UMESHMOTION subroutine in ABAQUS (New update)

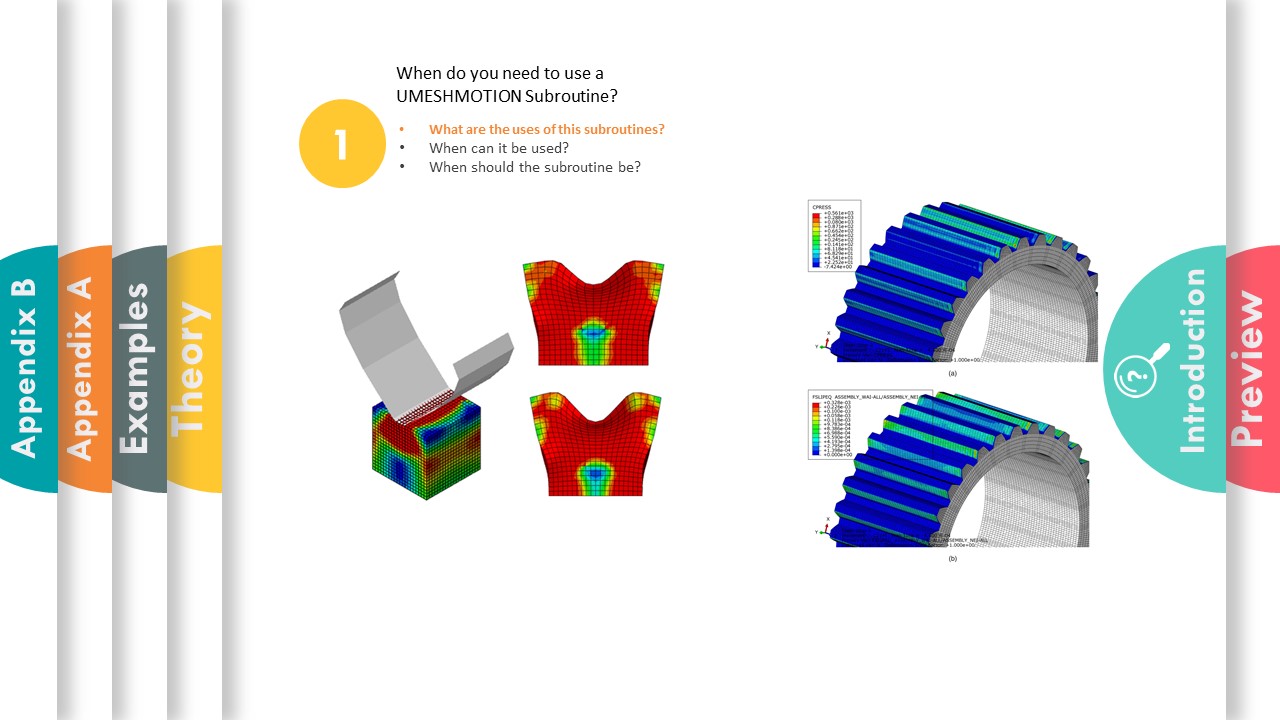

The UMESHMOTION subroutine in ABAQUS” package teaches you how to write this subroutine using a variety of examples. An example of the use of UMESHMOTION subroutine is in the wear process using the Archard model in Abaqus, which is very popular in academic and industrial projects.

