Search here for Abaqus tutorial videos, Abaqus course & training

FREE ABAQUS TUTORIAL VIDEOS

Taste our products

You can find all free packages in different content including Abaqus for beginner and writing UMAT/VUMAT subroutine and Python scripting

UMAT Subroutine (VUMAT Subroutine) in ABAQUS-Free Version- UMAT Abaqus example

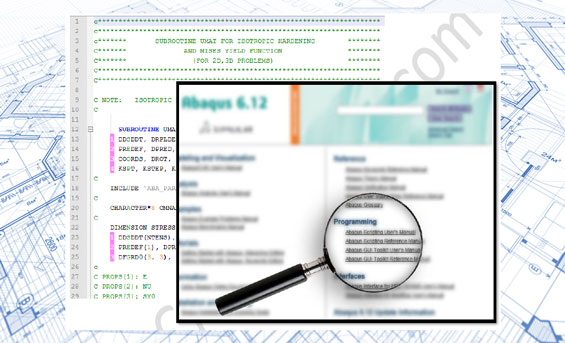

by 0-Abaqus-1-caeassistantpartnerm"UMAT Subroutine (VUMAT Subroutine) introduction" is used when the material model is not available in ABAQUS software. If you follow this tutorial package, including standard and explicit solver, you will have the ability to write, debug and verify your subroutine based on customized material to use this in complex structures. These lectures are the introduction to writing advanced UMAT and VUMAT subroutines in hyperelastic Martials, Composites, and Metal, and so on. Watch Demo

"Advanced UMAT Subroutine (VUMAT Subroutine)" training package helps Abaqus users to prepare complex UMAT and VUMAT subroutines. This training package is suitable for those who are familiar with subroutine or want to learn UMAT/VUMAT subroutine Professionally. Equations for computational plasticity based on kinematic stiffness are also discussed. In addition, metal damage has been implemented based on Johnson Cook's model. Watch DemoPython scripting in ABAQUS-(FREE Version)

by 0-Abaqus-1-caeassistantpartnermAbaqus for beginners (Mechanical Engineering)-Free Version

by 0-Abaqus-1-caeassistantpartnermABAQUS FEA Training (Free cantilever beam tutorial)

by 0-Abaqus-1-caeassistantpartnermFREE ABAQUS TUTORIAL PDF

How will Advanced Engineering Courses help me?

How can we learn to write an Abaqus subroutine correctly?

Here below, I have listed some Abaqus basics – main subroutines that you may encounter when using Abaqus CAE at an advanced level as a graduate student or researcher. Good news for you! You can learn each subroutine you want by clicking on that (Abaqus tutorial).

Get to know us with numbers

💿Abaqus for Beginners (Abaqus for Civil Engineering)

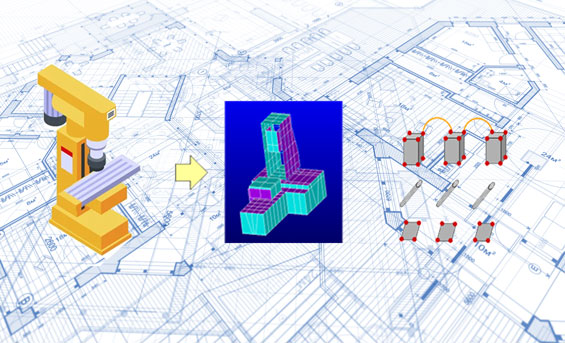

Additive Manufacturing or 3D Printing Abaqus simulation

Welding Simulation in ABAQUS

ABAQUS course for beginners | FEM simulation tutorial

Composite Fatigue Simulation with UMAT Subroutine in ABAQUS (unidirectional)

3D continuum Abaqus HASHIN progressive Damage for composite materials (VUMAT Subroutine)

