Pour.Sh

Fiber-reinforced composites, widely used across various industries, consist of reinforcing fibers embedded in a matrix. During the curing process, this mixture transforms into a stable material. Curing is a critical step to ensure the durability and strength of the final product. In one of our intermediate packages, we used Abaqus to analyze the curing process in composites with linear elastic models. While these models are straightforward and user-friendly, their accuracy is limited because composites exhibit viscoelastic behavior during curing, rather than elastic behavior.

To address this limitation, the current package introduces two more advanced and accurate models for analyzing residual stresses in composites: the viscoelastic model and the path-dependent model. These models offer significantly greater accuracy compared to linear elastic ones but involve added complexity. To simplify this complexity for users, the package begins with a comprehensive overview of the underlying theories and formulations for the viscoelastic and path-dependent models. It then provides detailed guidance on implementing these models using Abaqus subroutines. Finally, workshops are included to demonstrate how the viscoelastic model significantly improves the prediction of residual stresses in composites compared to the elastic models featured in our intermediate package.

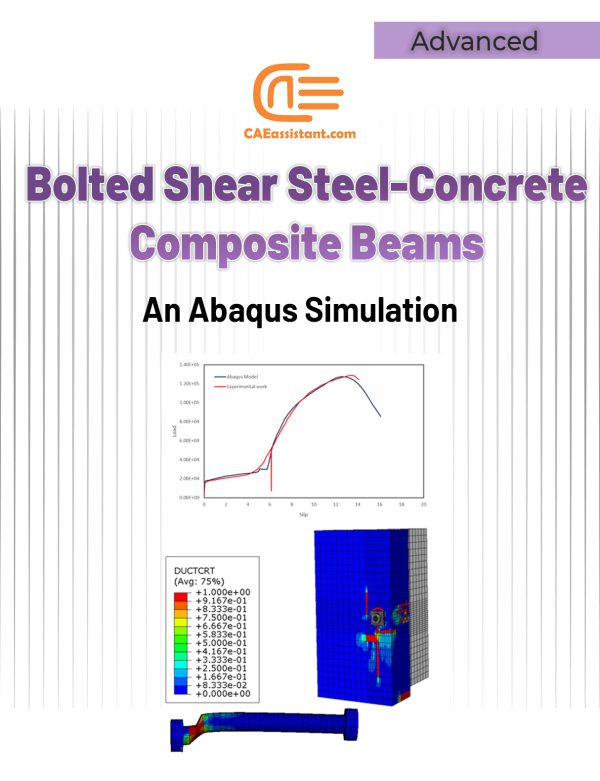

Bolting Steel to Concrete in Composite Beams: ABAQUS Simulation Validated Against Experiments

Composite beams with welded stud shear connectors pose challenges in terms of disassembly and reuse, which impacts their sustainability. By bolting steel to concrete, we can aquire a more sustainable alternative, facilitating easier disassembly and reuse. Engineers value concrete-steel bolted shear connections for their fatigue resistance, secure connections, and ease of disassembly. These factors make them suitable for various applications. Proper design is crucial for these connections to ensure effective shear force transfer and durability. This project provides valuable insights into analyzing bolted concrete-steel connections. It helps utilizing advanced modeling techniques in ABAQUS to simulate their behavior under different loading conditions. By addressing the benefits and challenges of experimental and numerical methods, this project enhances our understanding of composite connections. It enables improved construction practices. To ensure model’s accuracy, we compared the results with the experimental data, for steel concrete bolts. The project specifically helps you to simulate the bahavior of steel concrete composite beams in the following paper.

“A study on structural performance of deconstructable bolted shear connectors in composite beams”

Sloshing Simulation in Cylindrical Water Storage Tanks: An Abaqus Modeling Framework

Liquid storage tanks have many applications in water supply systems and industrial environments. However, seismic damages to these tanks present significant challenges. One of the well-known damages observed in tanks during earthquakes is roof fracture caused by liquid sloshing. Sloshing is a phenomenon that liquid surface moves during seismic events. In this project, we used ABAQUS for the sloshing simulation in ground-supported cylindrical tanks. The tank experiences the acceleration of the El-Centro earthquake. The Abaqus sloshing simulation involves the calculation of Rayleigh damping factors and natural frequencies, employing the ALE meshing technique, and incorporating hourglass controls in Abaqus. We have suggested two ways for the tank sloshing simulation: one involves assigning a low viscosity to the water, and the other is applying Rayleigh damping factors with the assumption of an inviscid fluid. For verification, we modeled a water tank and compared the results with those obtained in the following paper:

“Parametric study on the dynamic behavior of cylindrical ground-supported tanks”

Cold Forming Simulation Using Abaqus CAE | Residual Stress Analysis

Have you ever heard of cold forming process? It refers to the reshaping of metals into desired forms at room temperature. It suits well for parts requiring high precision and a good surface finish. While cold forming offers many advantages, it is important to consider the potential for residual stresses within the material. The residual stresses in cold-formed components can influence their behavior, potentially affecting the quality of the final product. Experimentally measuring these stresses can be challenging. Numerical simulations offer a solution for cold forming residual stress analysis. Among the available numerical methods, Abaqus cold forming simulation has gained significant attention from researchers and practitioners. This training explores Abaqus cold forming analysis in detail. It includes three workshops that cover different steps in the cold forming process. For validation purposes, we have compared the results for the numerical simulation of cold forming with a reference solution for each workshop.