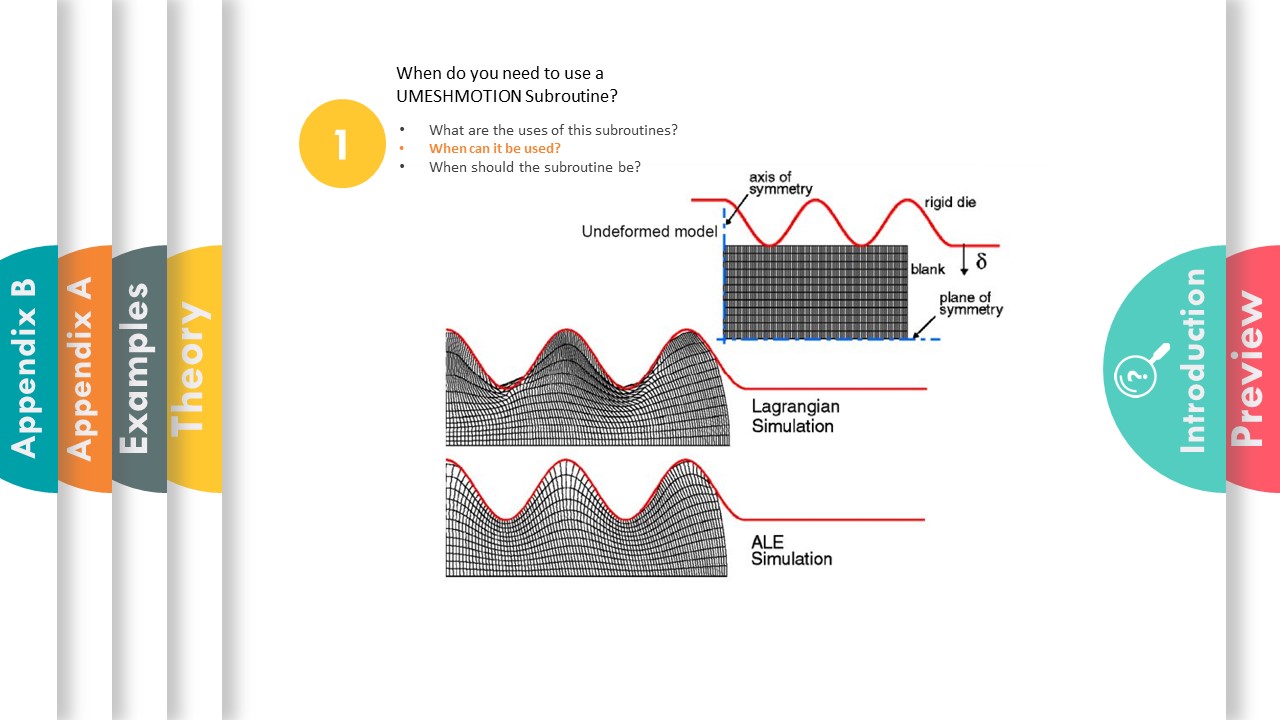

The UMESHMOTION subroutine could be used to define the motion of nodes in an adaptive mesh constraint node-set. This subroutine is called at the end of any increment where adaptive meshing is performed (as specified by the frequency in increments).

You can find general information about this subroutine in Abaqus documentation via this link.</span

In this package, you will first learn when and how to use UMESHMOTION subroutine. To use this subroutine, it is often necessary to use other internal(UTILITY) subroutines as well. Examples of these subroutines are GETVRN, GETNODETOELEMNET, GETVRMAVGATNODE. These subroutines are for obtaining material point or node information such as different Abaqus outputs, node part information, specific average output per node or etc.