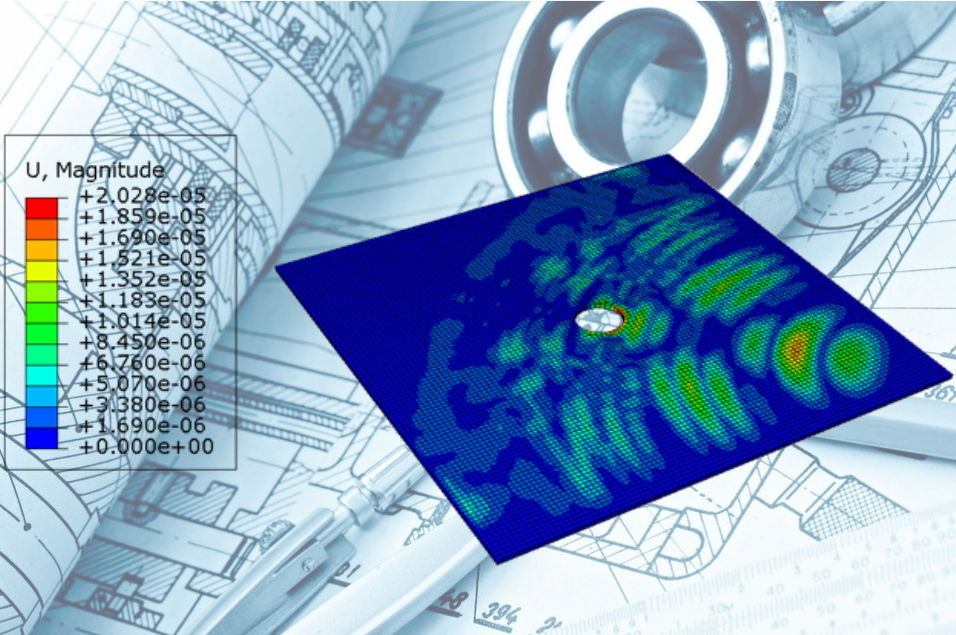

The Hashin failure criteria is a set of failure criteria developed specifically for composite materials. It predicts different failure modes in composites based on the stresses experienced by their constituents (fiber and matrix). The criteria are widely used in engineering and computational models to assess composite material performance under mechanical loading. The criteria, while highly efficient and widely used, pose challenges when implemented in numerical simulations. Abaqus has emerged as a powerful tool to address these challenges, enabling the prediction of damage initiation and its progression (via stiffness reduction) based on the Hashin criteria. However, a key limitation of Abaqus is its applicability being restricted to 2D plane stress elements. To overcome this limitation, we developed a VUMAT subroutine in this project. This custom subroutine extends the capabilities of Abaqus, allowing for the simulation of damage initiation and propagation in 3D problems in accordance with the Hashin criteria. It should be mentioned that this subroutine includes gradual progressive damage based on the energy method. This complex subroutine could be used for static and dynamic problems.

A notable point is that in one of our other packages, we also provide training on using Abaqus subroutines to analyze the Hashin criterion. However, in that package, damage occurs instantaneously. In the current package, we have modeled the progressive Damage, which is more complex but could be more beneficial for solving your specific problems.

Abaqus Crack Growth | Practical Examples

Abaqus Concrete Structure Modeling | Practical Examples (Part 4)

Abaqus Concrete Structure Modeling | Practical Examples (Part 3)

Abaqus Concrete Structure Modeling | Practical Examples (Part 2)

Abaqus Concrete Structure Modeling | Practical Examples (Part 1)

Abaqus steel material and structures | Practical examples

Our Courses

Introduction to finite element method (FEM)

The finite element method (FEM) is a powerful tool used to analyze complex physical problems in engineering and science. Imagine you have a car engine – a very intricate system. FEM helps us understand how it behaves under different conditions.

Here’s the gist:

- Divide and conquer: FEM breaks down the entire system (engine) into smaller, simpler pieces called finite elements. These elements could be tiny triangles, squares, or other shapes, forming a mesh over the system.

