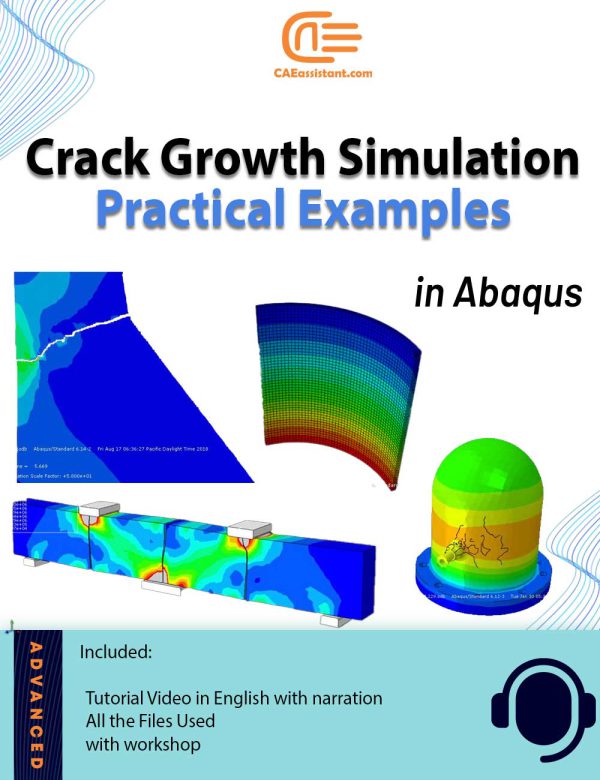

Abaqus Crack Growth | Practical Examples

Original price was: € 299.0.€ 270.0Current price is: € 270.0.Here in this training package, numerous methods of crack propagation modeling, such as the XFEM and H integral and so on, in concrete, steel, dams, bones, and other materials are examined through ten workshops. Each workshop includes all needed files and a step-by-step English videos and is explained from A to Z. For more details on this topic, including explanatory videos covering the necessary formulation and theory in the form of a course, you can check out our full package on Abaqus Crack Growth that we have uploaded on our website. The introduced package includes all the workshops within this package, along with several lessons in video format, to help you master the theory of crack growth simulation in Abaqus.

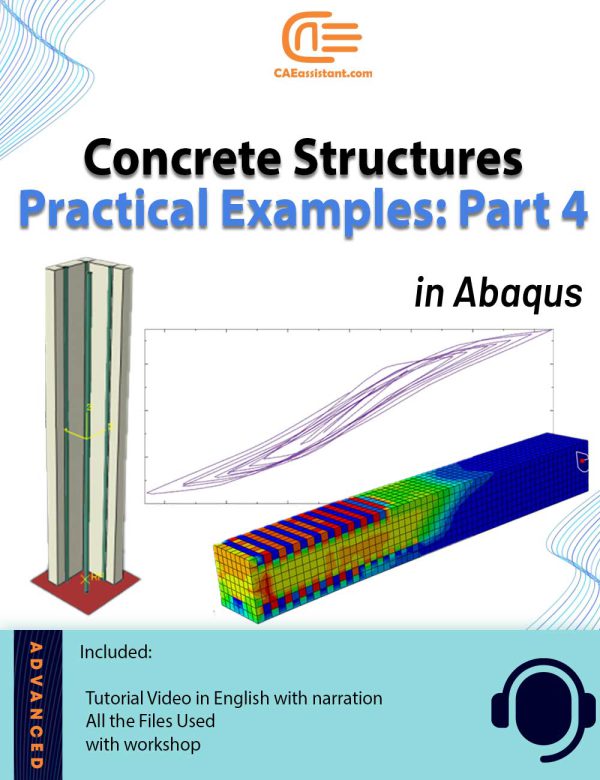

Abaqus Concrete Structure Modeling | Practical Examples (Part 4)

Original price was: € 299.0.€ 250.0Current price is: € 250.0.The package includes 5 workshops on topics such as concrete, beam-column structures, composites, steel rebars, Ultra-High-Performance-Fiber-Reinforcement Concrete columns, CFRP bars, hollow-core square reinforced concrete columns wrapped, damaged concrete beams, High Strength Concrete(HSC),ECC/Concrete Composite Beam-Column Joints, circular concrete-encased concrete-filled steel tube (CFST) stub columns, and etc. Every tutorial includes all needed files and step-by-step English videos and is explained from A to Z. For a more comprehensive lesson and theoretical presentation on the behavior and simulation of concrete structures, check out our full package on concrete structures, which includes detailed learning lessons. However, we have gathered all 20 workshops, along with several additional lessons in video format to help you gain more expertise on the topic, in the introduced package, which you can acquire for just 600 euros.

Abaqus Concrete Structure Modeling | Practical Examples (Part 3)

Original price was: € 299.0.€ 250.0Current price is: € 250.0.The package includes 5 workshops on topics such as concrete, beam-column structures, composites, steel rebars, Ultra-High-Performance-Fiber-Reinforcement Concrete columns, CFRP bars, hollow-core square reinforced concrete columns wrapped, damaged concrete beams, High Strength Concrete(HSC),ECC/Concrete Composite Beam-Column Joints, circular concrete-encased concrete-filled steel tube (CFST) stub columns, and etc. Every tutorial includes all needed files and step-by-step English videos and is explained from A to Z. For a more comprehensive lesson and theoretical presentation on the behavior and simulation of concrete structures, check out our full package on concrete structures, which includes detailed learning lessons. However, we have gathered all 20 workshops, along with several additional lessons in video format to help you gain more expertise on the topic, in the introduced package, which you can acquire for just 600 euros.

