Computational Predictions for Predicting the Performance of Structure

This package focuses on developing and applying predictive models for the structural analysis of steel and concrete components subjected to fire and subsequent earthquake loading. To accurately simulate the complex behavior of these structures, finite element analysis (FEA) using ABAQUS is employed. The Taguchi method optimizes the number of samples needed for FE analysis, and this method is used with SPSS after explanation its concept. However, due to the computational demands of FEA, various machine learning techniques, including regression models, Gene Expression Programming (GEP), Adaptive Network-Based Fuzzy Inference Systems (ANFIS), and ensemble methods, are explored as surrogate models. These models are trained on large datasets of FEA results to predict structural responses efficiently. The performance of these models is evaluated using statistical metrics such as RMSE, NMSE, and coefficient of determination.

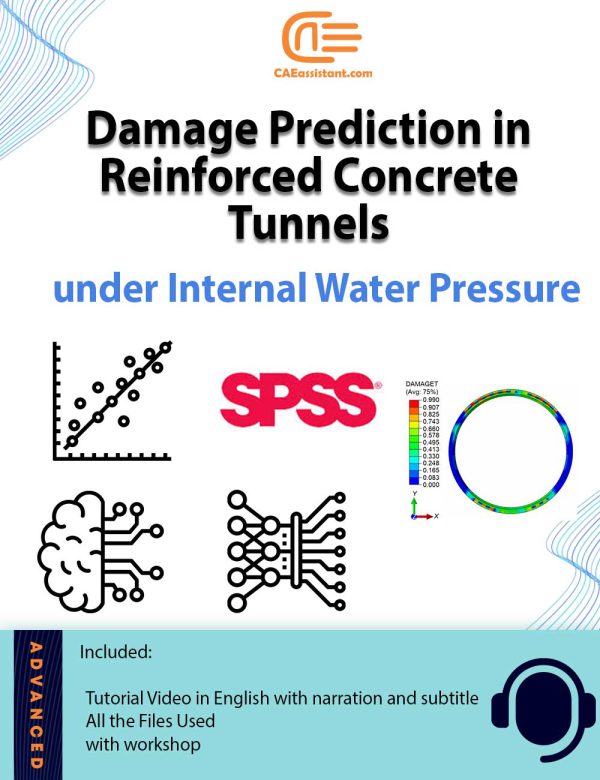

Damage Prediction in Reinforced Concrete Tunnels under Internal Water Pressure

This tutorial package equips you with the knowledge and tools to simulate the behavior of reinforced concrete tunnels (RCTs) subjected to internal water pressure. It combines the power of finite element (FE) modeling with artificial intelligence (AI) for efficient and accurate analysis. The Taguchi method optimizes the number of samples needed for FE analysis, and this method is used with SPSS after explanation its concept.

By leveraging Artificial Intelligence (AI) techniques such as regression, GEP, ML, DL, hybrid, and ensemble models, we significantly reduce computational costs and time while achieving high accuracy in predicting structural responses and optimizing designs.

Computational Modeling of Steel Plate Shear Wall (SPSW) Behavior

This course equips engineers with the tools to design and analyze Steel Plate Shear Wall (SPSW) and Reinforced Concrete Shear Walls (RCSW) subjected to explosive loads. Traditional Finite Element (FE) simulation is time-consuming and requires numerous samples for accurate results. This package offers a more efficient approach using Artificial Intelligence (AI) models trained on FEA data. You'll learn to develop FE models of SPSW and RCSW in ABAQUS software, considering material properties, interactions, and boundary conditions. The Taguchi method optimizes the number of samples needed for FE analysis, and this method is used with SPSS after explanation its concept.

We then delve into AI modeling using MATLAB. Explore various methods like regression, Machine Learning (ML), Deep Learning (DL), and ensemble models to predict the behavior of SPSW and RCSW under blast loads. Statistical analysis helps compare model accuracy. By combining FE analysis with AI models, you'll gain a powerful tool for designing blast-resistant structures while saving time and resources.

Abaqus advanced tutorials on concrete members

Welcome to the "Abaqus Advanced Tutorials on Concrete Members" course, designed to provide civil and structural engineers with cutting-edge expertise in finite element modeling (FEM) and simulation using Abaqus. This advanced-level course focuses on the detailed modeling of complex concrete and composite columns under various loading conditions. Topics include the simulation of tubed reinforced concrete columns, concrete-filled double skin steel columns, and fiber-reinforced polymer (FRP) composite columns. Participants will delve into axial and eccentric compression loading scenarios, with a special focus on hollow and tapered cross-sections. The course also emphasizes comparing simulation results with experimental data from published research, ensuring practical relevance and accuracy. By the end of the course, learners will be equipped with the necessary skills to tackle advanced structural analysis challenges using Abaqus, reinforcing their understanding of concrete member behavior in real-world applications.

