Essential Abaqus Training for Engineers: From Basics to Advanced Techniques

This beginner-friendly Abaqus course offers a complete guide to mastering finite element simulations through step-by-step tutorials and practical workshops. It covers essential topics such as Abaqus/CAE basics, finite element theory, composite material simulation, and thermal and impact analyses. Advanced sections delve into UMAT/VUMAT subroutines and Python scripting, equipping users with skills to automate workflows and solve complex engineering problems. Workshops include real-world examples like cantilever beams, forming processes, and fracture simulations. Perfect for engineering students and professionals, this course helps you build a solid foundation in Abaqus and expand your simulation capabilities.

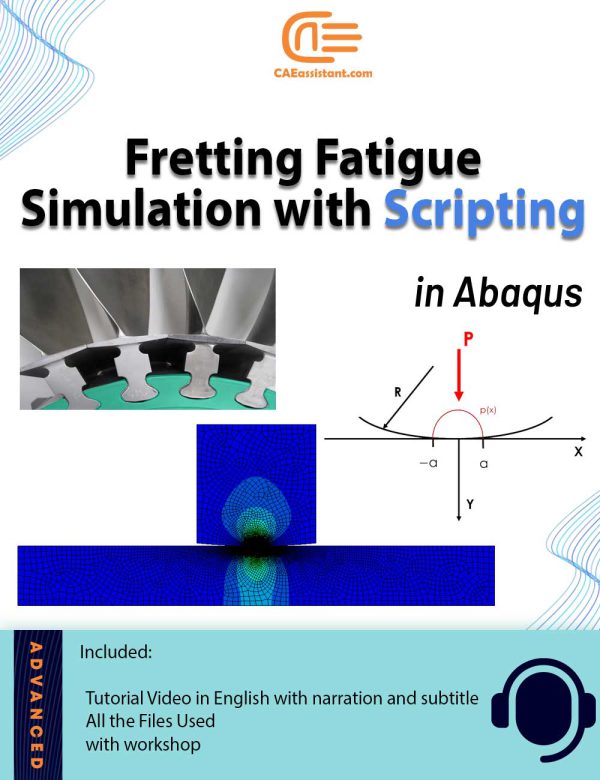

Fretting Fatigue Failure Simulation with Scripting in Abaqus

This Package offers a comprehensive tutorial on using Abaqus for Fretting Fatigue Failure Simulation. To do so, it combines theoretical knowledge with practical application in Finite Element Method (FEM) simulations. The package guides users through both detailed lessons and interactive workshops. In fact, it focuses on developing 2D Fretting-Fatigue models in Abaqus with three core areas: model creation with exclusively designed meshing methodologies, the development of custom Field Outputs for detailed analysis, and automated parameter selection and post-processing through Python scripting.

Throughout the tutorial, participants master critical aspects of Fretting Fatigue Failure simulation. It includes basics from mesh refinement techniques and step control optimization to complete workflow automation. The program distinctively integrates command prompt operations for extracting Field Outputs and modifying simulation parameters. For example, we can refer to the Coefficient of Friction (CoF). Users gain practical experience in creating robust models while understanding the fundamental principles of the Fretting Fatigue Failure phenomenon.

Upon completion, participants will acquire the skills to independently develop and analyze Fretting Fatigue failure simulations. Moreover, they can automate post-processing tasks, and implement custom analysis parameters for precise fatigue prediction in mechanical systems.