- Math magic: Each element has mathematical equations describing its behavior. By applying these equations to all the elements and connecting them together, FEM builds a large set of equations for the entire system.

- Computer power: Since solving these equations directly can be overwhelming, FEM relies on computers. Powerful software crunches the numbers to find approximate solutions for the whole system.

FEM is particularly useful when complex shapes or material properties make it difficult to solve the governing equations analytically. It’s widely used in various fields like:

- Structural analysis: Predicting stress and strain in bridges, buildings, or airplane wings.

- Heat transfer: Analyzing heat flow in engines or electronic devices.

- Fluid flow: Simulating how fluids move around airplane wings or inside pipes.

FEM provides valuable insights for engineers and scientists, allowing them to design better, more efficient systems. While the inner workings involve complex math, the basic idea is that FEM tackles tough problems by breaking them into smaller, more manageable pieces.

1. What is Abaqus and Abaqus CAE?

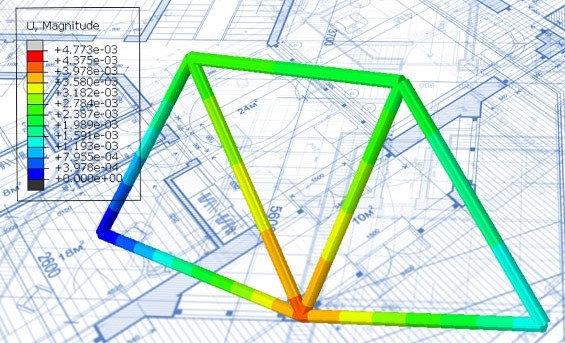

Abaqus is a software suite specifically designed for finite element analysis (FEA). FEA is a powerful computer simulation technique used by engineers to predict how complex structures will behave under different conditions. Imagine a bridge design – this software can be used to simulate how the bridge will respond to wind loads, traffic, or even an earthquake. (Abaqus tutorial)

- Build models of the structures they want to analyze (like the bridge example).

- Define the material properties of the different parts of the model (e.g., steel, concrete).

- Set up the simulation conditions, such as the type of loading the structure will experience.

- Visualize the results of the simulation to understand how the structure will deform or stress under those conditions.

In simpler terms, Abaqus CAE is the user-friendly interface you use to work with Abaqus. It’s where you prepare your questions (building the model and defining conditions) and then analyze the answers (visualizing the results).

Read More: ANSYS vs ABAQUS

To get the Simulia software go to 3ds.com.

2. Which ABAQUS product is right for you?

This software is renowned for its exceptional performance, quality, and ability to solve an extensive range of basics to complex simulations. It is comprised of three primary products: Abaqus/Standard and Explicit, and Abaqus/CAE, each offering optional modules to cater to specialized capabilities that specific customers may require. Even if you are using the student edition, these three products are available to you, and we have provided our student tutorials to be compatible with any edition you may have. By clicking on Abaqus students edition you can find complete information about this topic.

Furthermore, this software offers interfaces such as the Abaqus Interface for Moldflow and the Abaqus Interface for MSC.ADAMS, which allows interfacing with Moldflow and ADAMS/Flex, respectively. This software also provides translators that can convert geometry from third-party CAD systems to models for Abaqus/CAE, convert entities from third-party preprocessors to input for analyses, and convert output from analyses to entities for third-party postprocessors.

3. Capabilities and Benefits

- Abaqus CAE: This is the pre-processing and post-processing environment for Abaqus. It allows users to create models, define material properties, set up simulations, and visualize the results.

- Abaqus/Standard and Explicit: These are the two main solver products within Abaqus. The Standard is for static and quasi-static simulations, while the Explicit is for transient dynamic simulations.

- Capabilities: Abaqus offers a wide range of capabilities, including:

- Linear and non-linear analysis

- Material models for various materials (metals, rubber, etc.)

