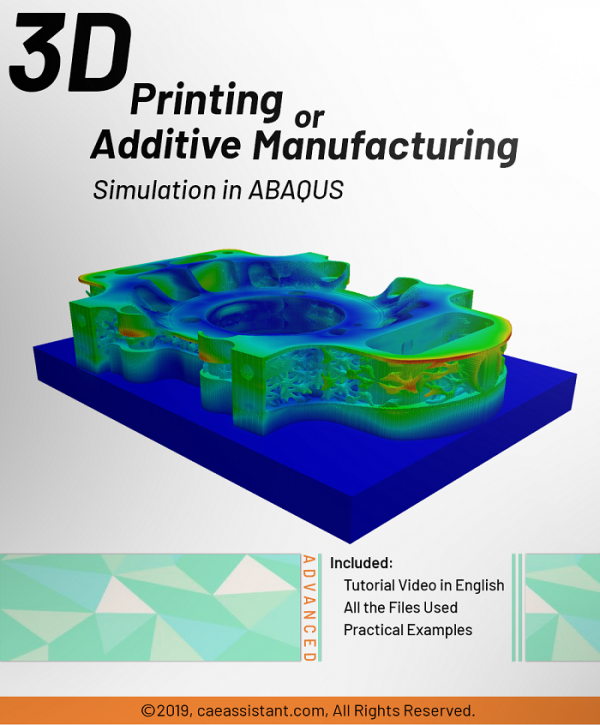

What is Additive manufacturing or 3D printing?

The process of building a three-dimensional object from a CAD model or digital 3D model is known as additive manufacturing or 3D printing. In an additive process, an object is made by adding layers of material one after another until the product is made. This process can be done via several methods in which material is joined, deposited, and solidified under computer control. The materials being added together could be made of plastics, liquids or powder grains being fused, etc. 3D printing python Abaqus modelling training package is a unique product that can help you to simulate 3D printing FEM fast and correctly.

Did you know we have 3D printing for composite materials as well?! You can learn all about it in our course: “3D Printing Composites with Continuous fiber Reinforced Structures: Design, Fabrication, and Applications“. The syllabus of this course.

Additive Manufacturing or 3D Printing Python ABAQUS simulation

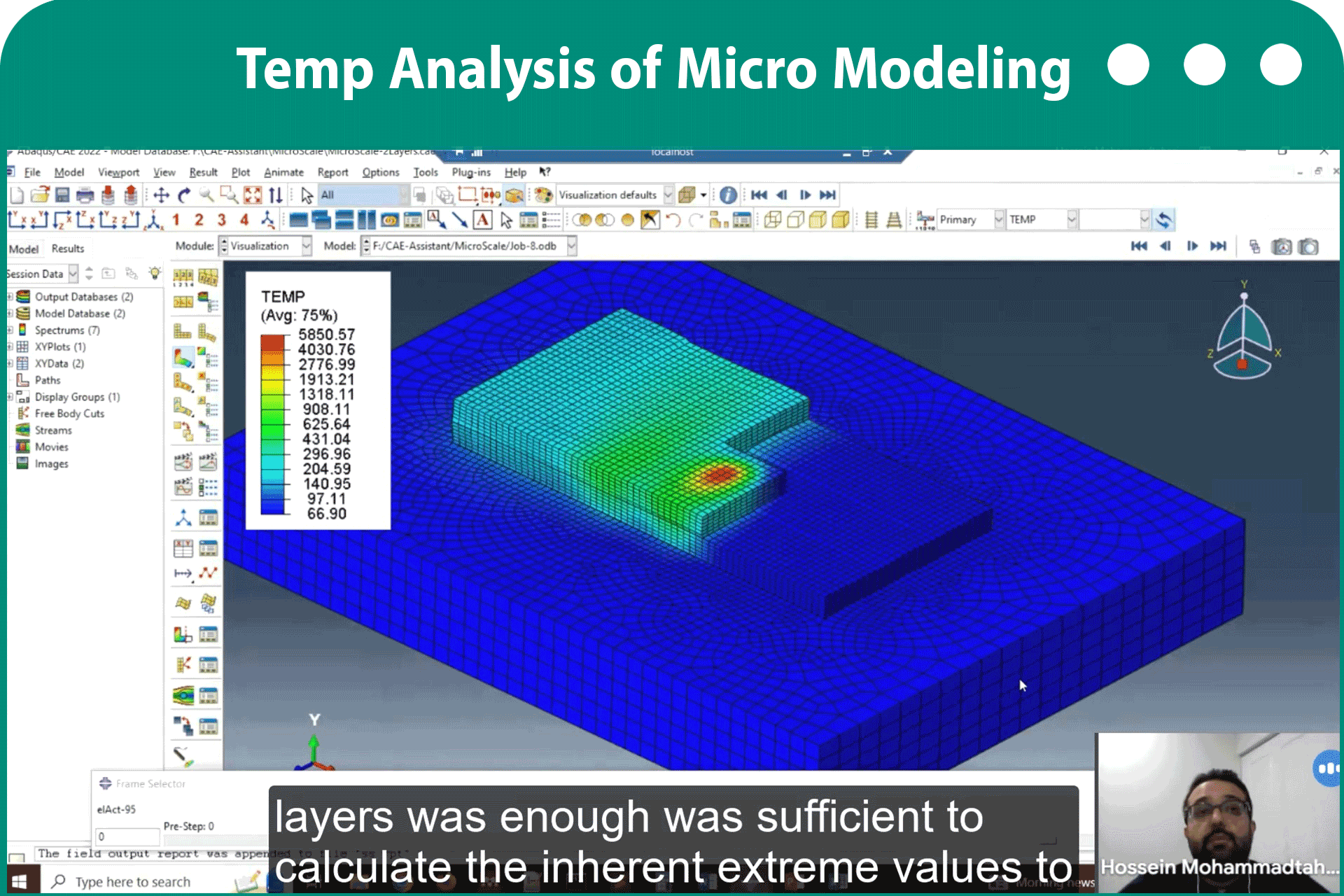

Why is Abaqus needed to model 3D printing? We do different simulations for the same reasons. examining the model’s deflection, the temperature and thermal conditions, the presence of any residual stress, etc. To prevent wasting money, it is also a good idea to check that the printer’s settings match the requirements of our model before printing. conditions such as temperature and material characteristics, etc.

This package will teach you to do this based on the use of subroutines and Python scripting and was done by a team with the goal of coding all the steps of 3D printing. 3D printing Python Abaqus simulation tutorial is one of the best training packages on the web about 3D printing FEM.

We are Up to date!! We also have a course for 4D printing for Fiber-Reinforced Polymer Composites!!

