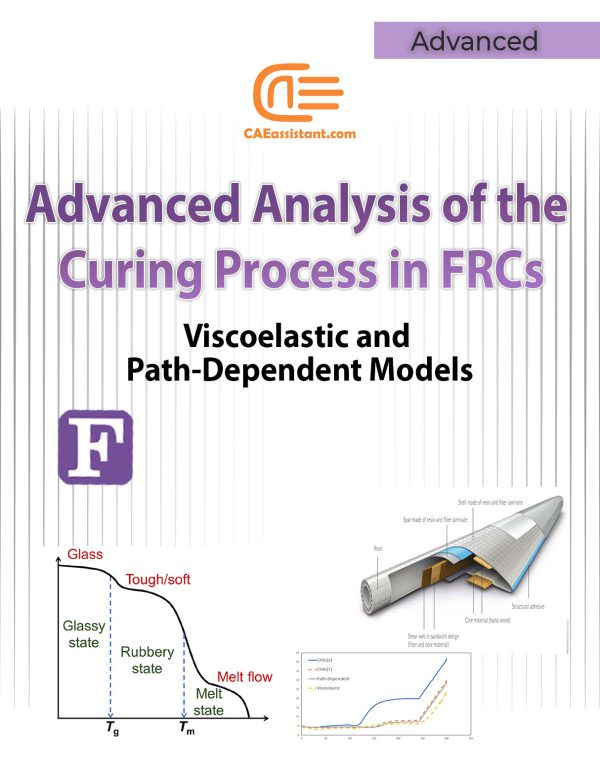

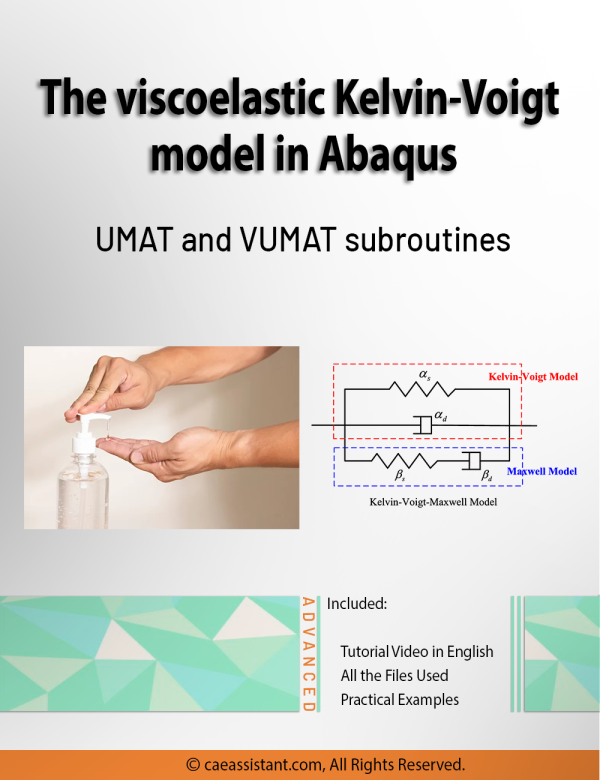

Abaqus Kelvin Voigt Model (Viscoelastic) Simulation Using UMAT and VUMAT Subroutines

This research presents a precise three-dimensional mechanical response of viscoelastic materials using Abaqus kelvin voigt viscoelastic model. We performed this kelvin voigt model Abaqus simulation using both UMAT and VUMAT subroutines for standard and explicit solvers.

The behavior of viscoelastic materials is a state between the behavior of a liquid and a solid. In other words, they behave both like liquids and solids. That is to say, there are many natural and synthetic materials that are classified as viscoelastic materials; From the biological structures of the body such as skin, cartilage and tissue to concrete, foams, rubbers, and synthetic polymers. Due to these unique properties, viscoelastic materials have many applications.

In this regard, the primary goals of this study include the development and implementation of an accurate three-dimensional Abaqus kelvin voigt viscoelastic model, and the integration of viscoelastic properties into the analysis, which can improve the prediction of viscoelastic materials response under different boundary and loading conditions.

