CFD

Mixing tank simulation with Ansys fluent(2D and 3D)

The mixing process is crucial and highly effective in various industrial applications. It finds application in industries such as food and cement manufacturing, among others. This course focuses on the implementation of mixing processes in both 2D and 3D spaces.

This course begins with designing the geometry with complete details. Next, we learn how to use Ansys Meshing software to mesh the geometry in detail and assess the mesh quality. Following this, we apply appropriate two-phase and turbulence models to simulate the process, allowing us to analyze the results. Additionally, we create animations of the process to visualize how the mixing process occurs.

Fluid-Structure Interaction (FSI) refers to the interaction between a deformable or movable structure and an internal or surrounding fluid flow. FSI simulations are vital for understanding and predicting the behavior of systems where fluid and solid components interact. These simulations enable engineers and researchers to study the effects of fluid forces on structures and vice versa.

FSI simulations are crucial in various fields, including aerospace, civil engineering, biomechanics, and automotive industries. They provide valuable insights into the performance, safety, and reliability of engineering systems. By accurately modeling the complex interactions between fluids and structures, FSI simulations can identify potential issues such as vibrations, instabilities, and structural failures.

In this package, you’ll learn simulating FSI in Abaqus within 3 workshops.

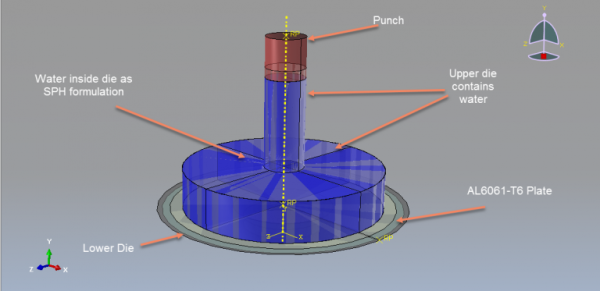

Hydroforming simulation in Abaqus

Notice: This package will be available one week after purchase.

Hydroforming is a metal forming process that allows the shaping of various metals, such as steel, stainless steel, copper, aluminum, and brass. It is a cost-effective and specialized form of die molding that utilizes highly pressurized fluid to shape the metal. Hydroforming can be classified into two main categories: sheet hydroforming and tube hydroforming. Sheet hydroforming uses a single die and a sheet of metal, while tube hydroforming involves expanding metal tubes using two die halves. Hydroforming simulation in Abaqus is a valuable tool for optimizing the hydroforming process. It enables engineers to predict and analyze important factors such as material flow, stress distribution, thinning, and wrinkling during the forming process. By accurately simulating the hydroforming process, engineers can optimize key parameters like fluid pressure, die design, and material properties to achieve the desired shape with minimal defects. In this package, you will learn hydroforming process simulation with the SPH method and using time-pressure curve.

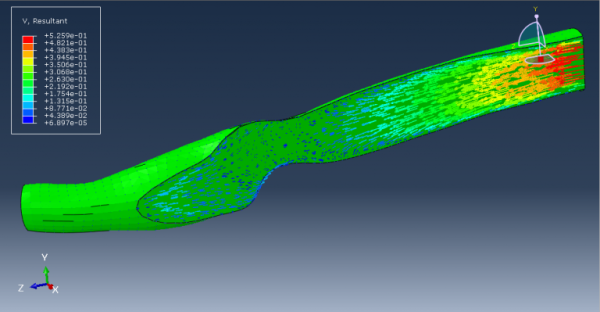

Human blood is a vital fluid that circulates through the body, carrying oxygen, nutrients, hormones, and immune cells. Simulation of human blood is crucial for understanding cardiovascular diseases, hemodynamics, and therapeutic interventions. It enables researchers to study the complex behavior of blood flow, investigate disease mechanisms, and develop improved diagnostic and treatment strategies. This package contains three workshops that would help you simulate blood flow in vessels: “Human blood with coronary vessel Fluid Structure Interaction simulation in Abaqus”, “Blood and vessel FSI simulation using Abaqus-Co Simulation process”, and “Non-Newtonian blood flow Simulation in Abaqus”.

Script to transfer load from CFD to structural model in Abaqus

FEA offers various loading types, such as force, pressure, and temperature, which can be applied to different parts of an object, such as points, surfaces, edges, nodes, and elements. Therefore, applying accurate loading conditions on these features is necessary for reliable simulation results and the safe design of structures. Sometimes, the loading conditions are obtained by another analysis, such as CFD, and need to be transferred and applied to the structural model for the structural analysis; during this transfer, the loads might not be appropriately applied to the model, especially when the loads are complicated like the pressure profile of a space rocket. So in this package, a Python script is presented to solve this issue and transfer the loads properly to the structural model.

9 Practical Workshops for SPH in Abaqus💡 | Abaqus SPH Tutorial

Smoothed Particle Hydrodynamics Tutorial: Abaqus SPH (Smoothed Particle Hydrodynamics) is a numerical method used in this software to model fluid-structure interaction problems. SPH in Abaqus is a meshless approach that uses a set of particles to discretize the fluid domain. The Abaqus SPH modeling tutorial is particularly useful for problems with large deformations, fragmentation, and free surface effects.

It can be used in combination with other Abaqus features, such as finite element analysis, to model coupled fluid-structure systems. This Abaqus SPH tutorial, created by CAE Assistant group, can help you understand and apply this method through practical examples, some of which include projectile impact simulation on a cementitious material, TNT explosion simulation inside a rock using the SPH method, bullet movement through a water pipe in Abaqus, and bird strike simulation in Abaqus.

Earthquake simulation in Abaqus

It is known that an earthquake is a disastrous event that can cause great damage to buildings, structures, and even people. So it's essential to know how a structure will behave when subjected to an earthquake. Therefore engineers must take into account the possibility of an earthquake when designing a structure. With finite element analyses, engineers can predict the behaviour of structures under earthquake loading. With this method, they can determine the best way to design a structure to withstand an earthquake. In this package, you can learn how to do earthquake simulation in Abaqus to have the best design for your structure to save human lives. Three practical examples are presented to you to start simulating earthquakes: “simulating an earthquake over a gravity dam in contact with water and soil”, “simulating an earthquake load over a water-filled tank”, “Abaqus-Micro model simulation of seismic load over masonry wall (concrete brick)”.

Fluid-Structure Interaction also known as FSI is a multiphysics problem where the fluid and structure are coupled. The fluid flow can cause the structure to deform, and the deformation of the structure can affect the flow. So when you want to design something, you need to know how the structure will deform and how that deformation affects the flow. Common examples of FSI analysis are airplanes, cars, spacecrafts, and buildings. Other examples like junctions in piping systems, or the human circulatory system. CFD is a branch of research that uses numerical methods to solve the mathematical equations governing fluid flow, heat transfer, mass transfer, chemical reactions, and related phenomena. In Abaqus, you can model both methods. In this package, we present to you three workshops to get you started with Abaqus CFD and FSI: “Using Abaqus CFD methods, examining heat mixing and reverse flow characteristics in a T-junction”, “impact of air velocity over the short column”, “simulate fluid structure interaction on an aluminum body with a flexible tail in Abaqus”.