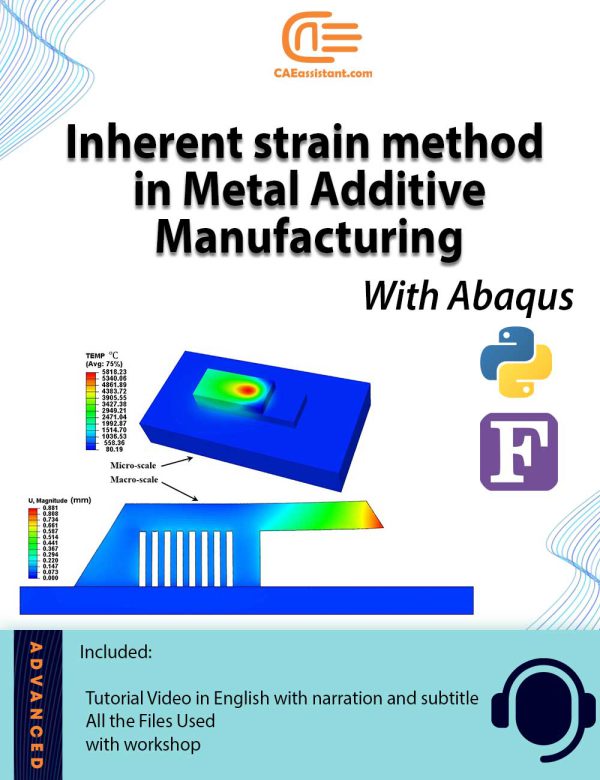

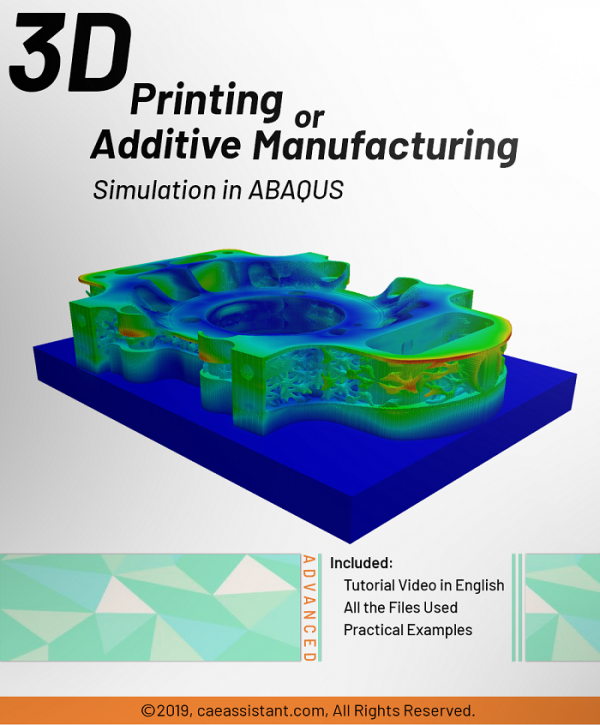

Inherent strain method in Metal Additive Manufacturing simulation (using subroutines and Python scripting in Abaqus)

This tutorial package focuses on the Inherent Strain method in Abaqus, an efficient numerical approach to simulate Laser Powder Bed Fusion (LPBF) in metal additive manufacturing.

It addresses the high computational cost of detailed thermo-mechanical LPBF simulations by utilizing an agglomeration approach to transfer inherent strain from micro to macro-scale models. Through theoretical explanations and practical workshops, users will learn to implement the ISM method, including Dflux and USDFLD subroutine coding and Python scripting, for improved LPBF process simulation control. This product does not utilize AM plugins, making it ideal for users who prioritize transparency in calculation methods and flexibility in variable modification for similar models.Simulation of Inertia Welding process in Abaqus | Fortran Subroutines and Python Scripts