Abaqus basic tutorials on concrete beams and columns

Welcome to the “Abaqus Basic Tutorials on Concrete Members,” a comprehensive course tailored for civil and structural engineers seeking to master finite element modeling (FEM) of concrete structures. This tutorial covers key concepts such as plain concrete beam and column modeling, reinforced concrete members, and fiber-reinforced polymer (FRP) composites. The course guides learners through the application of boundary conditions, material properties, and various loading conditions in Abaqus. Key topics include plain concrete beam and column modeling, reinforcement modeling with steel bars and stirrups, and fiber-reinforced polymer (FRP) reinforcement techniques. Participants will also explore comparing simulation results with experimental data, as well as interpreting critical outcomes such as stress distribution and failure modes. Through hands-on workshops, learners will simulate structural behaviors under axial, lateral, and compression loads, ensuring a practical understanding of FEM for concrete members. By the end of this course, participants will be proficient in using Abaqus to model and analyze concrete structures, reinforced elements, and advanced composites, providing them with a strong foundation for structural analysis and design.

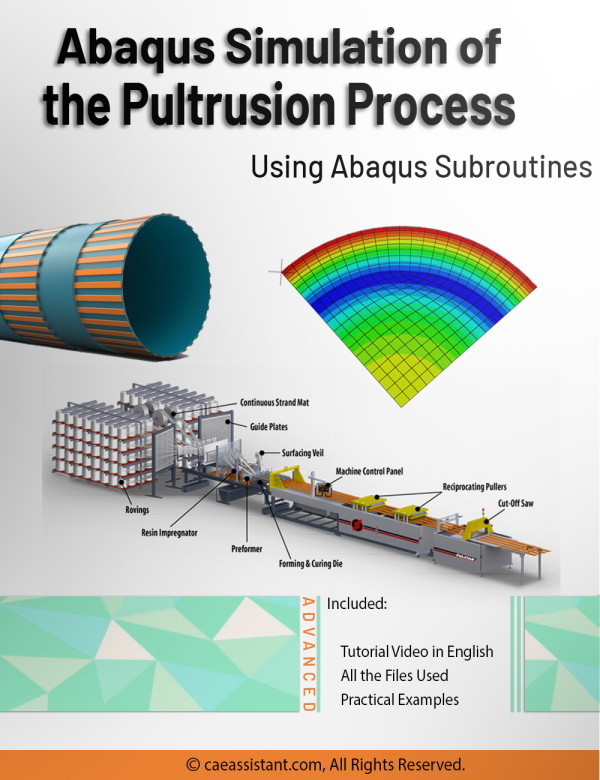

Abaqus Simulation of the Curing Process in Composites: A Specific Focus on the Pultrusion Method

Pultrusion is a crucial task for producing constant-profile composites by pulling fibers through a resin bath and heated die. Simulations play a vital role in optimizing parameters like pulling speed and die temperature to enhance product quality and efficiency. They predict material property changes and aid in process control, reducing reliance on extensive experimental trials. However, simulations face challenges such as accurately modeling complex material behaviors and requiring significant computational resources. These challenges underscore the need for precise simulation methods to improve Pultrusion processes. This study employs ABAQUS with user subroutines for detailed mechanical behavior simulations, including curing kinetics and resin properties. Key findings include insights into material property changes, and optimization strategies for enhancing manufacturing efficiency and product quality. This research provides practical knowledge for implementing findings in real-world applications, advancing composite material production.

Notice that, pultrusion is a composite curing method, which may share some overlapping features with our Intermediate and Advanced curing packages. However, what sets pultrusion apart is that the composite passes over a heated die during the process. In this project, the die has also been modeled, with environmental heat applied to it using convection and a film subroutine. The heat is subsequently transferred to the sample through contact with the die. Afterward the die is removed. All these procedure is modeled in this project, with Abaqus CAE step-by-step. In contrast, in our Intermediate and Advanced packages for the oven curing of prepregs, no die has been modeled. The heat is applied without convection and, for simplicity, the heat is treated as a first-type boundary condition, which introduces some errors.

Note: The files and video which explains how to use the code are available. The PDF file will be available two weeks after purchase.