Using Scripting and Subroutines

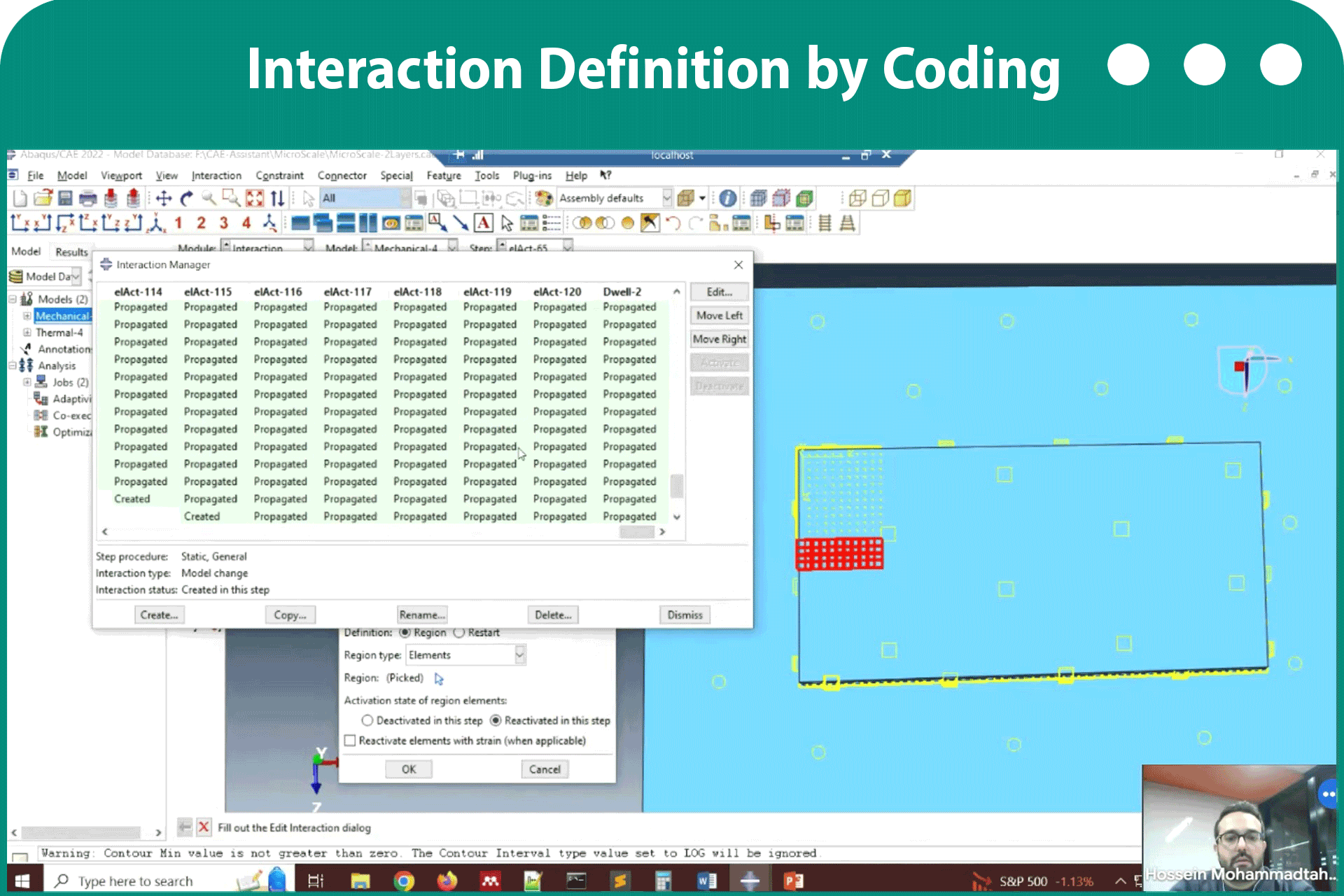

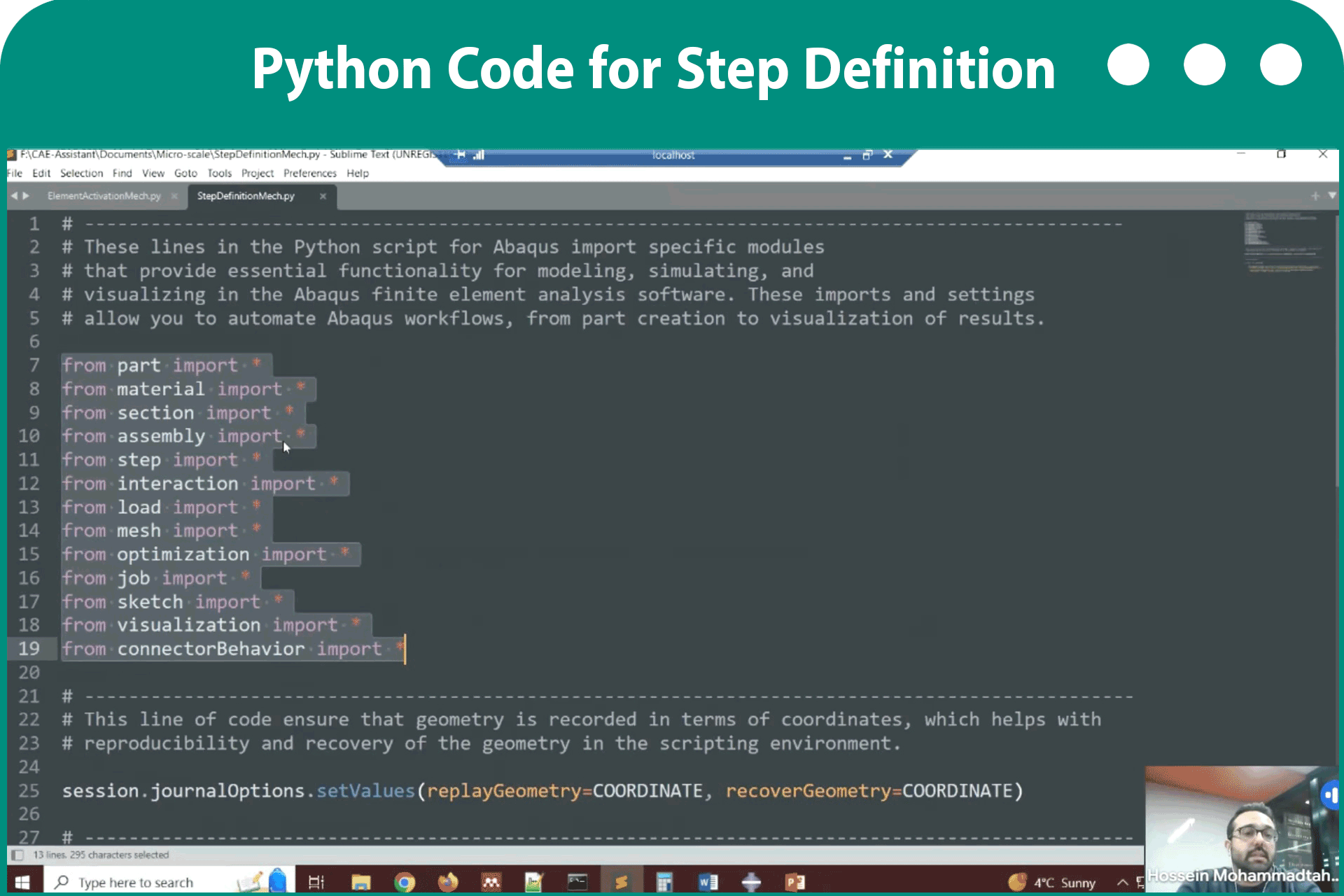

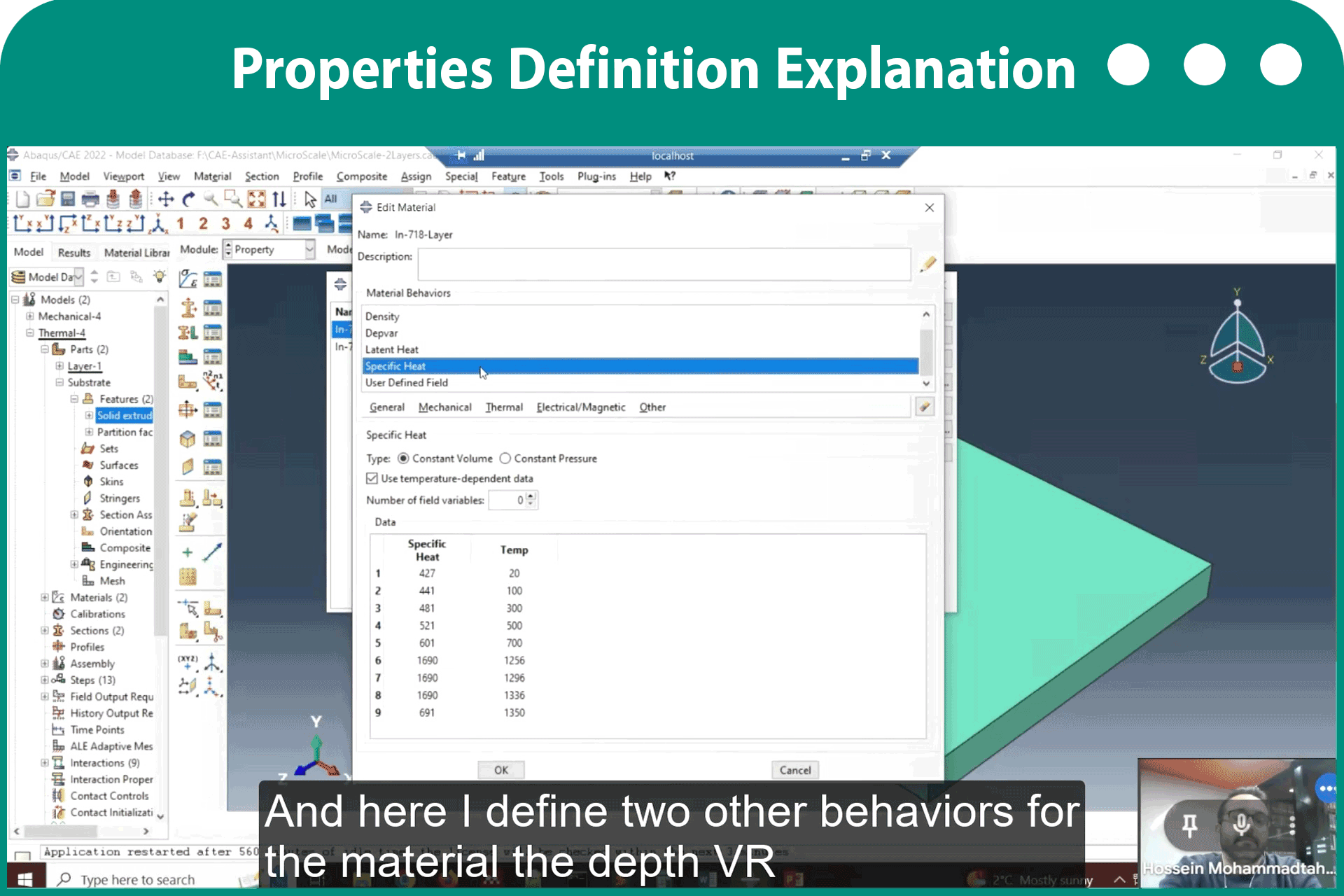

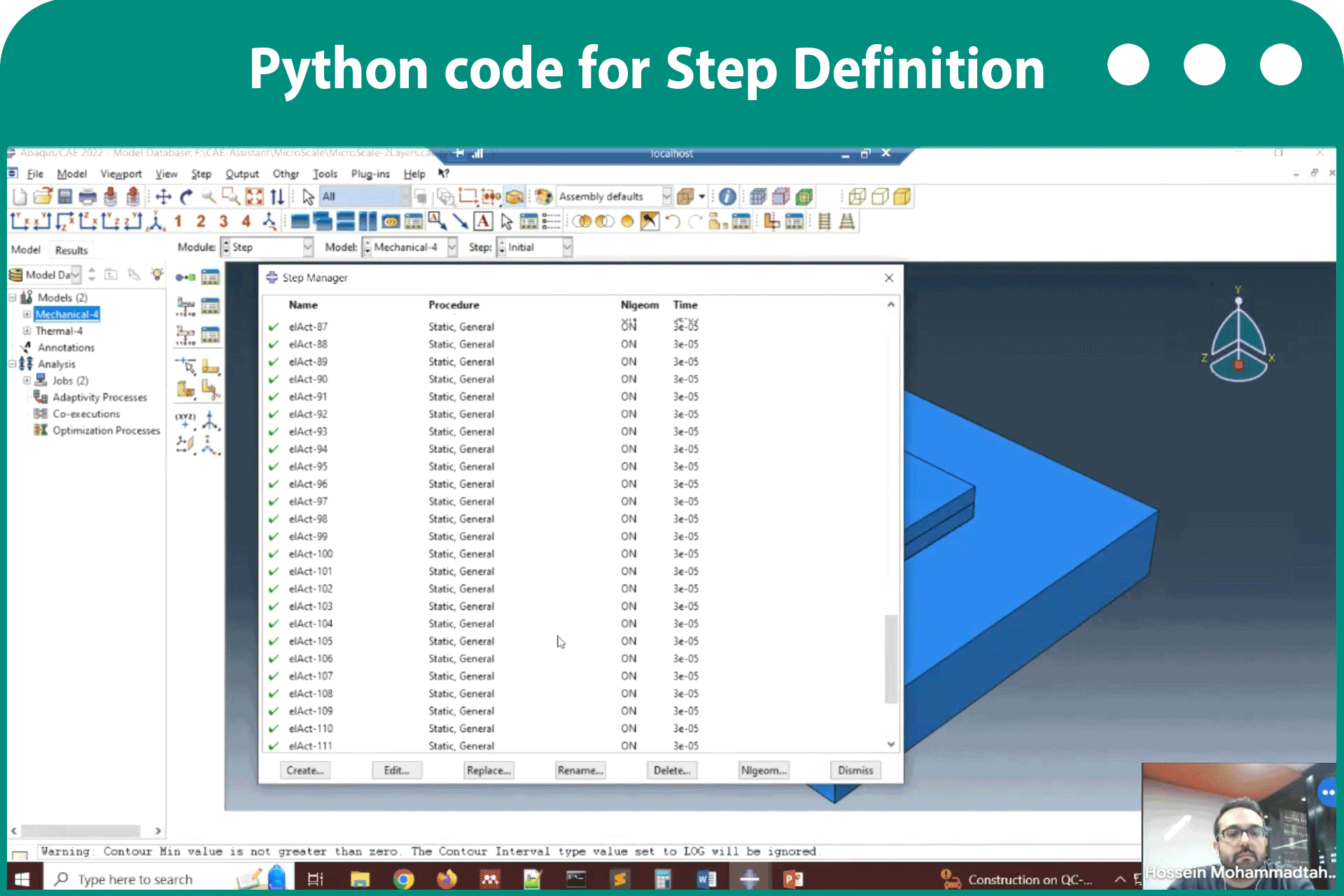

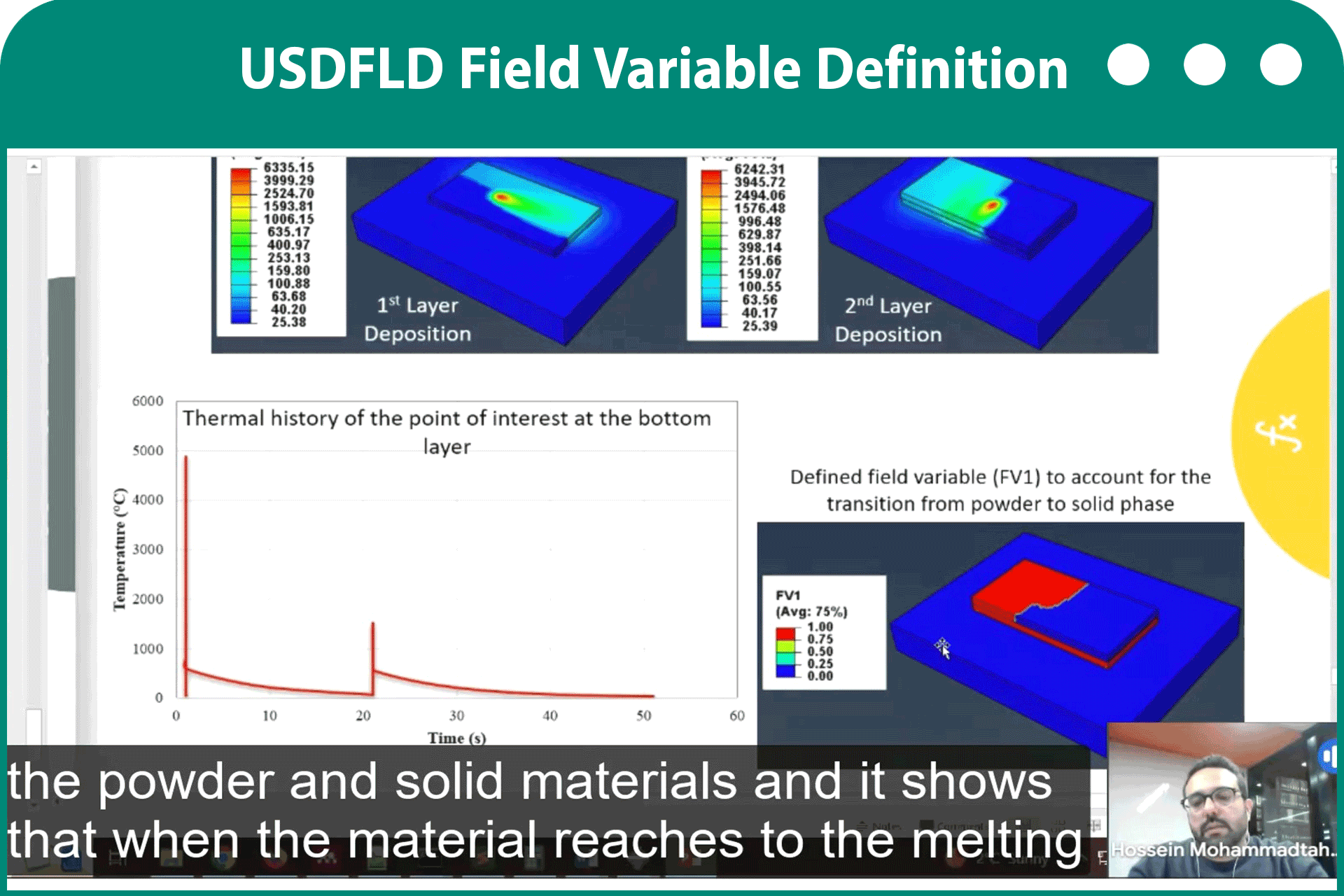

This method involves three coding files: a Python script and two subroutines, USDFLD and DISP.