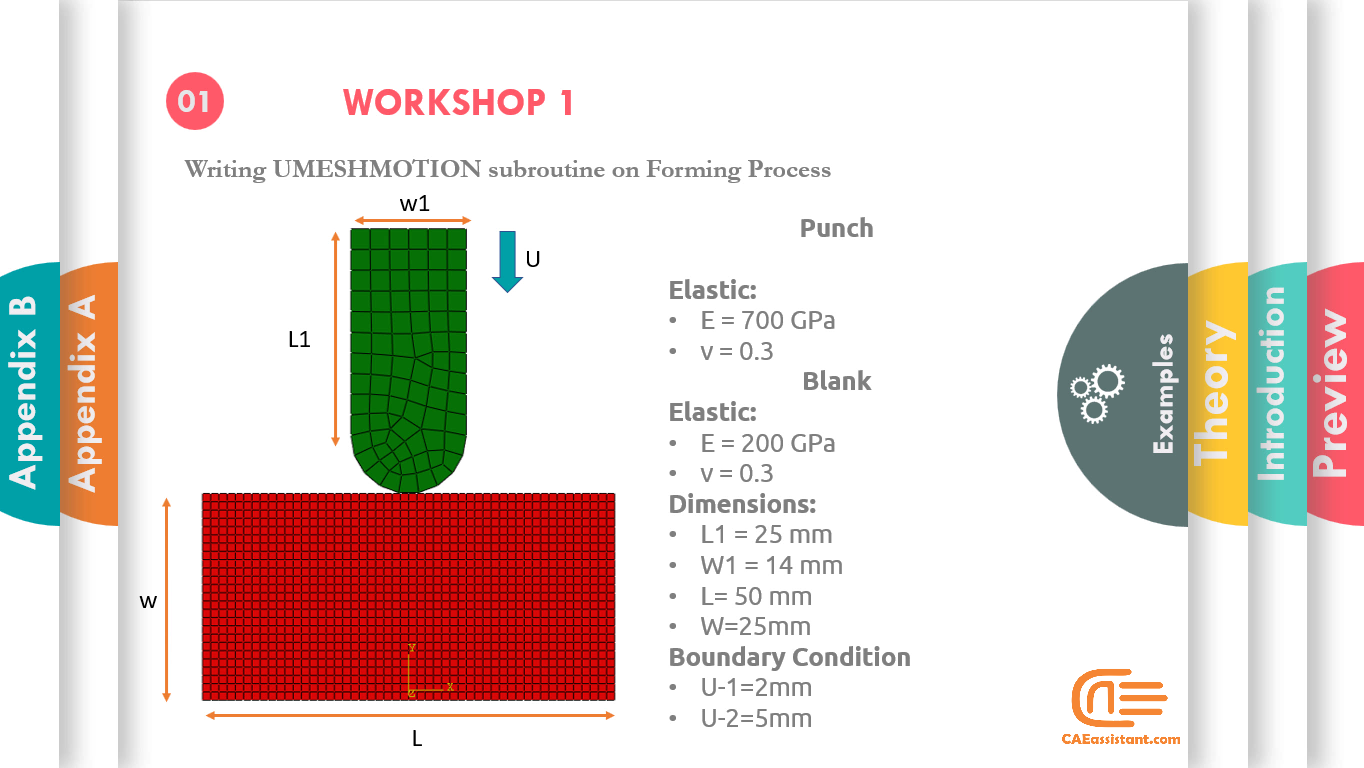

First workshop: Writing UMESHMOTION subroutine in Forming Process (2D wear)

In this workshop, firstly, the issue of the plate strain forming process and all the input information, including geometry dimension, material properties, boundary conditions, and loading information, are explained. To write the subroutine, the wear equations(Archad Model) to be implemented in this workshop are described. In the next step, the flowchart of this subroutine is fully presented and explained step by step. Then, the desired subroutine is written line by line according to the flowchart, and the necessary points in each line are explained to the relevant formulations. In this subroutine, how to enter textual information as input in the subroutine, calling the internal subroutines mentioned in the previous section, is also fully presented. Finally, the desired subroutine has been implemented in the software with full explanations of the necessary points, and the results have been discussed.

Second workshop: Writing UMESHMOTION subroutine in Rolling Process (2D wear)

In this workshop, wear is implemented on the rolling process model. The problem is first fully explained for this simulation and the geometric and material details. Then, tips on subroutine implementation, mesh convergency, and discussion of results are provided

Third workshop: Treadwear simulation using UMESHMOTION

In this workshop, the wear of a tire due to movement at a speed of 32 km / h during a time of 1000 hours is examined. Ablation is performed by Archard equations via the UMESHMOTION subroutine. In this simulation, some written inputs are used for modeling. Some of these inputs do not have a graphic equivalent(Abaqus/CAE) in the software. Tire modeling with a suitable Abaqus mesh is done in several steps. In the first step, the axisymmetric element is used to create the model geometry. In the next step, part of the three-dimensional model is made from axisymmetric elements. And in the final stage, a complete three-dimensional model is made from the previous model. Note that in calculating the amount of wear, two modes of slip and non-slip of the tire while moving have been considered.

DING KIM –

It was a good training package. How can I contact you for consultancy?

Experts of CAE Assistant Group –

Send your document to [email protected]. However, I recommend you fill out Consultancy Registration Form.

https://caeassistant.com/consultancy-application-from/

franck locas –

This training package is so comprehensive, and every single point is explained in detail within them. Also, their prices are incredible comparing to other similar websites. Thanks!!

Peter –

The content of this training package was of very high quality and comprehensive. As an advanced ABAQUS user, I am truly satisfied with it and recommend it to my colleagues.

William –

This training package helped me to have a systematic and organized approach for learning and using the UMESHMOTION subroutine in ABAQUS. The videos and documentation were very helpful.

Oswald –

I am really satisfied with this training package. The content was excellent and comprehensive, and enabled me to work as a proficient user of the UMESHMOTION subroutine.

Lowry –

The supplementary features like the certificate and assessment report really helped me to formally prove my skills and be recognized as a UMESHMOTION subroutine expert.