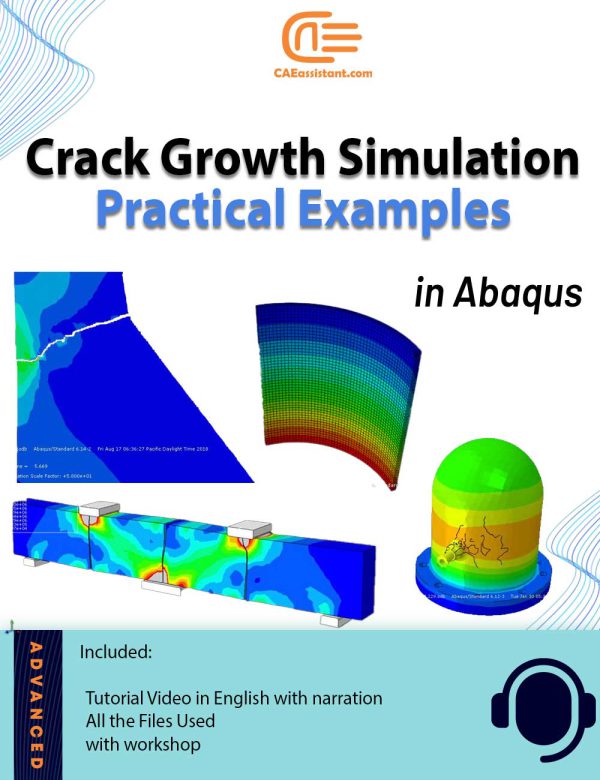

Abaqus Crack Growth | Practical Examples

Abaqus Concrete Structure Modeling | Practical Examples (Part 4)

Abaqus Concrete Structure Modeling | Practical Examples (Part 3)

Abaqus Concrete Structure Modeling | Practical Examples (Part 2)

Abaqus Concrete Structure Modeling | Practical Examples (Part 1)

