Steel Damage types in Abaqus

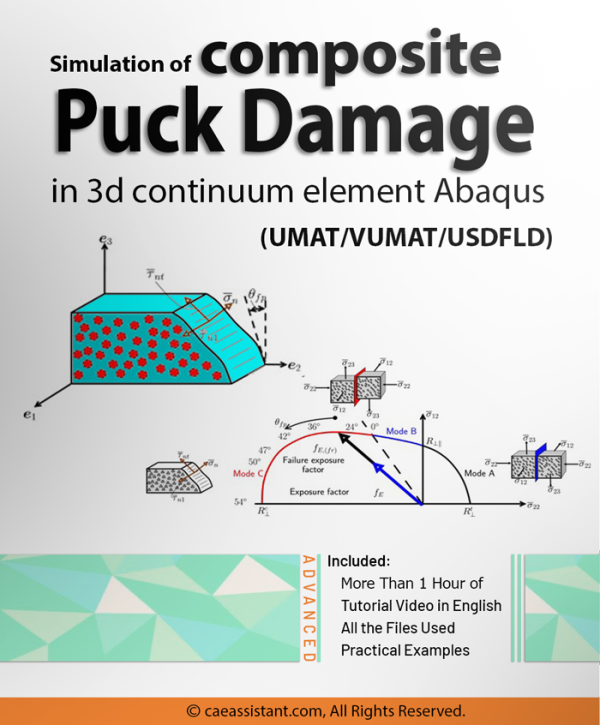

Simulation of composite Puck damage in 3d continuum element in Abaqus (UMAT-USDFLD-VUMAT)