Abaqus Concrete Structure Modeling | Practical Examples (Part 2)

Original price was: € 299.0.€ 250.0Current price is: € 250.0.The package includes 5 workshops on topics such as concrete, beam-column structures, steel rebars, Ultra-High-Performance-Fiber-Reinforcement Concrete columns, CFRP bars, hollow-core square reinforced concrete columns wrapped, damaged concrete beams, and etc. Every workshop includes all needed files and step-by-step English videos and is explained from A to Z. For a more comprehensive lesson and theoretical presentation on the behavior and simulation of concrete structures, check out our full package on concrete structures, which includes detailed learning lessons. However, we have gathered all 20 workshops, along with several additional lessons in video format to help you gain more expertise on the topic, in the introduced package, which you can acquire for just 600 euros.

Abaqus Concrete Structure Modeling | Practical Examples (Part 1)

Original price was: € 299.0.€ 230.0Current price is: € 230.0.The package includes 5 workshops on topics such as concrete, beam-column structures, steel rebars, Ultra-High-Performance-Fiber-Reinforcement Concrete columns, CFRP bars, hollow-core square reinforced concrete columns wrapped, damaged concrete beams, and etc. Every workshop includes all needed files and step-by-step English videos and is explained from A to Z. For a more comprehensive lesson and theoretical presentation on the behavior and simulation of concrete structures, check out our full package on concrete structures, which includes detailed learning lessons.

Abaqus steel material and structures | Practical examples

Original price was: € 299.0.€ 270.0Current price is: € 270.0.Here in this package, numerous models of crack steel material structures modeling, such as the shear failure, FLD criterion and different metal damage theories in concrete, steel, dams, and bones are examined through workshops. Every tutorial includes all needed files and step-by-step English videos. For a more comprehensive lesson and theoretical presentation on the behavior and simulation of steel materials and structures, check out our full package on steel structures, which includes detailed learning lessons. The introduced package includes all the workshops within this package, along with several lessons in video format, to help you master the theory of steel structure simulation in Abaqus.

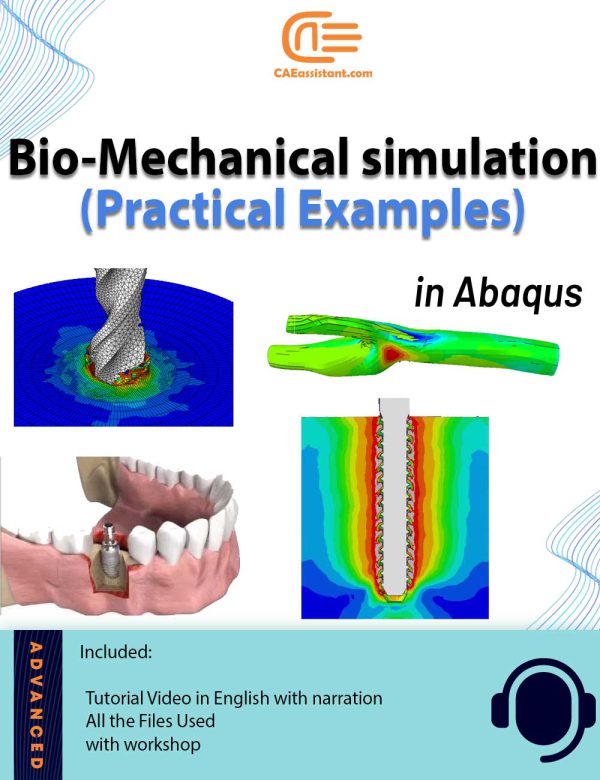

Bio-Mechanical Abaqus simulation | Practical Examples

Original price was: € 299.0.€ 250.0Current price is: € 250.0.This package offers multiple practical examples on biomechanical simulations using Abaqus, covering a range of applications from dental to orthopedic and cardiovascular analyses. The workshops delve into finite element method (FEM) simulations, exploring static loading on human teeth, crack growth in bones under bending, bone drilling, and the behavior of titanium foam implants. Each tutorial emphasizes the importance of precise modeling and meshing techniques, utilizing dynamic explicit procedures, Johnson-Cook material models, and various contact and boundary conditions to simulate realistic biomechanical behaviors. Additionally, the package includes fluid-structure interaction (FSI) simulations for blood flow within coronary vessels, addressing both Newtonian and non-Newtonian models, and demonstrates the integration of computational fluid dynamics (CFD) with structural analysis for enhanced accuracy. For more details on this topic, including explanatory videos covering the necessary formulation and theory in the form of a course, you can check out our full package on Abaqus Bio-mechanical simulation. The introduced package includes all the workshops within this package, along with several lessons in video format, to help you master the theory of biomedical simulation in Abaqus.

ADVANCED ABAQUS SUBROUTINE COURSE | FULL

€ 1958.0Gain mastery over complex engineering challenges in Abaqus through this comprehensive course focusing on advanced subroutines. Enhance the software’s capabilities and create highly tailored simulations.

Explore in-depth functionalities such as UMAT, VUMAT, USDFLD, VUSDFLD, UHARD, VUHARD, UMATHT, and UHYPER to develop unique material models, define hardening characteristics, simulate thermal effects, and manage internal heat generation using HETVAL.

Extend beyond standard features with DLOAD, VDLOAD, DFLUX, and VDFLUX to handle intricate loading scenarios and variations in heat flux. Implement time-dependent loads and boundary conditions with UAMP, VUAMP, DISP, and VDISP.

Take control with UMESHMOTION for mesh movement, and utilize UEL and VUEL for complex element behavior. Address complex friction scenarios with VFRICTION and VFRIC, and manage custom outputs and thermal strains using UVARM, VUVARM, UEXPAN, and VUEXPAN.

