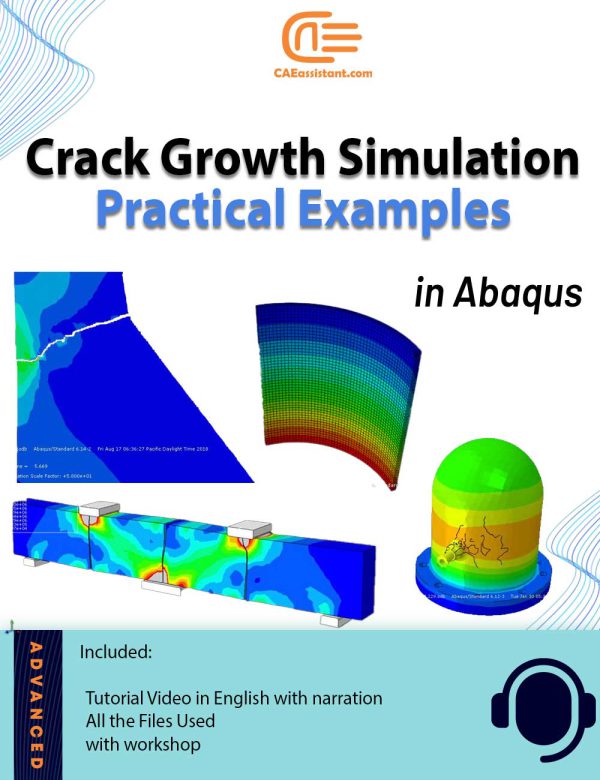

Abaqus Crack Growth | Practical Examples

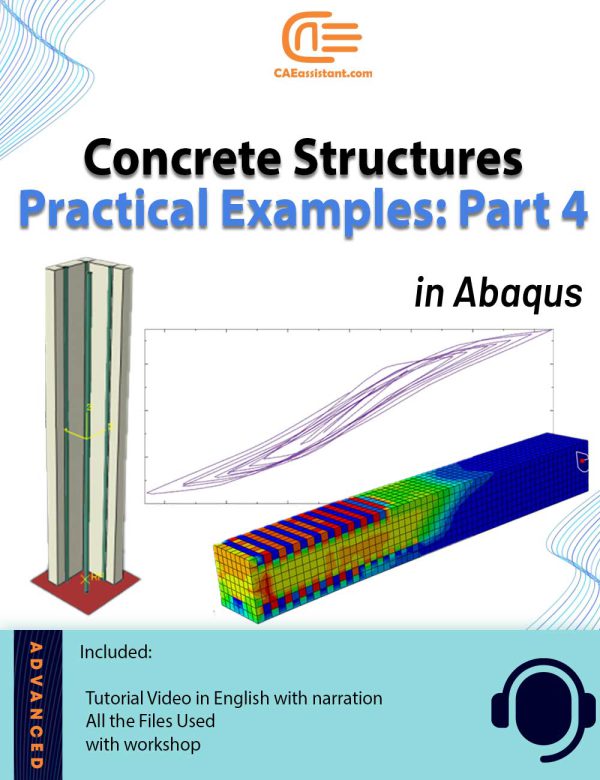

Abaqus Concrete Structure Modeling | Practical Examples (Part 4)

Abaqus Concrete Structure Modeling | Practical Examples (Part 3)

Abaqus Concrete Structure Modeling | Practical Examples (Part 2)

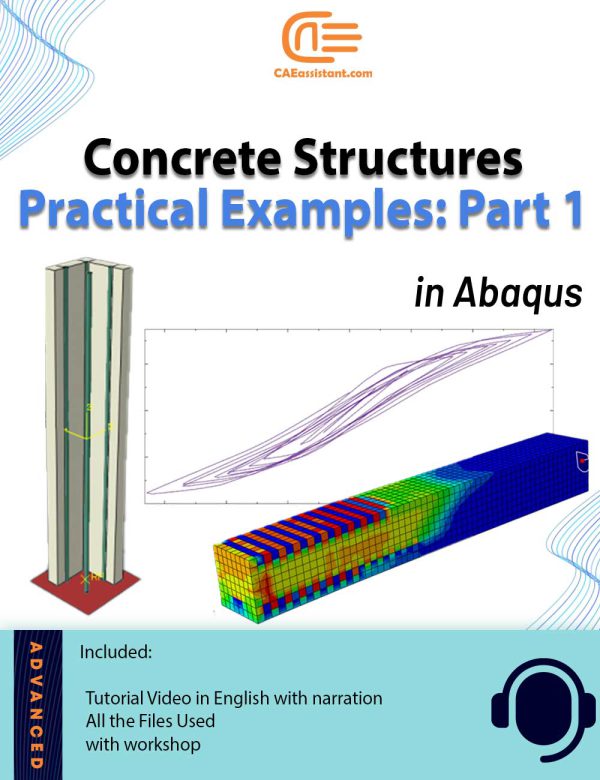

Abaqus Concrete Structure Modeling | Practical Examples (Part 1)

