Scripting

ABAQUS PYTHON COURSE FOR SCRIPTING IN FEM SIMULATION

The Abaqus Python Course aims to equip engineers and researchers with the skills needed to effectively use Python scripting within Abaqus. Whether you seek to optimize workflows, automate tasks, or maximize the capabilities of Abaqus simulations, this course offers tailored solutions.

Structured comprehensively, the course features dedicated modules covering MDB scripting, output management, and plugin development. Each module includes video lectures, hands-on workshops, and supplementary downloadable resources to enhance understanding. The practical workshops, which cover applications such as simulating a cantilever beam or a 3D truss, are especially valuable for reinforcing theoretical knowledge and practical skills.

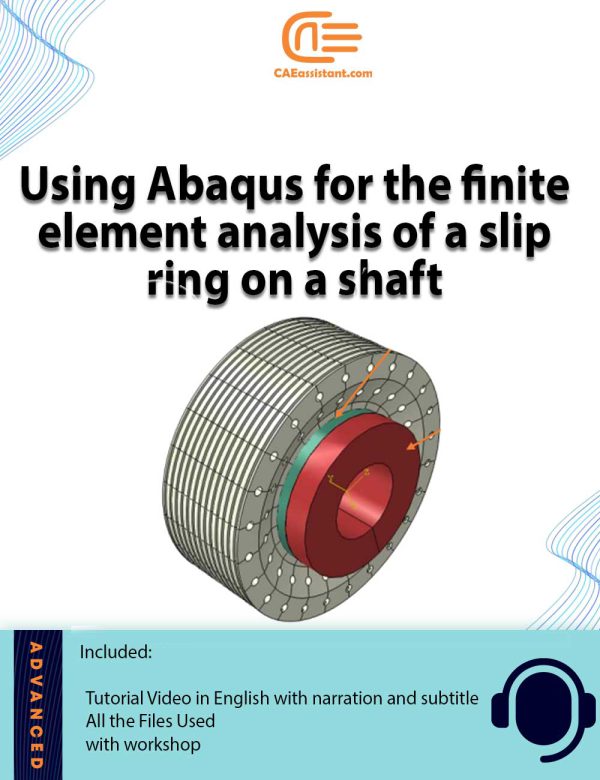

Abaqus shaft slip ring simulation | Using Python scripts for parametric analysis

The shaft slip ring is a crucial component enabling the transfer of power and signals in rotating systems. So, this tutorial delves into the intricate Abaqus shaft slip ring analysis. It focuses primarily on the mechanical aspects, offering insights into displacement, stress fields, and strains through the shaft analysis Abaqus model. The tutorial utilizes parametric modeling and Python scripting for the Abaqus shaft slip ring simulation. So, it enables you to optimize geometric parameters, material properties, and loading conditions, enhancing efficiency in modeling processes. It addresses complexities such as creep behavior and material interactions, providing a comprehensive approach tailored for realistic simulations. The tutorial meets various project requirements, supporting them with practical examples and adaptable simulation files.

Note: The Abaqus file will be delivered upon purchase, and the video will become available one week after payment.

