Abaqus Concrete Structure Modeling | Practical Examples (Part 4)

Abaqus Concrete Structure Modeling | Practical Examples (Part 3)

Abaqus Concrete Structure Modeling | Practical Examples (Part 2)

Abaqus Concrete Structure Modeling | Practical Examples (Part 1)

Essential Abaqus Training for Engineers: From Basics to Advanced Techniques

This beginner-friendly Abaqus course offers a complete guide to mastering finite element simulations through step-by-step tutorials and practical workshops. It covers essential topics such as Abaqus/CAE basics, finite element theory, composite material simulation, and thermal and impact analyses. Advanced sections delve into UMAT/VUMAT subroutines and Python scripting, equipping users with skills to automate workflows and solve complex engineering problems. Workshops include real-world examples like cantilever beams, forming processes, and fracture simulations. Perfect for engineering students and professionals, this course helps you build a solid foundation in Abaqus and expand your simulation capabilities.

Laser Assisted Machining (LAM): Modeling and Simulation in Abaqus/CAE

In this tutorial, a comprehensive discussion on modeling and simulation of laser assisted machining is presented. It includes building FEM-based models of machining, laser heating, and laser-assisted machining models in Abaqus/CAE. The finite element method (FEM) simulation is based on the coupled thermo-mechanical behavior. The package walks learners through building models that simulate the impact of laser heating on the workpiece. Detailed lessons cover constructing basic machining and laser heating models, setting boundary conditions like cutting speed and laser power, and writing subroutines such as DFLUX and VDFLUX to simulate laser heat sources. Additionally, learners will perform analyses to study temperature distribution, and stress-strain behavior. Through parametric analysis and comprehensive result evaluation, learners will gain a deep understanding of temperature distribution, stress behavior, and how laser heating can improve the machining process.

Hygrothermal effects on composite materials | Degradation in Fiber Reinforced Composites Abaqus Simulation: Python & Subroutines

In this tutorial, we explore the hygrothermal degradation composites using ABAQUS, a powerful tool for parallel finite element analysis. Industries like aerospace, marine, and automotive heavily rely on these composites due to their high strength-to-weight ratio and versatility. However, long-term exposure to moisture and temperature can degrade their mechanical properties, making an analysis of hygrothermal effects on composite materials essential for ensuring durability.

ABAQUS allows precise modeling of these environmental conditions through Python scripts and Fortran subroutines. This combination enables efficient simulations across multiple processors, offering insights into key elastic properties, such as Young’s modulus and shear modulus, under varying conditions. By leveraging the ABAQUS Python Scripting Micro Modeling (APSMM) algorithm and custom subroutines, engineers can predict the long-term performance of fiber-reinforced composites, optimizing design and enhancing material performance in critical sectors like aerospace and marine.

In the present Abaqus tutorial for parallel finite element analysis, we have presented the software skills that a person needs when he wants to perform a parallel finite element analysis such as a micro-macro scale analysis. The Abaqus tutorial for parallel finite element analysis covers all you need to write a python scripting code for noGUI environment and also Fortran code for the subroutine environment of Abaqus to execute a parallel finite element analysis via Abaqus software. You can download the syllabus of this package here.