This course is designed for proficient Abaqus users aiming to push the boundaries of simulation capabilities and effectively solve real-world engineering challenges beyond conventional methods.

ABAQUS PYTHON COURSE FOR SCRIPTING IN FEM SIMULATION | FULL

€ 958.0The Abaqus Python Course aims to equip engineers and researchers with the skills needed to effectively use Python scripting within Abaqus. Whether you seek to optimize workflows, automate tasks, or maximize the capabilities of Abaqus simulations, this course offers tailored solutions.

Structured comprehensively, the course features dedicated modules covering MDB scripting, output management, and plugin development. Each module includes video lectures, hands-on workshops, and supplementary downloadable resources to enhance understanding. The practical workshops, which cover applications such as simulating a cantilever beam or a 3D truss, are especially valuable for reinforcing theoretical knowledge and practical skills.

COMPREHENSIVE ABAQUS TUTORIAL FOR CIVIL ENGINEERS | FULL

€ 2258.0This comprehensive online course provides a robust skillset for civil engineers. Gain expertise in foundational Abaqus techniques, explore advanced modeling of concrete and soil, master fluid and dam analysis, study tunnel excavation and stability, and learn fastener modeling alongside material damage and fracture techniques (CRC & XFEM). Develop the ability to design intricate structures and analyze diverse materials such as concrete, soil, and steel through advanced simulations. Whether you’re new to Abaqus or an experienced specialist, this course is designed to equip you with the tools needed for real-world civil engineering projects.

Upon completion, you will possess the skills to confidently tackle complex civil engineering challenges using Abaqus, including advanced topics like subroutines and scripting. The course thoroughly covers Abaqus tutorials and finite element methods pertinent to civil engineering.

Brittle Damage in Abaqus | Brittle Cracking Abaqus

€ 240.0Brittle materials, such as ceramics, glass, and concrete, break or fracture easily under stress without extensive deformation. Unlike ductile materials, brittle materials snap suddenly, lacking the flexibility to rearrange their atomic structure under strain. These materials have low tensile strength but strong compressive resistance, making them vulnerable to brittle cracking Abaqus simulations when stretched or pulled.

Understanding brittle material damage is crucial in safety-critical fields like civil engineering, aerospace, and manufacturing, where unexpected fractures can lead to catastrophic failures. Simulations help engineers predict when and how brittle materials may break, guiding safer design choices. Brittle cracking Abaqus can be modeled using various methods, including the Johnson-Holmquist (JH) model, XFEM, and energy-based approaches, each suited to different types of loading conditions.

For dynamic, high-strain applications like impacts, the JH model is effective, particularly in Abaqus/Explicit with specific damage parameters. For general crack modeling, XFEM is versatile, allowing cracks to form naturally without predefined paths. The energy-based method is useful for slow-loading scenarios, defining an energy threshold for fracture initiation. Each method requires careful input of material properties, mesh refinement, and load conditions to reveal potential failure points and improve material performance in real applications.

MASTER COMPOSITE SIMULATION IN ABAQUS

€ 5300.0In this comprehensive online course, you’ll explore composite material modeling using Abaqus software. We’ll guide you through the process of creating precise finite element models for various composites, including unidirectional, woven, and chopped fiber configurations. You’ll also learn to model different types of damage within these composites, including wood composites like balsa wood.

But the course goes further, equipping you to develop custom material models and damage functionalities using subroutines that build on Abaqus’ built-in capabilities, such as 3D continuum, Hashin, and Puck models. Additionally, you’ll delve into simulating curing and fatigue behavior in composites, applying these advanced techniques for more accurate analysis.

ABAQUS PYTHON COURSE FOR SCRIPTING IN FEM SIMULATION

€ 330.0The Abaqus Python Course aims to equip engineers and researchers with the skills needed to effectively use Python scripting within Abaqus. Whether you seek to optimize workflows, automate tasks, or maximize the capabilities of Abaqus simulations, this course offers tailored solutions.

Structured comprehensively, the course features dedicated modules covering MDB scripting, output management, and plugin development. Each module includes video lectures, hands-on workshops, and supplementary downloadable resources to enhance understanding. The practical workshops, which cover applications such as simulating a cantilever beam or a 3D truss, are especially valuable for reinforcing theoretical knowledge and practical skills.

We also have a much more comprehensive course in this field, which includes more lessons and workshops, covering all the necessary topics in greater depth. If you’re interested, you can get it through this link.

ADVANCED ABAQUS SUBROUTINE COURSE

€ 340.0Gain mastery over complex engineering challenges in Abaqus through this comprehensive course focusing on advanced subroutines. Enhance the software’s capabilities and create highly tailored simulations.

Explore in-depth functionalities such as UMAT, USDFLD, DLOAD, DFLUX, and UEL subroutines to simulate complex problems in Abaqus.

This course is designed for proficient Abaqus users aiming to push the boundaries of simulation capabilities and effectively solve real-world engineering challenges beyond conventional methods.

We also have a much more comprehensive course in this field, which includes more lessons and workshops, covering all the necessary topics in greater depth. If you’re interested, you can get it at a discount through this link.

FSI analysis in Abaqus

€ 59.0Fluid-Structure Interaction (FSI) refers to the interaction between a deformable or movable structure and an internal or surrounding fluid flow. FSI simulations are vital for understanding and predicting the behavior of systems where fluid and solid components interact. These simulations enable engineers and researchers to study the effects of fluid forces on structures and vice versa.

FSI simulations are crucial in various fields, including aerospace, civil engineering, biomechanics, and automotive industries. They provide valuable insights into the performance, safety, and reliability of engineering systems. By accurately modeling the complex interactions between fluids and structures, FSI simulations can identify potential issues such as vibrations, instabilities, and structural failures.