- Contact mechanics

- Heat transfer analysis

- Coupled multiphysics simulations (e.g., thermal-structural, acoustic-structural)

- Benefits: also can be used to:

- Optimize designs

- Reduce development costs

- Efficiency: It allows for efficient design exploration and optimization by facilitating early-stage analysis through FEA.

- Versatility: The software tackles a wide range of engineering problems, from routine to complex.

- Integration: the software integrates with other CAD environments for seamless data exchange.

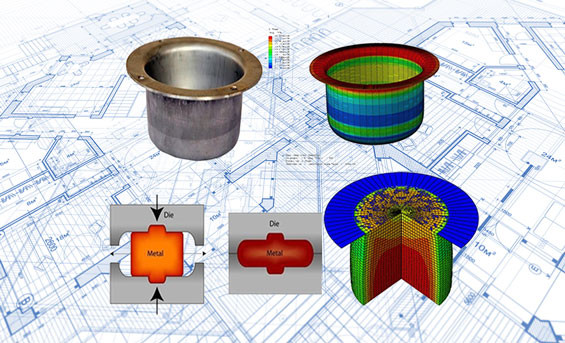

Abaqus CAE is regarded as the leader in finite element analysis (FEA) due to its exceptional capabilities and features. This software offers linear and nonlinear analysis capabilities, including geometric, material, and contact nonlinearities. It also provides material models for a broad range of materials, including metals, composites, human tissue, rubber, and thermoplastics, as well as material fracture and failure capabilities. This software also boasts robust contact capabilities and a convenient setup, making it an ideal solution for basics to complex simulations.

When you purchase this software, you gain access to several products, including Abaqus Standard, Explicit, fe-safe (for fatigue and durability analysis), Tosca (for shape and topology optimization), and Isight (for process automation and parametric optimization). Additionally, this software offers a vast range of multiphysics solver capabilities, including static stress/displacement with unstable collapse and post-buckling, linear elastic fatigue crack growth, and low-cycle fatigue, dynamic stress/displacement with implicit and explicit dynamic solvers, natural frequency extraction, and random response analysis, heat transfer and thermal stress analysis, electromagnetic with piezoelectric analysis, coupled thermal-electrical, or fully coupled thermal-electrical-structural analysis, mass diffusion and coupled pore fluid flow diffusion and stress analysis, acoustic, shock, and coupled acoustic-structural analysis, and fluid-structure interaction (FSI).

Abaqus software also provides open technology to couple with other codes, allowing for the performance of coupled multiphysics simulations between Abaqus and other codes. A comprehensive list of qualified partner products can be found on the Simulia website.

Abaqus CAE uses Python scripting, allowing for significant flexibility and customization. With scripts, you can automate repetitive tasks, such as creating a library of standard materials or generating remote queues for running analysis jobs. You can also perform parametric studies by incrementally modifying the geometry of a part and analyzing the resulting model. Additionally, the Scripting Interface provides an application programming interface (API) to create and modify model databases and models created interactively in Abaqus/CAE. You can also access data in an output database and perform your own postprocessing of analysis results.

The software comes with extensive documentation and well-written example problems that are easy to understand. New releases of the software include bug fixes, performance improvements, and new features, so it is recommended to install the latest version with an active lease or annual maintenance. Multiple versions of this software can be installed on the same machine, allowing testing of the latest version while continuing to use older versions. It is also recommended to test 3rd party tools for compatibility and upgrade them if needed.

Also, it can run on various hardware platforms, from a basic laptop to a multi-node HPC cluster. Computation times can be reduced significantly with parallel processing, using more CPU cores, GPU acceleration, or multiple machines in a network.

Moreover, this software is now available on the cloud, providing small or variable businesses with cost savings on hardware, utilities, IT staffing, etc. The SIMULIA cloud plans operate on a credits system to access hardware (CPU cores and solve time) and software.

What is our innovation in CAEassistant.com?