This tutorial, by customizing the UMAT and VUMAT subroutines to simulate flexible samples behavior, contributes to the advancement of viscoelastic materials design and analysis.

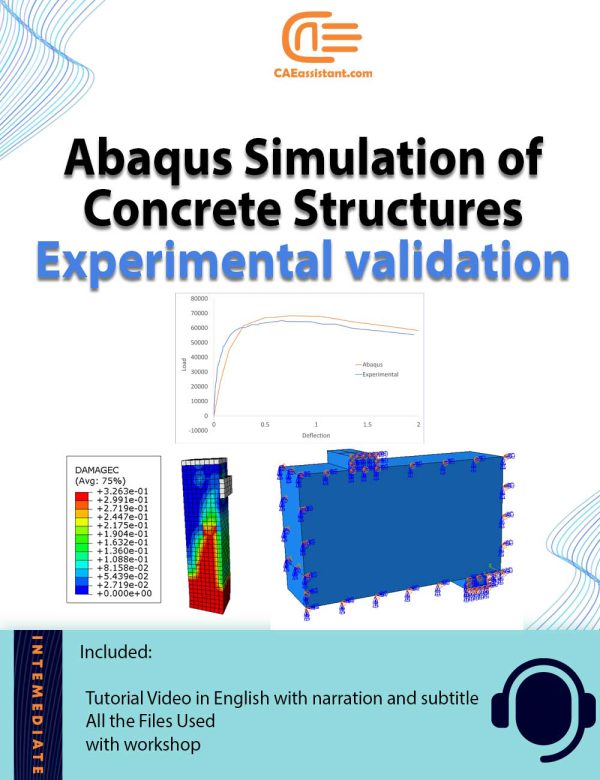

Analysis of Plain and Reinforced Concrete Structures with ABAQUS | Validation with Experiments

This comprehensive package offers four different workshops focused on the analysis of plain and fiber-reinforced concrete structures using ABAQUS. Designed for professionals, researchers, and students, it provides hands-on learning in modeling, simulating, and validating concrete structures under various conditions. Each workshop dives into specific aspects of concrete behavior, from flexural to compressive strength, incorporating the latest sustainable practices through the use of recycled materials. The package ensures mastery of ABAQUS, offering practical insights and a cost-effective path to advanced concrete analysis and safer, more durable infrastructure design.

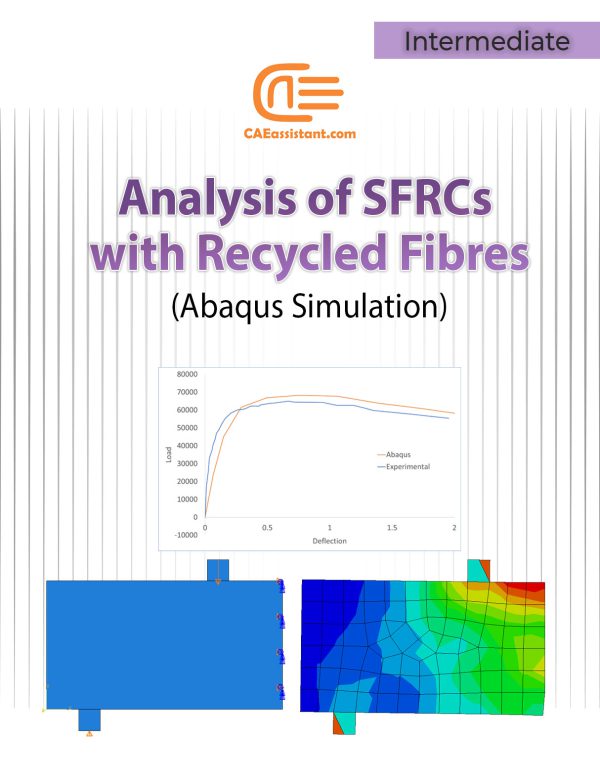

Note: Only the first workshop has video.Stress-strain characteristic of SFRC using recycled fibres | An Abaqus Simulation