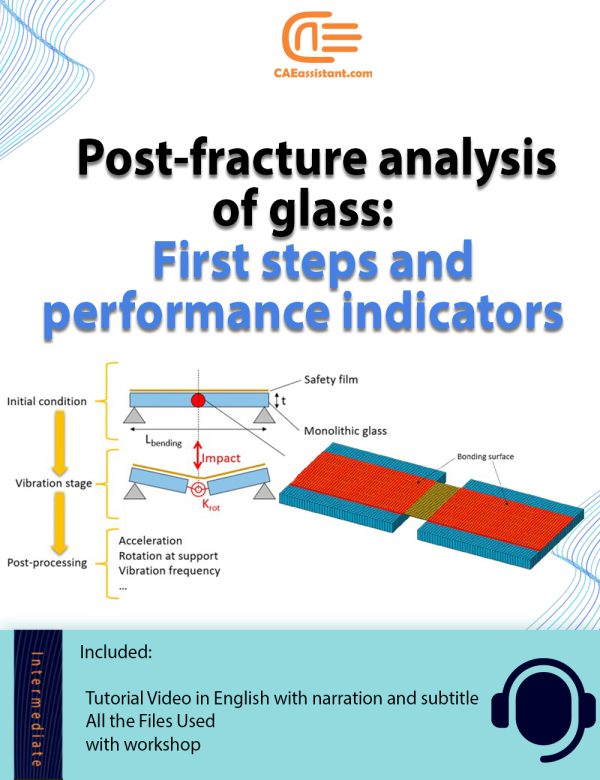

Glass Fracture Analysis with Abaqus | Post-Fracture

This tutorial explores a finite element method (FEM) simulation using Abaqus to analyze the post-fracture behavior of structural glass members retrofitted with anti-shatter safety films. In particular, it focuses on simulating and calibrating the vibration response of cracked glass elements under repeated impacts and temperature gradients, contributing to a comprehensive analysis of critical phenomena that take place in the post-fracture stage. This tutorial follows the methodology outlined in the research article “Effects of post-fracture repeated impacts and short-term temperature gradients on monolithic glass elements bonded by safety films”.

Key aspects include modeling glass fracture, assigning material properties, and defining boundary conditions to assess the vibration frequency and load-bearing capacity of cracked monolithic glass members. Additional topics cover basic concepts of dynamic identification techniques, definition of performance indicators for glass retrofit efficiency, and frequency sensitivity analysis of monolothic retrofitted glass elements under various operational and ambient conditions. The simulation results help quantify the expected contribution and residual strength of safety films in post-fracture scenarios, providing a robust framework for structural engineers to extend this investigation to other glass configurations.

This tutorial is ideal for users who want to understand FEM modeling in Abaqus and perform detailed simulations involving complex material interactions, with a focus on practical applications in glass retrofit technology.