In this package, you’ll learn simulating FSI in Abaqus within 3 workshops.

Johnson-Holmquist damage model in Abaqus

€ 220.0The Johnson-Holmquist damage model is used in solid mechanics to simulate the mechanical behavior of damaged brittle materials over a range of strain rates, including ceramics, rocks, and concrete. These materials typically exhibit gradual degradation under load due to the development of microfractures and typically have high compressive strength but low tensile strength. In this package, there are 13 practical examples to teach you how to use this damage model. The workshops are categorized into Ceramic materials, concrete, glass materials, and others.

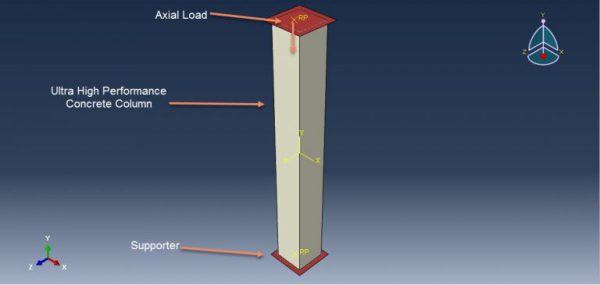

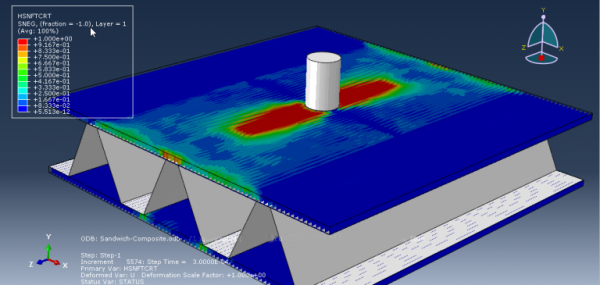

UHPC (Ultra-High Performance Concrete) structures simulation in Abaqus

€ 170.0Ultra-High Performance Concrete structures refer to structures that are constructed using Ultra-High Performance Concrete (UHPC). UHPC is a specialized type of concrete known for its exceptional strength, durability, and resistance to various environmental and loading conditions. UHPC structures can include bridges, high-rise buildings, infrastructure components, architectural elements, and more. Simulating UHPC structures is of significant importance. Through simulation, engineers can analyze and predict the structural behavior and performance of UHPC under different loading conditions. This includes assessing factors such as stress distribution, deformation, and failure mechanisms. By simulating UHPC structures, engineers can optimize the design, evaluate the structural integrity, and ensure the safety and reliability of these complex systems. In this project package, you will learn simulating the UHPC structures with many practical examples.

Here we have a special package for the UHPC Beams

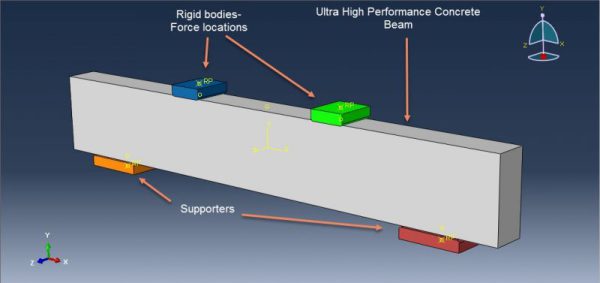

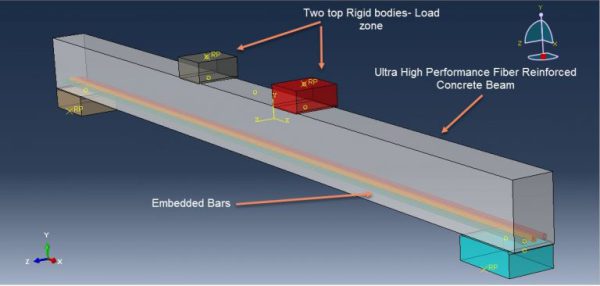

Ultra-High Performance Concrete (UHPC) beams simulation in Abaqus

€ 109.0UHPC (Ultra-High Performance Concrete) is an advanced type of concrete known for its exceptional strength, durability, and resistance. It consists of a dense matrix of fine particles, high-strength aggregates, and a low water-to-cement ratio. UHPC offers superior performance and is used in construction projects where high-strength and durability are required. UHPC (Ultra-High Performance Concrete) beams are advanced structural elements known for their exceptional strength, durability, and resistance. Simulating UHPC beams using software like Abaqus is crucial for evaluating their behavior under different loads and optimizing their design. With Abaqus simulations, engineers can analyze the structural response, stresses, and deformations of UHPC beams, ensuring they meet safety standards and design requirements. In this project package, you will learn how to simulate UHPC beams in 6 practical workshops.

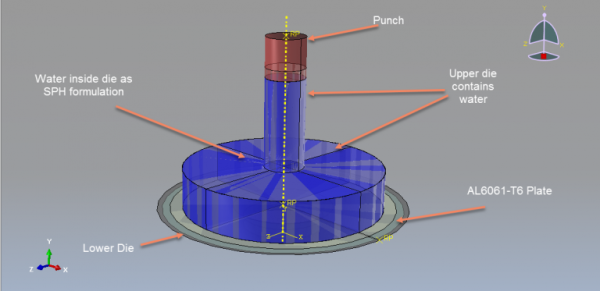

Hydroforming simulation in Abaqus

€ 39.0Notice: This package will be available one week after purchase.