This training utilizes Abaqus software to simulate and analyze the stress-strain characteristics of Steel Fiber Reinforced Concrete (SFRC) using recycled fibers. The importance of this work lies in its contribution to sustainable construction practices by validating the effectiveness of recycled steel fibers in enhancing concrete's mechanical properties. Through advanced finite element analysis (FEA), the project addresses challenges in accurately modeling SFRC's post-cracking behavior, ensuring that the simulations are aligned with experimental data for reliable results. Abaqus' capabilities in nonlinear material modeling, stress-strain simulation, and principal stress analysis significantly improve the accuracy and reliability of the research, making it a valuable tool for both academia and industry.

Nonlinear Analysis of RC Columns Using ABAQUS | Validation with Experimental Data

Reinforced Concrete (RC) columns are critical components in civil engineering, essential for the stability of buildings, bridges, and infrastructure during seismic events. This study leverages ABAQUS, a powerful finite element analysis (FEA) software, to simulate the seismic performance of RC columns. By modeling columns in 3D and using ABAQUS's advanced tools, we replicate experimental conditions to analyze their behavior under seismic loads. Numerical simulations offer the advantage of exploring various scenarios quickly and cost-effectively, while also allowing for extensive parametric studies. The study details how ABAQUS models both concrete and steel reinforcement, accounts for interaction effects, and applies appropriate loading and boundary conditions. The simulations provide valuable insights into failure modes, load-displacement responses, and crack patterns, offering a comprehensive understanding of RC column performance in seismic scenarios.

Analysis of Steel-Fiber Reinforced Concrete (SFRC) Beams with Abaqus

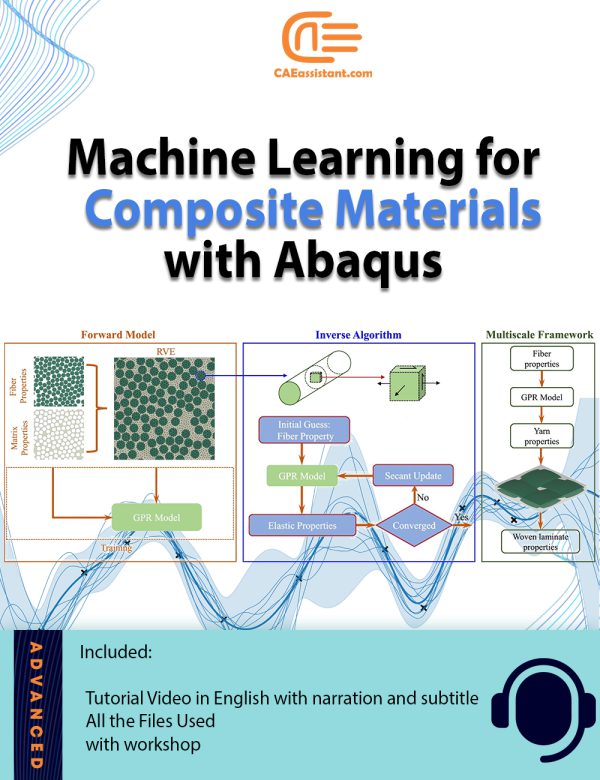

Machine Learning for Composite Materials with Abaqus

This tutorial package delves into an advanced inverse modeling approach for predicting carbon fiber properties in composite materials using a machine learning (ML) technique. Specifically, it covers the use of Gaussian Process Regression (GPR) to build a surrogate model for accurate predictions of fiber properties based on data from unidirectional (UD) lamina. By leveraging Finite Element (FE) homogenization, synthetic data is generated for training the GPR model, accounting for variations in fiber, matrix properties, and volume fractions. This framework’s efficiency and accuracy are validated using real-world data, highlighting its potential as a computational alternative to traditional experimental methods. The package includes detailed explanations, case studies, and practical exercises, equipping users with hands-on experience in applying this ML-based approach to composite material analysis.