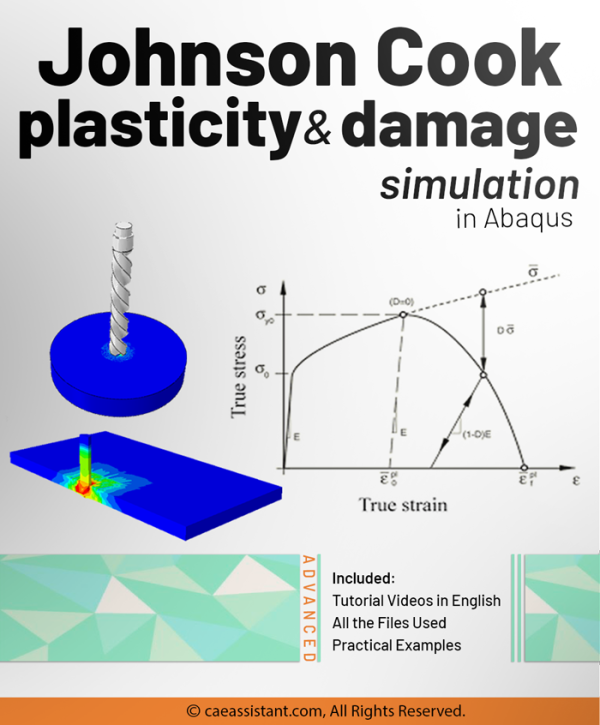

Johnson Cook plasticity and damage simulation

Foam simulation in Abaqus

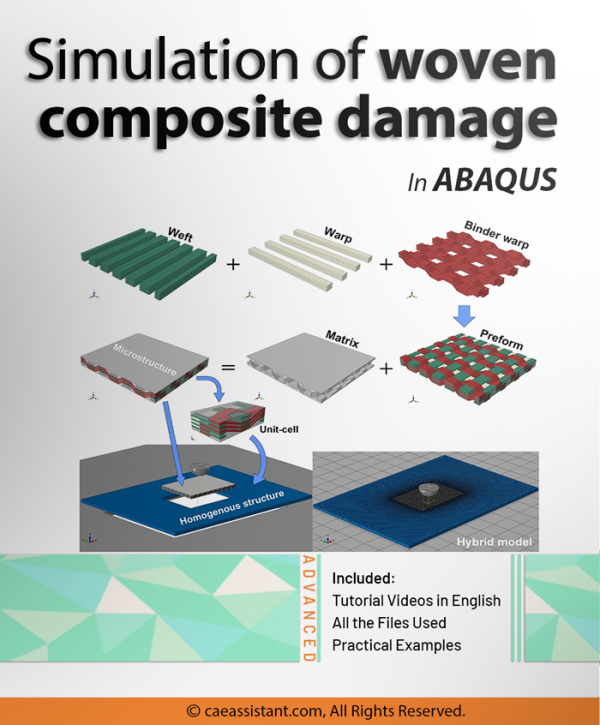

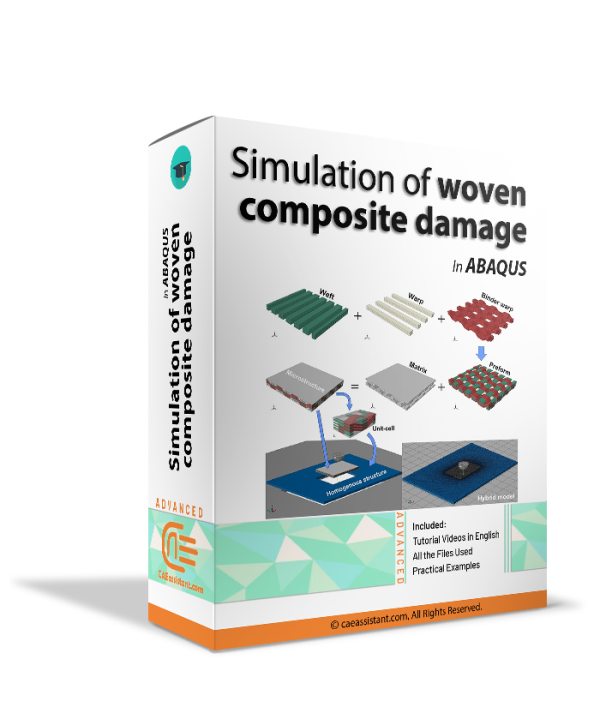

Simulation of woven composites damage in Abaqus

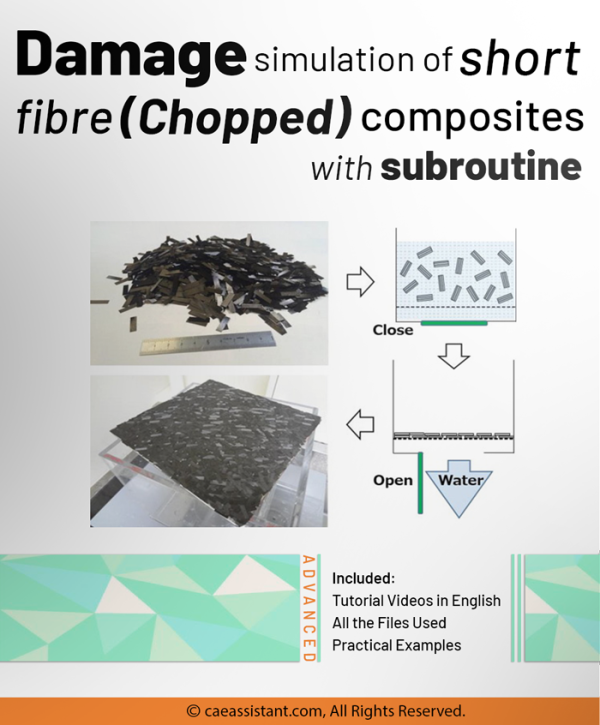

Damage simulation of short fibre composites with subroutine

