Forming

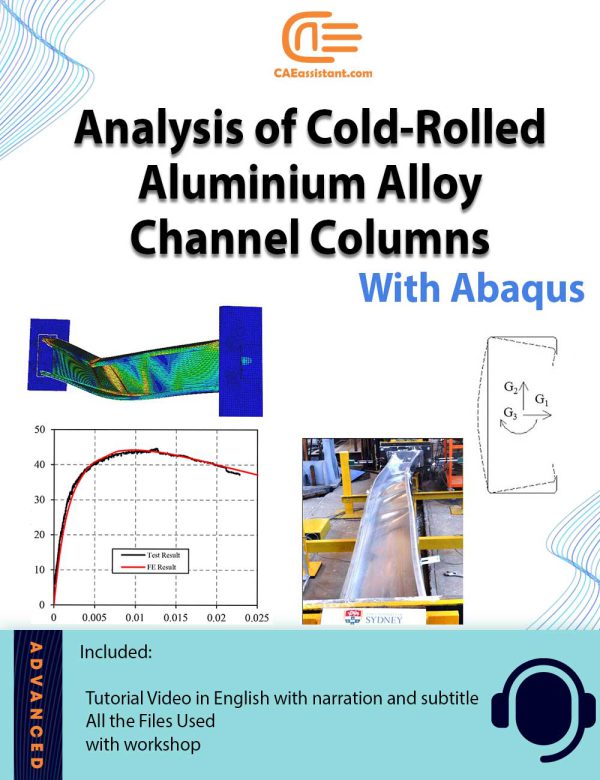

Analysis of Cold Rolled Aluminium Alloy Channel Columns With Abaqus CAE

Cold rolled aluminium alloy channel sections are manufactured using a cold-rolling method that is faster and less energy-intensive than traditional methods. It reduces labor, material costs, and construction time. These sections are ideal for green and sustainable buildings due to their recyclability, lightweight nature, and corrosion resistance, making them suitable for various structural applications. This project guides you in using Abaqus for numerical analysis of cold rolled aluminium alloy channel columns to ensure their safety and performance under various loads. This enables you to achieve accurate designs for these members, preventing structural failures, inefficiencies, and increased costs.

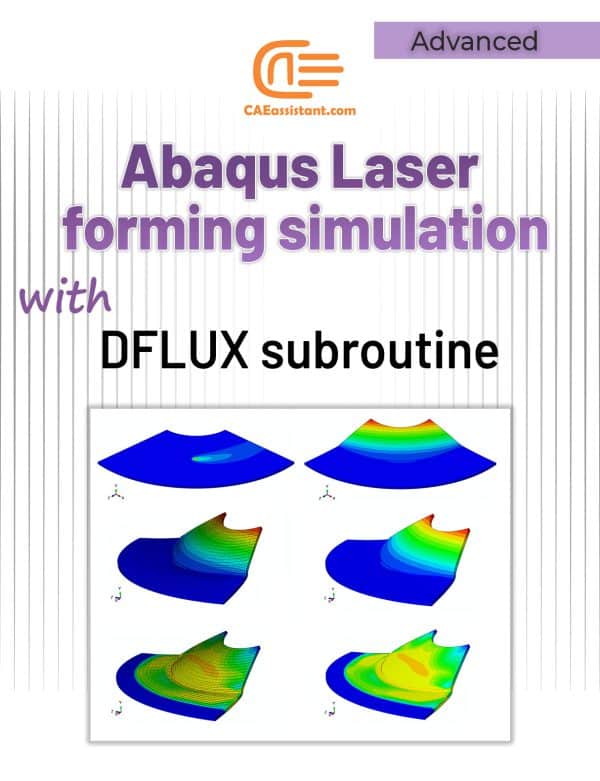

Laser Forming Process Tutorial in Abaqus

The laser forming process is performed by applying thermal stresses to the workpiece surface by heating the surface with a laser beam. These internal stresses induce plastic strains in the part resulting in local elastic-plastic deformation (Laser-induced plastic deformation). In this laser forming simulation tutorial the DFLUX subroutine is used to apply heat flux (Gaussian heat distribution) dependent on location and time in finite element simulation. For example, the linear heating processes of laser forming and welding (with a slight simplification) can be simulated by this subroutine. In the linear heating process, by applying heat flux to the surface of a sheet, a thermal gradient is created in its thickness. This thermal gradient causes permanent deformation of the sheet. To simulate the laser forming process, it is necessary to apply a time and location-dependent heat flux to the sheet. In this type of loading, a heat flux is applied on the plate, which is defined using the DFLUX subroutine, including the laser power, movement speed, beam diameter, absorption coefficient, and laser movement path according to the designed experiments (Laser forming process parameters). To verify this Abaqus laser forming simulation, the simulation results and experimental results of sheet deformation (U) are compared. The displacement of the sheet in the simulation is in good agreement with the experimental results.

