Emily Chen, an esteemed expert in Shape Memory Alloy (SMA) simulation using Abaqus, hails from Canada. With a strong educational background, extensive experience, and deep expertise in SMA behavior, Emily has emerged as a leading authority in the field of SMA material modeling and simulation.

Education and Early Career:

Emily completed her Bachelor’s degree in Materials Engineering from the University of Toronto, where she developed a keen interest in smart materials and their applications. Motivated by her fascination with SMA, she pursued further education and obtained a Master’s degree in Materials Science and Engineering from McGill University. During her studies, Emily focused on understanding the unique properties and behaviors of SMA alloys.

Professional Accomplishments:

After completing her education, Emily joined a prominent engineering consultancy firm in Toronto, where she specialized in SMA simulation using Abaqus. Her exceptional knowledge of SMA behavior and proficiency in utilizing Abaqus software quickly gained recognition. Emily’s expertise allowed her to work on a wide range of projects, including biomedical devices, aerospace applications, and robotics.

Expertise and Contributions:

Emily Chen’s expertise lies in simulating and modeling the behavior of Shape Memory Alloys using Abaqus. She has a deep understanding of SMA constitutive models, phase transformations, and the unique thermomechanical responses exhibited by these materials. Emily is skilled in accurately capturing the shape memory effect, superelasticity, and hysteresis behavior of SMAs through advanced material modeling techniques.

Using Abaqus, Emily has successfully simulated SMA components and systems, including SMA actuators, springs, and adaptive structures. She excels in modeling complex geometries, applying appropriate boundary conditions, and accurately predicting the thermomechanical response of SMA materials under different loading conditions. Emily’s expertise also extends to simulating the training and recovery processes of SMAs, optimizing their performance and durability.

Emily actively stays updated with the latest advancements in SMA modeling and simulation techniques. She continuously explores emerging research and incorporates innovative methods into her simulations. Emily is known for her ability to collaborate with multidisciplinary teams, including materials scientists, mechanical engineers, and designers, to deliver comprehensive solutions for SMA-based applications.

Conclusion:

Emily Chen’s expertise in SMA simulation using Abaqus, combined with her educational background and professional accomplishments, has positioned her as a respected authority in the field of SMA material modeling and simulation. Her proficiency in utilizing Abaqus software and her deep understanding of SMA behavior enable her to provide innovative solutions for a wide range of engineering challenges. Through her contributions, Emily continues to advance the field of SMA simulation, optimizing designs, improving performance, and unlocking the full potential of Shape Memory Alloys.

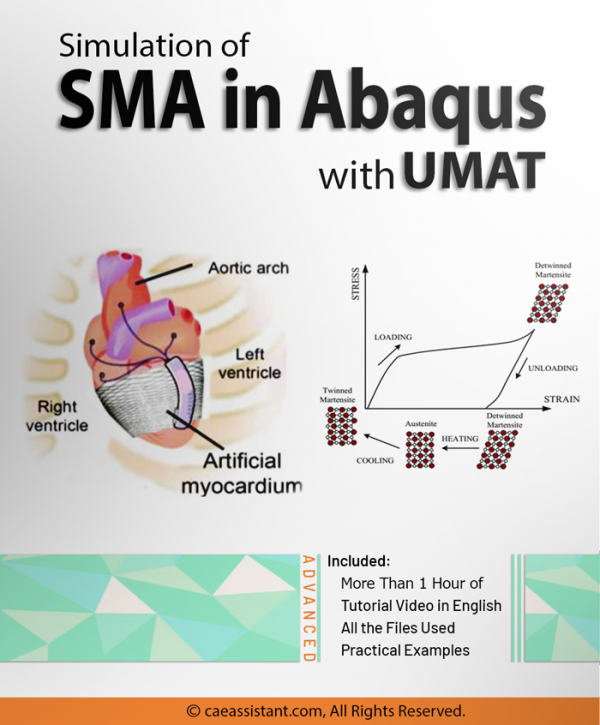

Simulation of SMA in Abaqus with UMAT