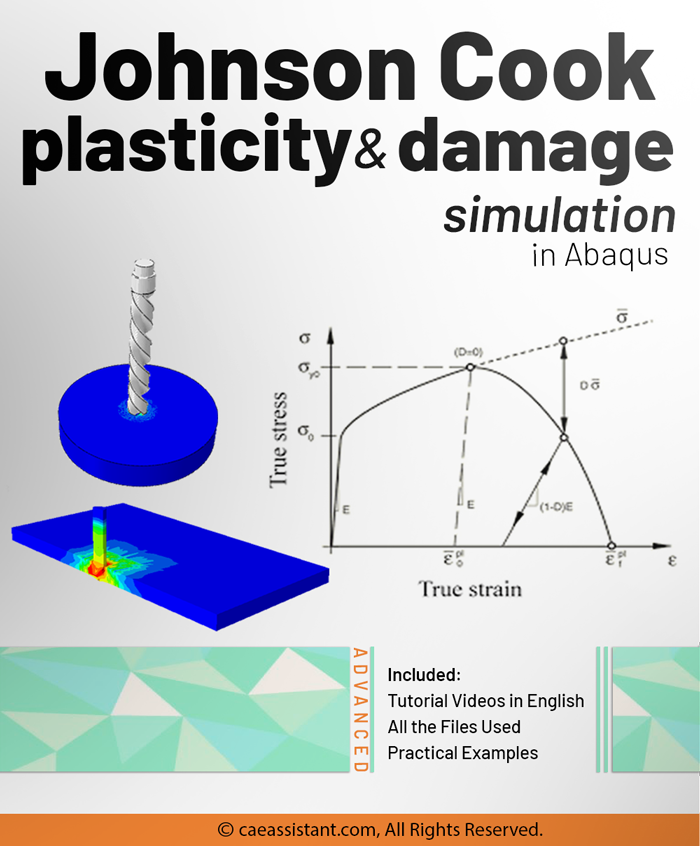

Johnson Cook plasticity and damage simulation

A phenomenological flow stress model based on operating conditions such as sheet temperature, strain-induced strain, and punch strain rate is known as the Johnson-Cook (JC) constitutive model. The JC model is frequently used for numerous types of materials over a range of temperatures and strain rates. Johnson Cook Abaqus modelling is thoroughly described in this video tutorial.

This package focus on johnson cook’s plasticity, johnson cook damage initiation, and johnson cook progressive damage. As you know, you can find the johnson cook models (three above) are available in Abaqus. Firstly, in two workshops, you will learn how to use the Abaqus model for the Johnson-Cook theory.

However, we sometimes need to change the theory of johnson cook’s equations to drive new theories. So, in this training package, we learn how to use the Abaqus model for johnson cook theory and how to write subroutines for this model. Two subroutines have been written. In the first one, you will learn how to implement Johnson-Cook plasticity and damage initiation and in the second one, you will learn how to implement Johnson-Cook progressive damage.

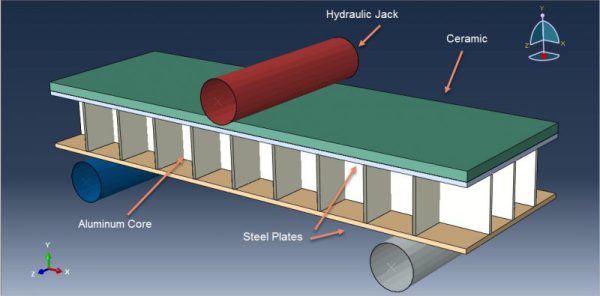

Workshop: Drilling simulation

In this workshop, plasticity, damage initiation, and progressive damage of the Johnson Cook Abaqus model have been used to simulate the drilling procedure in this session. In this instance, a titanium drill will be used to drill a hole in an aluminum block. We’ve previously modeled the drill using CAD software. Therefore, it has been brought in. In addition, we imported the material library’s material properties.