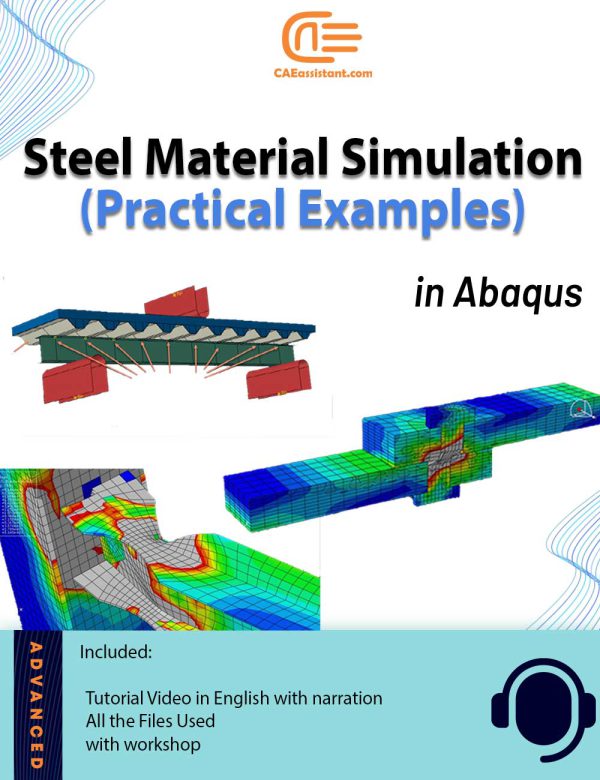

Abaqus steel material and structures | Practical examples

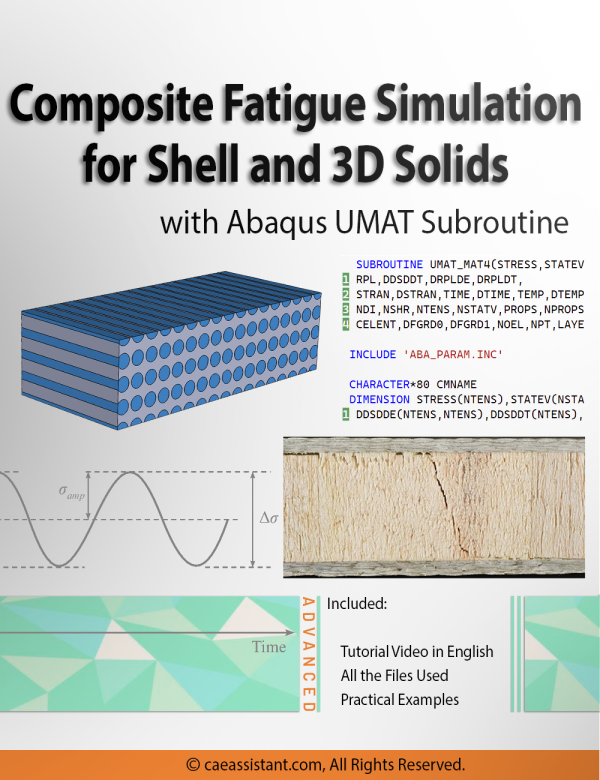

Composite Fatigue Simulation with Subroutine in ABAQUS (unidirectional) for 3D Element

Fatigue in composites refers to the weakening of a material caused by repeatedly applied loads or stress cycles over time. When a composite material is subjected to cyclic loading, small cracks or microdamage can form within the material, which may grow and lead to failure after a certain number of loading cycles. This is a significant consideration in the design and analysis of composite structures, especially in applications subjected to repeated stress, such as in aerospace, automotive, or civil engineering.

In one of our other packages, we have used the UMAT subroutine in Abaqus to simulate fatigue in composites in two-dimensional space. The current project is more comprehensive, as it addresses composite fatigue in both 2D and 3D spaces. So you can use it for the simulation of both shells and solids. In this project, you will first become familiar with simulating composite fatigue in 2D space using the Abaqus UMAT subroutine. Then, we will provide a complete UMAT code along with Abaqus files for extending the simulation to 3D space, enabling the 3D simulation of composite fatigue in Abaqus.

