Video Shop

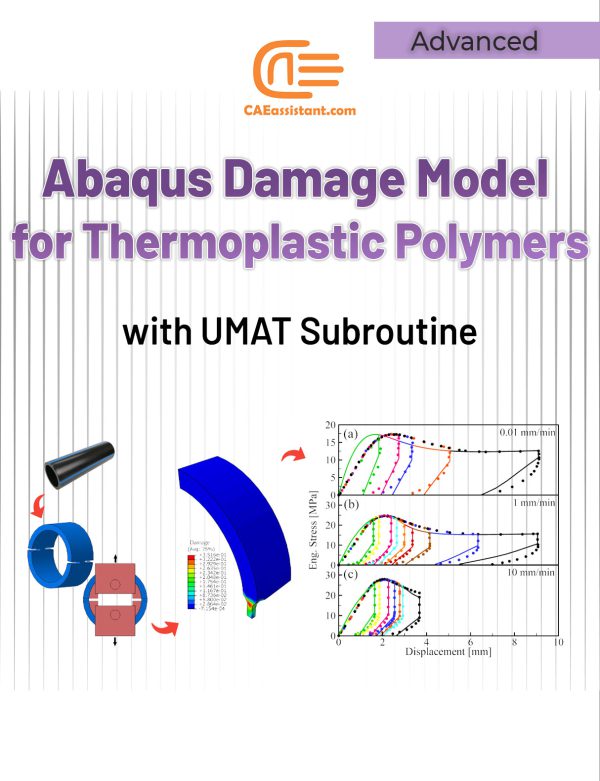

Damage Properties of Thermoplastic Polymers with UMAT Subroutine

Thermoplastic polymers are materials composed of long molecular chains primarily consisting of carbon. These polymers possess the unique ability to be shaped and molded under heat and pressure while retaining their stability once formed. This high formability makes them widely used in various industries, including furniture production, plumbing fixtures, automotive components, food packaging containers, and other consumer products. This package introduces a thermodynamically consistent damage model capable of accurately predicting failure in thermoplastic polymers. The implementation of this model is explained through the use of an ABAQUS user material (UMAT) subroutine.

The package is structured as follows. The introduction section Provides an overview of thermoplastic polymers and their mechanical properties. In the Theory section, the constitutive damage model and its formulation are reviewed. Then, an algorithm for numerically integrating the damage constitutive equations is presented in the Implementation section. In the UMAT Subroutine section, a detailed explanation of the flowchart and structure of the subroutine is provided. Finally, two simulation examples, namely the T-fitting burst pressure test and the D-Split test, are performed and the obtained results, are investigated.

Notice: Software files and A full PDF guideline (Problem description, theory, ...) are available; Videos are coming soon.

UHPC (Ultra-High Performance Concrete) structures simulation in Abaqus

Ultra-High Performance Concrete structures refer to structures that are constructed using Ultra-High Performance Concrete (UHPC). UHPC is a specialized type of concrete known for its exceptional strength, durability, and resistance to various environmental and loading conditions. UHPC structures can include bridges, high-rise buildings, infrastructure components, architectural elements, and more. Simulating UHPC structures is of significant importance. Through simulation, engineers can analyze and predict the structural behavior and performance of UHPC under different loading conditions. This includes assessing factors such as stress distribution, deformation, and failure mechanisms. By simulating UHPC structures, engineers can optimize the design, evaluate the structural integrity, and ensure the safety and reliability of these complex systems. In this project package, you will learn simulating the UHPC structures with many practical examples.