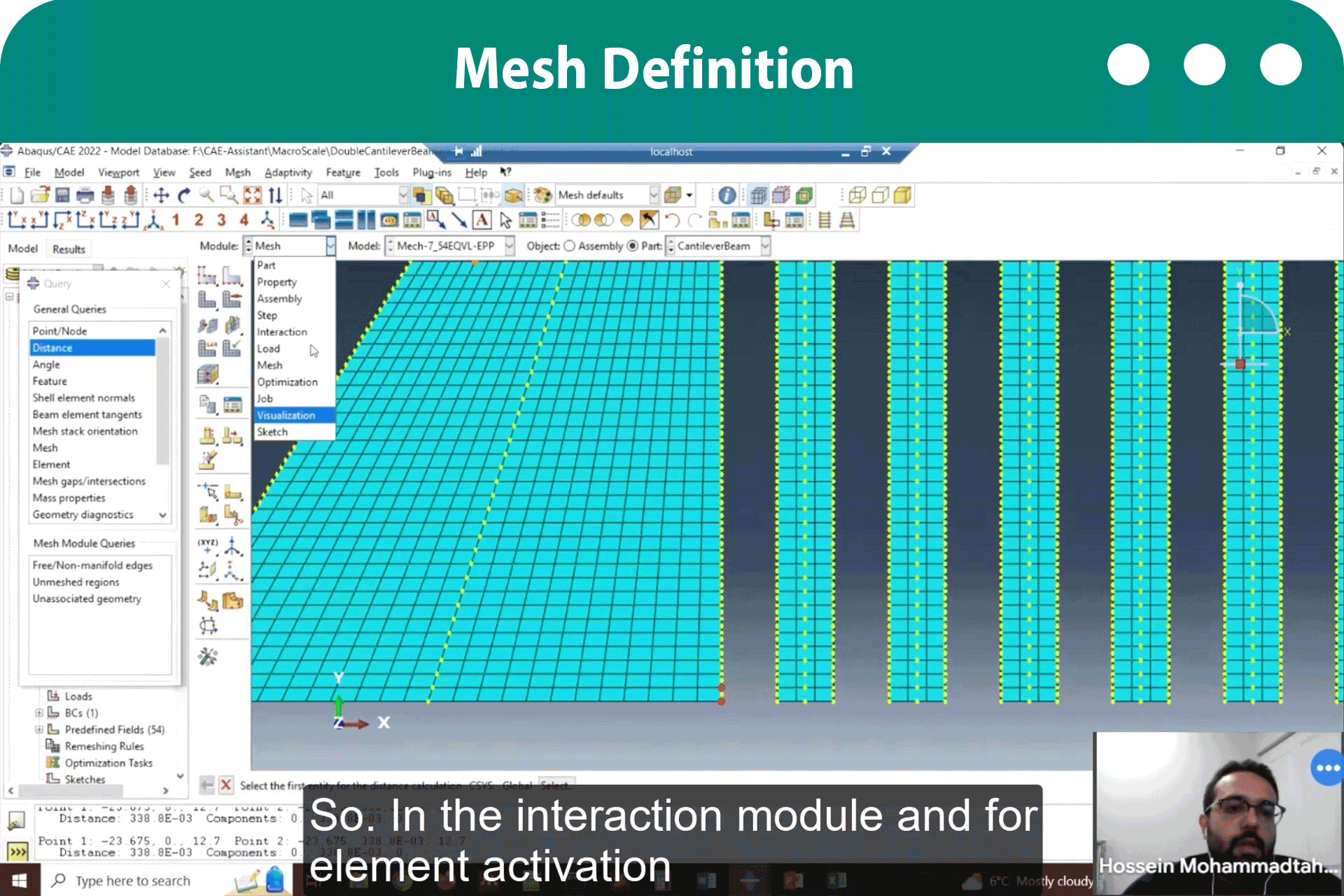

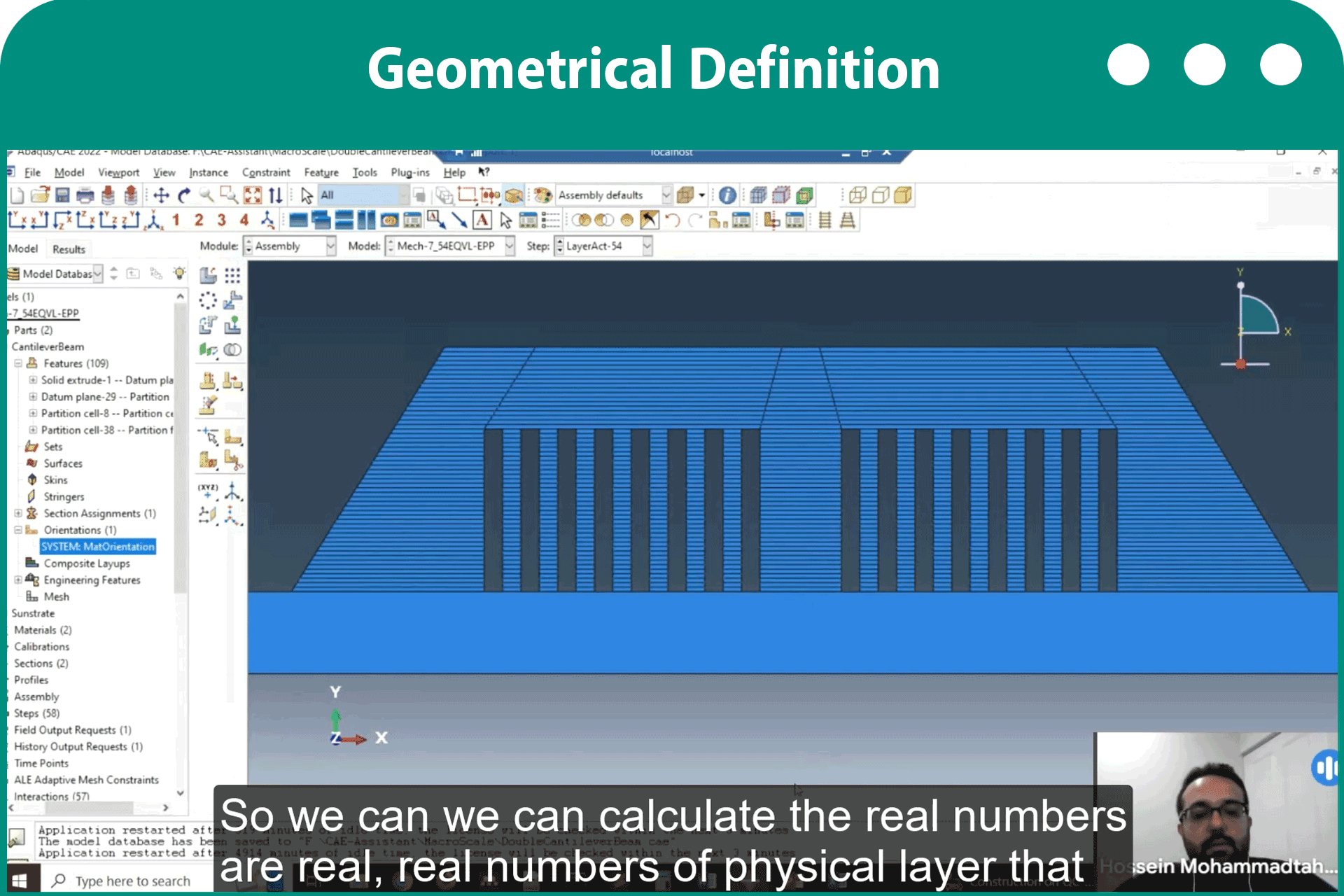

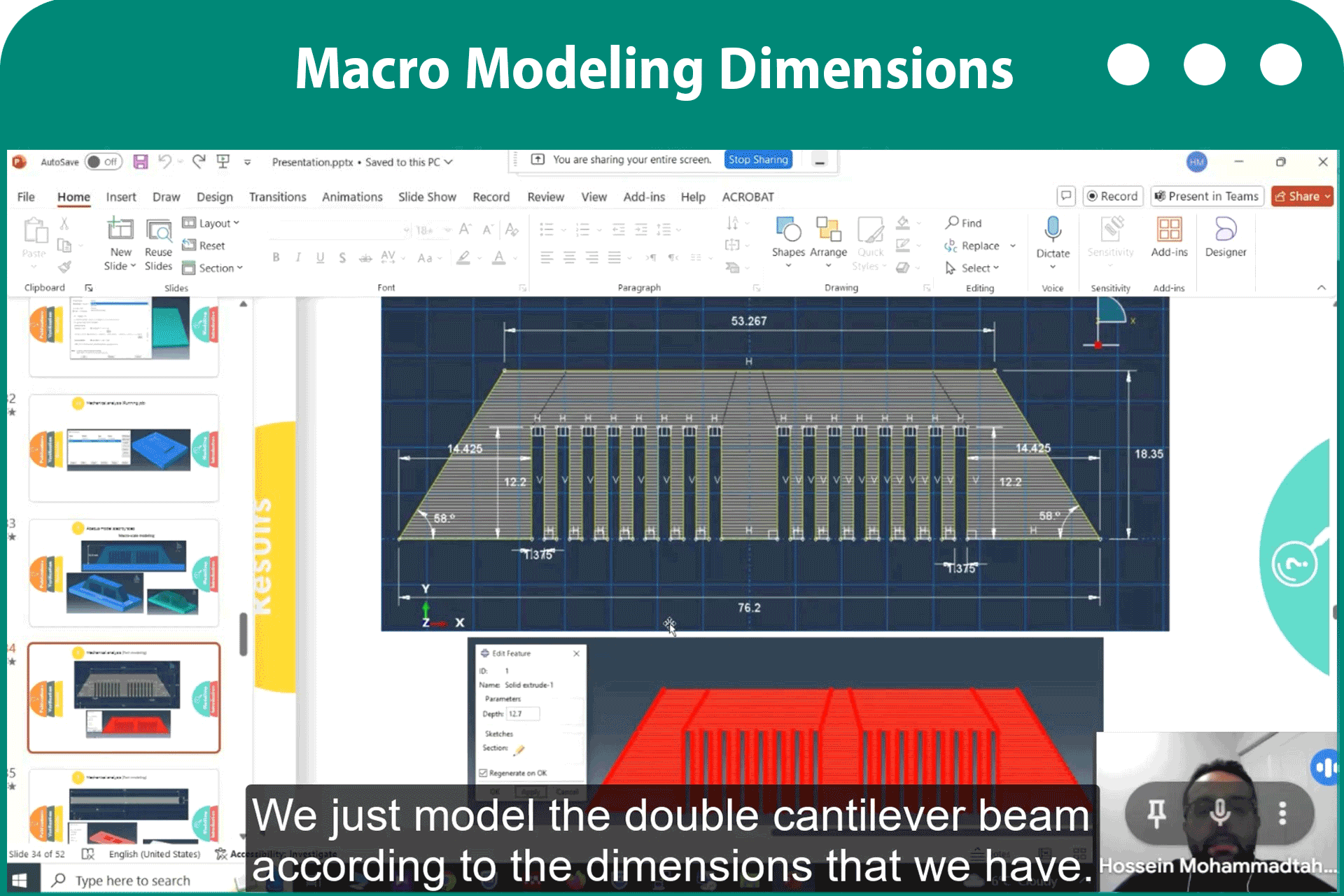

The Python program handles all necessary tasks, including creating material attributes, sections, and interactions in the Abaqus GUI. Users can execute the script, provide inputs, and wait for the simulation to complete. To build the model, users must use CAD software or Abaqus, layer it, and save individual layers as “igs” files. The directory path of these files should be an input when running the script.

The USDFLD subroutine calculates the elasticity properties of 3D printed objects, which are not constant and change throughout the process. According to the following references, the formulas used in this lesson to determine elasticity: “Rapid Prototyping & Manufacturing, Fundamentals of

Stereolithography“, “Curl Distortion Analysis During

Photopolymerisation of Stereolithography Using Dynamic Finite Element

Method“.

The equations and assumptions used to calculate the elasticity are explained in the “3D printing Python” tutorial video. Users can apply their own equations and assumptions if desired.

The DISP subroutine computes the temperature variations that occur during the process using calculations based on user presumptions. Users can also refer to other sources to apply their own calculations.