Read More: abaqus crack

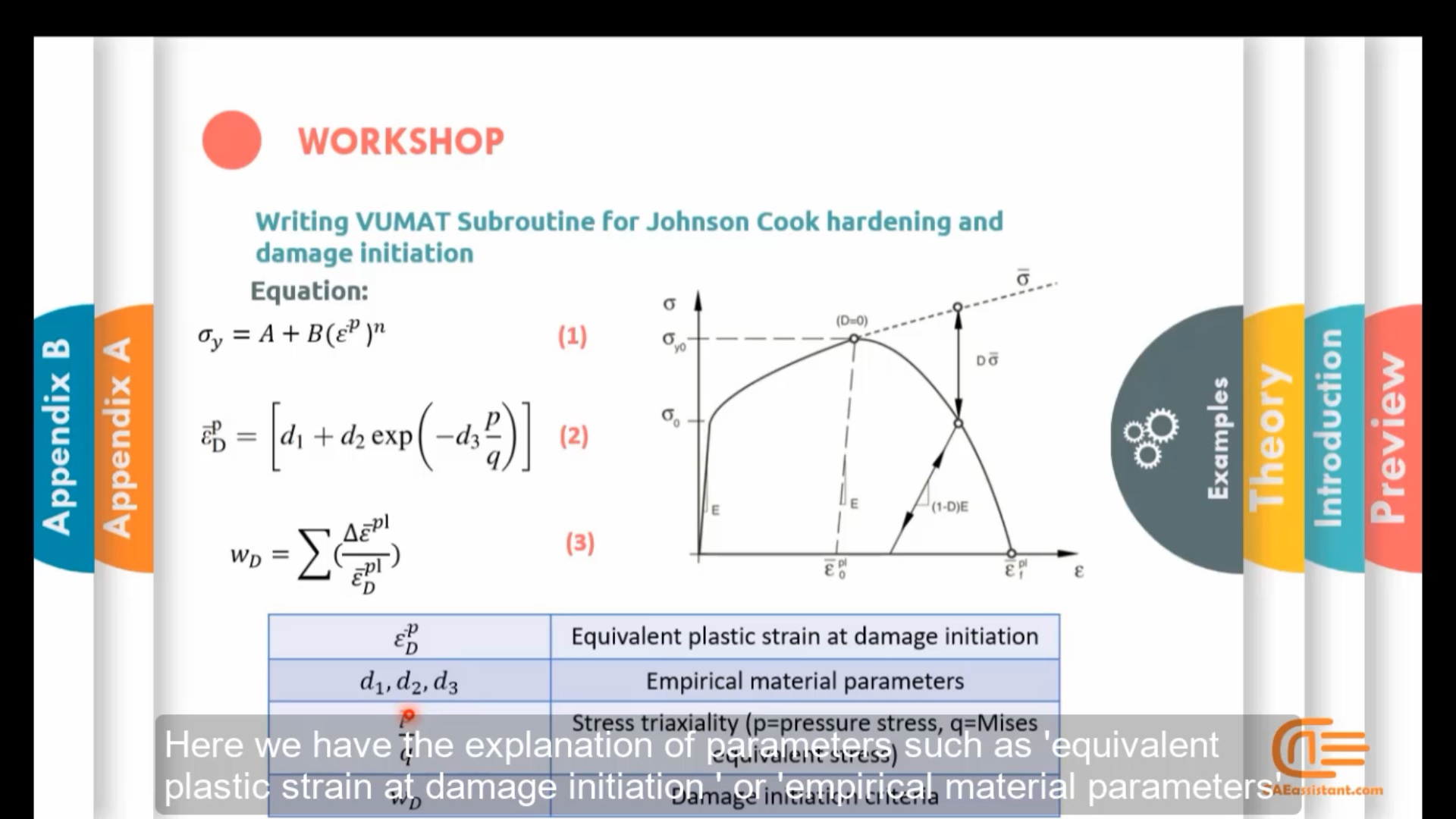

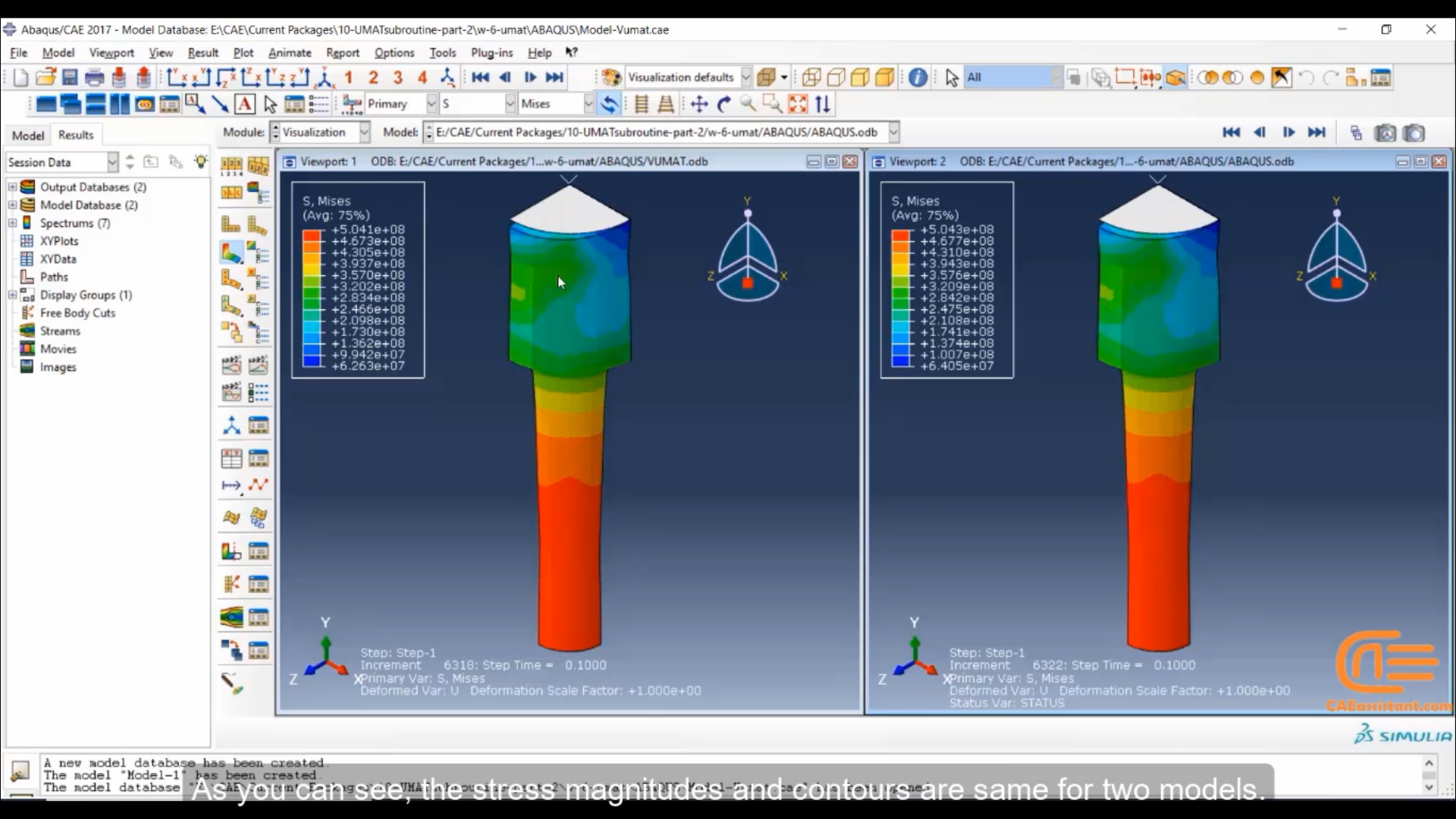

Workshop: Writing VUMAT Abaqus Subroutine for Johnson-Cook plasticity and damage initiation

For the purpose of hardening and the beginning of Johnson-Cook damage, plasticity equations are first put forward. For usage in subroutines, the following equations are produced. Additionally, the procedure introduces all necessary parameters. It should be mentioned that various approaches to calculating energy loss have been developed. Following the flowchart presentation, a line-by-line breakdown of subroutine writing is done. The findings of this subroutine are validated by comparing them to Abaqus material results after it has been used in an aluminum material extrusion process.