Here we have a special package for the UHPC Beams

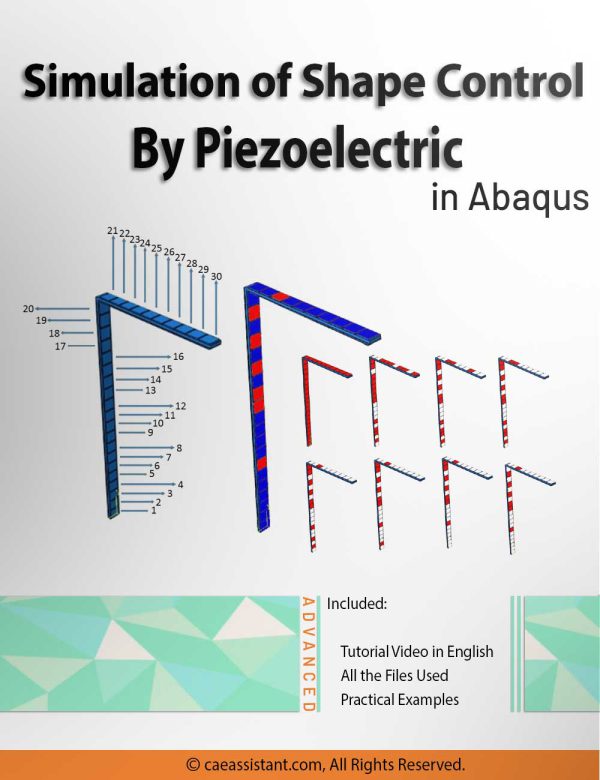

Simulation of shape control by piezoelectric in Abaqus

Piezoelectricity refers to the accumulation of electric charge in certain solid materials due to mechanical pressure. This phenomenon, known as the piezoelectric effect, is reversible. Some materials exhibit direct piezoelectricity, which involves the internal production of electric charge through the application of mechanical force, while others exhibit the inverse piezoelectric effect.

By harnessing piezoelectrics, it becomes possible to control the geometrical changes of objects in response to external forces. However, it is important to note that utilizing this property in all situations would not be cost-effective. Therefore, it is more practical to use piezoelectric structures selectively, specifically in special applications. One approach to determining the optimal placement of piezoelectric elements for controlling the geometric shape of various objects under internal or external forces involves utilizing the Abaqus and MATLAB software linkage. This software combination, along with optimization algorithms such as the particle swarm optimization algorithm, can be employed to achieve the desired objectives. By leveraging these tools and data, the primary goal of controlling object shape can be successfully accomplished.

In this training package, you will learn about piezoelectric and piezoelectric modeling in Abaqus, the particle swarm optimization algorithm, linking Abaqus and MATLAB, and how to use these tools for shape control.

Notice: Software files and A full PDF guideline (Problem description, theory, ...) are available; Videos are coming soon.

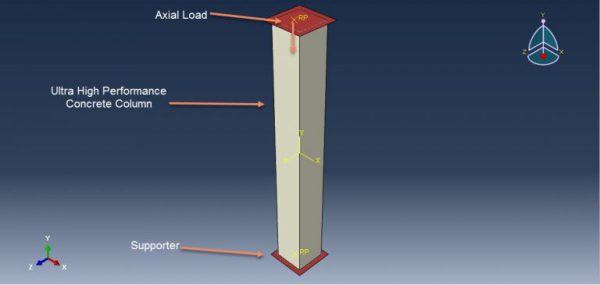

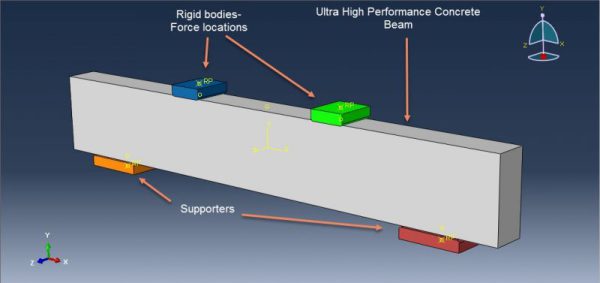

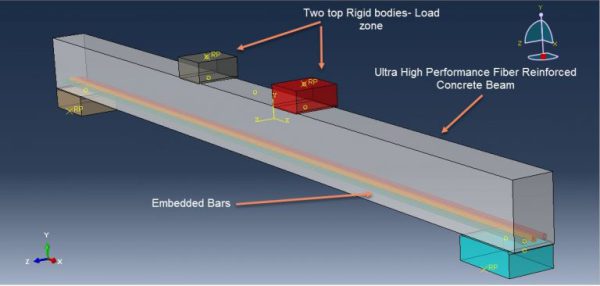

Ultra-High Performance Concrete (UHPC) beams simulation in Abaqus

UHPC (Ultra-High Performance Concrete) is an advanced type of concrete known for its exceptional strength, durability, and resistance. It consists of a dense matrix of fine particles, high-strength aggregates, and a low water-to-cement ratio. UHPC offers superior performance and is used in construction projects where high-strength and durability are required. UHPC (Ultra-High Performance Concrete) beams are advanced structural elements known for their exceptional strength, durability, and resistance. Simulating UHPC beams using software like Abaqus is crucial for evaluating their behavior under different loads and optimizing their design. With Abaqus simulations, engineers can analyze the structural response, stresses, and deformations of UHPC beams, ensuring they meet safety standards and design requirements. In this project package, you will learn how to simulate UHPC beams in 6 practical workshops.