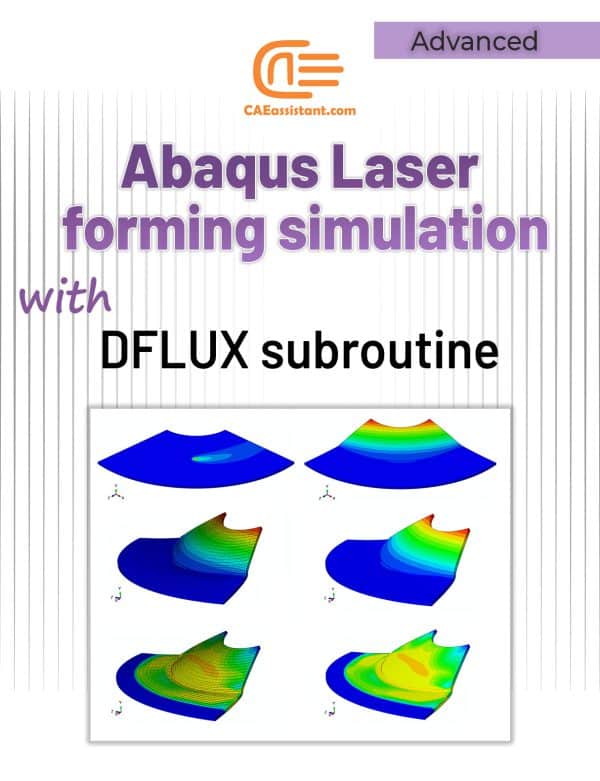

Laser Forming Process Tutorial in Abaqus

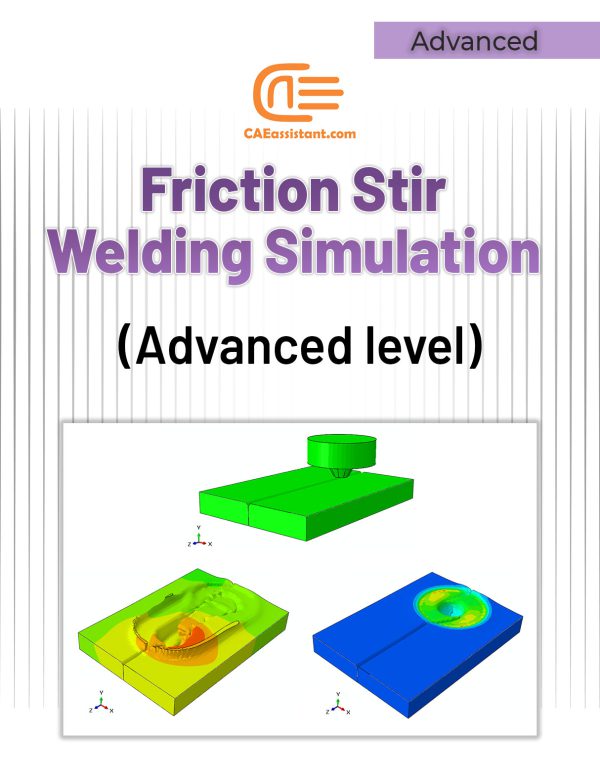

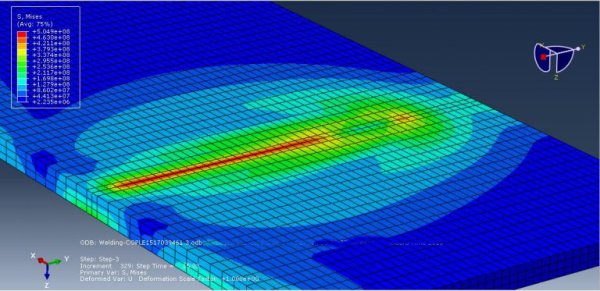

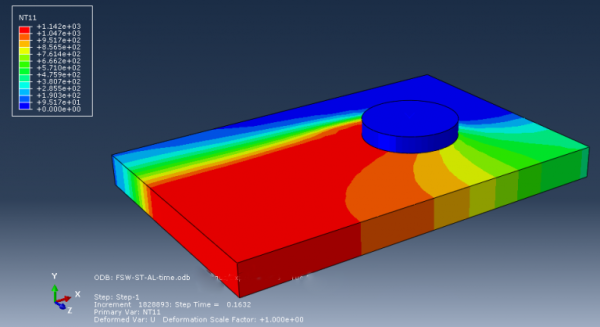

Friction Stir Welding simulation Tutorial | FSW Advanced level

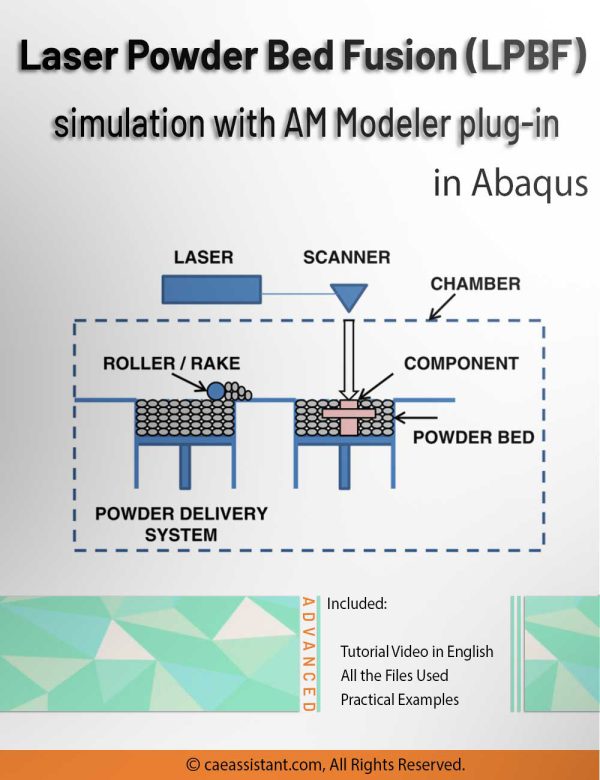

LPBF Printing Simulation in Abaqus | 3D Printing with Laser Powder Bed Fusion Process (LPBF) Method

