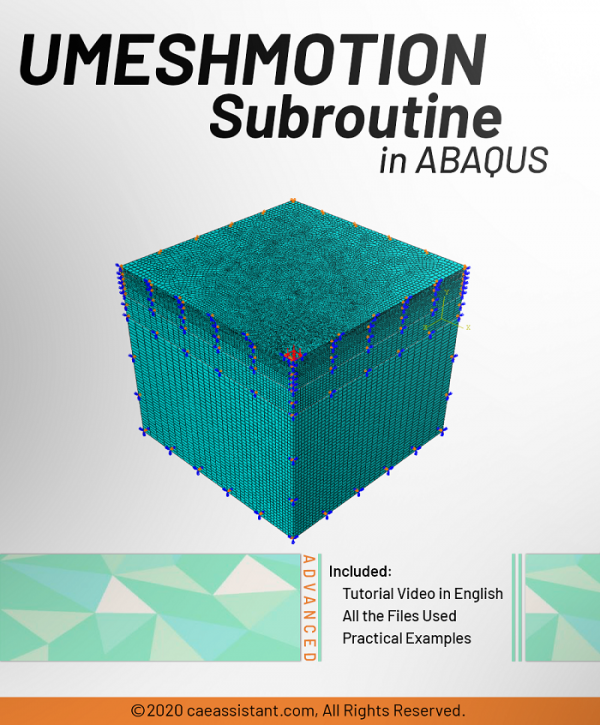

A brief intro to UMESHMOTION subroutine

The UMESHMOTION subroutine within the ABAQUS package provides instruction on creating this subroutine through various illustrative examples. One application of the UMESHMOTION subroutine is demonstrated in modeling wear processes using the Archard model in Abaqus, a widely utilized approach in both academic and industrial projects.

This subroutine is employed to specify the movement of nodes within a constrained node-set during adaptive meshing. Activation of the UMESHMOTION subroutine occurs at the conclusion of each increment where adaptive meshing takes place, as determined by the specified frequency of increments.

Within this resource, you will gain insights into the appropriate occasions and methodologies for implementing the UMESHMOTION subroutine. Utilizing this subroutine often entails the incorporation of other internal (UTILITY) subroutines. Notable examples of such subroutines include GETVRN, GETNODETOELEMENT, and GETVRMAVGATNODE. These additional subroutines serve the purpose of extracting material point or node-related information, encompassing various Abaqus outputs, node partition details, and specific average outputs per node.

Workshop: Simulation of tread wear in Abaqus

This workshop investigates tire wear resulting from movement at a speed of 32 km/h over a duration of 1000 hours. The Archard equations, implemented through the UMESHMOTION subroutine, are employed for the abrasion analysis. The simulation involves the utilization of written inputs for the modeling process, some of which lack a graphical equivalent in the Abaqus/CAE software.

The tire is modeled with an appropriate mesh in a stepwise manner. Initially, an axisymmetric element is employed to establish the model’s geometry. Subsequently, a portion of the three-dimensional model is created using axisymmetric elements. Finally, a complete three-dimensional model is generated based on the previous model.

It is essential to note that the calculation of wear considers two modes: slip and non-slip of the tire during movement.

It would be helpful to see Abaqus Documentation to understand how it would be hard to start an Abaqus simulation without any Abaqus tutorial. Moreover, the general description of how to write a subroutine is available in the article titled “Start Writing a Subroutine in Abaqus: Basics and Recommendations “. If you even do not familiar with the FORTRAN, you can learn the basics via this article: “Abaqus Fortran “Must-Knows” for Writing Subroutines”.

Alejandra –

Based on the content and features provided in this tutorial, I would like to express my gratitude to CAE Assistant for offering this instructional product. This product is recommended as a valuable resource for individuals seeking to enhance their knowledge and skills in the field of tire tread wear simulation, due to its comprehensive coverage of the subject matter within the Abaqus tool.

Experts Of CAE Assistant Group –

Thanks for kind comment. It helps us to produce valuable contents