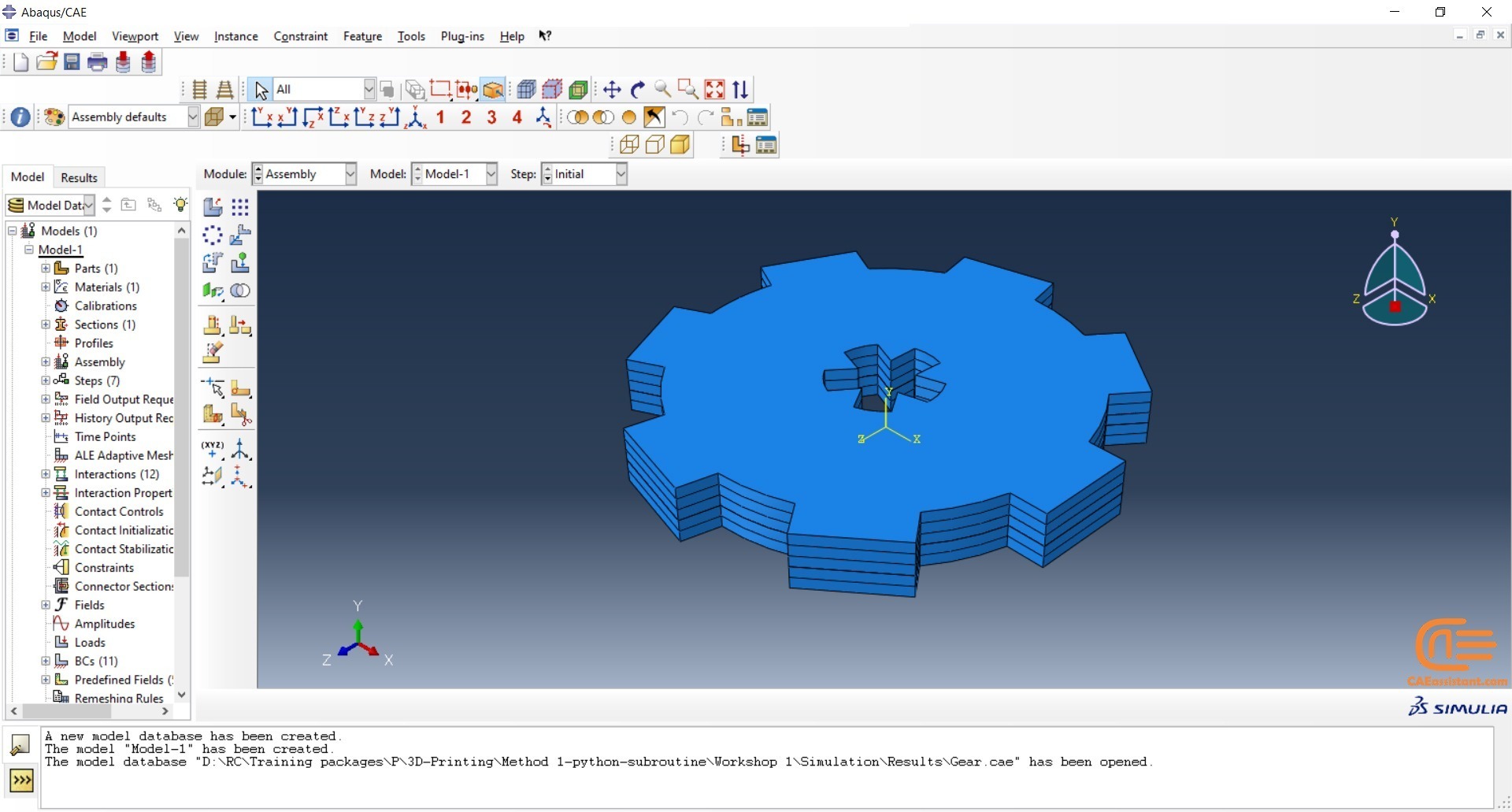

Each component utilizes a unique variation of the Python code. The first session involves replicating the 3D printing of a gear using a standardized, model-specific version of the Python programming language. To build the model, users only need to create one layer of the model in CAD software or Abaqus and save it as an “igs” file. When executing the code, users must enter the file’s directory path and a few other parameters before waiting for the task to complete.

Note: 3D printing can be used to produce complex components quickly and cost-effectively, allowing for more customization and reduced lead times, right? SO, it can be a great help in Smart manufacturing! But what is smart manufacturing anyway? Do not worry because we have a complete course of it: “Smart Manufacturing Course.”

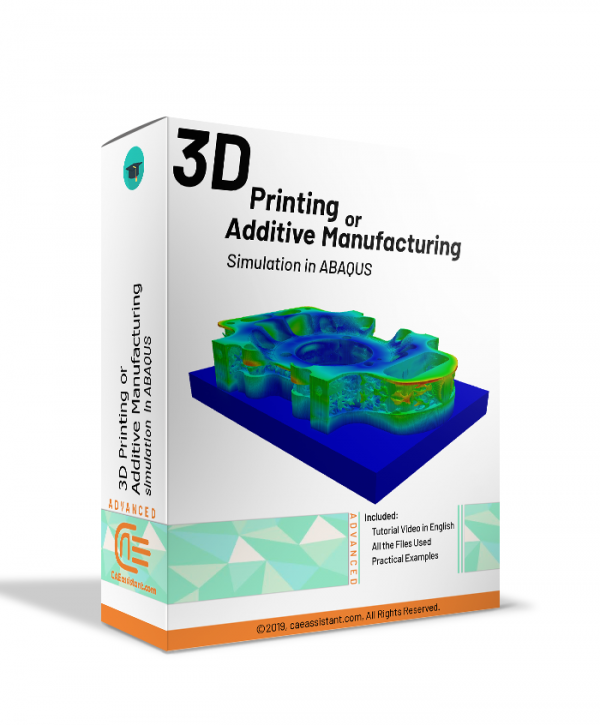

Workshop 1: 3D printing Abaqus simulation of Gear with DISP, USDFLD and Python scripting (Same cross-section)

