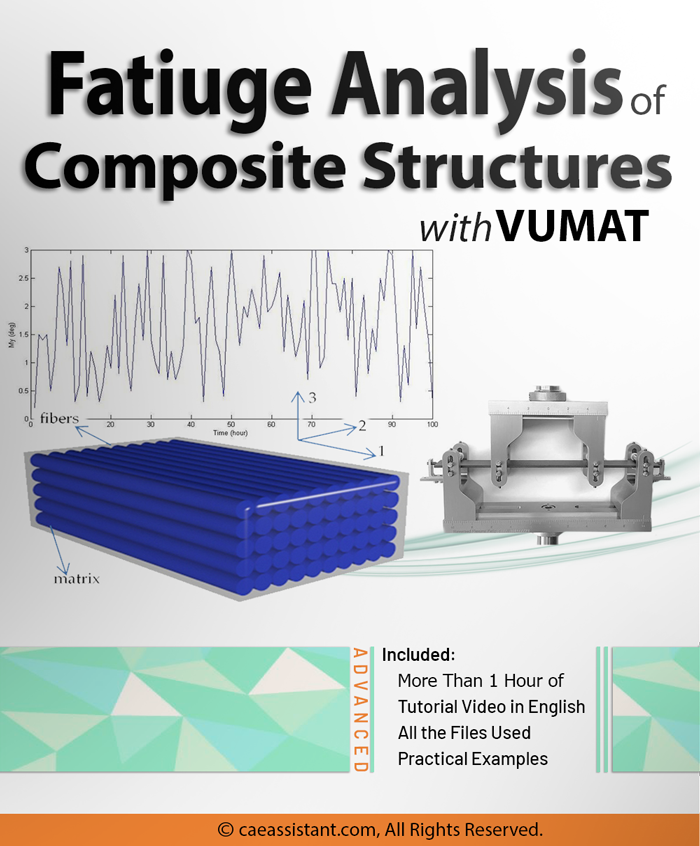

Fatigue analysis of unidirectional composites with VUMAT subroutine

Unidirectional composites are a composite material that differs from other composites in terms of their reinforcement structure. In unidirectional composites, the fibers are oriented in a single direction, which gives them high strength and stiffness in that direction. This makes them ideal for applications requiring high strength and stiffness in a specific direction. The main difference between unidirectional composites and other composites is their reinforcement structure, which affects their mechanical properties and performance in different applications.

The analysis of fatigue in unidirectional composites has significant industrial applications. For example, this composite type is used in aerospace, automotive, construction, and marine industries. Engineers in each of these industries must design composite structures that can withstand cyclic loading over extended periods. Understanding the fatigue behavior of unidirectional composites is crucial for designing these structures, as it enables engineers to optimize the design to ensure durability and reliability. Additionally, using advanced computational tools such as the VUMAT subroutine in Abaqus for fatigue analysis of unidirectional composites can improve the accuracy of the simulation, leading to more efficient and cost-effective design and testing processes.

Overall, this training package is an essential resource for engineers and researchers working with composite materials, as it provides a comprehensive understanding of composite fatigue behavior and the necessary tools to simulate it accurately using the VUMAT subroutine in Abaqus.