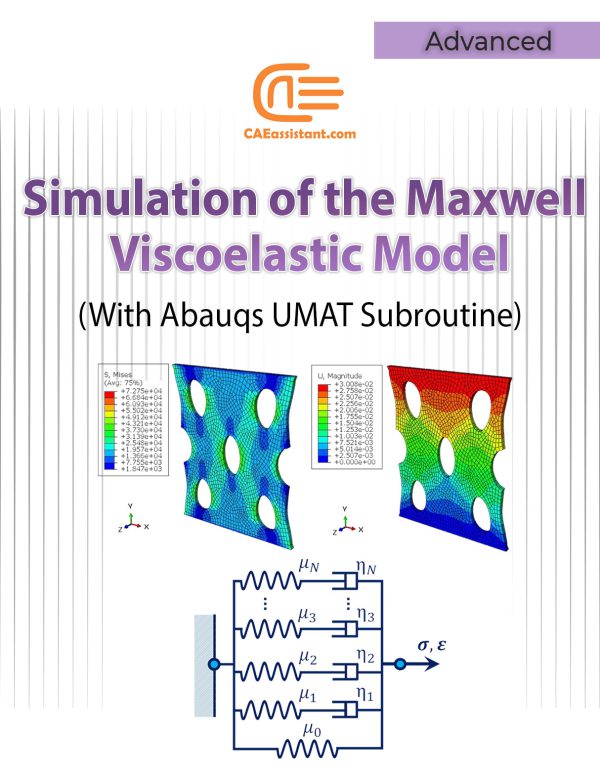

Simulation of the Generalized Maxwell Viscoelastic Model using UMAT Subroutine

This research presents a precise three-dimensional mechanical response of viscoelastic materials, such as polymers and elastomers, using the generalized rheological Maxwell viscoelastic model (considering the five Maxwell elements). That is to say, we implement the Maxwell model of viscoelasticity using the UMAT subroutine for the Abaqus standard solver. To clarify, using the concepts in this tutorial, you can implement the model for any N-Maxwell elements, using the viscoelastic Maxwell model.

The Maxwell viscoelastic model is appropriate for qualitative and conceptual analysis, but the single Maxwell element is not sufficient to describe the behavior of elastomers and polymers. For a more precise definition of these materials, the generalized Maxwell viscoelastic model is used. In the generalized Maxwell viscoelastic model, N piece of Maxwell elements and a single spring (the Hooke-element) are assembled in parallel. This tutorial, by customizing the UMAT subroutine to simulate flexible samples behavior, contributes to the advancement of viscoelastic materials design and analysis.

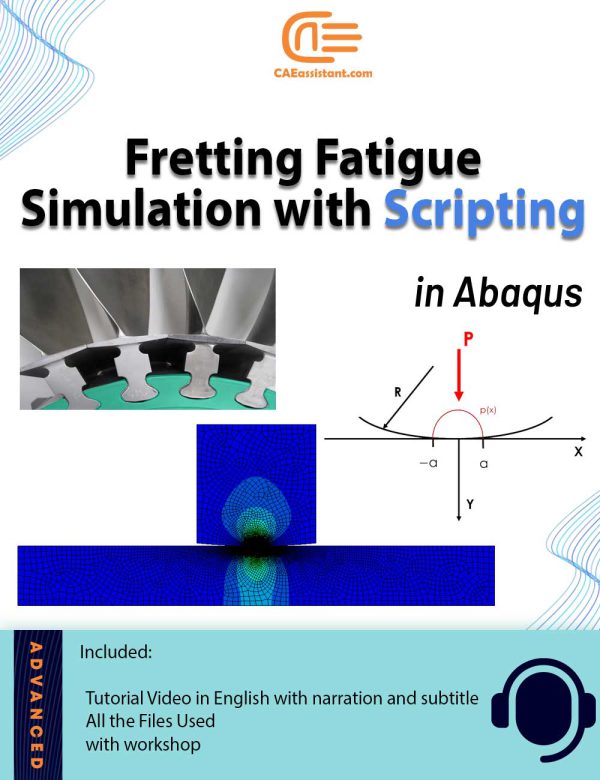

Fretting Fatigue Failure Simulation with Scripting in Abaqus

This Package offers a comprehensive tutorial on using Abaqus for Fretting Fatigue Failure Simulation. To do so, it combines theoretical knowledge with practical application in Finite Element Method (FEM) simulations. The package guides users through both detailed lessons and interactive workshops. In fact, it focuses on developing 2D Fretting-Fatigue models in Abaqus with three core areas: model creation with exclusively designed meshing methodologies, the development of custom Field Outputs for detailed analysis, and automated parameter selection and post-processing through Python scripting.