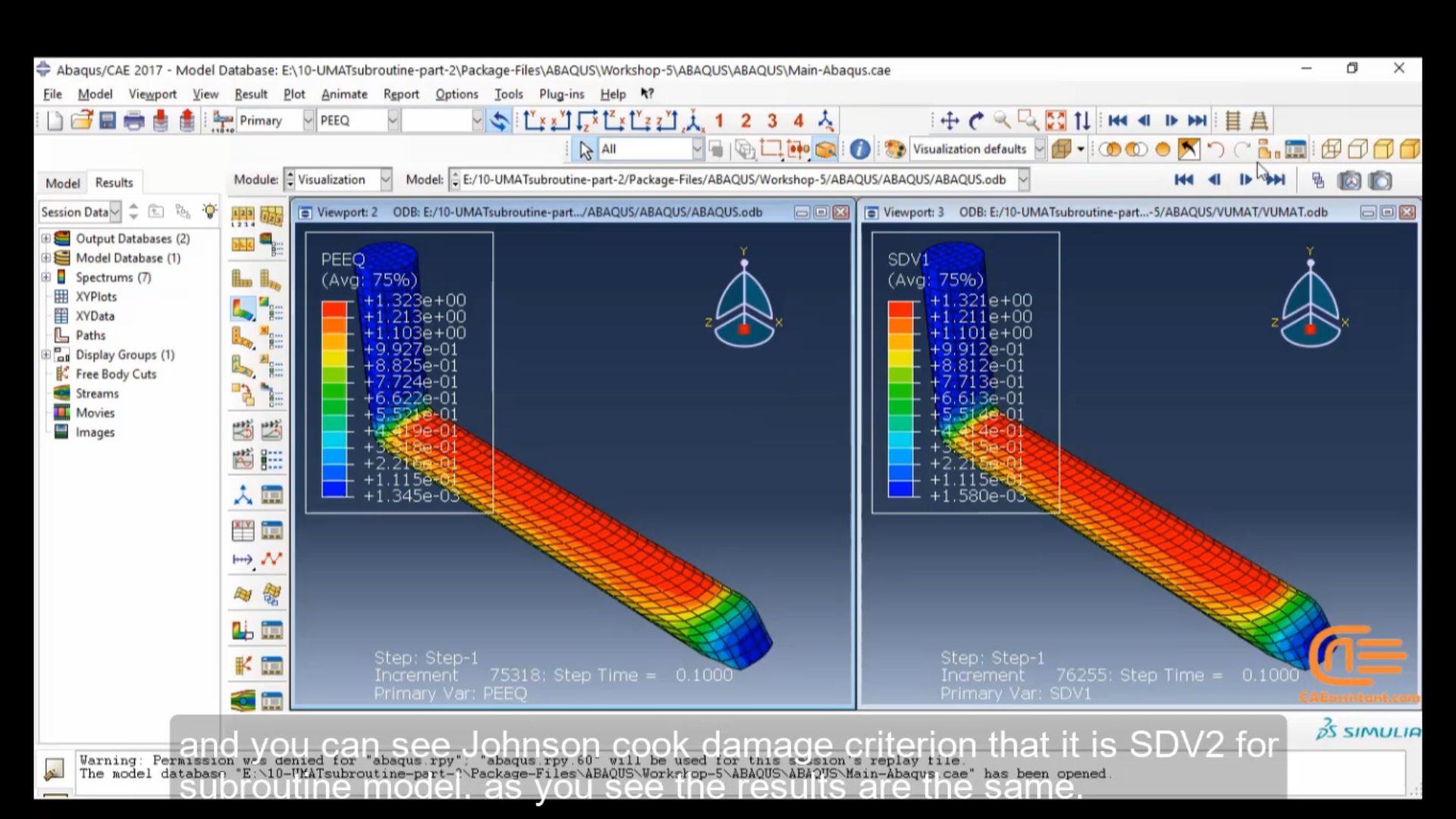

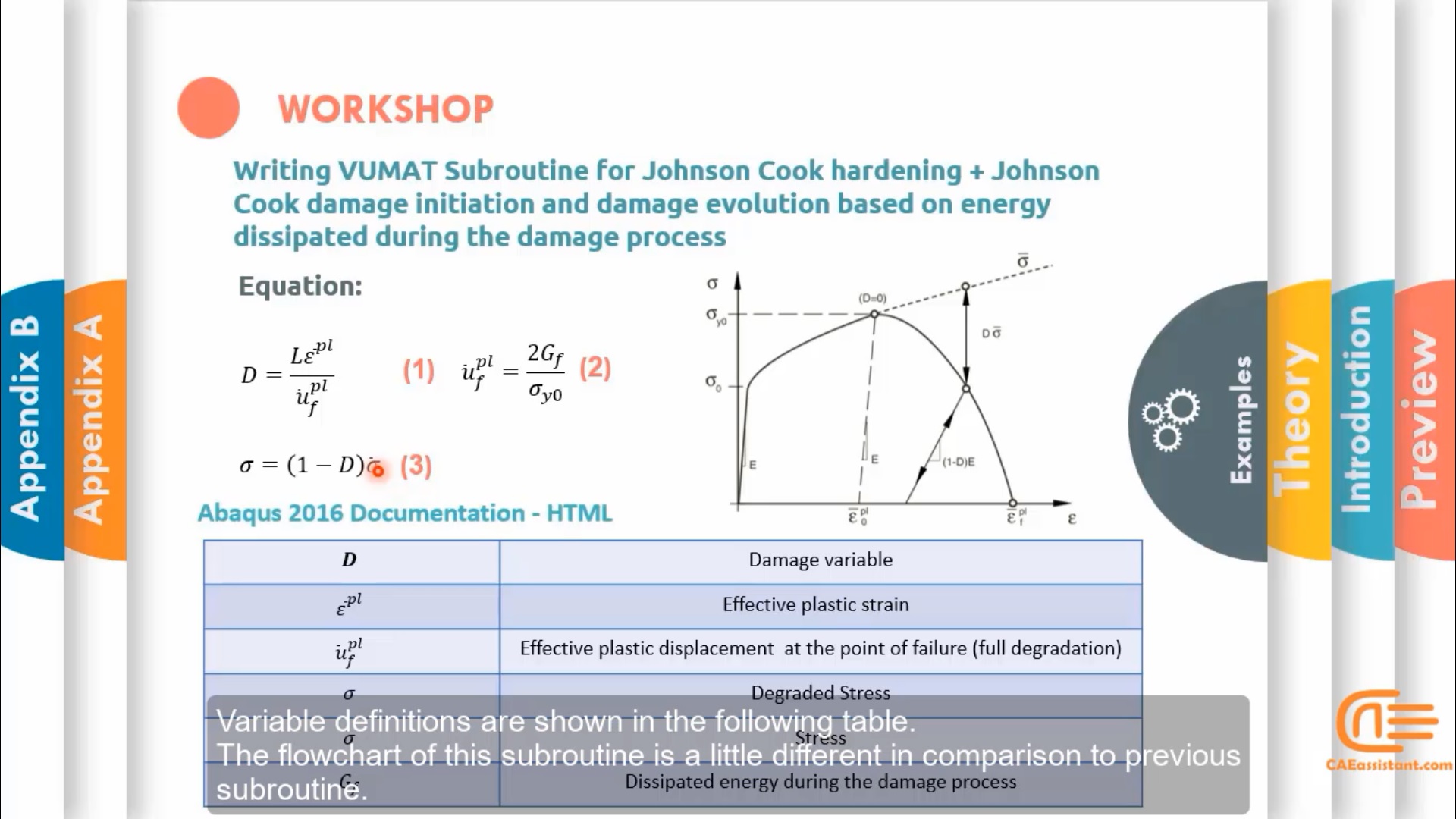

Workshop: Writing VUMAT Abaqus Subroutine for Johnson-Cook progressive damage

The beginning of this workshop’s Abaqus VUMAT course provides a graphic explanation of the damage and its mechanics. Johnson Cook’s increasing damage is described in the following equations. The full flowchart, which describes Johnson Cook’s gradual deterioration and its severity and point of initiation, is described last. Following that, each line of the subroutine is explained. The findings of this subroutine are run on a straightforward stretch of a three-dimensional model, and they are validated against Abaqus results in the areas of plasticity, damage initiation, and progressive damage.

I hope you have got enough information about the Johnson-Cook Abaqus simulation; if you need more information about this package, please get in touch with us via online chat on the left side of this page. It would be helpful to see Abaqus Documentation to understand how it would be hard to start an Abaqus simulation without any Abaqus course.

Suphachai –

The Johnson-Cook Plasticity and Damage Simulation package provided a very positive experience. This tool significantly enhanced the performance and accuracy of my simulations, helping me conduct more precise analyses of plastic behavior and material damage. The user interface is very intuitive, making it easy to use. I am completely satisfied with this package and would definitely recommend it to others looking for advanced simulation tools.

MICHAEL –

This package covers everything you need to know about Johnson Cook’s plasticity, damage initiation, and progressive damage, and the workshops, which simulate a drilling procedure and extrusion process, are an excellent way to apply the theory in practice. thank you to provide this package.

Kittipong –