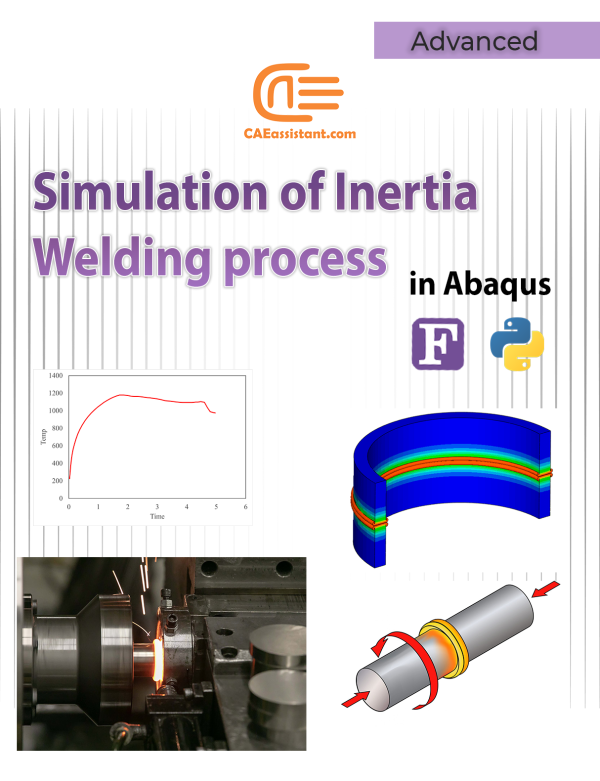

This tutorial provides a comprehensive guide to simulating inertia friction welding process using Abaqus, a powerful Finite Element Analysis (FEA) tool. Inertia welding process, commonly used in aerospace, automotive, and manufacturing industries, is a solid-state process that joins metal parts using kinetic energy. The simulation focuses on modeling frictional heating, temperature distribution, and material behavior through integrated Fortran subroutines and Python scripts. These scripts automate tasks such as remeshing and model generation, enhancing efficiency. Key steps include defining axisymmetric models, applying material properties, and simulating thermal and mechanical interactions during the inertia welding process. This guide equips researchers and engineers with a robust methodology for inertia welding simulation, to optimize welding parameters and analyze weld quality.

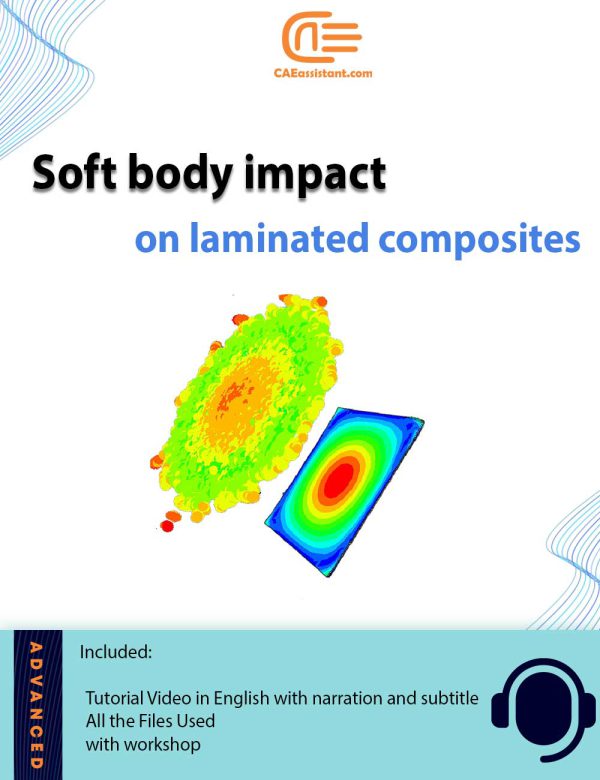

A Comprehensive Tutorial for Soft Body Impact Composites Simulation

This comprehensive tutorial package focuses on simulating soft body impact composites on laminated composite materials using the Finite Element Method (FEM) in Abaqus. The course covers key topics such as soft body modeling, metal material modeling, composite material modeling, composite to composite interface modeling, metal to composite interface modeling, interaction between soft bodies and FML, interaction between layers, and Python scripting for parametric studies. Users will explore different material models and learn about impact failure mechanisms, including matrix failure, fiber failure, shear failure, and delamination. The course is structured into lessons that cover theoretical aspects, followed by hands-on workshops to model soft body impacts, apply material properties, and analyze post-processing results such as forces, displacements, and energy dissipation. It also includes an advanced section on Python scripting, enabling users to automate parametric studies for complex simulations. This package is ideal for engineers, researchers, and students looking to deepen their understanding of soft body impact phenomena and composite material behavior.