Throughout the tutorial, participants master critical aspects of Fretting Fatigue Failure simulation. It includes basics from mesh refinement techniques and step control optimization to complete workflow automation. The program distinctively integrates command prompt operations for extracting Field Outputs and modifying simulation parameters. For example, we can refer to the Coefficient of Friction (CoF). Users gain practical experience in creating robust models while understanding the fundamental principles of the Fretting Fatigue Failure phenomenon.

Upon completion, participants will acquire the skills to independently develop and analyze Fretting Fatigue failure simulations. Moreover, they can automate post-processing tasks, and implement custom analysis parameters for precise fatigue prediction in mechanical systems.

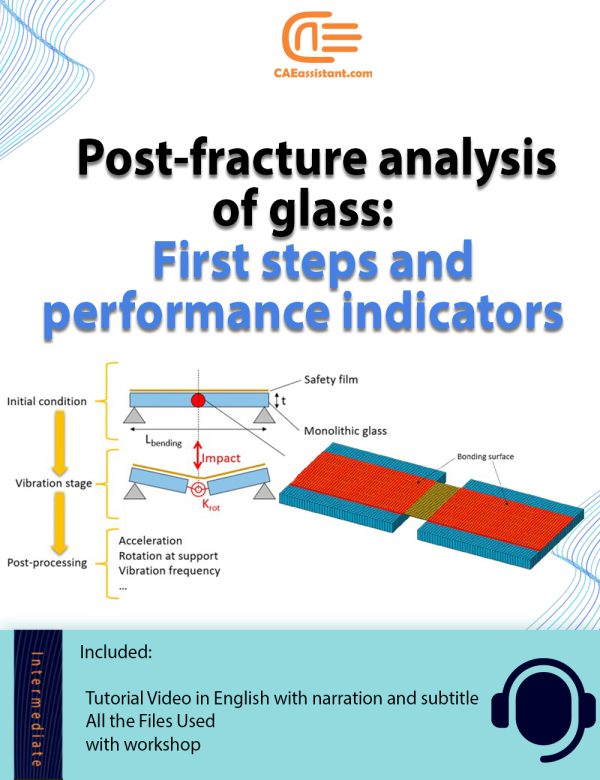

Glass Fracture Analysis with Abaqus | Post-Fracture

This tutorial explores a finite element method (FEM) simulation using Abaqus to analyze the post-fracture behavior of structural glass members retrofitted with anti-shatter safety films. In particular, it focuses on simulating and calibrating the vibration response of cracked glass elements under repeated impacts and temperature gradients, contributing to a comprehensive analysis of critical phenomena that take place in the post-fracture stage. This tutorial follows the methodology outlined in the research article “Effects of post-fracture repeated impacts and short-term temperature gradients on monolithic glass elements bonded by safety films”.

Key aspects include modeling glass fracture, assigning material properties, and defining boundary conditions to assess the vibration frequency and load-bearing capacity of cracked monolithic glass members. Additional topics cover basic concepts of dynamic identification techniques, definition of performance indicators for glass retrofit efficiency, and frequency sensitivity analysis of monolothic retrofitted glass elements under various operational and ambient conditions. The simulation results help quantify the expected contribution and residual strength of safety films in post-fracture scenarios, providing a robust framework for structural engineers to extend this investigation to other glass configurations.

This tutorial is ideal for users who want to understand FEM modeling in Abaqus and perform detailed simulations involving complex material interactions, with a focus on practical applications in glass retrofit technology.