The CAE Assistant community is rapidly increasing its coding speed by using basic codes of the main and essential theories of solid mechanics and their video tutorials, leading to accelerated industrial and scientific development.

ABAQUS TUTORIAL

Abaqus tutorial | Basics to Advanced

It is a software program used for pre-processing (modeling and analyzing mechanical parts and assemblies) and viewing finite element analysis results. If you are new to the software, our “free tutorial” improves your basic knowledge of Abaqus. “The beginners” course is the best Abaqus basics training on the web. Here you can find some tutorial PDFs that include practical examples of software and useful description of how to model them. In the free video tutorial packages or student tutorials, just some parts of the training packages are presented. If you are interested, you can find complete packages on the CAE Assistant shop.

| FEA is a topic that is well worth learning for a mechanical engineer. You won’t regret doing it. The following advice will guide you in your education and help you become an expert in FEA, and the Abaqus training available here can boost your learning path. |

- Start with your education in the specific field of Mechanics/ physics you want to simulate.

- Engage in FEA basic courses such as the above tutorial videos.

- Study modeling techniques rather than merely learning software.

- Recognize how your mechanical problem behaves.

- Always strive to comprehend anything thoroughly.

- Begin with simple problems.

- Practice often and intensify your efforts.

- Attend FEA courses (For example, Abaqus trainings)

- Study your peers’ work.

- Be patient; becoming a specialist takes time.

Why Abaqus Training matters?

Abaqus Training is essential for engineers, analysts, and researchers who seek to enhance their skills in finite element analysis (FEA). Abaqus is a powerful software suite used to simulate the physical response of materials and structures under various conditions, including stress, heat, and fluid flow. Mastery of this tool through structured Abaqus Training is crucial as it enables professionals to conduct complex simulations accurately, leading to better product designs, improved safety, and optimized performance across industries such as automotive, aerospace, and civil engineering.

Abaqus Training Online

How Can we help as CAE assistants?

| If we want to categorize the educational content available on the CAE Assistant site about the software, we can say that the following items are covered on this site in various Abaqus tutorial: |

1-Analysis Procedures, Solution, and Control:

- Static stress-displacement analysis,

- Dynamic stress-displacement analysis,

- Steady-state transport analysis,

- Heat transfer and thermal stress analysis,

- Fluid dynamic analysis,

- Coupled pore fluid flow and stress analysis,

- Mass diffusion analysis,

- Acoustic and shock analysis,

- Aqua analysis,

- Electromagnetic analysis,

- Annealing,

2- Analysis Techniques

- Adaptivity Techniques

- Particle Methods

- Analysis Continuation Techniques

- Modeling Abstractions

- Special-Purpose Techniques

- Optimization Techniques

- Eulerian Analysis

- Sequentially Coupled Multiphysics Analyses

- Extending Analysis Functionality

- Co-simulation

- Design Sensitivity Analysis

- Parametric Studies

3- Materials

- “Elastic Mechanical Properties”

- “Inelastic Mechanical Properties”

- “Progressive Damage and Failure”

- “Hydrodynamic Properties”

In the above topics, we have some Abaqus tutorial packages, and you can get them from the CAEassistant shop.

Embarking on the journey to master Abaqus, the premier finite element method (FEM) software, requires a strategic approach distinct from conventional software like Microsoft Office. Unlike more user-friendly tools, Abaqus necessitates structured education, making Abaqus tutorials, courses, and training crucial for engineers aiming to harness its powerful simulation capabilities.

This section serves as your launchpad into the world of Abaqus. Our introductory tutorial will provide a foundational understanding of the software’s core functionalities. You’ll learn how to:

- Navigate the user interface and access essential tools.

- Create and manage basic models.

- Define material properties and apply loads.

- Run simple simulations and visualize results.

This tutorial lays the groundwork for your exploration of more advanced capabilities.