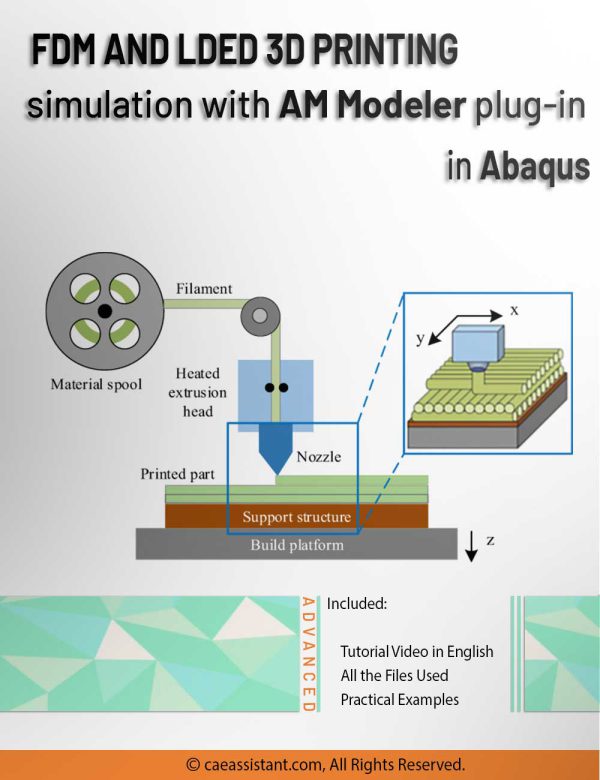

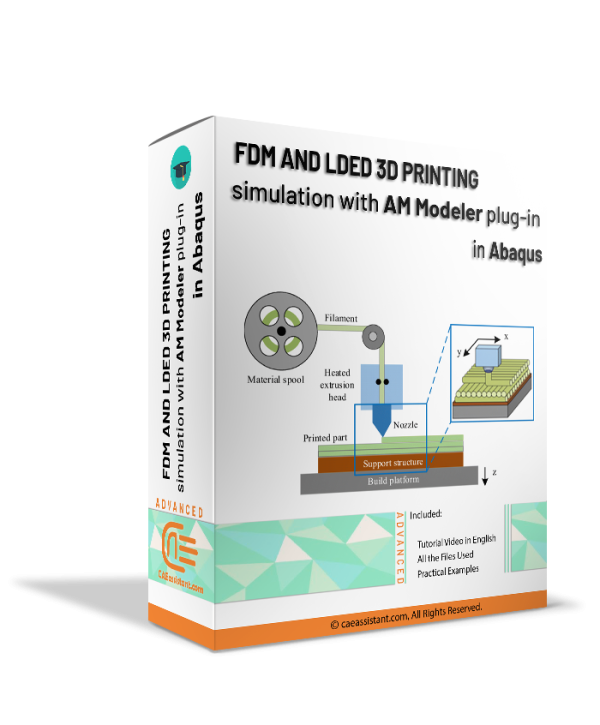

FDM Simulation in Abaqus | Simulating 3D Printing with Fused Deposition Modeling

Abaqus for Civil Engineering Part-1

Arc welding simulation in Abaqus

Friction Stir Welding (FSW) Simulation in Abaqus

Car part industrial simulation

Abaqus CFD Analysis

Thermal Heat Transfer in Abaqus

- Uncoupled heat transfer analysis

- Sequentially coupled thermal-stress analysis

- Fully coupled thermal-stress analysis

- Adiabatic analysis

Analysis of Heat Transfer in Abaqus

Thermal Heat Transfer in Abaqus

This Analysis of Heat Transfer in Abaqus package includes workshops that help you to fully learn how to simulate the temperature distribution and heat flux in solids under thermal loads. This tutorial package enables you to model thermal responses including all the modes of heat transfer, namely conduction, convection and radiation. The subjects such as using film conditions to simulate the convective heat transfer, the dissipation of the frictional heat generated, thermomechanical analysis and etc. are covered in this packageAbaqus Concrete structure Modeling Full Tutorial

We also offer similar budget-friendly packages that include the workshops from this package.

- The first package includes Workshops 1 to 5.

- The second package includes Workshops 6 to 10.

- The third package includes Workshops 11 to 15.

- The fourth package includes Workshops 16 to 20.

Since these packages do not include the lessons and contain a limited number of workshops, they are available at a lower price (250 euros each).

However, we recommend choosing the current full package instead of purchasing parts 1 to 4 separately, as it includes all 20 workshops and exclusive lessons not available on similar platforms, while still being priced lower than competing offerings.