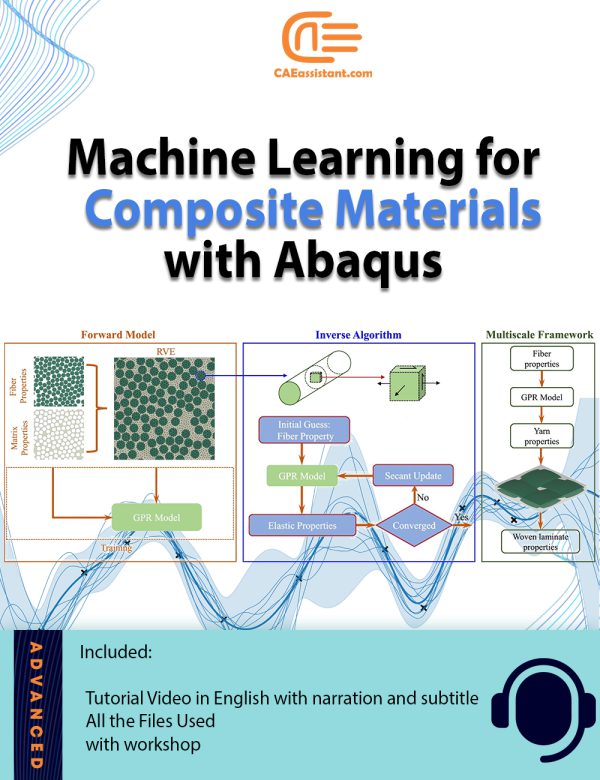

Machine Learning for Composite Materials with Abaqus

This tutorial package delves into an advanced inverse modeling approach for predicting carbon fiber properties in composite materials using a machine learning (ML) technique. Focused on machine learning for composite materials applications, it covers the use of Gaussian Process Regression (GPR) to build a surrogate model for accurate predictions of fiber properties based on data from unidirectional (UD) lamina. By leveraging Finite Element (FE) homogenization, synthetic data is generated for training the GPR model, accounting for variations in fiber, matrix properties, and volume fractions. This framework’s efficiency and accuracy are validated using real-world data, highlighting its potential as a computational alternative to traditional experimental methods. The package includes detailed explanations, case studies, and practical exercises, equipping users with hands-on experience in applying this ML-based approach to composite material analysis.

Abaqus basic tutorials on concrete beams and columns

Welcome to the “Abaqus Basic Tutorials on Concrete Members,” a comprehensive course tailored for civil and structural engineers seeking to master finite element modeling (FEM) of concrete structures. This tutorial covers key concepts such as plain concrete beam and column modeling, reinforced concrete members, and fiber-reinforced polymer (FRP) composites. The course guides learners through the application of boundary conditions, material properties, and various loading conditions in Abaqus. Key topics include plain concrete beam and column modeling, reinforcement modeling with steel bars and stirrups, and fiber-reinforced polymer (FRP) reinforcement techniques. Participants will also explore comparing simulation results with experimental data, as well as interpreting critical outcomes such as stress distribution and failure modes. Through hands-on workshops, learners will simulate structural behaviors under axial, lateral, and compression loads, ensuring a practical understanding of FEM for concrete members. By the end of this course, participants will be proficient in using Abaqus to model and analyze concrete structures, reinforced elements, and advanced composites, providing them with a strong foundation for structural analysis and design.