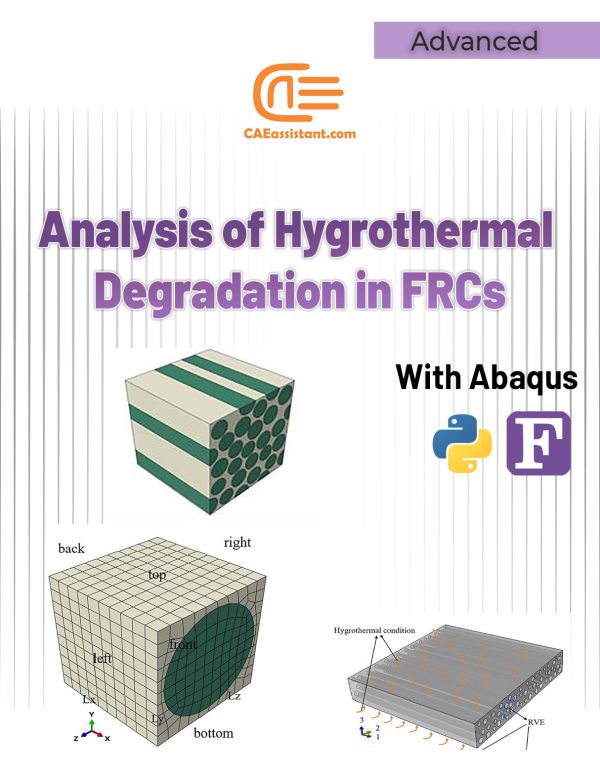

Hygrothermal effects on composite materials | Degradation in Fiber Reinforced Composites Abaqus Simulation: Python & Subroutines

In this tutorial, we explore the hygrothermal degradation composites using ABAQUS, a powerful tool for parallel finite element analysis. Industries like aerospace, marine, and automotive heavily rely on these composites due to their high strength-to-weight ratio and versatility. However, long-term exposure to moisture and temperature can degrade their mechanical properties, making an analysis of hygrothermal effects on composite materials essential for ensuring durability.

ABAQUS allows precise modeling of these environmental conditions through Python scripts and Fortran subroutines. This combination enables efficient simulations across multiple processors, offering insights into key elastic properties, such as Young’s modulus and shear modulus, under varying conditions. By leveraging the ABAQUS Python Scripting Micro Modeling (APSMM) algorithm and custom subroutines, engineers can predict the long-term performance of fiber-reinforced composites, optimizing design and enhancing material performance in critical sectors like aerospace and marine.

In the present Abaqus tutorial for parallel finite element analysis, we have presented the software skills that a person needs when he wants to perform a parallel finite element analysis such as a micro-macro scale analysis. The Abaqus tutorial for parallel finite element analysis covers all you need to write a python scripting code for noGUI environment and also Fortran code for the subroutine environment of Abaqus to execute a parallel finite element analysis via Abaqus software. You can download the syllabus of this package here.

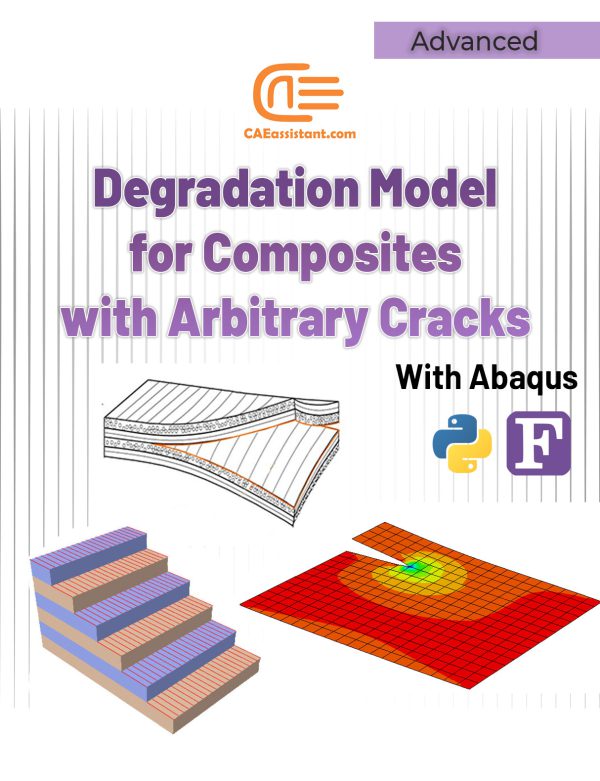

An Efficient Stiffness Degradation Composites Model with Arbitrary Cracks | An Abaqus Simulation