Abaqus Software Tutorial

Taking you a step further, our Abaqus software tutorial delves deeper into specific features and functionalities. This section offers focused tutorials on:

- Mesh generation techniques for accurate simulations.

- Defining complex material behavior, including plasticity and damage.

- Advanced analysis types like heat transfer and dynamic analysis.

- Post-processing techniques to extract valuable insights from simulation results.

By following these in-depth tutorials, you’ll gain a strong grasp of Abaqus’ potent capabilities and unlock its potential for tackling intricate engineering problems.

Abaqus Tutorials

Our extensive library of Abaqus tutorials caters to a wide range of engineering disciplines. Explore tutorials specific to:

- Structural Analysis: Simulate the behavior of structures under various loading conditions.

- Thermal Analysis: Analyze heat transfer through materials and components.

- Fluid Analysis: Understand fluid flow and interaction with solid objects.

- Contact Mechanics: Model the interaction between contacting surfaces, including friction and wear.

With this diverse collection, you’ll find the perfect tutorial to enhance your expertise in your chosen engineering field.

Abaqus Beginner Tutorial

Feeling overwhelmed by the vastness of Abaqus? Fear not! We offer a dedicated Abaqus beginner tutorial designed specifically for those new to FEA. This tutorial provides a gentle introduction to:

- The fundamental concepts of finite element analysis.

- The basic building blocks of creating an Abaqus model.

- Running a simple simulation and interpreting the results.

This beginner-friendly tutorial will equip you with the essential knowledge to confidently navigate your initial steps in the world of Abaqus.

Abaqus CAE Tutorial

Abaqus CAE, the graphical user interface (GUI) of Abaqus, simplifies model creation and analysis setup. Our tutorial will guide you through:

- Utilizing the CAE interface for efficient model creation and editing.

- Assigning material properties and boundary conditions through the GUI.

- Setting up analysis steps and managing simulation jobs.

By mastering Abaqus CAE, you’ll streamline your workflow and maximize your productivity while performing FEA tasks.

The importance of proper education

Positioned at the forefront of engineering simulation, Abaqus caters to a broad spectrum of complex problems. A foundational understanding of its principles, workflows, and applications is essential for engineers to unlock its full potential. Proper education ensures that engineers not only navigate the software effectively but also leverage its capabilities for intricate analyses and simulations.

Choosing the right Abaqus tutorials is the initial step toward mastery. To cater to the diverse needs and applications of engineers, specialized tutorials are essential. Reputable platforms and educational institutions offer tutorials tailored to specific domains such as structural analysis, thermal simulations, and more. This strategic selection of tutorials aids engineers in building practical skills and confidence as they navigate the complexities of Abaqus.

Read More: Introduction to Finite Element Method | Finite Element Analysis

Read More: The Best Guide to Abaqus Mesh

Read More: Abaqus Terminate Job | Pause Abaqus Job | Abaqus Job Command

Read More: What is Abaqus Load Torque (Moment) and How to Apply it in Abaqus?

Read More: Applying Abaqus Velocity | Angular Velocity VS Linear Velocity

Read More: What is Hard Contact Abaqus? | Defining Abaqus Normal Behavior

AI in Mechanical Engineering: This blog explores the applications of AI in mechanical engineering, including CAD, CFD, FEA, and emerging technologies like digital twins and quantum computing.

Explore advanced composite damage and fatigue analysis techniques with our insightful articles. Learn about Composite Damage, their damage mechanisms, and failure criteria, as well as how to simulate these damages in Abaqus. Dive into the fatigue analysis of composite fatigue analysis, understanding fatigue damage, behavior, and simulation using the UMAT subroutine. Enhance your knowledge and simulation accuracy with these comprehensive guides.

Hashin Failure Criteria: This blog explains the Hashin Failure Criteria, a tool for predicting failure modes in composite materials.

Tsai-Hill Failure Criterion: This blog discusses the Tsai-Hill failure criterion, another tool for predicting failure in composite structures.

