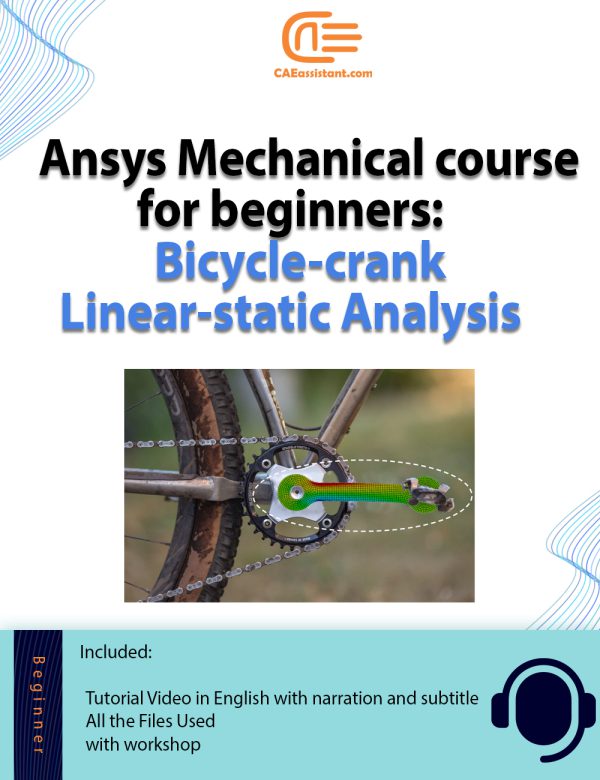

Bicycle Stress Analysis with Ansys Mechanical

This tutorial package offers a comprehensive introduction to linear-static analysis using Ansys Mechanical, focusing on a bicycle stress analysis with the case study which is a bicycle crank made from Aluminum 6061-T6. Whether you're a beginner looking to get started with FEA or an experienced engineer seeking to refine your skills, the package provides a strong foundation in the fundamental techniques needed to succeed in real-world applications.

The tutorial covers the essential steps in finite element analysis (FEA), including the model setup, simulation, and interpretation of results. By leveraging Ansys Mechanical, users will perform a full simulation on the crank geometry to assess stress distribution, deformation, and safety under load conditions. Key topics include mesh generation along with mesh refinement, and the application of boundary conditions. The tutorial guides users through material property assignment, mesh independence, and validation with hand calculations, ensuring accuracy.

Ansys-specific features, including post-processing tools for analyzing total deformation, bending stress, and the factor of safety, are thoroughly demonstrated. This package also highlights the power and efficiency of Ansys Mechanical, emphasizing its user-friendly interface and ability to handle complex simulations with greater precision compared to competitors, making it one of the best-in-class structural analysis FEA software.