Techniques of simulating Large and Complex models in Abaqus

Sometimes, there is a need to simulate large or complex models in Abaqus, such as airplanes and cars. Generally, models with more than 5 million variables or take at least 12 hours to analyze are considered large. Processing such models requires a significant amount of time and energy, in addition to potential issues with modeling, loading, boundary conditions, and more. Therefore, it is necessary to find ways to simplify and accelerate the analysis of such models.

In this training package, you will learn various methods to address these challenges. Dealing with large models typically involves simplifying the model, making efficient use of system resources, and minimizing CPU time. These techniques are explained in detail here. Additionally, you will be taught various techniques to aid in the management of large models, including submodeling, history output filtering, restart functionality, and parts and assemblies.

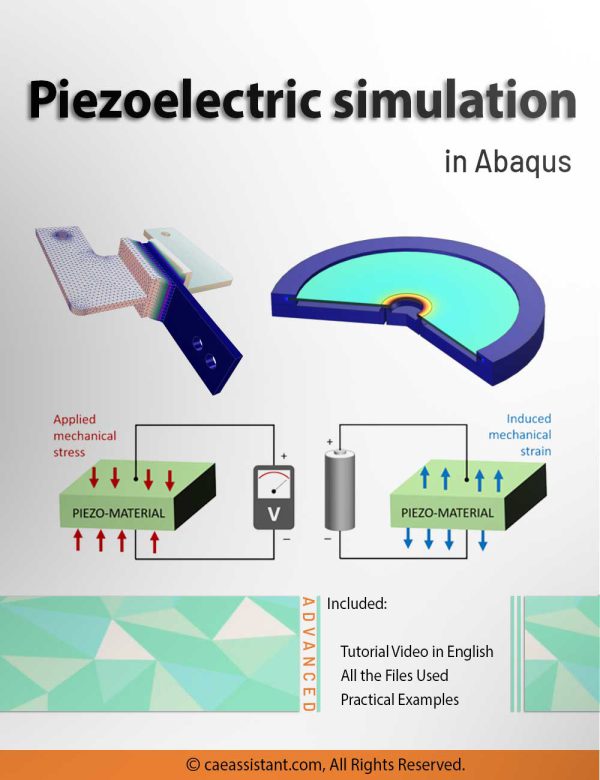

Piezoelectric simulation in Abaqus

Piezoelectric materials exhibit a unique property known as piezoelectricity, where they can generate electric charges when subjected to mechanical stress or deformation, and conversely, deform when an electric field is applied. This phenomenon arises from their crystal structure, enabling the conversion of mechanical energy into electrical energy and vice versa.

Simulating piezoelectric materials is of great importance as it allows engineers to optimize the design and performance of devices and systems that utilize these materials. Through simulations, engineers can analyze factors like stress distribution, deformation, and electrical response, aiding in performance prediction and failure analysis. Simulations also enable the study of parameter sensitivity, understanding how changes in parameters impact piezoelectric devices. This information helps in making informed design decisions and optimizing the integration of piezoelectric components into larger systems. Furthermore, simulating piezoelectric materials reduces the need for physical prototypes, saving time and costs associated with experimental setups. It enhances the understanding and development of piezoelectric technology, facilitating its widespread application in various industries.

In this training package, you will learn what is a piezoelectric, types of piezoelectric, piezoelectric applications, and how to simulate piezoelectrics in Abaqus.

Abaqus for Civil Engineering Part-1

The "Abaqus for Civil Engineering” package is a comprehensive and invaluable resource designed to cater to the needs of civil engineering professionals, students, and enthusiasts alike. This all-inclusive package comprises a collection of several specialized tutorial packages, making it an essential tool for mastering various aspects of civil engineering.

With this package, you gain access to an extensive library of high-quality video tutorials that cover a wide range of topics within civil engineering. Each tutorial provides clear, concise, and engaging explanations of fundamental concepts, advanced techniques, and practical applications.