Hydroforming is a metal forming process that allows the shaping of various metals, such as steel, stainless steel, copper, aluminum, and brass. It is a cost-effective and specialized form of die molding that utilizes highly pressurized fluid to shape the metal. Hydroforming can be classified into two main categories: sheet hydroforming and tube hydroforming. Sheet hydroforming uses a single die and a sheet of metal, while tube hydroforming involves expanding metal tubes using two die halves. Hydroforming simulation in Abaqus is a valuable tool for optimizing the hydroforming process. It enables engineers to predict and analyze important factors such as material flow, stress distribution, thinning, and wrinkling during the forming process. By accurately simulating the hydroforming process, engineers can optimize key parameters like fluid pressure, die design, and material properties to achieve the desired shape with minimal defects. In this package, you will learn hydroforming process simulation with the SPH method and using time-pressure curve.

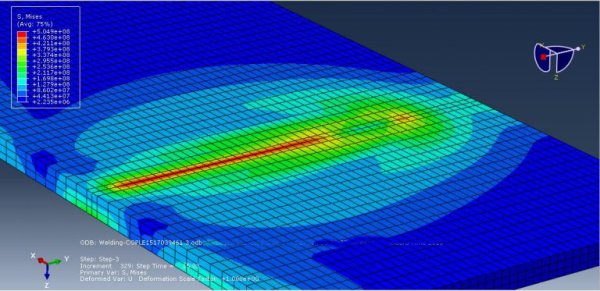

Arc welding simulation in Abaqus

€ 39.0

Arc welding is a fusion process that involves joining metals by applying intense heat, causing them to melt and mix. The resulting metallurgical bond provides strength and integrity to the welded joint. Arc welding is widely used in various industries for fabricating structures and components. Arc welding simulation in Abaqus is essential for optimizing the welding process and ensuring high-quality welds. It allows engineers to predict and analyze factors such as temperature distribution, residual stresses, distortion, and microstructure evolution during welding. By accurately simulating the welding process, parameters like welding speed, heat input, and electrode positioning can be optimized to achieve desired weld characteristics and minimize defects.

Tunnel excavation simulation using TBM in Abaqus

€ 49.0Notice: This package will be available one week after purchase.

Tunnel Boring Machines (TBMs) are advanced construction equipment used to excavate tunnels with efficiency and precision. These massive machines consist of a rotating cutting wheel equipped with disc cutters, which excavate the soil or rock, and a conveyor system that removes the excavated material from the tunnel. TBMs play a crucial role in various industries, including transportation, mining, and underground infrastructure development. TBM simulation is of utmost importance in the planning and execution of tunneling projects. It allows engineers and project managers to evaluate the feasibility of different tunneling methods, optimize the design and operation of TBMs, and predict potential challenges and risks. By simulating the TBM’s performance and behavior under various geological conditions, factors such as ground stability, excavation rates, cutter wear, and potential impacts on surrounding structures can be analyzed and mitigated. In this package, you will learn how to do a TBM simulations by several practical examples.

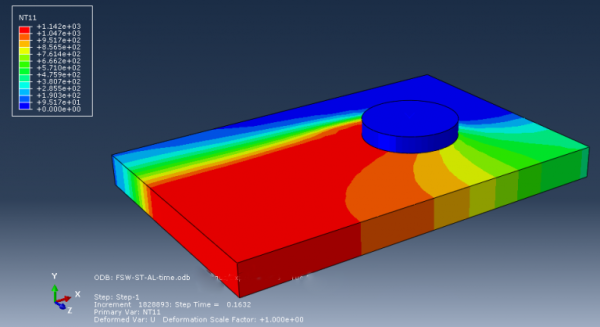

Friction Stir Welding (FSW) Simulation in Abaqus

€ 138.0Friction stir welding (FSW) is a solid-state joining process that utilizes a rotating tool to generate frictional heat, enabling the consolidation of materials without melting. FSW offers numerous benefits and is particularly valuable for welding challenging materials like aluminum alloys. It finds widespread applications in industries such as automotive, aerospace, shipbuilding, and construction, providing enhanced strength, weight reduction, and structural integrity. FSW minimizes distortion, reduces the need for post-weld machining, and eliminates issues related to solidification and cooling. Simulations using Abaqus, a popular finite element analysis software, play a crucial role in optimizing FSW processes. Engineers can investigate process parameters, evaluate weld quality, predict residual stresses and distortions, and optimize weld designs through Abaqus simulations. These simulations enable cost-effective development, improved weld quality, reduced material waste, and enhanced productivity in industrial applications. In this package, you will learn how to simulate FSW simulations in a variety of examples with different methods.

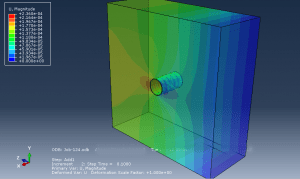

Soil Impact Analysis in Abaqus

€ 68.0Soil impact refers to the interaction between a solid object and the soil, wherein the object collides with or penetrates into the soil. This issue holds great importance across various industries, including civil engineering, geotechnical engineering, construction, and transportation. Understanding soil impact behavior is crucial for designing and assessing the safety and performance of structures and systems subjected to dynamic loads, such as vehicle collisions, pile driving, and projectile impacts. Simulation plays a vital role in studying soil impact. By employing advanced numerical methods and software tools like Abaqus, researchers and engineers can accurately model and analyze the complex interactions between objects and soil. Simulation allows for the investigation of various parameters, such as impact velocity, soil properties, object geometry, and boundary conditions, to assess their influence on the response and behavior of the system. In this package, you will learn how to do soil impact simulations in several practical examples.