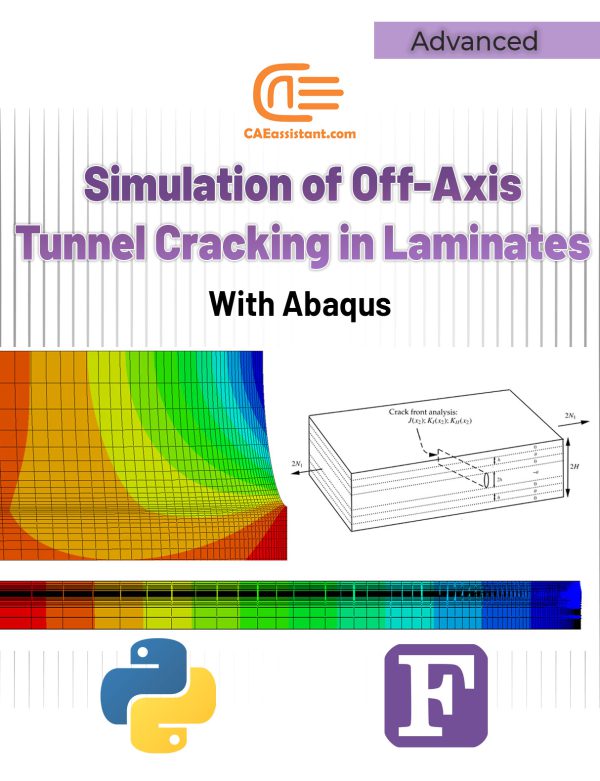

Advanced Finite Element Analysis of Off-Axis Tunnel Cracking Laminates

Abaqus shaft slip ring simulation | Using Python scripts for parametric analysis

Simulation of Pitting Corrosion Mechanism with Scripting in Abaqus

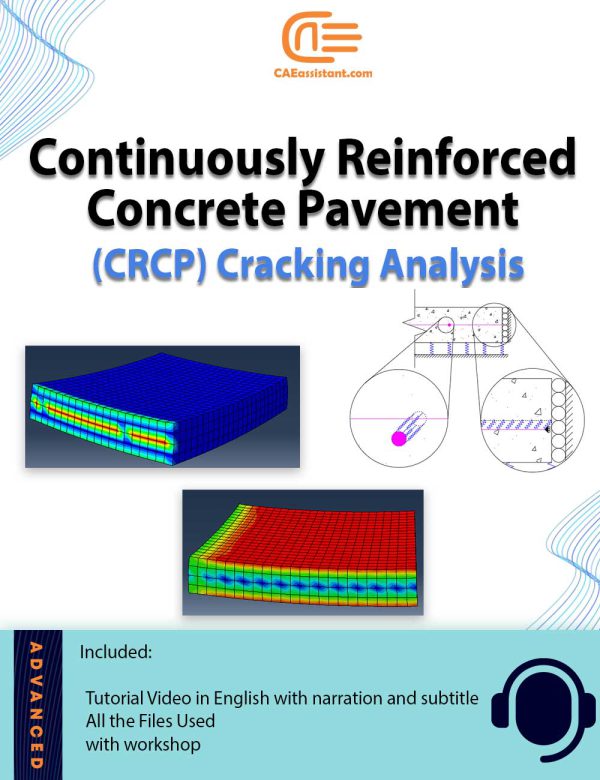

continuously reinforced concrete pavement (CRCP) Analysis

|

The increasing adoption of continuously reinforced concrete pavement (CRCP) in highway pavement design is driven by its demonstrated superior performance. Critical to evaluating the long-term effectiveness of CRCP is the understanding of early-age cracks, which has garnered significant interest from highway departments. This Abaqus Continuously reinforced concrete pavement modeling project aims to establish precise design parameters for CRCP and analyze the formation of crack patterns. By accounting for stress factors such as environmental conditions and CRCP shrinkage modeling, the project offers valuable insights into predicting the likelihood of crack initiation and propagation within the concrete slab. These insights are instrumental in enhancing the durability and performance of CRCP structures, thus advancing the efficiency and effectiveness of highway infrastructure. |