DISP and VDISP Subroutines in ABAQUS

In a very simple form, DISP and VDISP subroutines are used to define user-defined boundary conditions. For example, when you need to define a boundary condition to be time-dependent, location-dependent, or even both, you should use the DISP and VDISP subroutines. ABAQUS features cannot be sufficient for problems with location-dependent and time-dependent boundary conditions simultaneously. In these cases, this subroutine can be useful to solve the challenges. In This package, you will understand the usages of these subroutines and how to work with them in three conceptual and simple workshops.

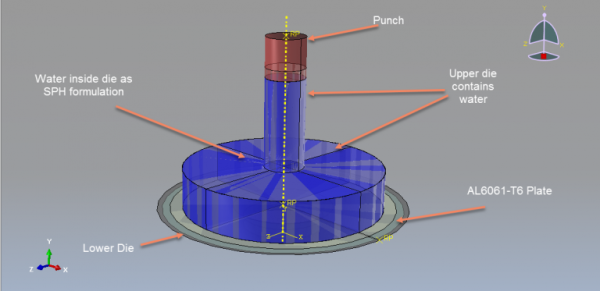

Hydroforming simulation in Abaqus

Notice: This package will be available one week after purchase.

Hydroforming is a metal forming process that allows the shaping of various metals, such as steel, stainless steel, copper, aluminum, and brass. It is a cost-effective and specialized form of die molding that utilizes highly pressurized fluid to shape the metal. Hydroforming can be classified into two main categories: sheet hydroforming and tube hydroforming. Sheet hydroforming uses a single die and a sheet of metal, while tube hydroforming involves expanding metal tubes using two die halves. Hydroforming simulation in Abaqus is a valuable tool for optimizing the hydroforming process. It enables engineers to predict and analyze important factors such as material flow, stress distribution, thinning, and wrinkling during the forming process. By accurately simulating the hydroforming process, engineers can optimize key parameters like fluid pressure, die design, and material properties to achieve the desired shape with minimal defects. In this package, you will learn hydroforming process simulation with the SPH method and using time-pressure curve.

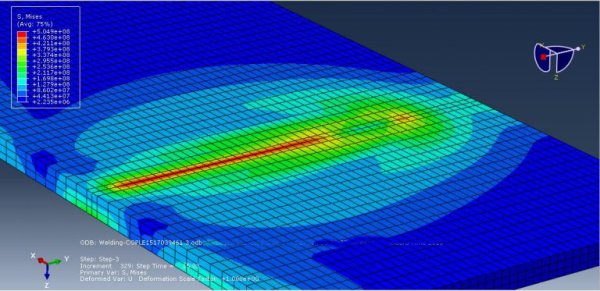

Arc welding simulation in Abaqus

Arc welding is a fusion process that involves joining metals by applying intense heat, causing them to melt and mix. The resulting metallurgical bond provides strength and integrity to the welded joint. Arc welding is widely used in various industries for fabricating structures and components. Arc welding simulation in Abaqus is essential for optimizing the welding process and ensuring high-quality welds. It allows engineers to predict and analyze factors such as temperature distribution, residual stresses, distortion, and microstructure evolution during welding. By accurately simulating the welding process, parameters like welding speed, heat input, and electrode positioning can be optimized to achieve desired weld characteristics and minimize defects.

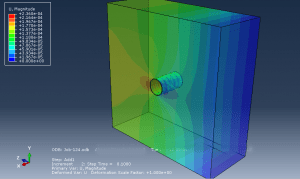

Tunnel excavation simulation using TBM in Abaqus

Notice: This package will be available one week after purchase.

Tunnel Boring Machines (TBMs) are advanced construction equipment used to excavate tunnels with efficiency and precision. These massive machines consist of a rotating cutting wheel equipped with disc cutters, which excavate the soil or rock, and a conveyor system that removes the excavated material from the tunnel. TBMs play a crucial role in various industries, including transportation, mining, and underground infrastructure development. TBM simulation is of utmost importance in the planning and execution of tunneling projects. It allows engineers and project managers to evaluate the feasibility of different tunneling methods, optimize the design and operation of TBMs, and predict potential challenges and risks. By simulating the TBM's performance and behavior under various geological conditions, factors such as ground stability, excavation rates, cutter wear, and potential impacts on surrounding structures can be analyzed and mitigated. In this package, you will learn how to do a TBM simulations by several practical examples.