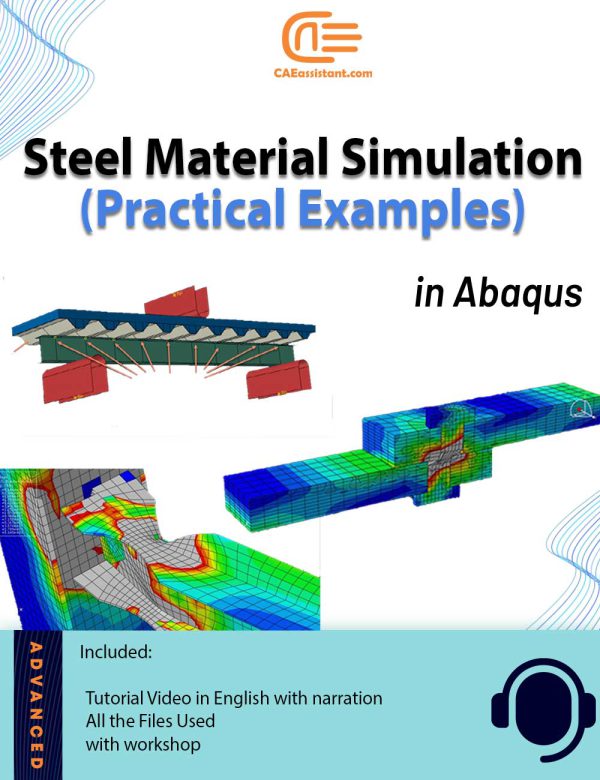

Abaqus steel material and structures | Practical examples

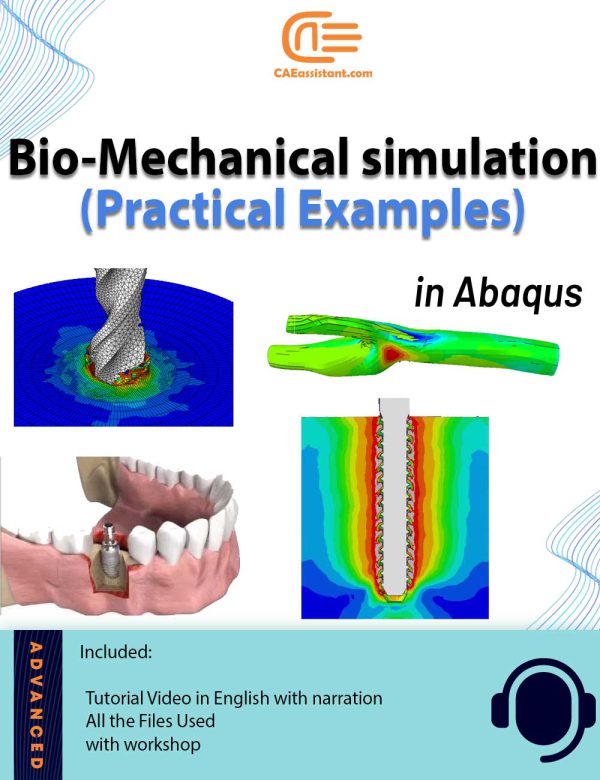

Bio-Mechanical Abaqus simulation | Practical Examples

This package offers multiple practical examples on biomechanical simulations using Abaqus, covering a range of applications from dental to orthopedic and cardiovascular analyses. The workshops delve into finite element method (FEM) simulations, exploring static loading on human teeth, crack growth in bones under bending, bone drilling, and the behavior of titanium foam implants. Each tutorial emphasizes the importance of precise modeling and meshing techniques, utilizing dynamic explicit procedures, Johnson-Cook material models, and various contact and boundary conditions to simulate realistic biomechanical behaviors. Additionally, the package includes fluid-structure interaction (FSI) simulations for blood flow within coronary vessels, addressing both Newtonian and non-Newtonian models, and demonstrates the integration of computational fluid dynamics (CFD) with structural analysis for enhanced accuracy. For more details on this topic, including explanatory videos covering the necessary formulation and theory in the form of a course, you can check out our full package on Abaqus Bio-mechanical simulation. The introduced package includes all the workshops within this package, along with several lessons in video format, to help you master the theory of biomedical simulation in Abaqus.

ADVANCED ABAQUS SUBROUTINE COURSE | FULL

ABAQUS PYTHON COURSE FOR SCRIPTING IN FEM SIMULATION | FULL

COMPREHENSIVE ABAQUS TUTORIAL FOR CIVIL ENGINEERS | FULL

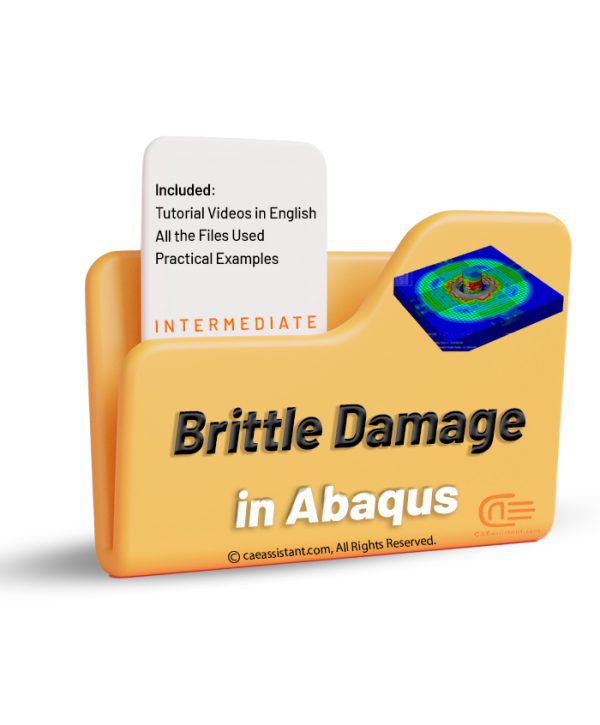

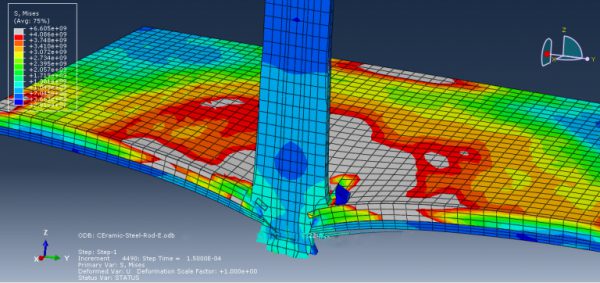

Brittle Damage in Abaqus | Brittle Cracking Abaqus

Brittle materials, such as ceramics, glass, and concrete, break or fracture easily under stress without extensive deformation. Unlike ductile materials, brittle materials snap suddenly, lacking the flexibility to rearrange their atomic structure under strain. These materials have low tensile strength but strong compressive resistance, making them vulnerable to brittle cracking Abaqus simulations when stretched or pulled.

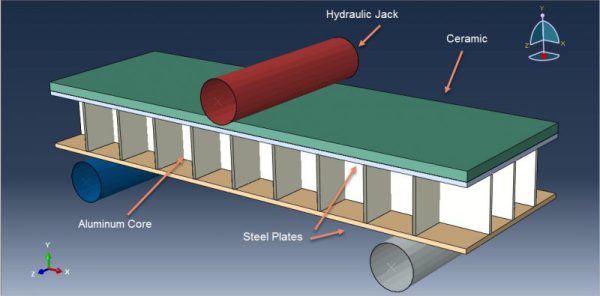

Understanding brittle material damage is crucial in safety-critical fields like civil engineering, aerospace, and manufacturing, where unexpected fractures can lead to catastrophic failures. Simulations help engineers predict when and how brittle materials may break, guiding safer design choices. Brittle cracking Abaqus can be modeled using various methods, including the Johnson-Holmquist (JH) model, XFEM, and energy-based approaches, each suited to different types of loading conditions.

For dynamic, high-strain applications like impacts, the JH model is effective, particularly in Abaqus/Explicit with specific damage parameters. For general crack modeling, XFEM is versatile, allowing cracks to form naturally without predefined paths. The energy-based method is useful for slow-loading scenarios, defining an energy threshold for fracture initiation. Each method requires careful input of material properties, mesh refinement, and load conditions to reveal potential failure points and improve material performance in real applications.