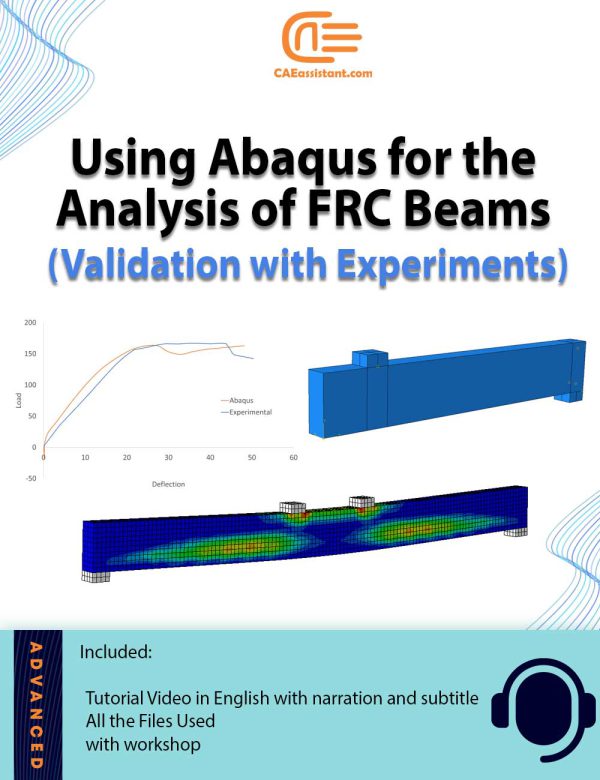

Fiber Reinforced Concrete Beams | An Abaqus Simulation

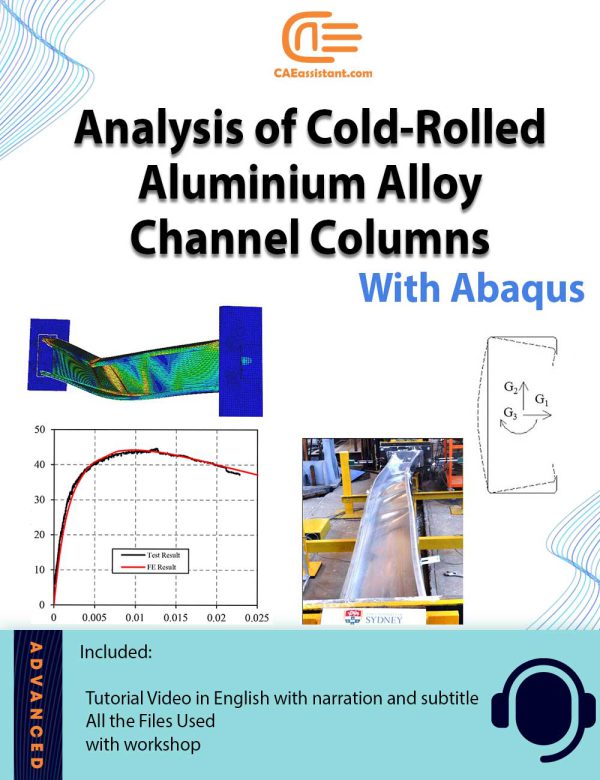

Analysis of Cold Rolled Aluminium Alloy Channel Columns With Abaqus CAE

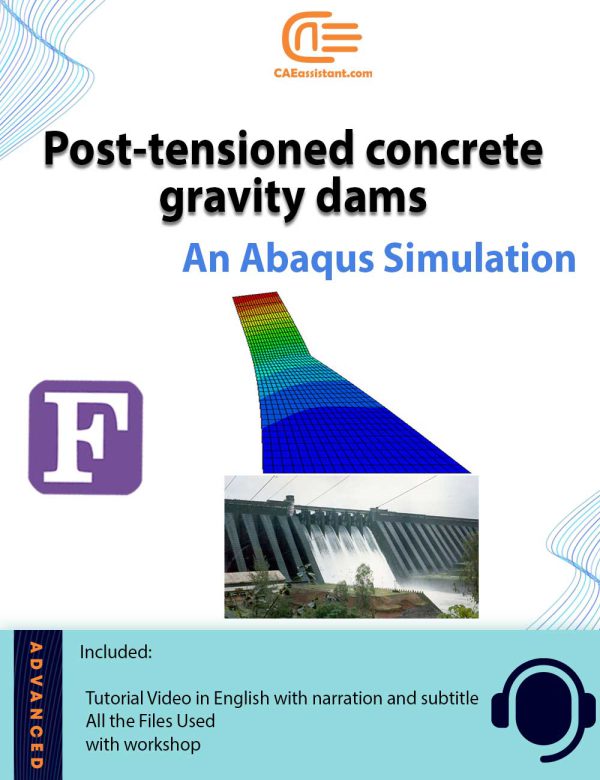