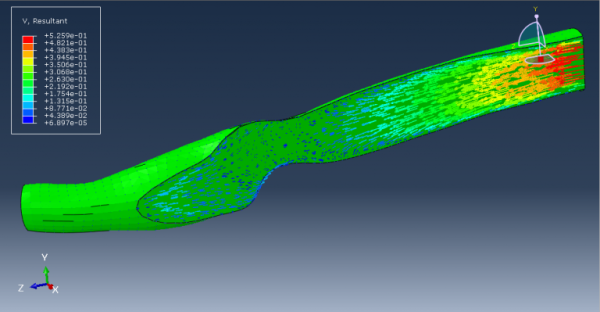

Blood Flow Analysis in Abaqus

Human blood is a vital fluid that circulates through the body, carrying oxygen, nutrients, hormones, and immune cells. Simulation of human blood is crucial for understanding cardiovascular diseases, hemodynamics, and therapeutic interventions. It enables researchers to study the complex behavior of blood flow, investigate disease mechanisms, and develop improved diagnostic and treatment strategies. This package contains three workshops that would help you simulate blood flow in vessels: “Human blood with coronary vessel Fluid Structure Interaction simulation in Abaqus”, “Blood and vessel FSI simulation using Abaqus-Co Simulation process”, and “Non-Newtonian blood flow Simulation in Abaqus”.

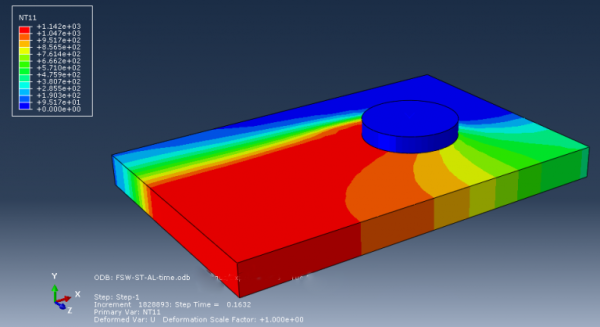

Friction Stir Welding (FSW) Simulation in Abaqus

Friction stir welding (FSW) is a solid-state joining process that utilizes a rotating tool to generate frictional heat, enabling the consolidation of materials without melting. FSW offers numerous benefits and is particularly valuable for welding challenging materials like aluminum alloys. It finds widespread applications in industries such as automotive, aerospace, shipbuilding, and construction, providing enhanced strength, weight reduction, and structural integrity. FSW minimizes distortion, reduces the need for post-weld machining, and eliminates issues related to solidification and cooling. Simulations using Abaqus, a popular finite element analysis software, play a crucial role in optimizing FSW processes. Engineers can investigate process parameters, evaluate weld quality, predict residual stresses and distortions, and optimize weld designs through Abaqus simulations. These simulations enable cost-effective development, improved weld quality, reduced material waste, and enhanced productivity in industrial applications. In this package, you will learn how to simulate FSW simulations in a variety of examples with different methods.

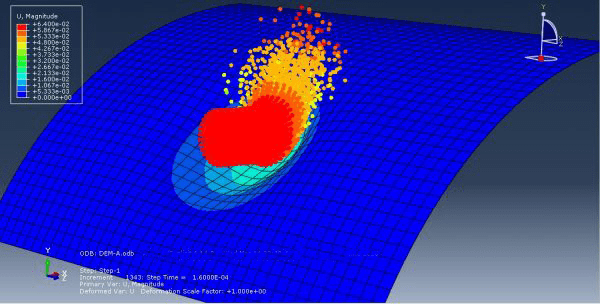

Soil Impact Analysis in Abaqus

Soil impact refers to the interaction between a solid object and the soil, wherein the object collides with or penetrates into the soil. This issue holds great importance across various industries, including civil engineering, geotechnical engineering, construction, and transportation. Understanding soil impact behavior is crucial for designing and assessing the safety and performance of structures and systems subjected to dynamic loads, such as vehicle collisions, pile driving, and projectile impacts. Simulation plays a vital role in studying soil impact. By employing advanced numerical methods and software tools like Abaqus, researchers and engineers can accurately model and analyze the complex interactions between objects and soil. Simulation allows for the investigation of various parameters, such as impact velocity, soil properties, object geometry, and boundary conditions, to assess their influence on the response and behavior of the system. In this package, you will learn how to do soil impact simulations in several practical examples.