Low-Velocity Impact simulation

€ 98.0Low-velocity impact refers to the collision between objects at relatively low speeds. While the impact energy may be lower compared to high-speed impacts, low-velocity impacts can still cause significant damage and deformation. Assessing the effects of low-velocity impact is crucial for various industries to ensure the structural integrity, safety, and performance of their products. For example, in the automotive industry, understanding the response of vehicles to low-velocity impacts is essential for designing crashworthy structures and improving occupant safety. In aerospace, assessing the impact resistance of aircraft components, such as fuselage panels or wings, helps ensure their ability to withstand ground handling incidents or bird strikes. In this package, you will learn how to do low-velocity impact simulations with several practical examples.

UHPFRC (Ultra-High-Performance Fiber Reinforced Concrete) structures in Abaqus

€ 210.0UHPFRC (Ultra-High-Performance Fiber Reinforced Concrete) structures have emerged as a groundbreaking innovation in construction. These structures offer exceptional strength, durability, and performance, revolutionizing the industry. UHPFRC incorporates a precise combination of Portland cement, fine aggregates, admixtures, and steel or synthetic fibers, resulting in an extraordinarily dense and robust composite material. With compressive strengths exceeding 150 MPa, UHPFRC structures exhibit enhanced resistance to cracking, increased load-bearing capacity, and improved durability against environmental factors such as corrosion and freeze-thaw cycles. The superior mechanical properties of UHPFRC enable the design of slimmer and lighter elements, leading to reduced material consumption and more sustainable construction practices. UHPFRC structures find applications in various fields, including bridges, high-rise buildings, marine structures, and precast elements, offering long-term performance and contributing to the advancement of modern construction. In this package, you will learn how to simulate these structures with many practical examples.

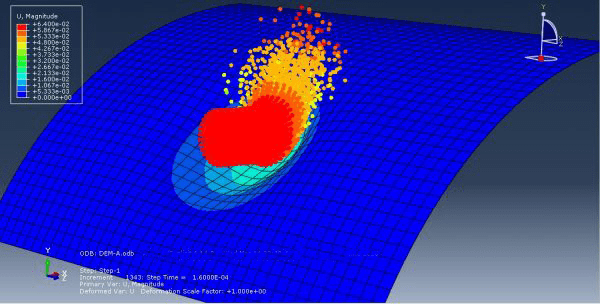

High Velocity Impact Simulation

€ 140.0High-velocity impact refers to the collision between two bodies at extremely high speeds, typically involving projectiles and targets. It is a phenomenon of great interest in various fields, including defense, aerospace, and automotive industries. High-velocity impact simulation in Abaqus is a computational approach used to analyze and predict the behavior of materials and structures subjected to such impacts. Abaqus, a powerful finite element analysis software, enables engineers and researchers to model and simulate the complex interactions between impacting bodies, accurately predicting factors like stress, strain, deformation, and damage. By simulating high-velocity impacts in Abaqus, engineers can gain valuable insights into the performance and integrity of materials and structures, ultimately aiding in the design of safer and more resilient systems. In this package, you will learn how to do these simulations in many practical examples.

Abaqus Bolt Load Tutorial: Simplify Bolt Modeling in Abaqus

€ 109.0Bolts and joints play a vital role in the stability and structural integrity of various engineering structures, including buildings, bridges, and machines. Bolts are used to fasten or connect different components together, providing a means of transferring loads and ensuring the continuity of load paths. Joints connect structural elements, allowing them to move and deform while maintaining their overall stability. Proper design and selection of bolts and joints are crucial to ensuring the safety and durability of the structure. Factors such as the type of load, the materials used, and the environmental conditions must be considered when selecting bolts and joints. Failure to properly design and install bolts and joints can result in catastrophic failure of the structure. In this package, you will learn how to model bolts and joints, simulating the failure of connections and other things with practical examples.

Car part industrial simulation

€ 39.0Car industrial parts are complex and critical components that play a vital role in the operation of a car. Two such parts are the exhaust manifold and the internal combustion engine (IC engine). The exhaust manifold directs hot exhaust gases from the engine’s cylinders into the exhaust system and is typically made of cast iron or stainless steel. The IC engine converts fuel into mechanical energy by burning fuel in a controlled explosion within the engine cylinder. High temperatures and pressures must be considered in the design, and the components must be made of durable materials that can withstand the stresses of constant combustion. Therefore, it is important to know how these parts respond under different loading conditions to have the best design possible. In this package, there are two workshops to help you with this job: Heat transfer analysis in an exhaust manifold and Thermomechanical analysis of an exhaust manifold.

Rock simulation in Abaqus

€ 49.0Rock simulation is essential for evaluating the behaviour of rock masses under various loading conditions, such as earthquakes, landslides, and blasting. It enables engineers and geologists to assess the stability and integrity of rock structures, predicts potential failure modes, and develop effective mitigation strategies. Rock simulation is crucial in the design and planning of mining operations, tunnels, and underground constructions to ensure the safety and longevity of the structures. It also plays a vital role in assessing the seismic hazard of an area and evaluating the potential impact of earthquakes on the built environment. In this package, you will learn how to do an impact simulation on a granite stone using the JH-2 model; also an explosion simulation inside a rock for excavation purposes. You can learn more detail in the description of the workshops.

Piezoelectric simulation in Abaqus

€ 29.0Piezoelectric materials are unique materials that generate an electric charge in response to applied mechanical stress, such as pressure or vibration. They are used in a wide range of applications, including sensors, actuators, and energy harvesting devices. The piezoelectric analysis is the process of studying the mechanical and electrical behavior of piezoelectric materials under various loading conditions. It involves modeling and simulating the response of piezoelectric materials to external stimuli, such as electrical potential or mechanical stress. The importance of piezoelectric analysis lies in its ability to evaluate the performance and optimize the design of piezoelectric devices, which are becoming increasingly important in various industries, including medical, automotive, aerospace, and energy. Piezoelectric analysis can help improve the efficiency, accuracy, and durability of piezoelectric devices, leading to advancements in technology and innovation. In this package you will learn how to model piezoelectric materials in Abaqus.