Seismic Analysis in Post-Tensioned Concrete Gravity Dam Design Using Abaqus Subroutines

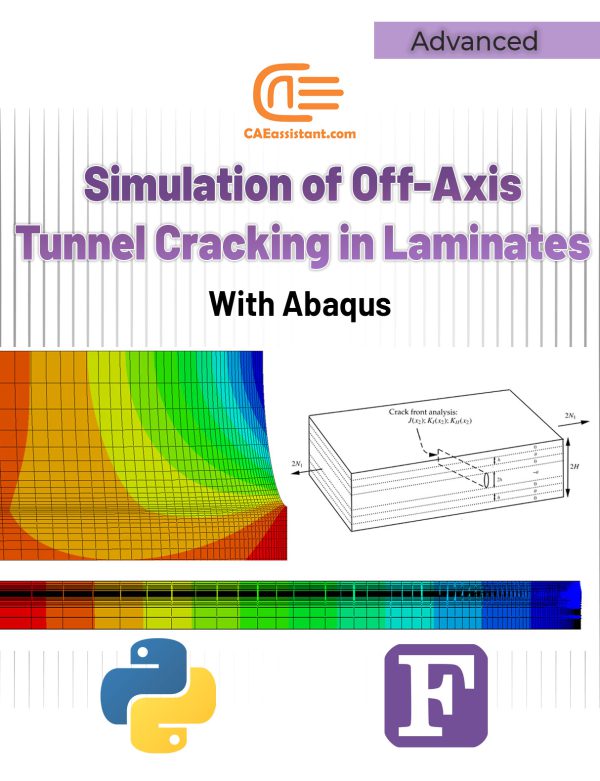

Advanced Finite Element Analysis of Off-Axis Tunnel Cracking Laminates

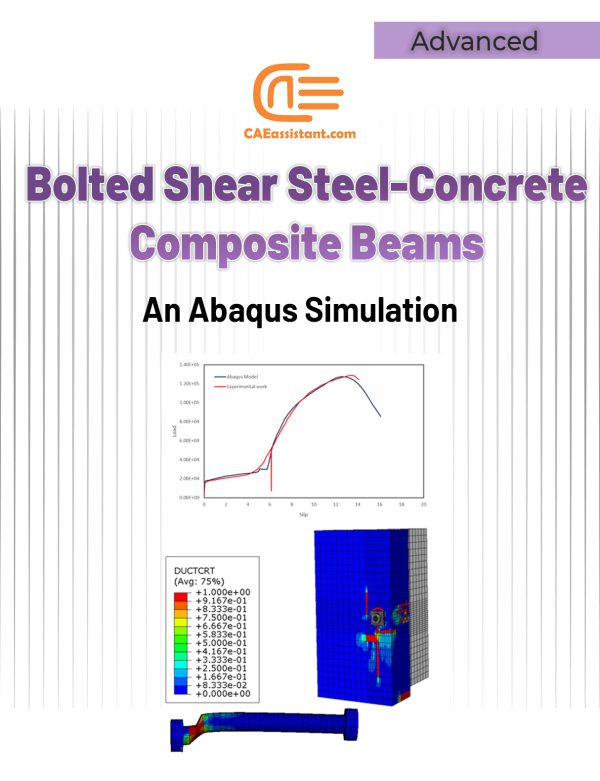

Bolting Steel to Concrete in Composite Beams: ABAQUS Simulation Validated Against Experiments