Analysis of Cold Rolled Aluminium Alloy Channel Columns With Abaqus CAE

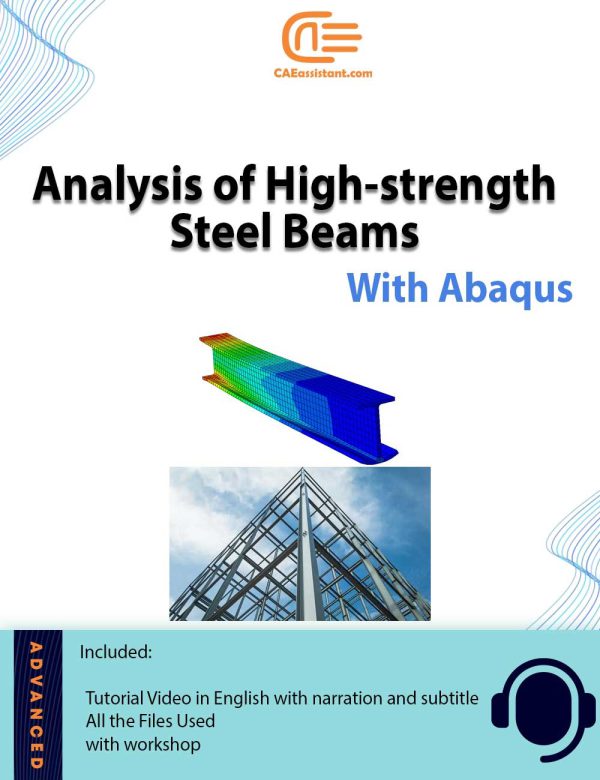

Fiber-based Model for High-Strength Steel Beam Analysis with Abaqus

Abaqus shaft slip ring simulation | Using Python scripts for parametric analysis

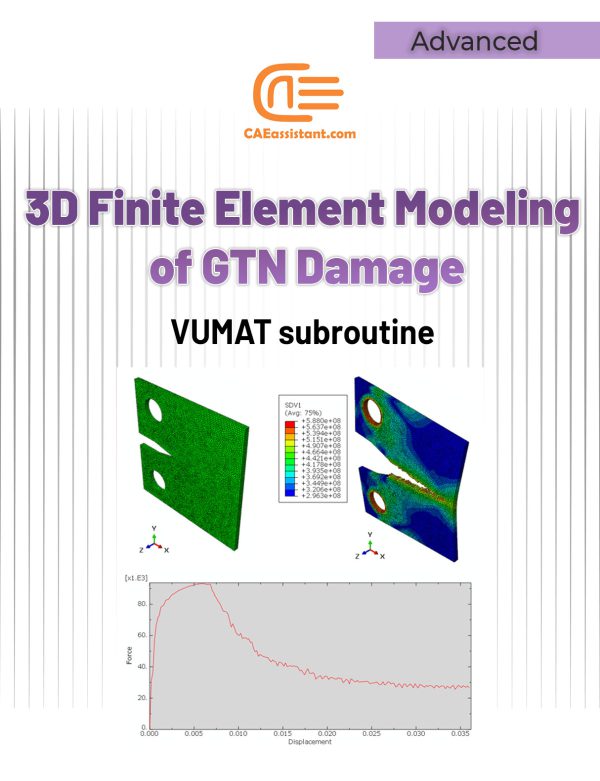

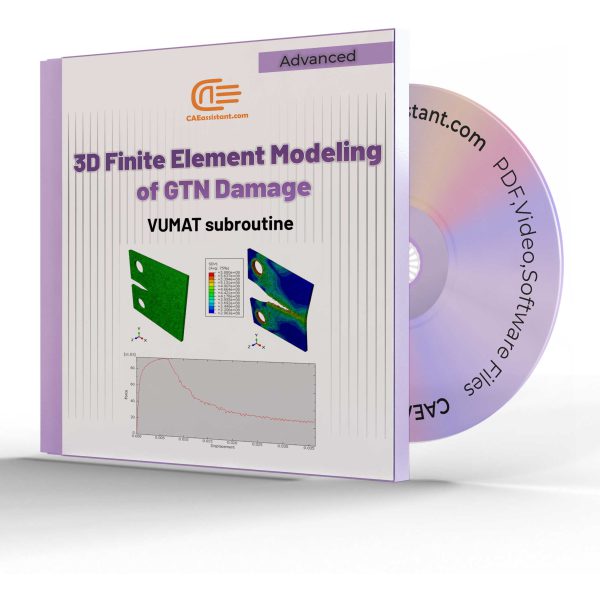

3D Simulation of Gurson-Tvergaard-Needleman (GTN) Damage Model

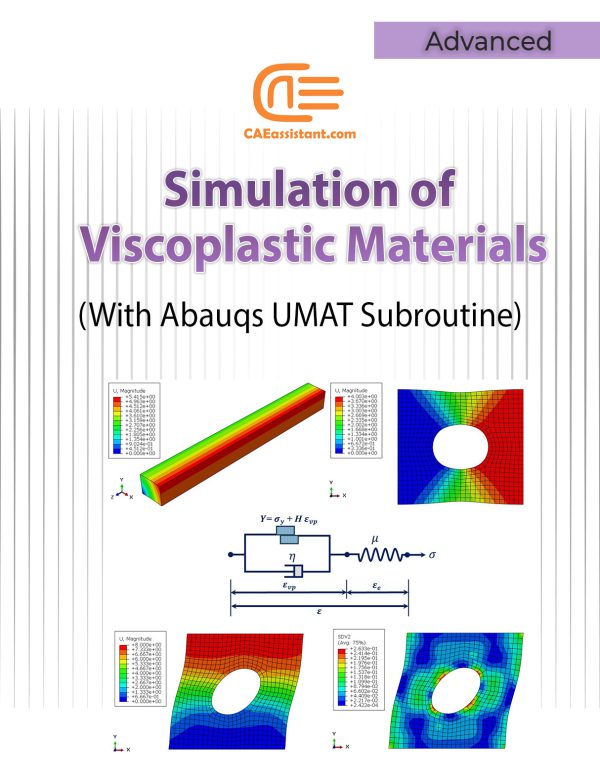

Viscoplasticity Abaqus Simulation Using UMAT Subroutine | Perzyna Viscoplastic Model