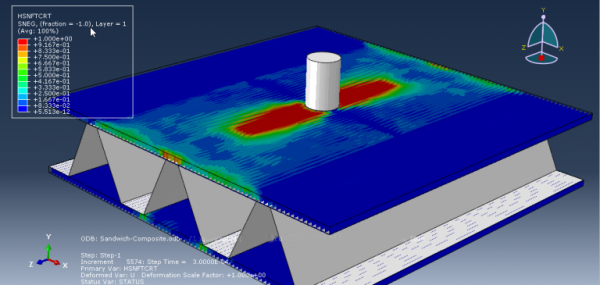

Low-Velocity Impact simulation

Low-velocity impact refers to the collision between objects at relatively low speeds. While the impact energy may be lower compared to high-speed impacts, low-velocity impacts can still cause significant damage and deformation. Assessing the effects of low-velocity impact is crucial for various industries to ensure the structural integrity, safety, and performance of their products. For example, in the automotive industry, understanding the response of vehicles to low-velocity impacts is essential for designing crashworthy structures and improving occupant safety. In aerospace, assessing the impact resistance of aircraft components, such as fuselage panels or wings, helps ensure their ability to withstand ground handling incidents or bird strikes. In this package, you will learn how to do low-velocity impact simulations with several practical examples.

UHPFRC (Ultra-High-Performance Fiber Reinforced Concrete) structures in Abaqus

UHPFRC (Ultra-High-Performance Fiber Reinforced Concrete) structures have emerged as a groundbreaking innovation in construction. These structures offer exceptional strength, durability, and performance, revolutionizing the industry. UHPFRC incorporates a precise combination of Portland cement, fine aggregates, admixtures, and steel or synthetic fibers, resulting in an extraordinarily dense and robust composite material. With compressive strengths exceeding 150 MPa, UHPFRC structures exhibit enhanced resistance to cracking, increased load-bearing capacity, and improved durability against environmental factors such as corrosion and freeze-thaw cycles. The superior mechanical properties of UHPFRC enable the design of slimmer and lighter elements, leading to reduced material consumption and more sustainable construction practices. UHPFRC structures find applications in various fields, including bridges, high-rise buildings, marine structures, and precast elements, offering long-term performance and contributing to the advancement of modern construction. In this package, you will learn how to simulate these structures with many practical examples.

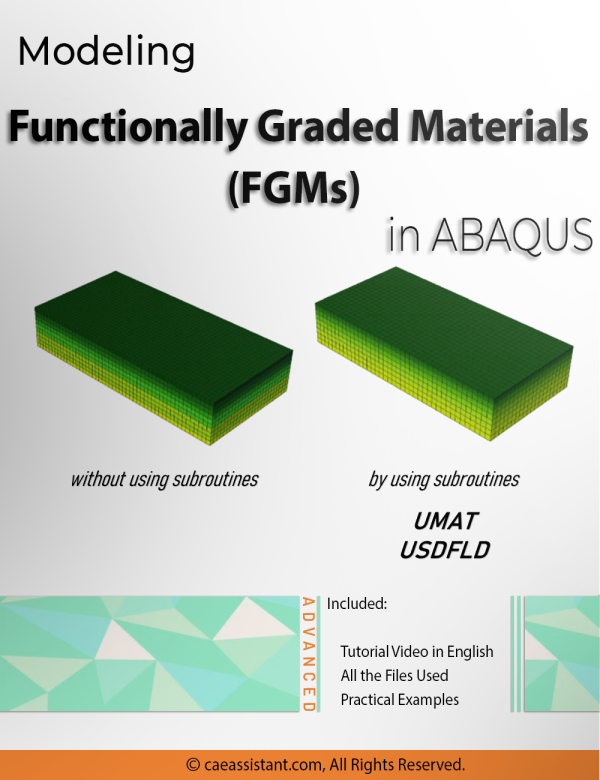

Modeling Functionally Graded Materials (FGMs) in ABAQUS

Dive into the realm of innovative engineering with our comprehensive tutorial package, designed to empower you in modeling Functionally Graded Materials (FGM) using the Abaqus USDFLD subroutine. Uncover the fascinating world of FGMs, materials that ingeniously vary their composition and microstructure, offering a nuanced control over mechanical, thermal, and other properties.