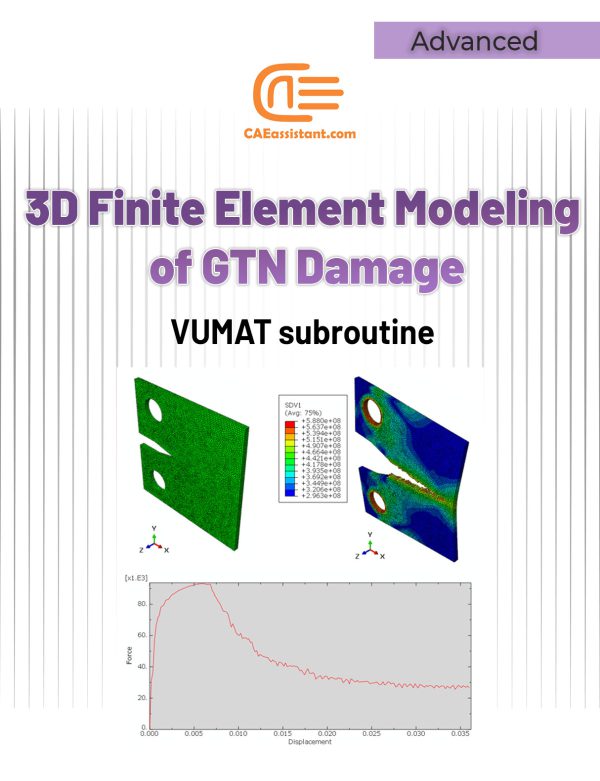

3D Simulation of Gurson-Tvergaard-Needleman (GTN) Damage Model

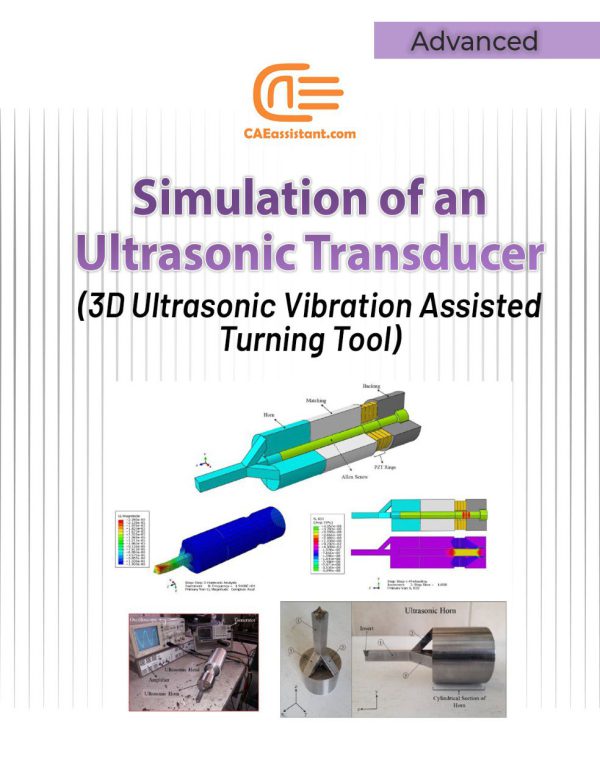

Simulation of an Ultrasonic Transducer (3D Ultrasonic Vibration Assisted Turning Tool)

Since the invention of ultrasonic vibration assisted turning, this process has been widely considered and investigated. The reason for this consideration is the unique features of this process which include reducing machining forces, reducing wear and friction, increasing the tool life, creating periodic cutting conditions, increasing the machinability of difficult-to-cut material, increasing the surface quality, creating a hierarchical structure (micro-nano textures) on the surface and so on. Different methods have hitherto been used to apply ultrasonic vibration to the tip of the tool during the turning process. In this research, a unique horn has been designed and constructed to convert linear vibrations of piezoelectrics to three-dimensional vibrations (longitudinal vibrations along the z-axis, bending vibrations around the x-axis, and bending vibrations around the y-axis). The advantage of this ultrasonic machining tool compared with other similar tools is that in most other tools it is only possible to apply one-dimensional (linear) and two-dimensional (elliptical) vibrations, while this tool can create three-dimensional vibrations. Additionally, since the nature of the designed horn can lead to the creation of three-dimensional vibrations, there is no need for piezoelectric half-rings (which are stimulated by a 180-phase difference) to create bending vibrations around the x and y axes. Reduction of costs as well as the simplicity of applying three-dimensional vibrations in this new method can play an important role in industrializing the process of three-dimensional ultrasonic vibration assisted turning.