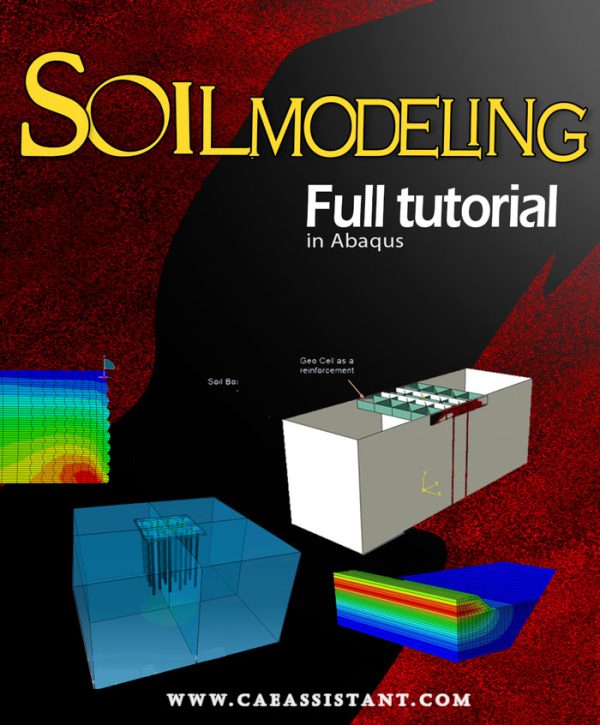

Abaqus Soil Modeling Full Tutorial

Abaqus steel material and structures Full Tutorial

Balsa wood fatigue simulation with Abaqus subroutine

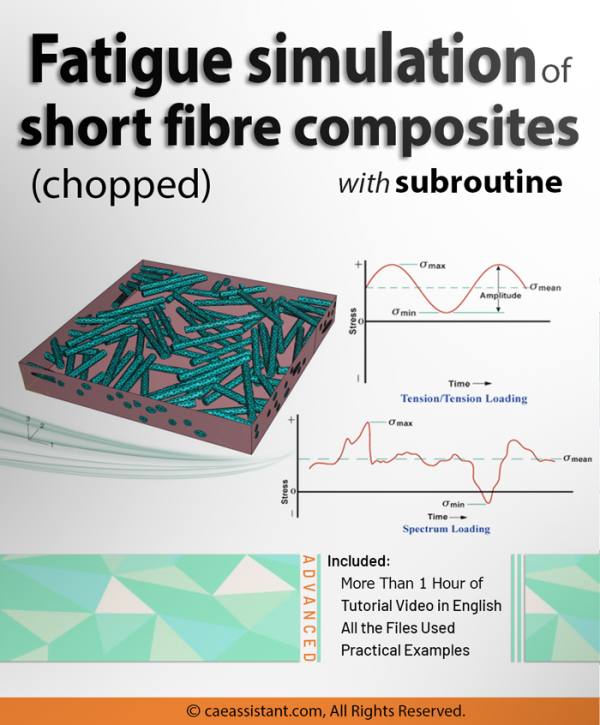

Fatigue damage simulation of short fibre composites with subroutine

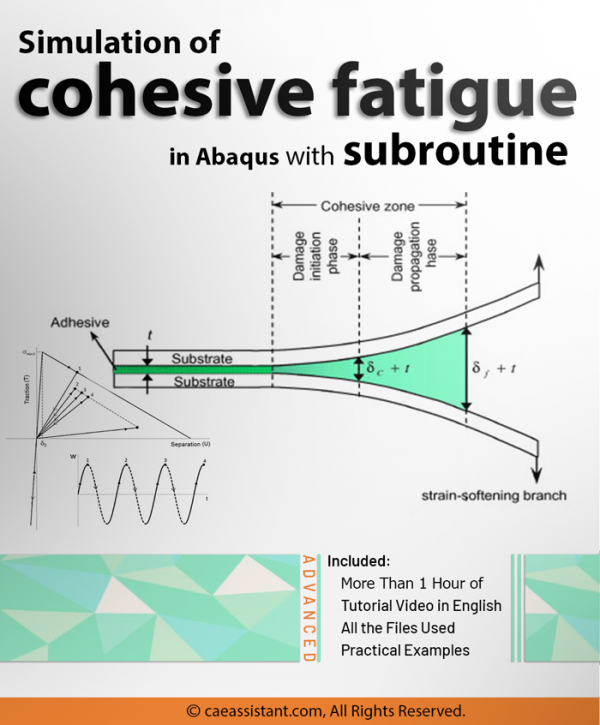