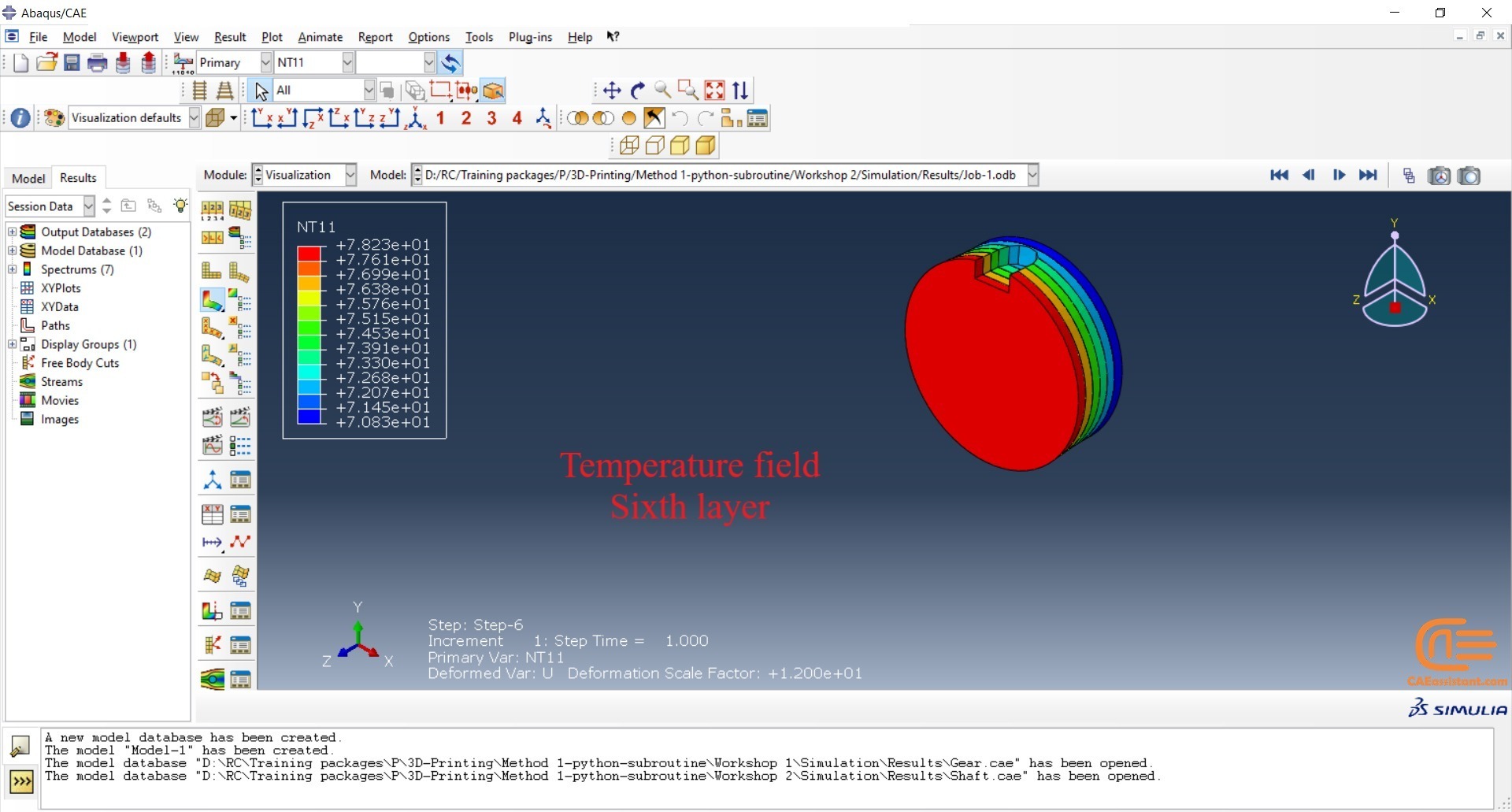

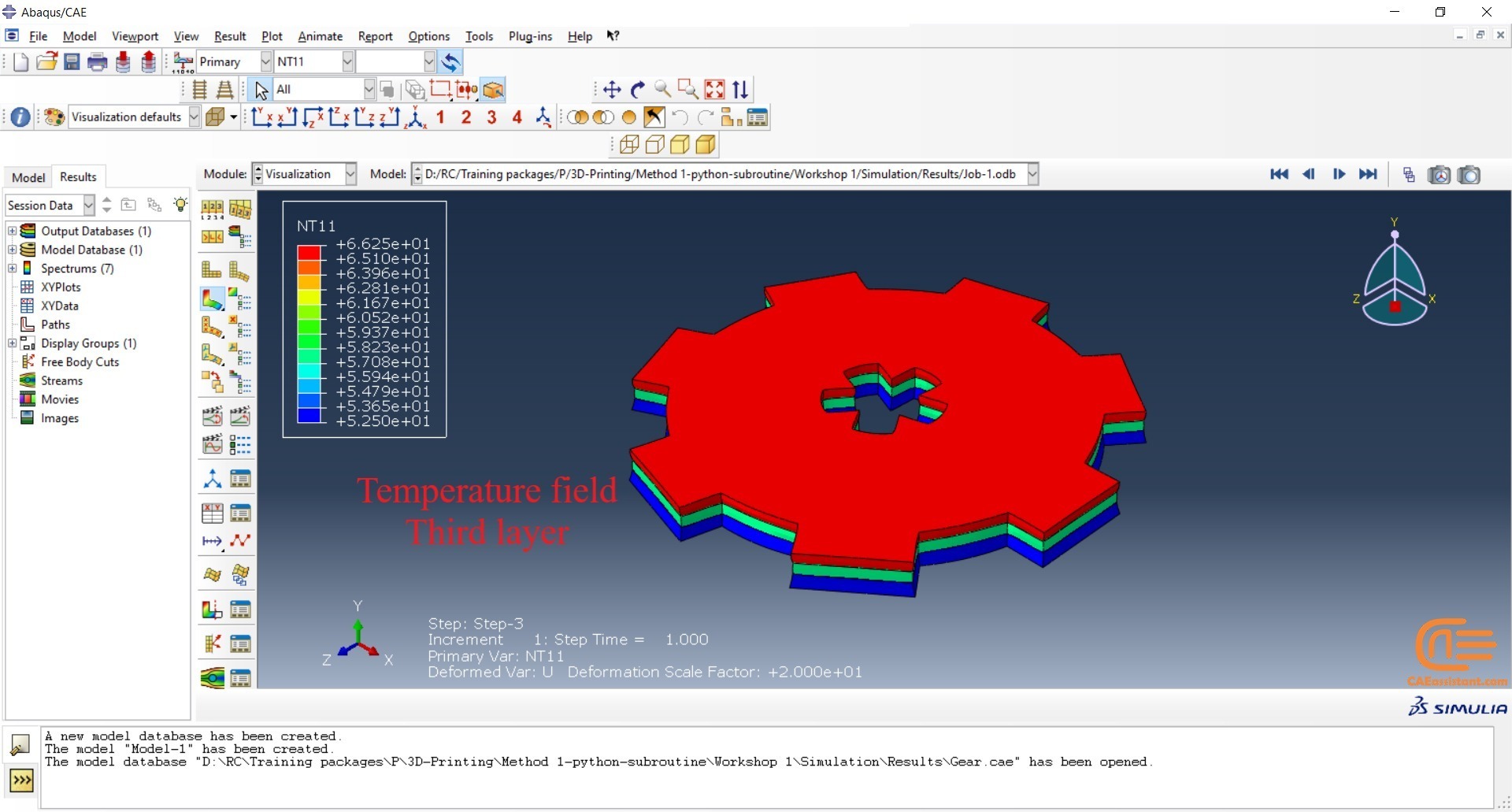

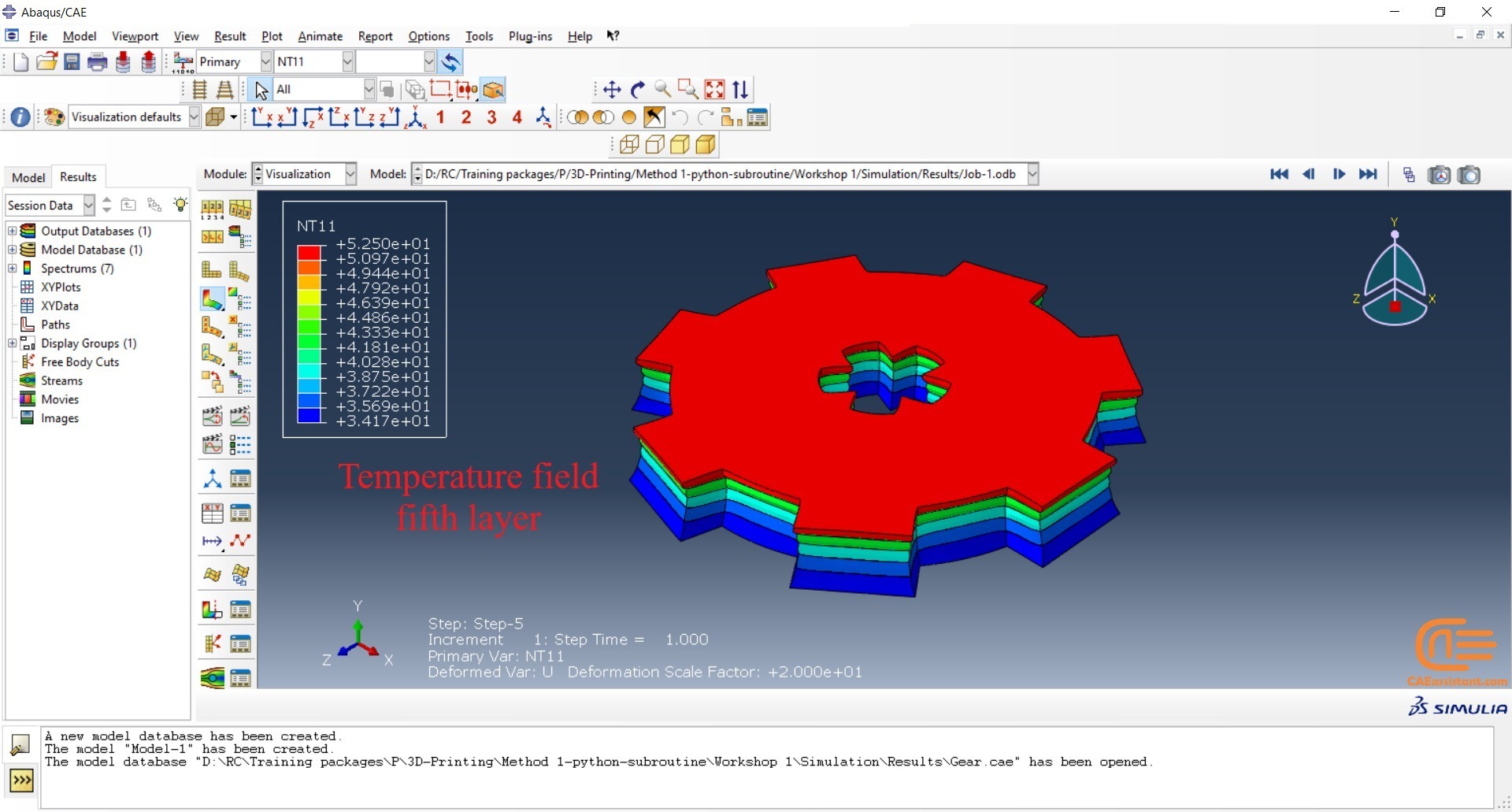

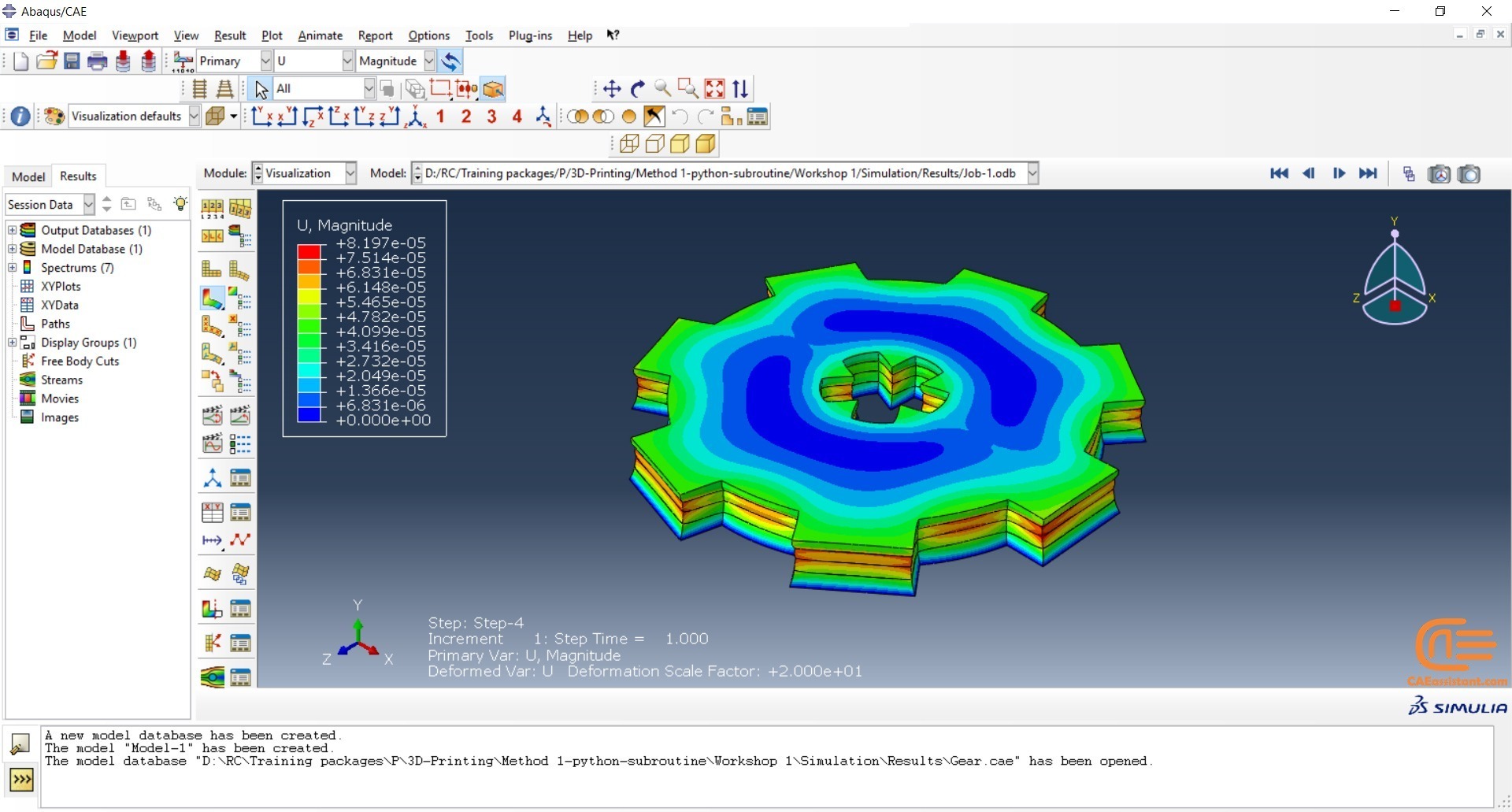

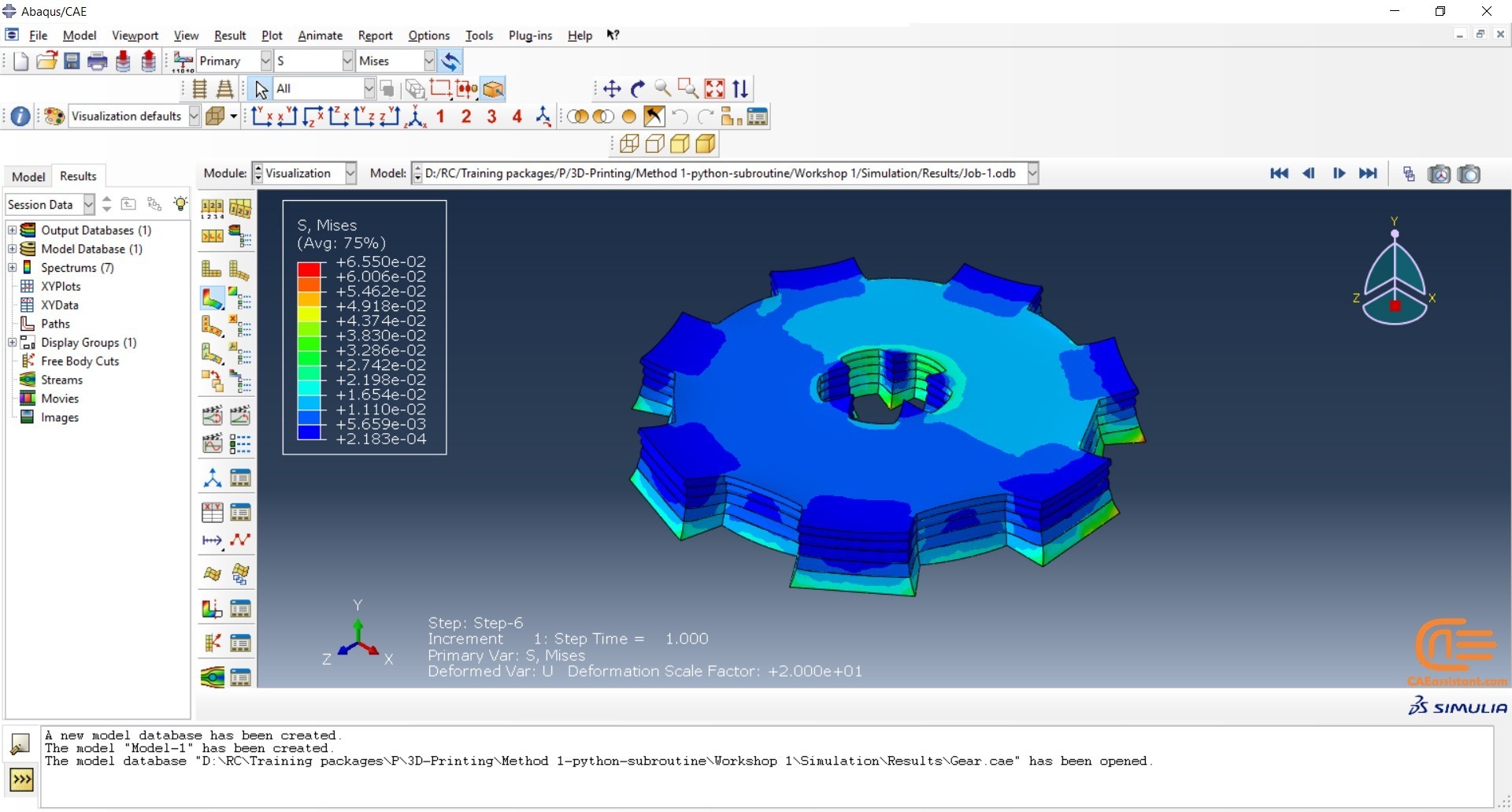

This workshop begins by explaining the model’s geometry. The difference between continuous and discontinuous layers is then discussed, which is an important issue when using the Python script for these types of examples. Material properties are explained in detail, along with their equations, and are defined using the USDFLD subroutine. Boundary conditions are then explained, followed by a discussion of temperature changes and their relationships, which are applied to the model using the DISP subroutine. Finally, the Python code and subroutines are described, and the simulation is performed. The results are then discussed.

Note: Sometimes there is a need for optimization in 3D printing. You are asking why and how?? We have a complete course for this: “Advanced Space–Time Topology Optimization in Multi-Axis Additive Manufacturing.”