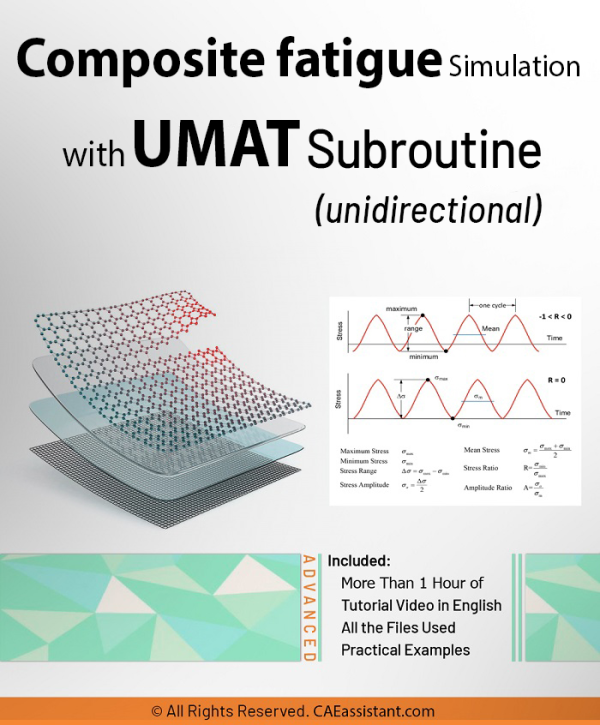

The difference between this package and Composite Fatigue Simulation with UMAT Subroutine in ABAQUS is that acceleration effects are also included in each cycle because VUMAT subroutine works with a dynamic solver. In this training package, after the explanation of the Shokrieh fatigue theory, which is similar to mentioned package, the flowchart of the subroutine is explained. In the next step, the used subroutine is explained line by line in the undirectional composite fatigue problem.

Lesson1: Fatigue of composite materials

Lesson 1 covers the topic of fatigue in composite materials. The chapter starts by explaining the differences between composites and traditional materials regarding fatigue behavior. It then discusses the various factors contributing to fatigue in composites, including the material properties, loading conditions, and environmental effects.

The chapter emphasizes the importance of considering fatigue in designing and testing composite structures, as these materials are often subjected to cyclic loading over extended periods. Engineers must understand the fatigue behavior of composites to ensure that the structures they design can withstand fatigue and have acceptable levels of durability and reliability.

By understanding these concepts, engineers can develop more robust composite structures that can withstand cyclic loading over extended periods.

Lesson2: Failure of composite materials

Lesson 2 covers the topic of failure in composite materials. The chapter starts by exploring the different failure mechanisms that can occur in composites under fatigue loading, including delamination, matrix cracking, fiber breakage, and other forms of damage.

The chapter then discusses the various testing methods used to evaluate the fatigue behavior of composite materials, including tension-tension, tension-compression, and flexural fatigue testing. These methods are essential for understanding the fatigue behavior of composites and developing accurate models for predicting their fatigue life.