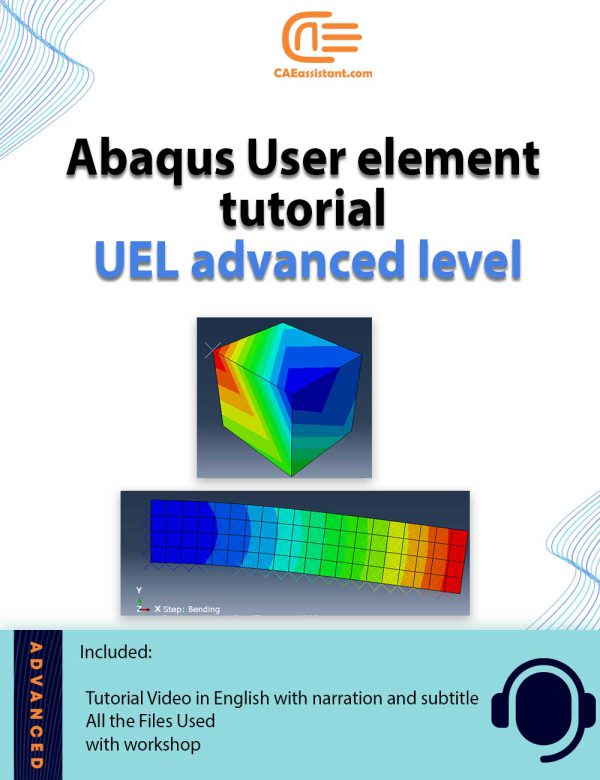

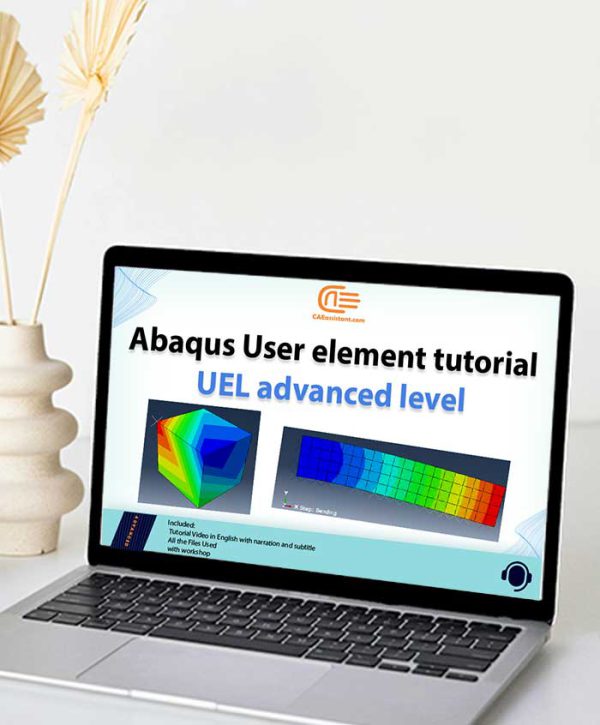

Abaqus User element tutorial | UEL advanced level

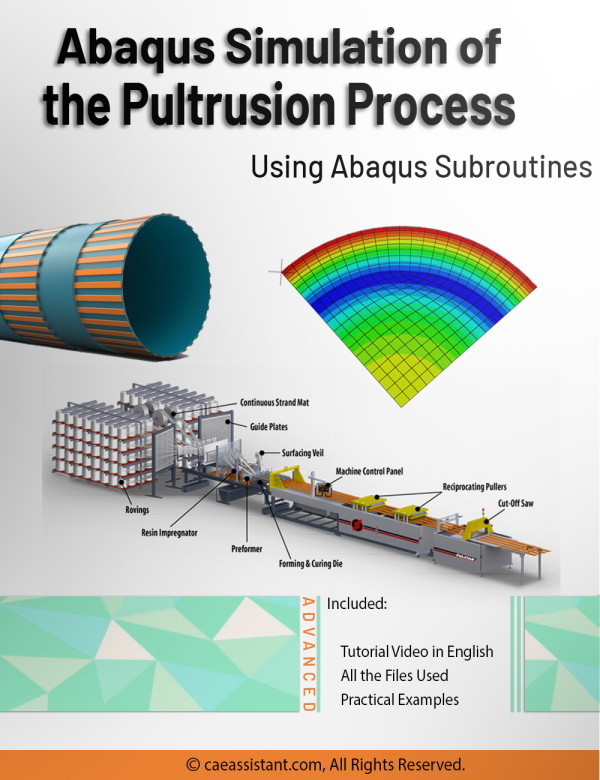

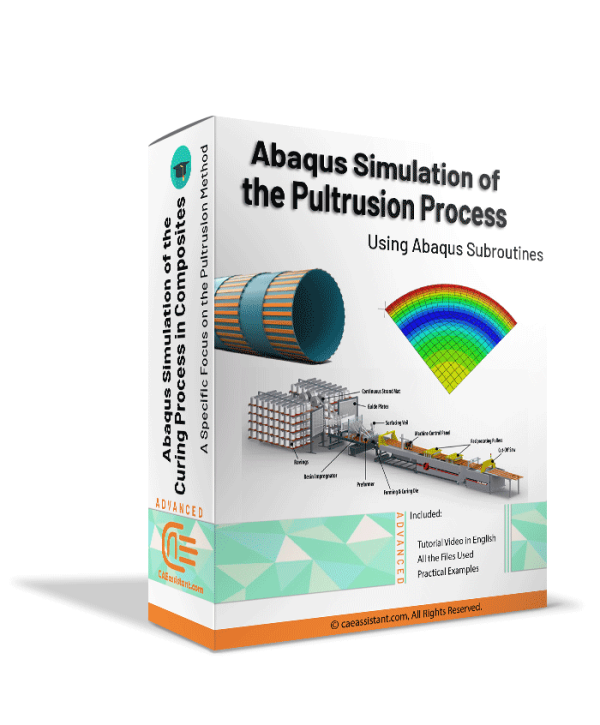

Abaqus Simulation of the Curing Process in Composites: A Specific Focus on the Pultrusion Method

Pultrusion is a crucial task for producing constant-profile composites by pulling fibers through a resin bath and heated die. Simulations play a vital role in optimizing parameters like pulling speed and die temperature to enhance product quality and efficiency. They predict material property changes and aid in process control, reducing reliance on extensive experimental trials. However, simulations face challenges such as accurately modeling complex material behaviors and requiring significant computational resources. These challenges underscore the need for precise simulation methods to improve Pultrusion processes. This study employs ABAQUS with user subroutines for detailed mechanical behavior simulations, including curing kinetics and resin properties. Key findings include insights into material property changes, and optimization strategies for enhancing manufacturing efficiency and product quality. This research provides practical knowledge for implementing findings in real-world applications, advancing composite material production.

Notice that, pultrusion is a composite curing method, which may share some overlapping features with our Intermediate and Advanced curing packages. However, what sets pultrusion apart is that the composite passes over a heated die during the process. In this project, the die has also been modeled, with environmental heat applied to it using convection and a film subroutine. The heat is subsequently transferred to the sample through contact with the die. Afterward the die is removed. All these procedure is modeled in this project, with Abaqus CAE step-by-step. In contrast, in our Intermediate and Advanced packages for the oven curing of prepregs, no die has been modeled. The heat is applied without convection and, for simplicity, the heat is treated as a first-type boundary condition, which introduces some errors.