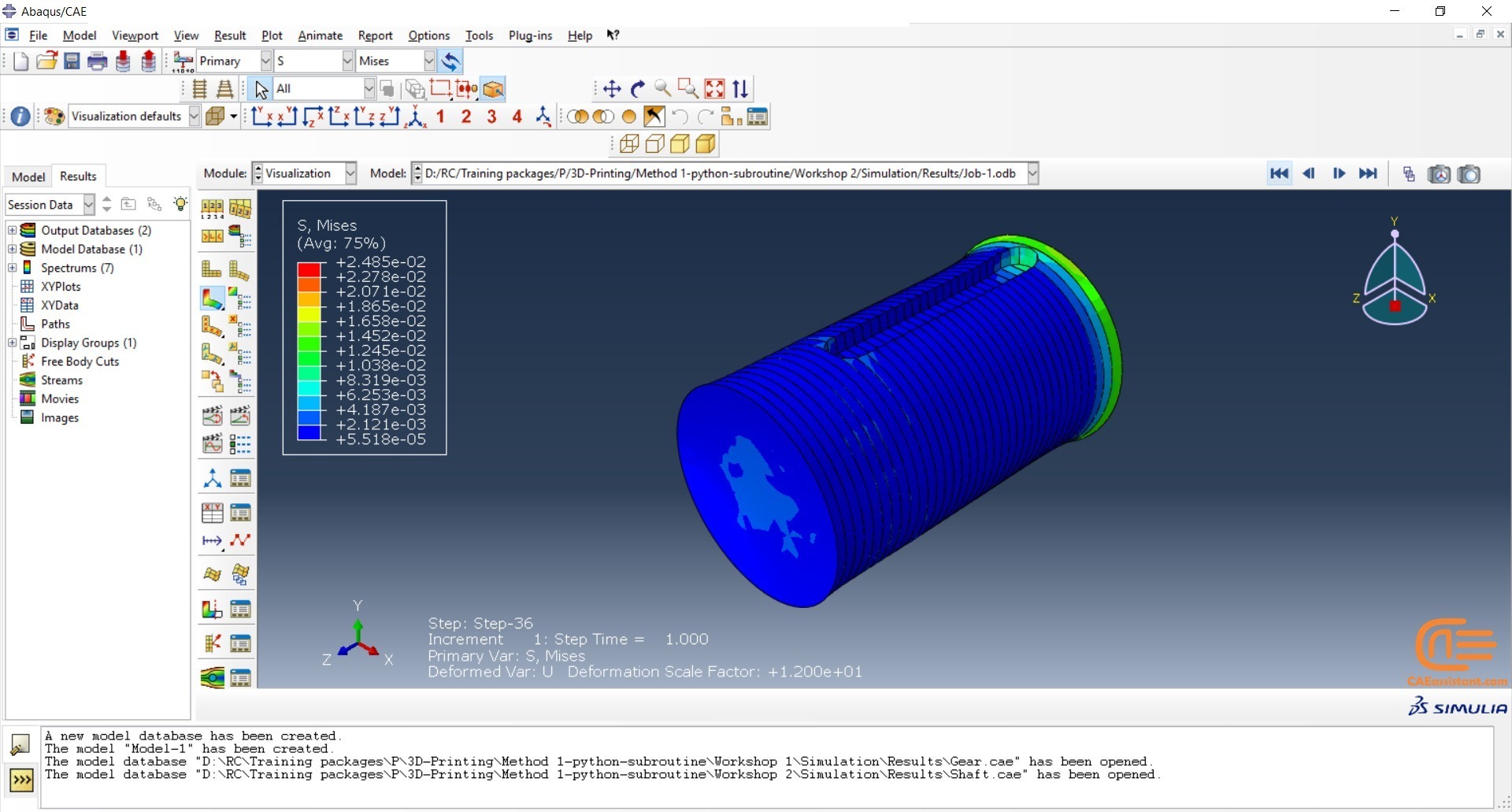

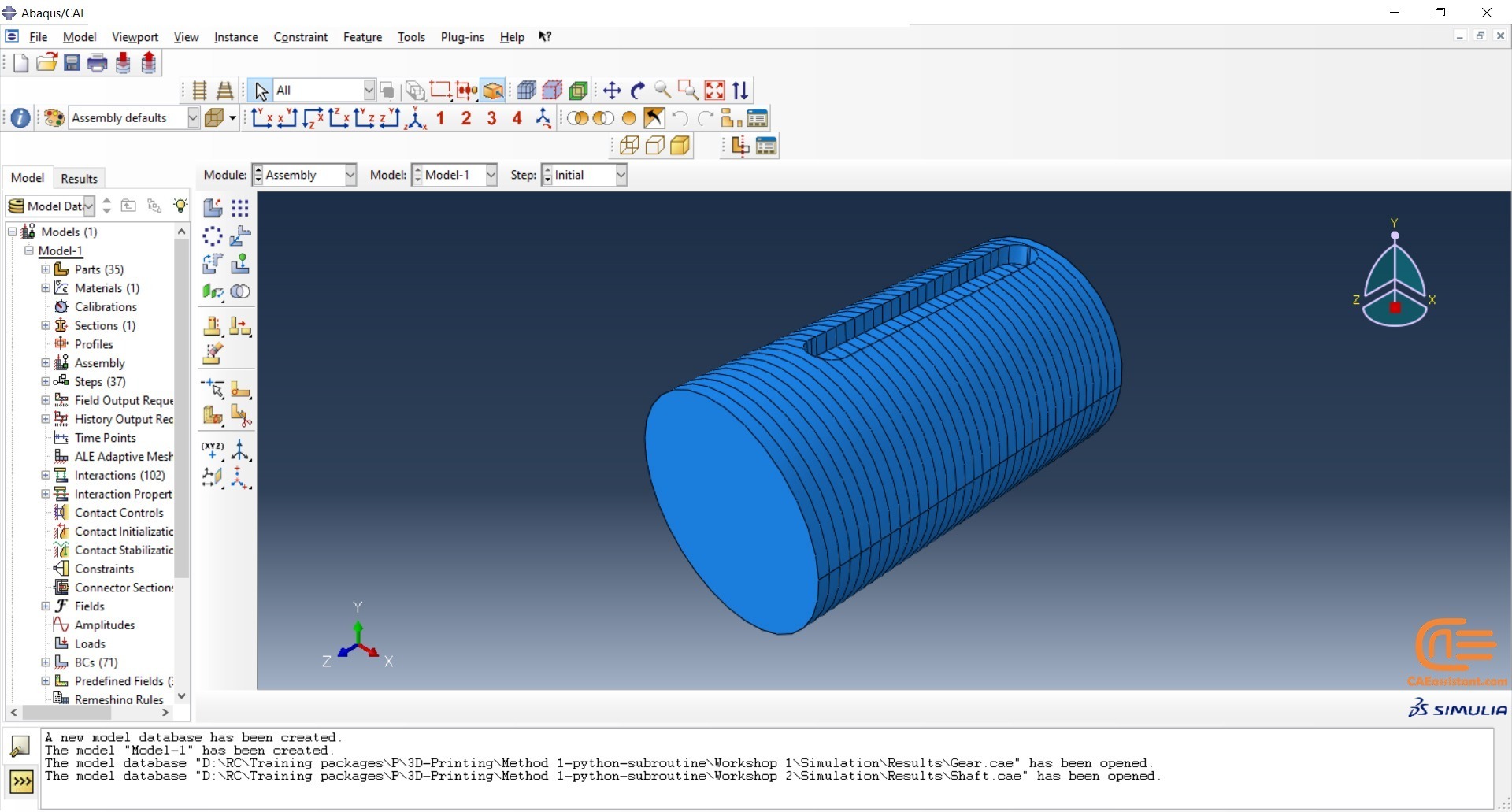

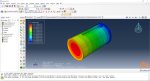

Workshop 2: 3D printing Abaqus simulation of shaft with DISP, USDFLD and Python scripting (non-uniform section)