0

days

00

hr

00

min

00

sc

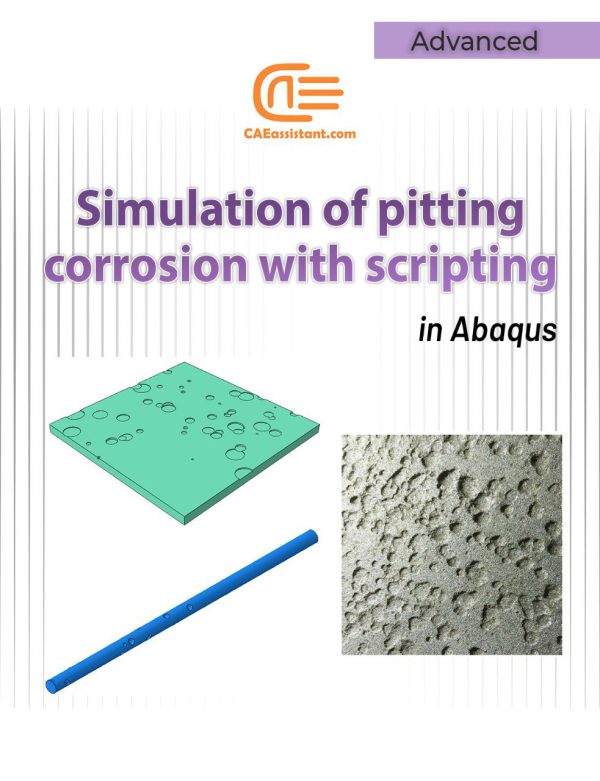

Simulation of Pitting Corrosion Mechanism with Scripting in Abaqus

Pitting corrosion is a form of extremely localized corrosion that leads to the random creation of small holes in metal. It can occur with random sizes and distributions, typically modeled as conical or cylindrical shapes. This type of corrosion reduces the strength of structures and increases stress concentration. So, it can lead to various destructive effects such as pipes bursting and reduced resistance to internal pressure. By pitting corrosion simulation, you can assess how corrosion affects stress, vibration, heat transfer, and other factors. This is crucial for enhancing the durability and safety of structures such as storage tanks, shafts, tubes, pipes, and other industrial components. This tutorial includes two scripts for pitting corrosion analysis. They help you to conduct Abaqus pitting corrosion simulation for different examples including a simple plate and a shaft.

0

days

00

hr

00

min

00

sc

Script to transfer load from CFD to structural model in Abaqus

FEA offers various loading types, such as force, pressure, and temperature, which can be applied to different parts of an object, such as points, surfaces, edges, nodes, and elements. Therefore, applying accurate loading conditions on these features is necessary for reliable simulation results and the safe design of structures. Sometimes, the loading conditions are obtained by another analysis, such as CFD, and need to be transferred and applied to the structural model for the structural analysis; during this transfer, the loads might not be appropriately applied to the model, especially when the loads are complicated like the pressure profile of a space rocket. So in this package, a Python script is presented to solve this issue and transfer the loads properly to the structural model.

Python Scripting in Abaqus Full Tutorial

If you are a graduate or Ph.D. student, if you are a university professor or an expert engineer in the industry who deals with simulation software, you are definitely familiar with the limitations of this software in defining the material properties, loading or meshing, interaction properties, etc. You have certainly tried to define the properties of materials or geometry based on available features in the software, but sometimes you need to code on your own to define some complex issues.

Now, here is your solution. This full tutorial package includes 3 training packages that help you to learn how to use Python scripting in Abaqus software. This is likewise the most comprehensive tutorial for the script, and it is appropriate for beginners to advanced users.

Python scripting in ABAQUS Part 2

This training package includes workshops that help you to learn about advanced Python scripting in Abaqus software. This is the most comprehensive tutorial containing advanced ways to write the Abaqus script. The subjects such as interrogation in output databases, Kernel plug-ins, RSG plug-ins, etc., are covered in this tutorial.

Python scripting in ABAQUS Part1

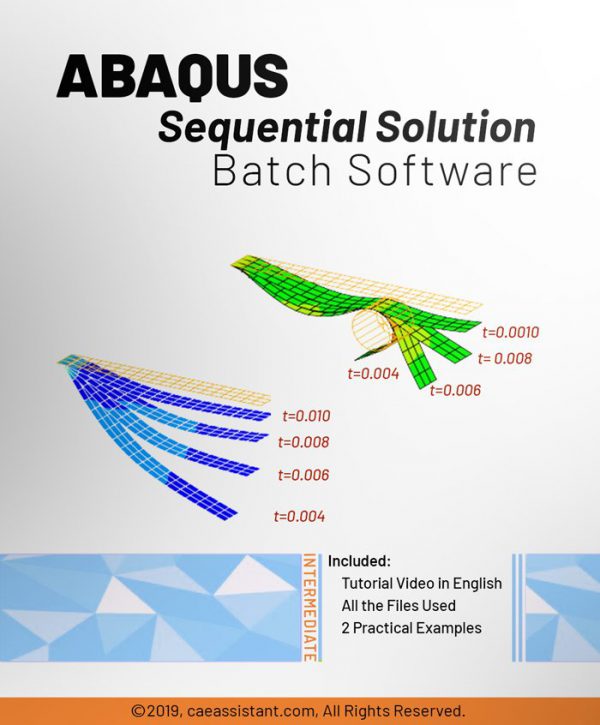

This training package includes workshops that help you to learn how to use Python scripting in Abaqus software. This is likewise the most comprehensive tutorial for the script, and it is appropriate for beginners to advanced users. The subjects such as parameterization, optimization, sequential running and etc., are covered in this tutorial.

This package presents a technique to bridge the gap between ABAQUS and MATLAB. It is especially useful when you want to set up an automated optimization loop between these two PC applications. The key points for linking are presented in a case study that is about topology optimization of an end-fixed 2D plate by the BESO approach.

0

days

00

hr

00

min

00

sc