Note: The files and video which explains how to use the code are available. The PDF file will be available two weeks after purchase.Curing process simulation in Abaqus

Composite Pressure Vessel simulation in ABAQUS

Johnson Cook plasticity and damage simulation

Bio-Mechanical Abaqus simulation Full package

This video tutorial package offers a comprehensive guide to biomechanical simulations using Abaqus, covering a range of applications from dental to orthopedic and cardiovascular analyses. The workshops delve into finite element method (FEM) simulations, exploring static loading on human teeth, crack growth in bones under bending, bone drilling, and the behavior of titanium foam implants. Each tutorial emphasizes the importance of precise modeling and meshing techniques, utilizing dynamic explicit procedures, Johnson-Cook material models, and various contact and boundary conditions to simulate realistic biomechanical behaviors. Additionally, the package includes fluid-structure interaction (FSI) simulations for blood flow within coronary vessels, addressing both Newtonian and non-Newtonian models, and demonstrates the integration of computational fluid dynamics (CFD) with structural analysis for enhanced accuracy. The lessons complement the workshops by introducing fundamental FEM concepts, solver selection, explicit analysis considerations, and damage modeling, ensuring users gain a solid understanding of both theoretical and practical aspects of biomechanical simulations in Abaqus.

We also offer a similar budget-friendly package that includes all the workshops from this package. However, since it does not include the lessons, it is available at a lower price. You can purchase it on our website at a more competitive rate than similar platforms.