The workshop component takes you on an exploration of crack paths in Spherical Functionally Graded Materials, emphasizing simulation techniques using Abaqus Standard and the USDFLD subroutine. Uncover the secrets of stress distribution within a pressured, empty sphere, and enhance your skills by implementing the XFEM method for precise crack characterization. This training ensures you gain valuable insights into subroutine development, empowering materials engineers and designers to innovate and elevate the performance of structures across various industries. Embark on your journey to mastery with this all-encompassing tutorial package.

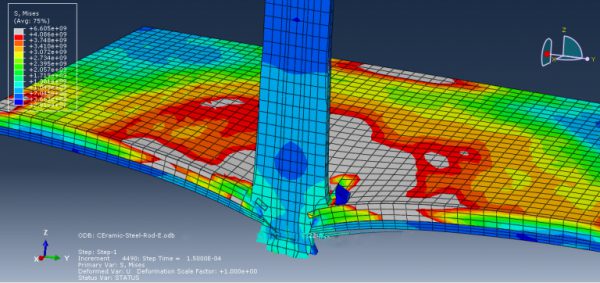

High Velocity Impact Simulation

High-velocity impact refers to the collision between two bodies at extremely high speeds, typically involving projectiles and targets. It is a phenomenon of great interest in various fields, including defense, aerospace, and automotive industries. High-velocity impact simulation in Abaqus is a computational approach used to analyze and predict the behavior of materials and structures subjected to such impacts. Abaqus, a powerful finite element analysis software, enables engineers and researchers to model and simulate the complex interactions between impacting bodies, accurately predicting factors like stress, strain, deformation, and damage. By simulating high-velocity impacts in Abaqus, engineers can gain valuable insights into the performance and integrity of materials and structures, ultimately aiding in the design of safer and more resilient systems. In this package, you will learn how to do these simulations in many practical examples.

Composite Pressure Vessel simulation in ABAQUS

Pressure vessels are made using different methods today, and one of them is filament winding. This package shows the simulation of composite pressure vessels made using the filament winding method.

In this training package, three winding methods, planar, geodesic, and isotensoid, have been taught for filament winding pressure vessels. In this tutorial, two general methods also have been presented for simulating filament wound pressure vessels. One uses the Abaqus graphical user interface(GUI), and the other uses the Python script. On the other hand, two criteria, Tsai-Hill and Puck, have been used to model damage in the composite. A UMAT subroutine has been used to use the Puck criterion.

Hypermesh Course for Beginners

This training package includes workshops that help you to learn about basics of hypermesh and how to use it. This is the most comprehensive tutorial containing ways to do the basic designing, importing and exporting abaqus file.

The subjects such as creating lines,nodes,2D mesh, surfaces, creating tetramesh, creating 3d bodies,enhancing mesh quality etc are covered in this tutorial.