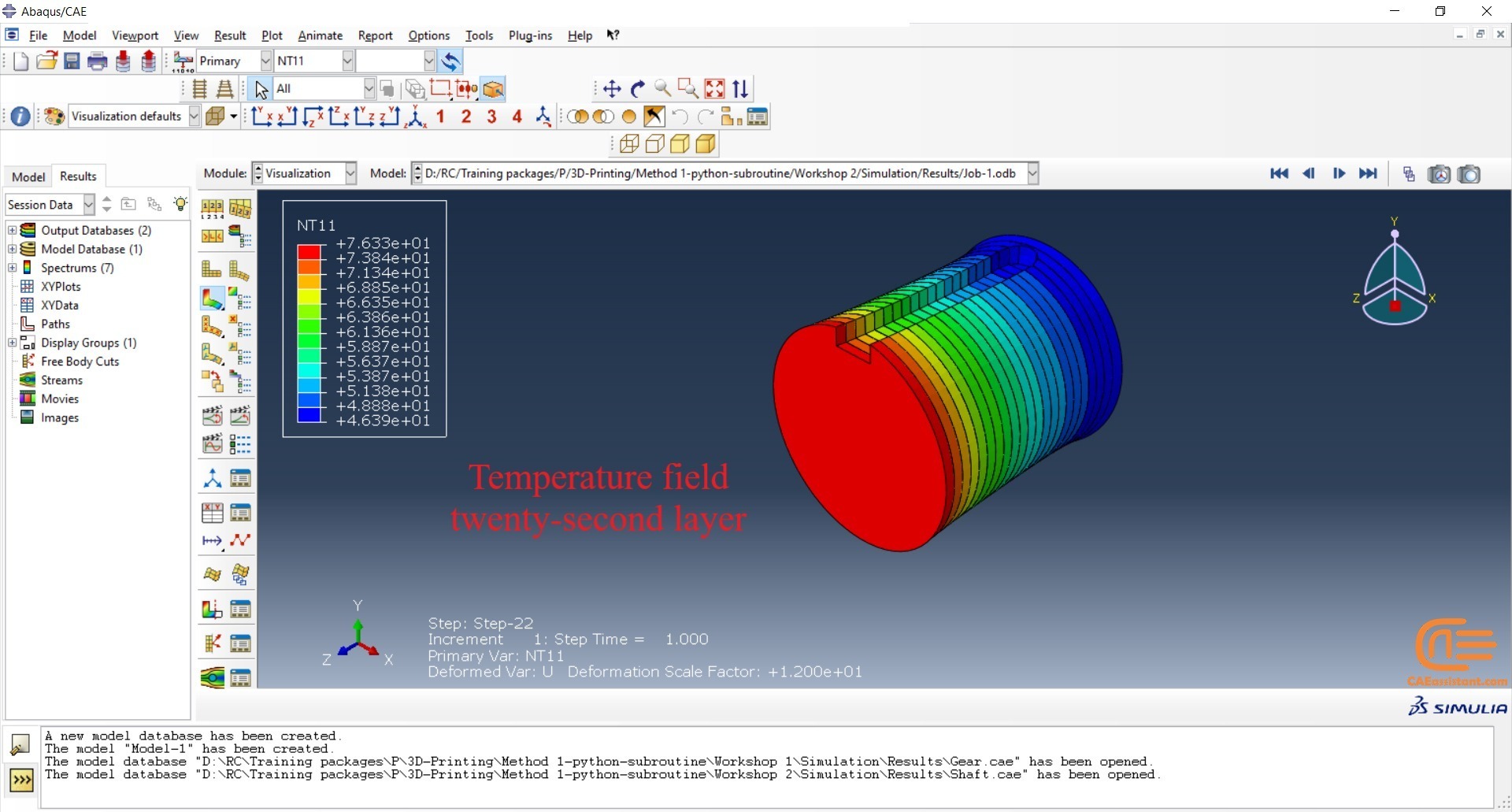

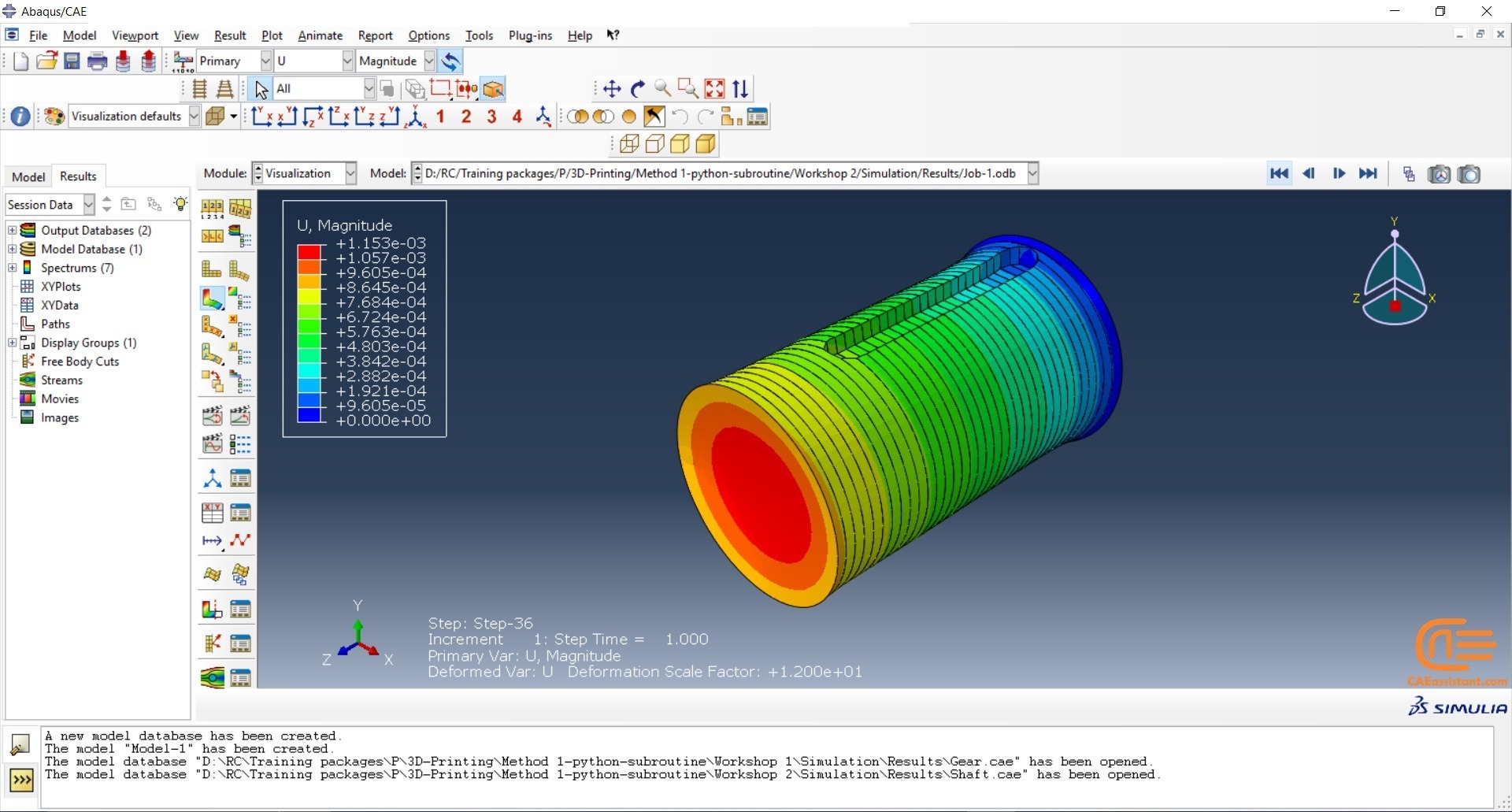

Similar to the previous workshop, this workshop begins by explaining the model’s geometry. The model layering is then presented, and all other stages are the same as the previous workshop. The only differences are in the model’s geometry, Python code, and layers, as this model has a non-uniform cross-section.

Enroll for this advanced course to complete you education in Additive manufacturing:

“Machine Learning for Predicting Fatigue Properties in Additive Manufacturing Course”

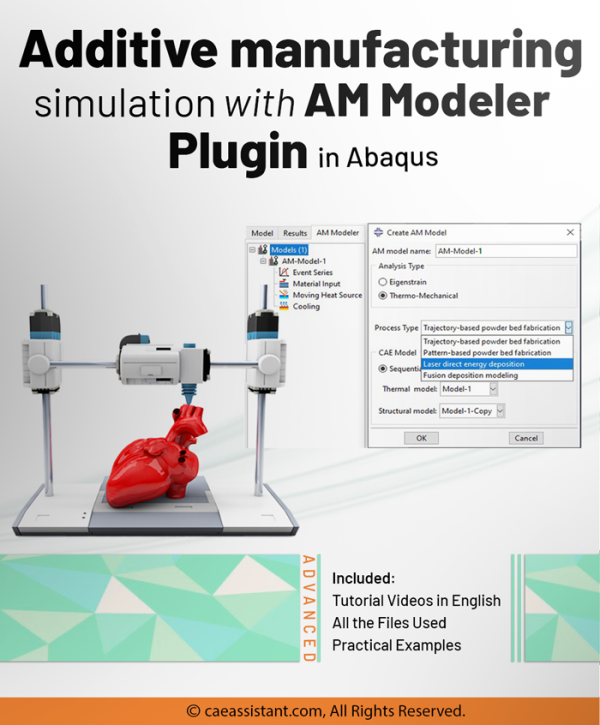

We can also use Abaqus AM Modeler plug-in to simulate additive manufacturing or 3d printing FEM. If you are interested in having both methods or even want to learn more about 3D printing itself, I recommend going to this page: “Additive Manufacturing or 3D Printing Abaqus simulation”.

Other packages in 3D printing in Abaqus:

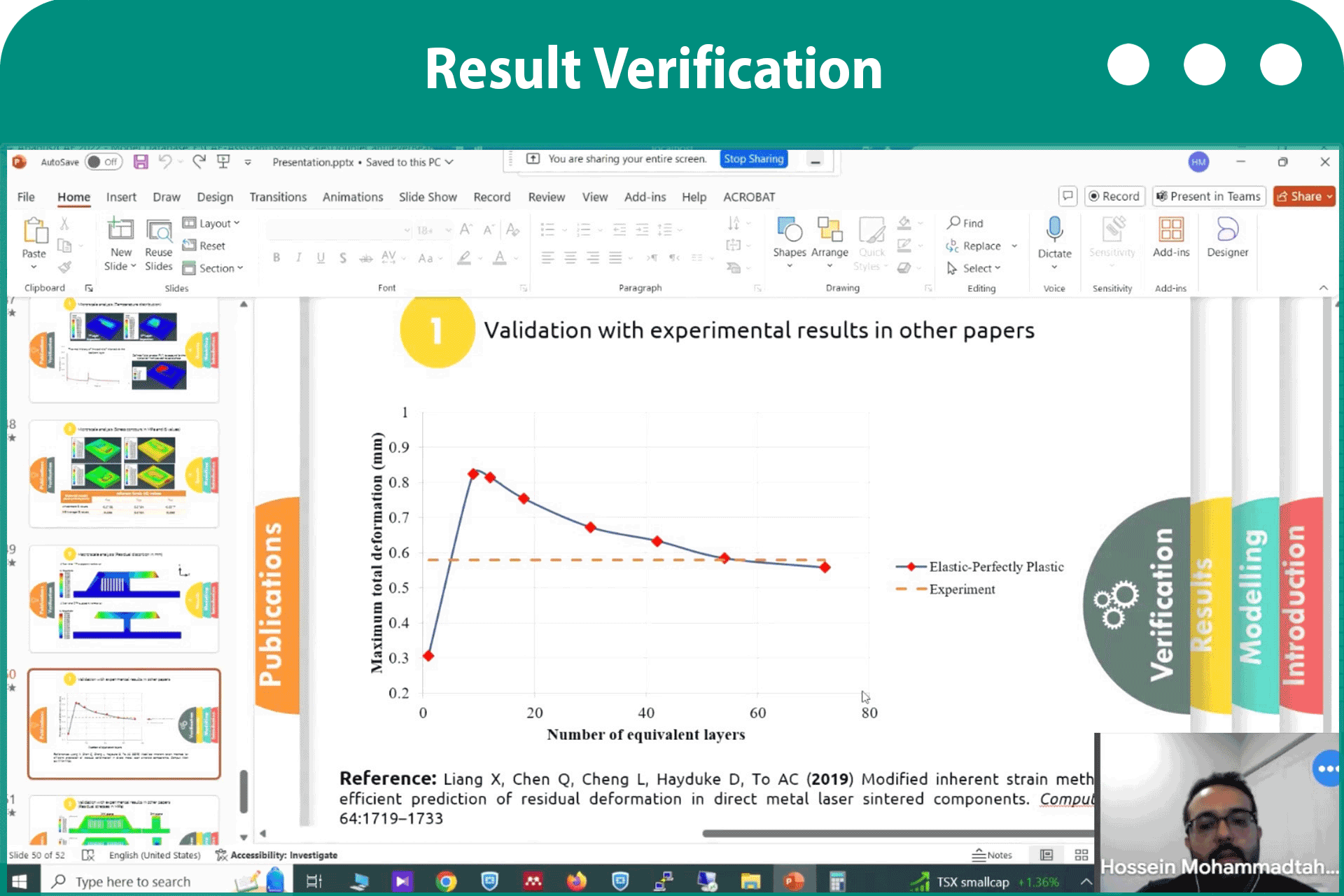

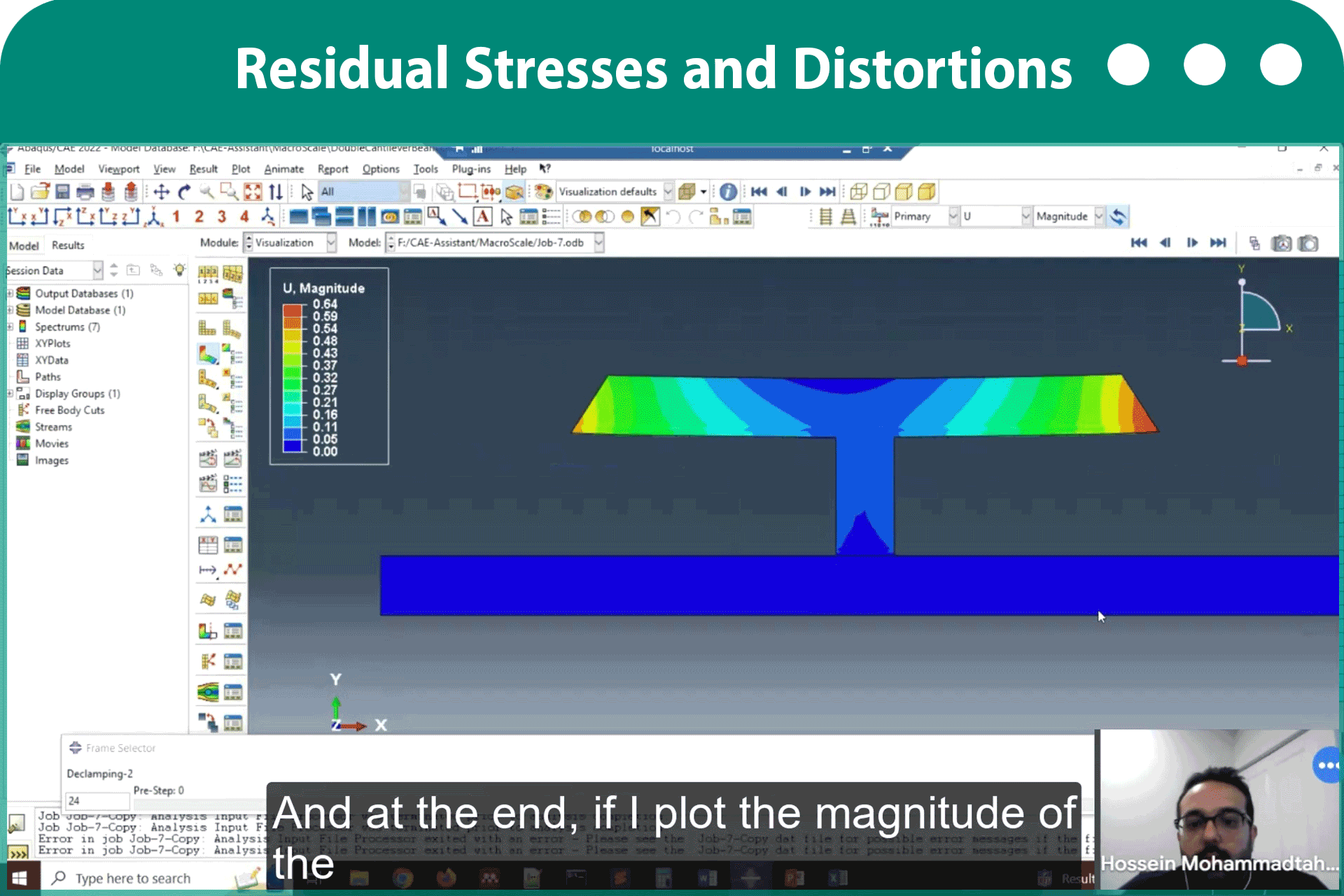

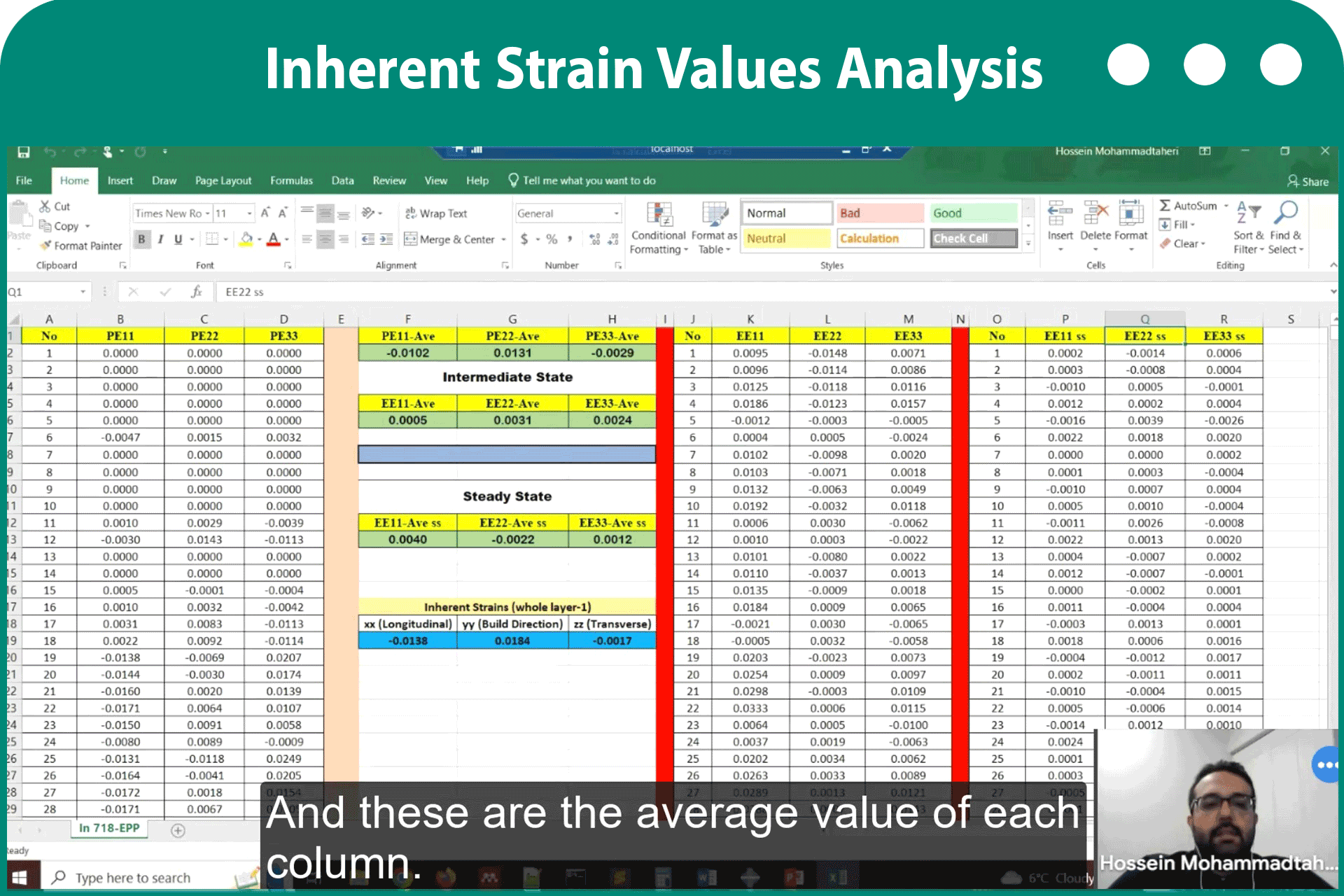

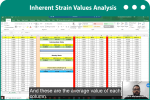

- Inherent strain method in Metal Additive Manufacturing simulation

- FDM Simulation in Abaqus | Simulating 3D Printing with Fused Deposition Modeling

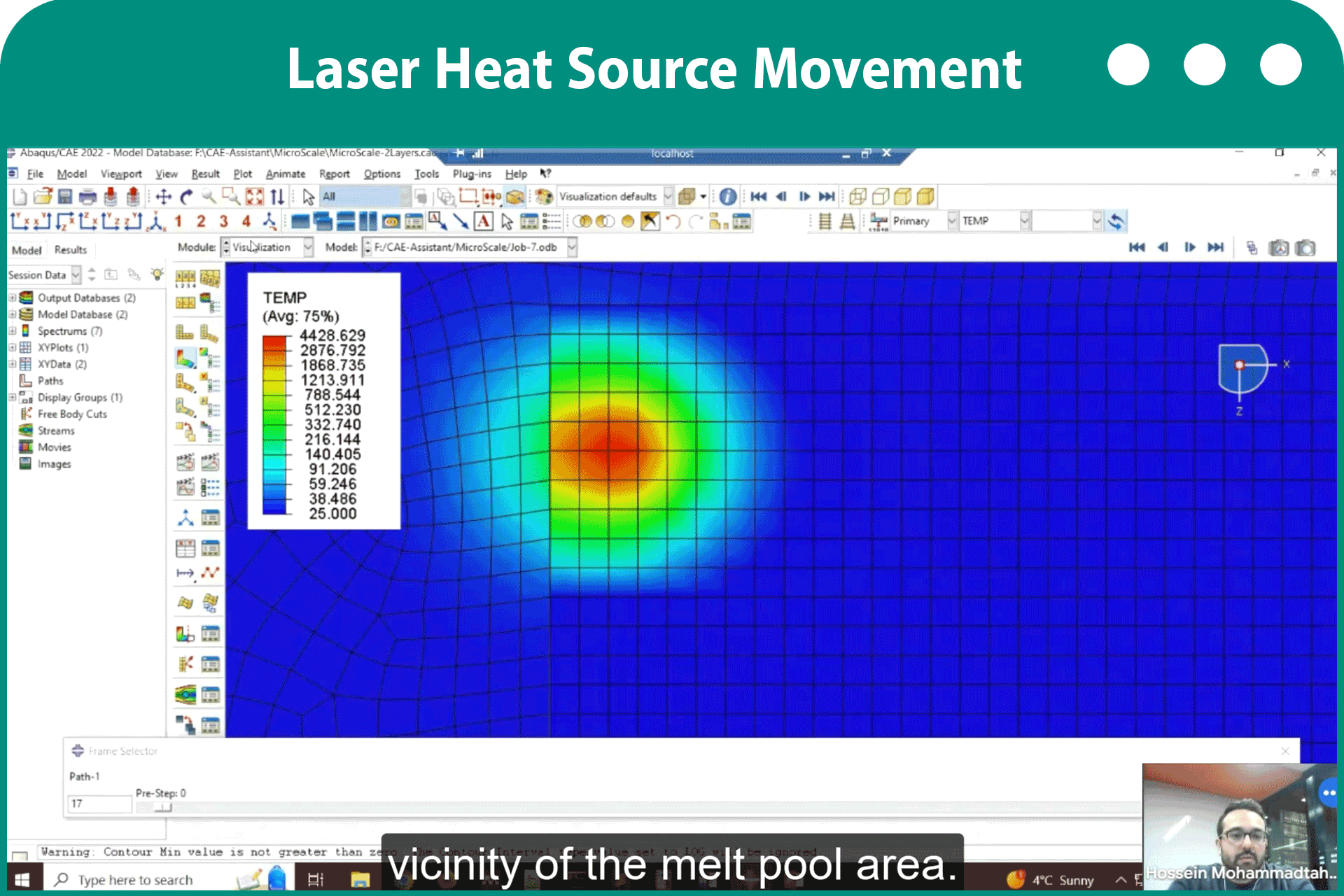

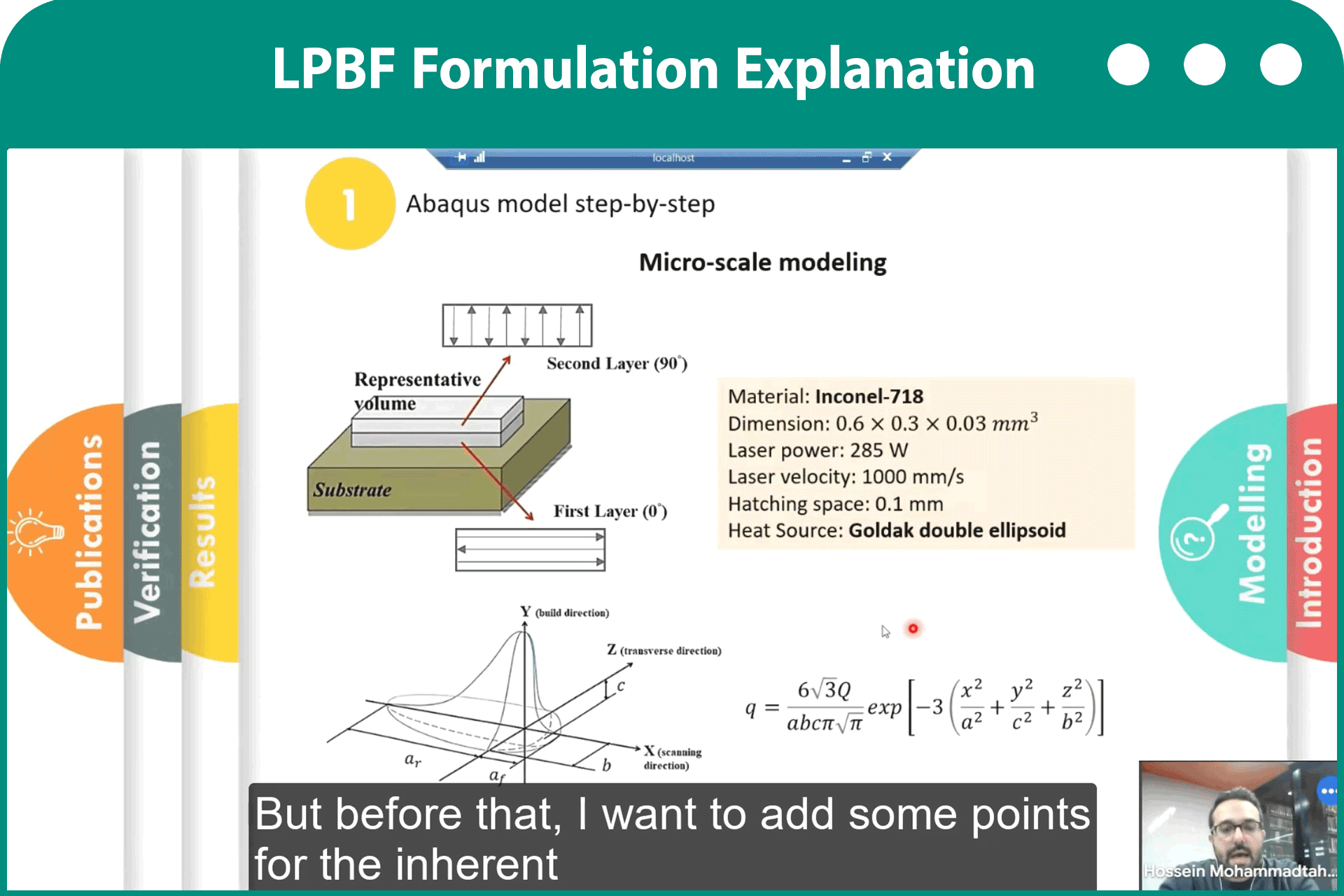

- LPBF Printing Simulation in Abaqus | 3D Printing with Laser Powder Bed Fusion Process (LPBF) Method

The CAE Assistant is committed to addressing all your CAE needs, and your feedback greatly assists us in achieving this goal. If you have any questions or encounter complications, please feel free to share it with us through our social media accounts including WhatsApp.

emre –

I recommend this to anyone looking for a organized and professional tutorial videos.

furk.simon –

This course give to you a chance to create objects from reality or just using your imagination. Enjoy this course, guys.

henzo –

Great instructor accurate and to the point explanations. Each project seem to be professionally prepared, definitely not a let’s see how it goes kind of tutorials. Highly recommended!

eian.hilen –

I started this course with absolutely no experience in 3D printing or 3D design. It was a good training for me, But do you have a tutorial that is suitable for beginners?

max.efa –

Thank you I understand all the topics due to this course, but the information could have been much better packaged and organized.

Experts Of CAE Assistant Group –

Thank you for your feedback. We appreciate your understanding of the topics covered in the course. We take your comment about the packaging and organization of the information seriously, and we apologize if it fell short of your expectations. We strive to continuously improve our course materials, and your input will help us in that process. If you have any specific suggestions or areas where you feel we can enhance the packaging and organization, we would be grateful to hear them. Thank you again for your feedback, and we’re glad that you found value in the course content.