The Johnson-Cook Plasticity and Damage Simulation package is one of the best tools I have used for complex simulations. The quality and accuracy of the simulation results are unparalleled, and I have been able to perform precise analyses of material behavior under various loads. Using this package has been straightforward and efficient, allowing me to quickly achieve the desired results. I highly recommend this package and am confident that it will be very useful for anyone working in simulation. How can I use the advanced features of the package for specific analyses? Is there information available on this?

Phanuwat –

I recently tested the Johnson-Cook Plasticity and Damage Simulation package in my research projects, and I must say that the results were excellent. This package significantly improved the accuracy of my simulations and was very easy and quick to use. Its various features allowed me to perform deeper analyses of plastic behavior and material damage. Overall, this package is valuable and effective, and I recommend it to anyone looking for a powerful tool for complex simulations.

Anuwat –

The Johnson-Cook Plasticity and Damage Simulation package provided a very good experience for me. This tool helped me conduct more precise simulations and perform in-depth analyses of material behavior. The speed and accuracy of the simulations were notably improved, and the package is worth the investment. I am completely satisfied with this package and strongly recommend it to others involved in simulation.

Chatchai –

The Johnson-Cook Plasticity and Damage Simulation package significantly improved the accuracy of my simulations and provided a very positive experience. Using this tool has been very easy and fast, and its results are highly reliable and precise. This package allowed me to conduct more complex analyses and achieve better outcomes. I am very satisfied with this package and recommend it to anyone working in simulation.