Simulation of cohesive fatigue in Abaqus with subroutine

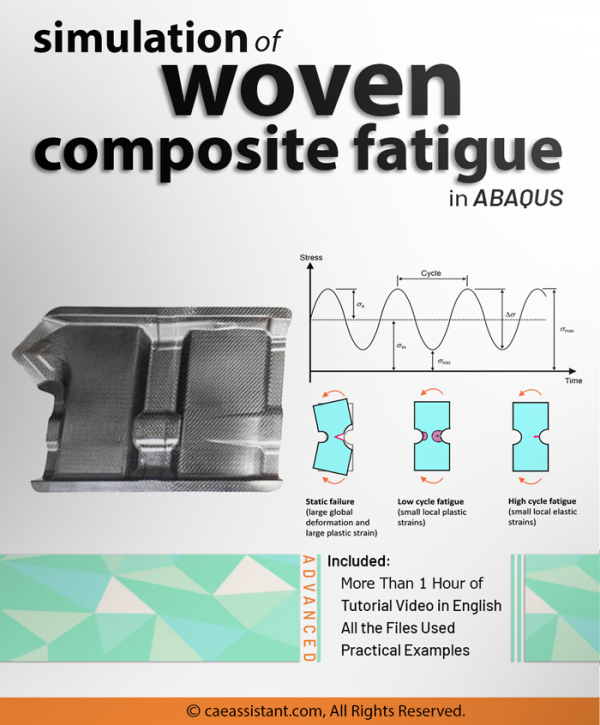

Simulation of woven composite fatigue in Abaqus

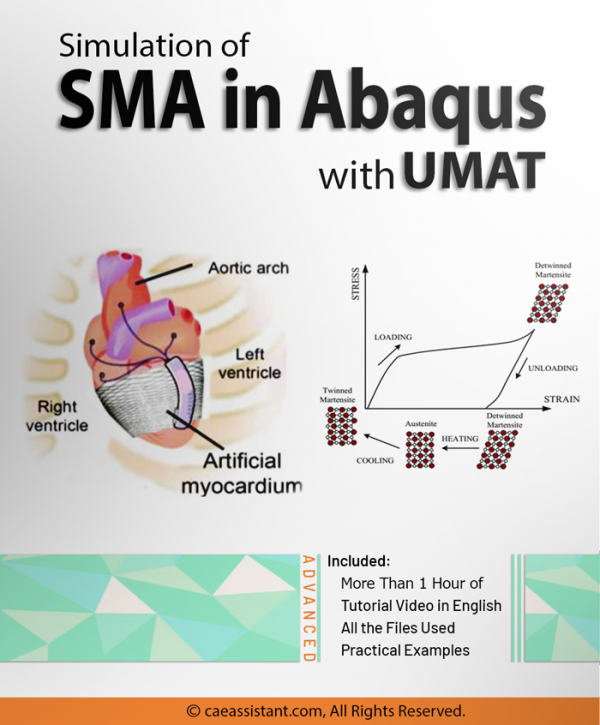

Simulation of SMA in Abaqus with UMAT

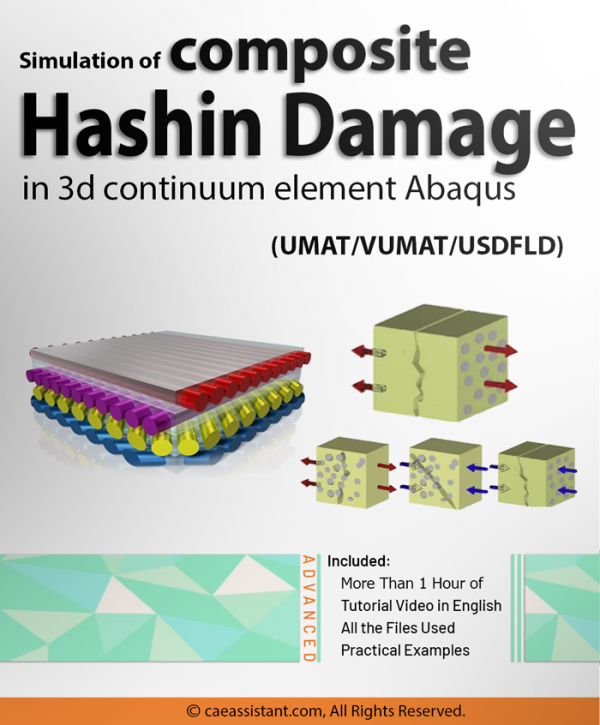

Simulation of composite Hashin damage in 3d continuum element in Abaqus (UMAT-VUMAT-USDFLD)