Fire Analysis in Abaqus

€ 49.0The aim of fire analysis is to evaluate the performance of structures in real fire scenarios and to develop strategies to improve their fire resistance and safety. Fire analysis is commonly used in the design and evaluation of buildings, bridges, and other structures. Fire analysis is the process of simulating the behavior of structures under fire conditions. Fire analysis typically involves two main steps: (i) heat transfer analysis to estimate the propagation of heat in the structure and (ii) structural analysis taking into account the effects of heat and mechanical loads. In this package, you will learn how to do a fire simulation on some structures and parts like concrete beams. You can find more details about how to do this simulation in the description of the workshops.

Tunnel Simulation in Abaqus

€ 39.0A tunnel is an underground or underwater passage for transportation, utility lines, or water pipelines. Tunnels are critical infrastructure, and their safety and reliability are essential for ensuring public safety and the smooth functioning of society. Tunnel simulation involves using computer models to predict the behaviour of tunnels under different types of loading conditions, such as earthquakes, floods, or explosions. These simulations can help engineers and policymakers assess the safety and reliability of tunnels, identify potential failure modes, and develop strategies to mitigate risks. By using advanced simulation techniques, engineers can better understand the complex behavior of tunnels and design more effective and durable structures. Tunnel simulation is an essential tool for ensuring the safety and resilience of tunnels and the infrastructure they support. Some workshops are presented in this package to teach you how to simulate and analyze tunnels in Abaqus; two of these workshops are Damage analysis of an underground box tunnel subjected to surface explosion and Tunnel dynamic analysis subjected to internal blast loading using CEL method.

Eulerian Abaqus and CEL modeling

€ 260.0The Eulerian method is a numerical technique used to analyze fluid mechanics problems. In this approach, the fluid is treated as a fixed grid, where the nodes remain stationary while the fluid flows through them. The Eulerian Abaqus method can be used to analyze fluid-structure interactions, such as fluid impact on structures or the behavior of fluids in containers. To use the Eulerian method in Abaqus, the desired geometry must first be meshed using Eulerian elements. The material behavior of the fluid is then defined using appropriate equations of state. Finally, the boundary conditions and loading are applied, and the system is solved using the appropriate numerical method, such as the finite element method. This package will teach you how to use this method and various practical examples. Also, this package covers several practical examples in Abaqus CEL method.

Cold spray & Shot peening simulation in Abaqus

€ 109.0Cold spray is a process used to deposit materials onto a substrate by accelerating fine powder particles to high velocities using compressed gas. Upon impact with the substrate, the particles undergo rapid plastic deformation, disrupting surface oxide films and promoting bonding between metal surfaces. Unlike thermal spray processes, cold spray avoids thermal degradation and partial oxidation of the coating material, resulting in coatings with low porosity and oxygen content. The process is highly efficient, with deposition efficiencies often exceeding 90%. Shot peening is a metal treatment process that involves bombarding a surface with small, round metallic (usually steel), ceramic, or glass beads at high velocity. This process creates small indentations on the surface, which in turn introduces compressive residual stress into the material. These two processes are different and use for separate purposes but their simulations are the same.

Cold spray is particularly important in applications where thermal degradation or oxidation of the coating material is a concern or where the coating is required to be thick and free from defects. In this package, you will learn how to simulate this process with different methods, such as ALE and SPH, with different materials. For example, Cold spray simulation of steel particles impacts on the Inconel target using ALE method.

Dam simulation in Abaqus

€ 49.0A dam is a large concrete or earthen barrier built across a river or other waterway to create a reservoir for storing water. Dams are critical infrastructure for providing water for irrigation, drinking, and hydroelectric power generation. However, they are also susceptible to damage from natural disasters and human-made threats, such as earthquakes, landslides, and terrorist attacks. Abaqus can predict the behavior of dams under different loading conditions, including earthquakes, floods, and explosions. It also can model the interaction between the dam, water, and soil, making it a comprehensive and powerful tool for dam engineering. In this package, you will learn how to model dams in different conditions, such as dam simulation subjected to earthquakes in interaction with water and soil and dam simulation subjected to an underwater explosion.

Abaqus Explosion

€ 89.0An explosion is a rapid and violent release of energy, usually accompanied by a loud noise, heat, and pressure waves. Explosions can be caused by a variety of factors such as chemical reactions, combustion, nuclear reactions, or mechanical failure. Explosions can cause severe damage to buildings, infrastructure, and human life. To minimize the impact of such incidents, accurate and reliable simulation of explosions is crucial. Explosion simulation involves modeling the complex interactions of blast waves, shock waves, and debris with the surrounding environment. By simulating explosions, engineers and scientists can identify potential risks and develop effective safety measures. In this package, you will learn how to model explosions in different situations with practical examples, such as Air blast explosion simulation inside an RC room and Subsurface explosion simulation on buried steel pipelines.

9 Practical Workshops for SPH in Abaqus💡 | Abaqus SPH Tutorial

€ 109.0Smoothed Particle Hydrodynamics Tutorial: Abaqus SPH (Smoothed Particle Hydrodynamics) is a numerical method used in this software to model fluid-structure interaction problems. SPH in Abaqus is a meshless approach that uses a set of particles to discretize the fluid domain. The Abaqus SPH modeling tutorial is particularly useful for problems with large deformations, fragmentation, and free surface effects.