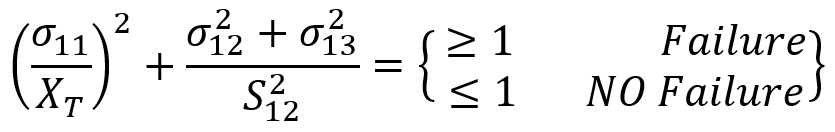

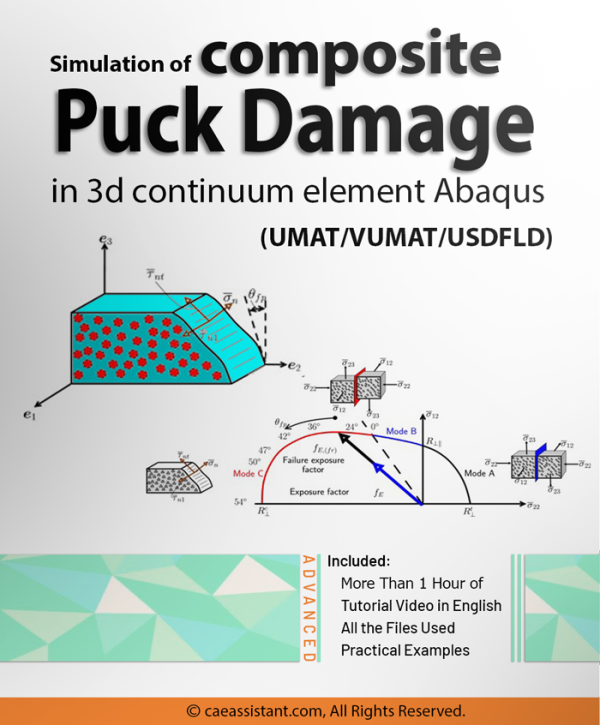

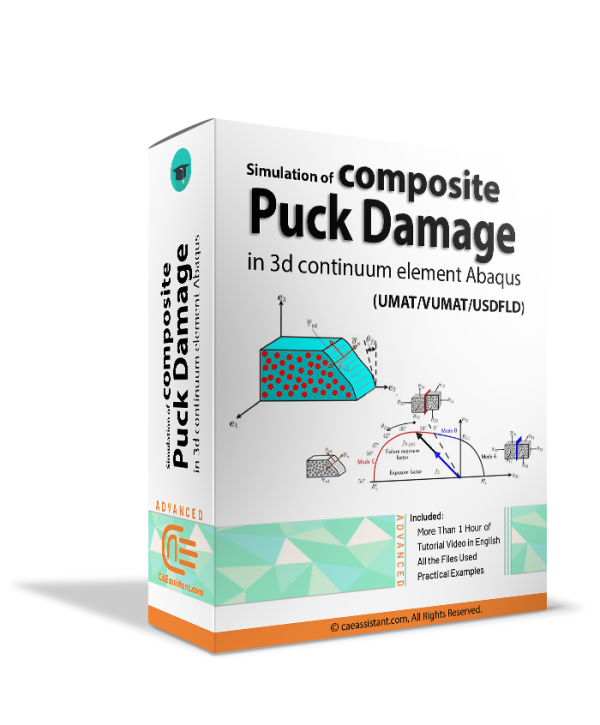

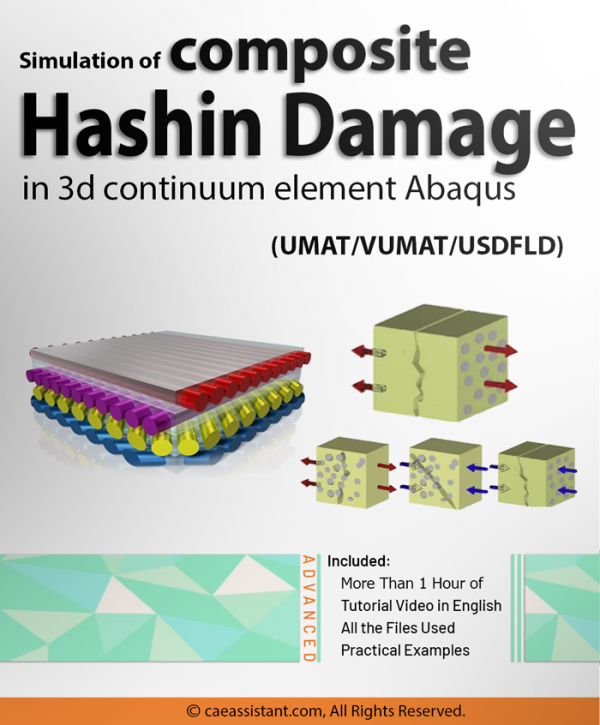

Finally, the chapter introduces the Hashin failure criteria, which are widely used to predict failure in composite materials. The Hashin criteria identify the critical stresses and strains that can cause failure in composites and provide a framework for developing accurate models for predicting the fatigue behavior of composites.

To use the Hashin criteria to predict failure in composites, engineers must first determine the composite’s material properties and loading conditions. They then apply the appropriate version of the Hashin criteria to calculate the critical stresses or strains that could cause failure in the material. By comparing these critical values to the actual stresses or strains in the composite, engineers can determine whether or not the material is at risk of failure under the given loading conditions.

- Fiber debonding under tension

- Fiber debonding under compression

- Matrix debonding under tension

- Matrix debonding under compression

Lesson 3: Fatigue effects in composites

Lesson 3 covers the topic of fatigue effects in composite materials. The chapter starts by explaining how repeated loading can affect the properties and performance of composite materials over time. It then discusses the reduction of the fatigue life of composites and the reduction of their strength and mechanical properties.

The reduction of the fatigue life of composite materials is a complex phenomenon that involves progressive damage accumulation and eventual failure under cyclic loading. This damage can take many forms, including delamination, matrix cracking, fiber breakage, and other types of damage that contribute to the degradation of composite materials over time.