Cold Forming Simulation Using Abaqus CAE | Residual Stress Analysis

Have you ever heard of cold forming process? It refers to the reshaping of metals into desired forms at room temperature. It suits well for parts requiring high precision and a good surface finish. While cold forming offers many advantages, it is important to consider the potential for residual stresses within the material. The residual stresses in cold-formed components can influence their behavior, potentially affecting the quality of the final product. Experimentally measuring these stresses can be challenging. Numerical simulations offer a solution for cold forming residual stress analysis. Among the available numerical methods, Abaqus cold forming simulation has gained significant attention from researchers and practitioners. This training explores Abaqus cold forming analysis in detail. It includes three workshops that cover different steps in the cold forming process. For validation purposes, we have compared the results for the numerical simulation of cold forming with a reference solution for each workshop.

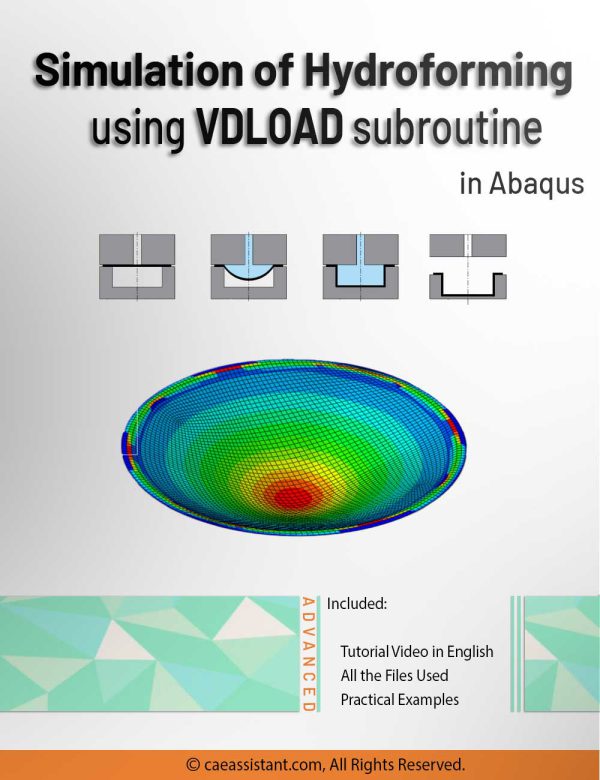

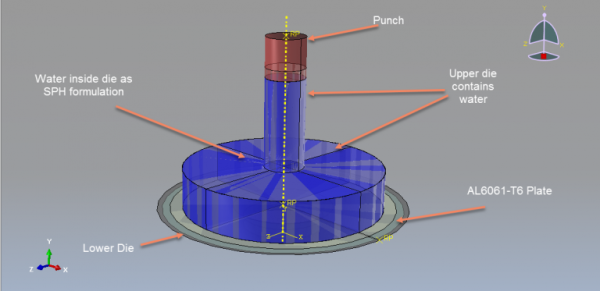

Hydroforming process simulation using VDLOAD subroutine in Abaqus

Dive into the intricacies of hydroforming simulation in Abaqus alongside the VDLOAD subroutine with our comprehensive guide. This tutorial delves into the essence of the Abaqus hydroforming simulation, unraveling the nuances of the hydroforming process simulation. Hydroforming, a specialized metal shaping technique applicable to diverse materials like steel, copper, and aluminum, is explored in depth.

In the workshop component, we specifically focus on advanced hydroforming simulation using the VDLOAD subroutine, highlighting its pivotal role in specifying fluid pressure on sheet metal forming. Learn how to apply the Functional Fluid Pressure Loading feature for precise control over fluid pressure dynamics. Additionally, explore the Smooth Amplitude option for defining part displacement seamlessly, without introducing dynamic changes during problem-solving.

Conclude your exploration with a comparative analysis of simulation outcomes, dissecting scenarios with and without fluid pressure using Abaqus hydroforming simulation. Engage in discussions on subroutine writing, delving into the intricacies of incorporating Fluid Pressure Loading into your simulations. This guide offers a natural progression through hydroforming and VDLOAD, providing valuable insights for efficient and accurate simulations.