It can be used in combination with other Abaqus features, such as finite element analysis, to model coupled fluid-structure systems. This Abaqus SPH tutorial, created by CAE Assistant group, can help you understand and apply this method through practical examples, some of which include projectile impact simulation on a cementitious material, TNT explosion simulation inside a rock using the SPH method, bullet movement through a water pipe in Abaqus, and bird strike simulation in Abaqus.

Masonry wall Abaqus simulation

€ 109.0The term masonry can refer to the construction materials brick, stone, etc. An assembly of masonry units, such as concrete blocks, burnt clay bricks, sundried bricks, stone bricks, and natural stones, linked together with mortar or grout is referred to as a masonry wall. It is important to know how these structures behave under different loading conditions, such as explosion, tension, earthquake, etc. to have the best design. In this package, you’ll learn all of that in four workshops: Behavior of a masonry wall under a couple Eulerian-Lagrangian explosion, micro modeling of a masonry wall, modeling of reinforced bricks masonry beams using GFRP reinforcement, earthquake simulation over masonry wall.

Geostatic analysis in Abaqus

€ 89.0Geostatic Relates to the pressure exerted by the earth or similar substance. Total stress at a point due to the combined weight of the soil or rock (solids plus water) and the load on the foundation is called Geostatic stress. Geostatic analysis is used in cases such as earthquakes, designing a dam, analyzing the foundation of a structure, etc. In this package, three workshops are presented to learn the Geostatic analysis: The first workshop analyzes a water column broke under the weight of gravity, the second workshop simulates an earthquake load over a gravity dam in contact with water and dirt, the last workshop models cylindrical tank’s water sloshing phenomenon.

Mohr-coulomb usage in Abaqus

€ 89.0A mathematical model called the Mohr-Coulomb theory describes how brittle materials, such as concrete or rubble piles, react to both shear stress and normal stress. This rule is followed by the majority of traditional engineered materials in at least some of their shear failure envelope. In this package, you will learn how to use this theory in four practical examples: Analysis of surface explosion damage to an underground box tube in ABAQUS, dynamic analysis of a tunnel in soil subjected to internal blast loading, An internal explosion-related numerical simulation of the behavior of a pipeline’s damage mechanics, and for cases utilizing crashworthiness, simulate an Eulerian method to soil impact analysis.

Steel Damage types in Abaqus

€ 119.0Steel materials are everywhere and used in almost every structure, from the building you live into the car you drive. Therefore, it’s essential to know the steel properties and behaviors when it’s under different loading conditions such as compression, tension, cyclic load, impact, etc. moreover, knowing the damage mechanism of steel structures helps to have better designing. In this tutorial package, you will learn how to analyze steel structures when they’re damaged with practical examples. There are five workshops here that could teach you the damage mechanism of steel structures: Simulation of bolt failure on the steal beam, reinforced concrete containment damage mechanism under internal explosion, tensile test of a steel specimen, impact on ceramic plate reinforced by steel plate, water jet cutting simulation.

Water Simulation in Abaqus

€ 149.0Water is the primary component of the Earth’s hydrosphere and the fluids of all known living things. Therefore, we build dams to store the water and transfer it through piping systems to use it for daily activities and produce energy. In industries, we use it as a cooler, solvent, hydroforming, cutting, etc. In this package, there are nine practical examples, such as the ones mentioned to teach you how to simulate water in Abaqus. These examples are explosions in the depth of the water, gravity dam simulation subjected to the underwater explosion, ball impact to the water, water jet cutting, etc.

Acoustic simulation in Abaqus

€ 109.0The study of mechanical waves in gases, liquids, and solids, including issues like vibration, sound, ultrasound, and infrasound, is the focus of the physics subfield of acoustics. A shock wave is a sort of disturbance that propagates across a medium faster than the local speed of sound. In industry, we use acoustic loading in cases such as hydraulic forming, SONAR, seismology, acoustic emission, vibration analysis, engine testing, etc. In this package, you will learn how to model acoustic loadings and shock loadings in four workshops: Deformation behavior of a stiffened panel subjected to underwater shock loading, Acoustic method-based numerical simulation of the electro-hydraulic forming process, Failure modes of concrete gravity dams simulation exposed to an underwater explosion, and Simulation of hull Coupled acoustic-structural response subjected to an underwater explosion.

Foam simulation in Abaqus

€ 159.0Foam is a type of expanded plastic and rubber produced by forcing gas bubbles into a polymer material. It is a permeating, lightweight material. Along with corrugated packaging, foam fabric can protect goods during transportation. Foams, a novel family of ultra-light materials, have the capacity to undergo significant deformation at practically constant plateau stress, which allows them to absorb a significant amount of kinetic energy. In this tutorial package, you will learn how to analyze sandwich panels with an interior layer of foam, Foam-Filled Aluminum Tubes subjected to compressive loads, simulation of a reinforced foamed concrete beam, concrete-titanium foam panel explosion, etc. All of these cool practical examples with their complete tutorial videos are in this package which you can read their description below.

Earthquake simulation in Abaqus

€ 89.0It is known that an earthquake is a disastrous event that can cause great damage to buildings, structures, and even people. So it’s essential to know how a structure will behave when subjected to an earthquake. Therefore engineers must take into account the possibility of an earthquake when designing a structure. With finite element analyses, engineers can predict the behaviour of structures under earthquake loading. With this method, they can determine the best way to design a structure to withstand an earthquake. In this package, you can learn how to do earthquake simulation in Abaqus to have the best design for your structure to save human lives. Three practical examples are presented to you to start simulating earthquakes: “simulating an earthquake over a gravity dam in contact with water and soil”, “simulating an earthquake load over a water-filled tank”, “Abaqus-Micro model simulation of seismic load over masonry wall (concrete brick)”.