Lesson 4: Composite fatigue analysis with VUMAT

Lesson 4 of “Composite Fatigue Simulation with VUMAT Subroutine in ABAQUS” covers the topic of fatigue simulation using the VUMAT subroutine in ABAQUS. The chapter starts by explaining the importance of accurate fatigue simulation in designing and testing composite structures. It then discusses the various steps involved in setting up and running a fatigue simulation using VUMAT Subroutine in ABAQUS.

The chapter provides a detailed explanation of the VUMAT Subroutine. The VUMAT Subroutine is a powerful tool that can be used to accurately model the complex behavior of composite materials under fatigue loading and predict their fatigue life.

The chapter also covers the different types of fatigue simulations that can be performed using the VUMAT Subroutine in ABAQUS, including stress-life and strain-life methods. These methods are used to predict the fatigue life of composite materials under different loading conditions and provide valuable insights into the behavior of these materials under cyclic loading.

Finally, the chapter provides a step-by-step guide to setting up and running a fatigue simulation using VUMAT Subroutine in ABAQUS. This includes creating the input file, defining the material properties, and specifying the simulation’s loading and boundary conditions.

Workshop1: VUMAT Subroutine validation with reference for one element

Workshop 2 ” focuses on validating the VUMAT Subroutine for one element. The workshop is designed to help engineers better understand the VUMAT Subroutine and its application in composite fatigue simulation.

The workshop begins by introducing the concept of one-element validation, which involves testing and validating a single-element model. This approach is used to verify the accuracy and reliability of the VUMAT Subroutine and ensure that it can accurately predict the behavior of composite materials under fatigue loading. The workshop then discusses the various steps involved in setting up and running a one-element validation test using VUMAT Subroutine in ABAQUS. This includes defining the material properties, specifying the loading conditions and boundary conditions, and analyzing the results of the simulation.

Workshop 2: VUMAT Subroutine validation with reference for complex model

Workshop 2 focuses on validating the VUMAT Subroutine for a complex model. The workshop is designed to help engineers better understand the VUMAT Subroutine and its application in composite fatigue simulation for more complex models.

The workshop introduces a complex model of a notched composite panel, which is commonly used in aerospace and other industrial applications. This model presents several challenges for fatigue simulation and requires a more advanced approach to ensure accurate and reliable results.

The workshop discusses the various steps involved in setting up and running a fatigue simulation using VUMAT Subroutine for the complex model. This includes defining the material properties, specifying the loading and boundary conditions, and analyzing the simulation results.

Overall, Workshop 2 provides a comprehensive overview of the validation of the VUMAT Subroutine for a complex model. By understanding these concepts and techniques, engineers can develop more accurate and reliable models for predicting the fatigue behavior of composite materials and designing more robust composite structures that can withstand cyclic loading over extended periods, even for more complex geometries and configurations.

You can access all subroutine and software files immediately after purchase on your dashboard. Then, the video training will be available on your dashboard with delay. Using this tutorial package, you will learn how to model unidirectional composite fatigue with VUMAT in a dynamic problem. If you are working on Abaqus composite damage and need some resources about composite FEM simulation, click on the Abaqus composite analysis page to get more than 20 hours of video training packages of composite materials simulation.

Nikhil –

This package provides a comprehensive understanding of composite fatigue behavior and equips engineers and researchers with the necessary tools for its analysis and simulation. The chapters are well-organized and cover all the essential aspects, from a general overview of fatigue behavior to the practical application of the VUMAT subroutine. This package maintains a suitable balance between theory and practical implementation, making it appropriate for both beginners and professionals.

Arjun –

I am thoroughly impressed with the training package on composite fatigue analysis with the VUMAT subroutine in ABAQUS. The package provides a comprehensive and systematic approach to understanding and simulating composite fatigue. Each chapter builds upon the previous one, gradually deepening the knowledge and skills required for accurate fatigue analysis. The inclusion of practical examples and case studies enhances the learning experience, allowing for a better grasp of the concepts. The package has significantly enhanced my understanding of composite fatigue and equipped me with the necessary tools to tackle real-world projects. I highly recommend it to engineers and researchers in the industry.