Composite simulation for experts-Part-1

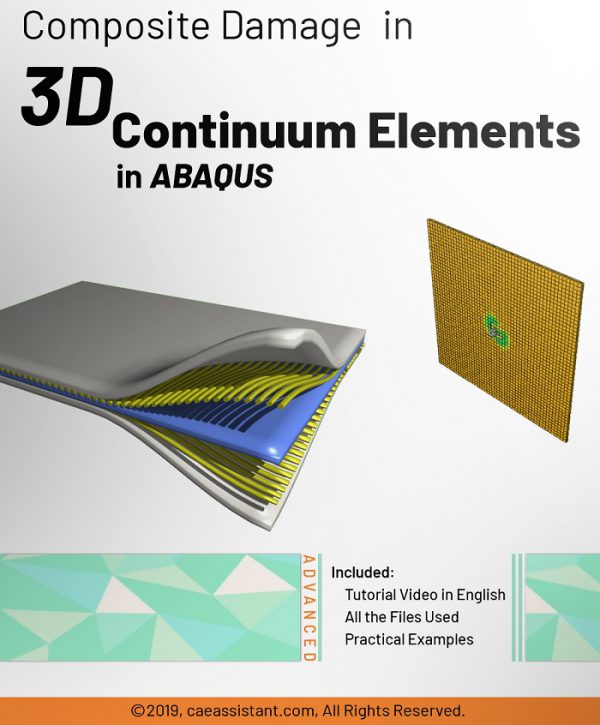

3D continuum Abaqus HASHIN progressive Damage for composite materials (VUMAT Subroutine)

The Hashin failure criteria is a set of failure criteria developed specifically for composite materials. It predicts different failure modes in composites based on the stresses experienced by their constituents (fiber and matrix). The criteria are widely used in engineering and computational models to assess composite material performance under mechanical loading. The criteria, while highly efficient and widely used, pose challenges when implemented in numerical simulations. Abaqus has emerged as a powerful tool to address these challenges, enabling the prediction of damage initiation and its progression (via stiffness reduction) based on the Hashin criteria. However, a key limitation of Abaqus is its applicability being restricted to 2D plane stress elements. To overcome this limitation, we developed a VUMAT subroutine in this project. This custom subroutine extends the capabilities of Abaqus, allowing for the simulation of damage initiation and propagation in 3D problems in accordance with the Hashin criteria. It should be mentioned that this subroutine includes gradual progressive damage based on the energy method. This complex subroutine could be used for static and dynamic problems.

A notable point is that in one of our other packages, we also provide training on using Abaqus subroutines to analyze the Hashin criterion. However, in that package, damage occurs instantaneously. In the current package, we have modeled the progressive Damage, which is more complex but could be more beneficial for solving your specific problems.

Composite Fatigue Simulation with UMAT Subroutine in ABAQUS (unidirectional)

Simulation of Unidirectional Composite Damage in ABAQUS

Abaqus Concrete structure Modeling Full Tutorial

We also offer similar budget-friendly packages that include the workshops from this package.

- The first package includes Workshops 1 to 5.

- The second package includes Workshops 6 to 10.

- The third package includes Workshops 11 to 15.

- The fourth package includes Workshops 16 to 20.

Since these packages do not include the lessons and contain a limited number of workshops, they are available at a lower price (250 euros each).

However, we recommend choosing the current full package instead of purchasing parts 1 to 4 separately, as it includes all 20 workshops and exclusive lessons not available on similar platforms, while still being priced lower than competing offerings.

Concrete reinforcement and column beam joint structures in ABAQUS

Abaqus composite modeling of Woven & Unidirectional + RVE method

This training package provides comprehensive basic information and examples on for composite modeling in ABAQUS FEM software in accordance with subsequent packages. The methods of modeling these materials are in two ways: micro and macro, which vary according to the type of material selected and how they are used. Next packages focus on two modeling types professionally.

Implementation of Cohesive by interaction & element based methods in ABAQUS

This package teaches you how to choose the method and apply cohesive modeling for various simple and complex problems. The training package also teaches you how to define the basic geometry of the adhesive elements and how to define the mechanical behavior in elastic and damaged regions in ABAQUS FEM software.