Composite Curing Process: This blog explores the composite curing process, including different curing methods and simulation techniques using Abaqus.

Fatigue Analysis: This blog discusses fatigue analysis, a method for predicting the lifespan of materials under cyclic loading.

Composite Pressure Vessel Design: This blog explores the design and applications of composite pressure vessels.

Buckling Analysis: This blog discusses buckling analysis, a method for predicting the stability of structures under compressive loads.

Types of Structure Building: This blog explains the different types of structures used in civil engineering.

Types of Supports in Building: This blog discusses the different types of supports used in structural engineering.

Plane Stress vs. Plane Strain: This blog explains the concepts of plane stress and plane strain, two common states of stress and strain in engineering applications.

Cohesive Elements in Abaqus: This blog discusses cohesive elements in Abaqus, a tool for modeling the failure of interfaces between materials.

Energy Concepts in Abaqus: This blog explains the concept of energy in Abaqus simulations, including specific internal energy and dissipated inelastic specific energy.

Explore the top 10 composite pressure vessel manufacturers driving clean energy! Leaders like Hexagon Composites and Luxfer Gas Cylinders are innovating lightweight, durable solutions for hydrogen storage, fueling the shift toward a sustainable future.

Discover how XFEM Abaqus simplifies crack and fracture simulations! Our latest blog covers key concepts like enrichment functions and cohesive crack modeling, plus step-by-step guides for 2D and 3D simulations. Solve complex engineering challenges with precision.

Explore how Additive manufacturing simulation can transform 3D printing by solving issues like warping, enhancing design accuracy, and ensuring precise results. Our blog breaks down crucial parameters and showcases three leading software solutions to help you refine your simulations and achieve better outcomes.

Discover the power of structural optimization in Abaqus with our easy-to-follow guide on topology and shape optimization.

Curious about metal 3D printing and how to simulate it in Abaqus? Our guide on the Inherent Strain Method for metal additive manufacturing walks you through the process of accurately predicting residual stresses and deformations.

Need to apply custom heat fluxes or temperature distributions in Abaqus? Our article on the DFLUX and VDFLUX subroutines gives you a step-by-step guide on how to incorporate these powerful tools into your simulations.

Looking to strengthen your basics in shear force and bending moments? Our latest blog post makes it super easy to learn with step-by-step example.

Struggling to understand moment of inertia and moment of area? This simple, beginner-friendly guide breaks down everything you need to know — with clear examples and visuals. Whether you’re a student or a working engineer, this is the only blog you need to finally get these essential concepts.

If you’re looking to understand how structures vibrate and how to prevent resonance issues, our latest blog post on modal analysis in Abaqus is a must-read. It breaks down the essentials of modal analysis in a clear and approachable way, helping you grasp how to identify natural frequencies and mode shapes.

Our blog delves into steel structure analysis, highlighting the importance of beam and joint evaluation, understanding structural models, and optimizing steel structure design. Discover effective techniques, compare Abaqus FEM with analytical approaches, and gain practical insights for designing strong and efficient steel structures.

Abaqus Modules Video Tutorial

A full Abaqus environment, Abaqus/CAE offers a straightforward, consistent user interface for creating, submitting, tracking, and assessing the results of Standard and Explicit simulations. Each module defines a logical step in the modeling process, such as specifying the geometry, defining the properties of the materials, and creating a mesh. Building the model used by Abaqus/CAE to produce the input file you give to the Standard or Explicit analysis product happens as you progress through the modules. The analysis tool performs the analysis, provides data to Abaqus/CAE so you can keep track of the job’s development, and creates an output database. Here, in the below training videos, you can get enough information about the modules and start simulating in this software.

| ✅ Subscribed students | +80,000 |

| ✅ Upcoming courses | +300 |

| ✅ Tutorial hours | +300 |

| ✅ Tutorial packages | +100 |