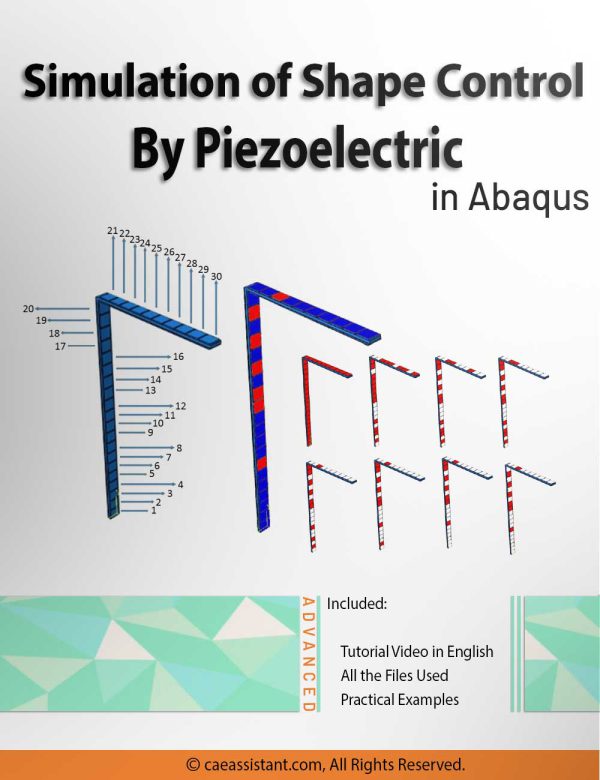

Simulation of shape control by piezoelectric in Abaqus

Piezoelectricity refers to the accumulation of electric charge in certain solid materials due to mechanical pressure. This phenomenon, known as the piezoelectric effect, is reversible. Some materials exhibit direct piezoelectricity, which involves the internal production of electric charge through the application of mechanical force, while others exhibit the inverse piezoelectric effect.

By harnessing piezoelectrics, it becomes possible to control the geometrical changes of objects in response to external forces. However, it is important to note that utilizing this property in all situations would not be cost-effective. Therefore, it is more practical to use piezoelectric structures selectively, specifically in special applications. One approach to determining the optimal placement of piezoelectric elements for controlling the geometric shape of various objects under internal or external forces involves utilizing the Abaqus and MATLAB software linkage. This software combination, along with optimization algorithms such as the particle swarm optimization algorithm, can be employed to achieve the desired objectives. By leveraging these tools and data, the primary goal of controlling object shape can be successfully accomplished.

In this training package, you will learn about piezoelectric and piezoelectric modeling in Abaqus, the particle swarm optimization algorithm, linking Abaqus and MATLAB, and how to use these tools for shape control.

Notice: Software files and A full PDF guideline (Problem description, theory, ...) are available; Videos are coming soon.

Hydroforming simulation in Abaqus

Notice: This package will be available one week after purchase.

Hydroforming is a metal forming process that allows the shaping of various metals, such as steel, stainless steel, copper, aluminum, and brass. It is a cost-effective and specialized form of die molding that utilizes highly pressurized fluid to shape the metal. Hydroforming can be classified into two main categories: sheet hydroforming and tube hydroforming. Sheet hydroforming uses a single die and a sheet of metal, while tube hydroforming involves expanding metal tubes using two die halves. Hydroforming simulation in Abaqus is a valuable tool for optimizing the hydroforming process. It enables engineers to predict and analyze important factors such as material flow, stress distribution, thinning, and wrinkling during the forming process. By accurately simulating the hydroforming process, engineers can optimize key parameters like fluid pressure, die design, and material properties to achieve the desired shape with minimal defects. In this package, you will learn hydroforming process simulation with the SPH method and using time-pressure curve.

Simulation of forming in ABAQUS

The forming in Abaqus is one of the most important manufacturing processes that can be used for producing different components. In this package, you will learn how to simulate the forming process in Abaqus and you can see the behavior of the material along this process. This package contains some examples that cover rolling, hydroforming, extrusion, ECAP, Cold forging, and drilling processes.

Notice: You can access this package 3 days after purchase.

Module by module Abaqus Training

If you are new to Abaqus software and the topic of finite element analysis, you definitely need to get acquainted with the user interface of this software and the general features of each module.

In this software, we perform different simulation steps in the following different modules and at the end, we receive the analysis results from the software solver.

In this package, you will learn how to work with the software in each module and perform your simulation in each module properly.