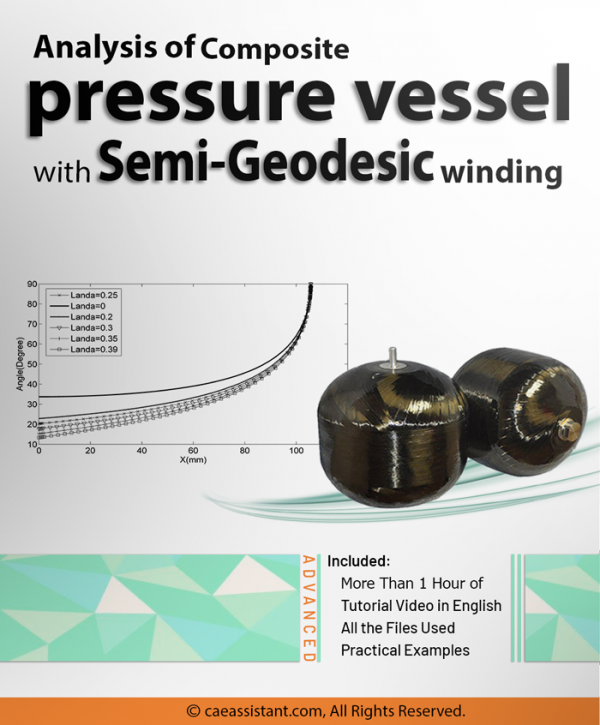

Composite pressure vessel analysis with Semi-Geodesic winding

Nowadays, pressure vessels are produced using various methods, one of which is filament winding. This package teaches the simulation of composite pressure vessels produced using the filament winding method. Filament winding itself has different methods, and one of the most widely used winding methods for producing composite vessels is the semi-geodesic filament winding method. In this package, first, the semi-geodesic method is described. Then, the simulation of a semi-geodesic vessel is performed using a Python script. Additionally, a UMAT subroutine is used to simulate the failure of composite materials used in the vessel.

Full Composite fatigue Add-on (Academic and industrial usage)

This package is designed to instruct users on how to utilize the composite fatigue modeling Add-on, which removes the need to write a subroutine for composite fatigue modeling. Instead, users can select the composite type, input material properties, and generate the subroutine by clicking a button. The Add-on includes four types of composites, and the generated subroutine for all types is the UMAT. These four types are Unidirectional, Woven, short fiber composites (chopped), and wood. The fatigue criteria used for each type are the same as its respective package. For example, the fatigue criteria for woven composites are identical to that used in the "Simulation of woven composite fatigue in Abaqus" package. This Add-on provides a simple graphical user interface for composite fatigue modeling, which can be utilized for both academic and industrial applications.

Full Composite damage Add-on (Academic and industrial usage)

This package will teach you how to use the composite damage modeling Add-on. The Add-on eliminates the need for writing a subroutine for composite damage modeling. Instead, you only need to select the desired composite type, input the material properties, and click a button. The Add-on will then generate the subroutine for you. The Add-on includes four types of composites: Unidirectional, Woven, short fiber composites (chopped), and wood. The generated subroutine for all types is the VUSDFLD. The damage criteria used in each type is the same as the one used in its respective package. For instance, the damage criteria for the woven composite is identical to the one used in the "Simulation of woven composite damage in the Abaqus" package. This Add-on offers a user-friendly graphical user interface for composite damage modeling, which can be used for academic and industrial purposes.

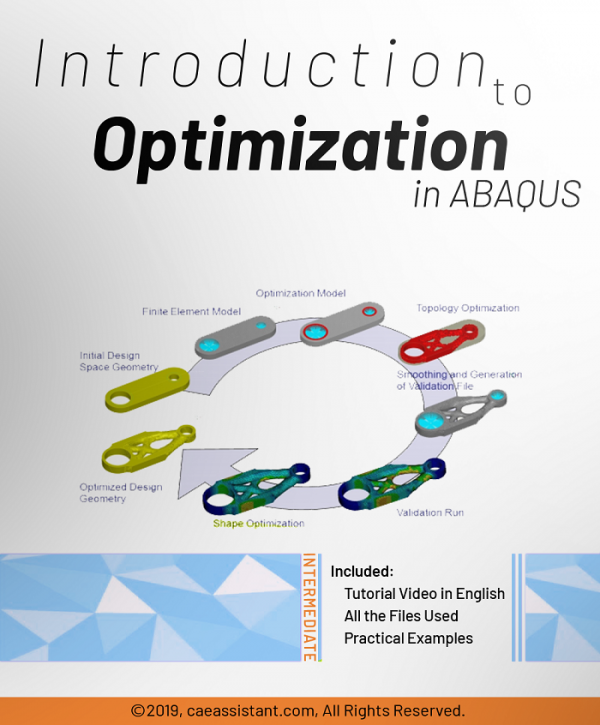

Optimization in ABAQUS

Notice: 2 hours of the package is available now; during 1-month after purchase, it will be completed.

Optimization is a process of finding the best solution to a problem within a set of constraints. It involves maximizing or minimizing an objective function while satisfying a set of constraints. Optimization in Abaqus involves the use of advanced algorithms and techniques to improve the design of structures and systems. Abaqus provides a range of optimization tools, including topology optimization, size optimization, and shape optimization. These tools help in improving the performance of structures by reducing their weight, increasing their stiffness, and minimizing their stress levels. In this package, all types of optimization, such as Topology, will be discussed; after each lesson, there will be workshops to help you to understand optimization with practical examples.