In this example, how to model all the components of an ultrasonic transducer and its modal and harmonic analysis are taught in full detail.

Simulation of Pitting Corrosion Mechanism with Scripting in Abaqus

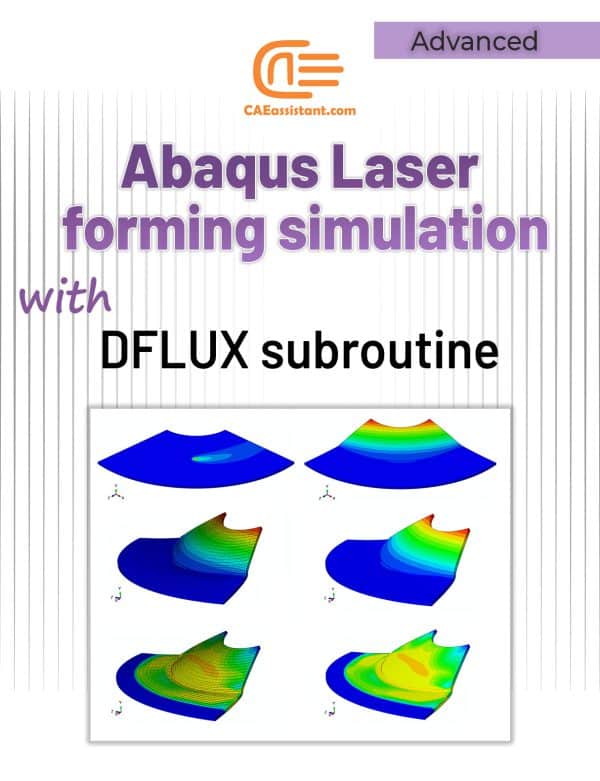

Laser Forming Process Tutorial in Abaqus

Friction Stir Welding simulation Tutorial | FSW Advanced level

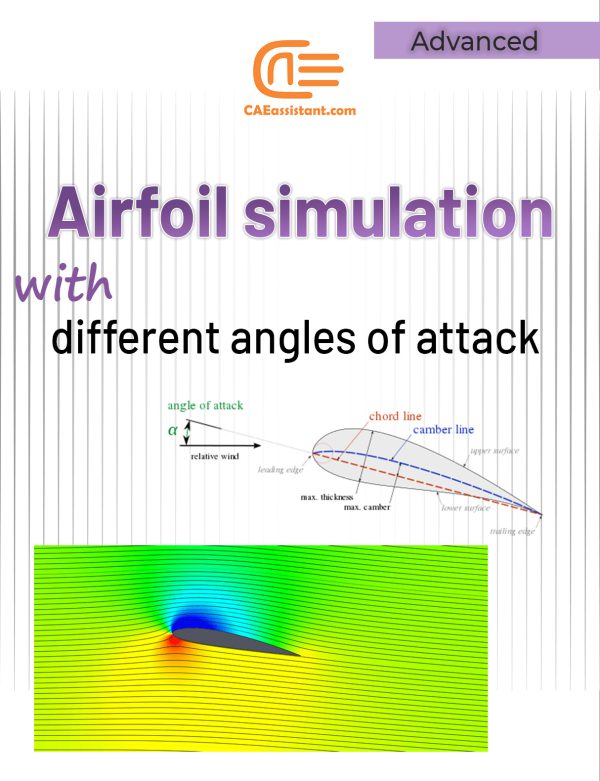

Airfoil simulation with different angles of Attack | Ansys fluent

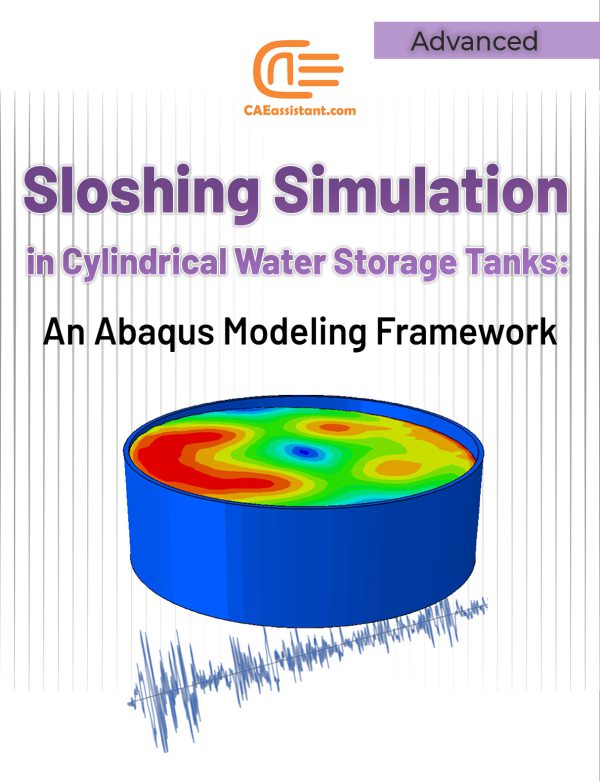

Sloshing Simulation in Cylindrical Water Storage Tanks: An Abaqus Modeling Framework

Simulation and analysis of a 6-cylinder V engine with MSC Adams

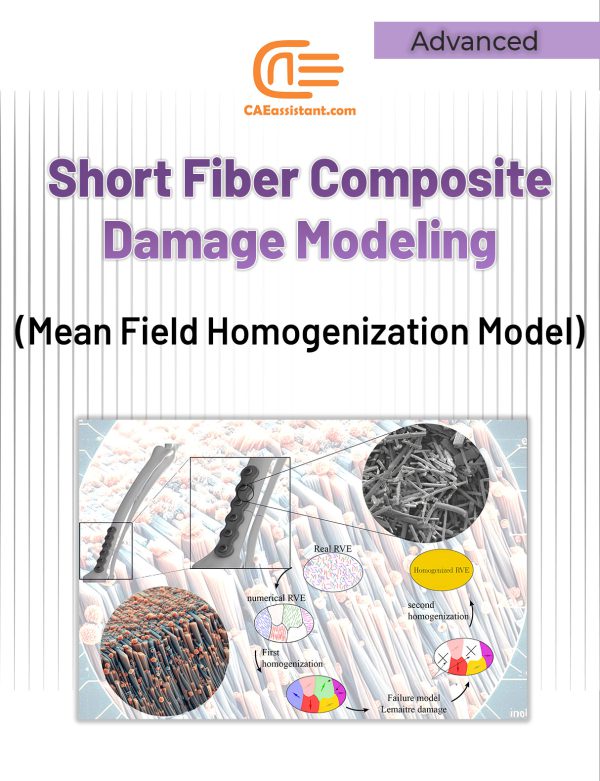

Short fiber composite damage (Mean Field Homogenization Model)

In this tutorial, how to define increments of thermal strains, in order to model thermal expansion, is taught. The implementation of thermal expansion in model is done with UEXPAN and VUEXPAN subroutines for Abaqus/Standard solver (implicit method). In user subroutines UEXPAN or VUEXPAN, the increments of thermal strains can be defined as functions of predefined field variables, temperature, and state variables.

UEXPAN and VUEXPAN are called for all integration points of part elements where the definition of material or gasket behavior includes user-subroutine-defined thermal expansion.

The subroutines are used when the material’s thermal expansion behavior is too complex to model with the "EXPANSION" option in the Abaqus software environment. For example, the subroutines are used in problems where the thermal strains are complexly dependent on temperature, predefined field variables, and state variables, and there is a need to update these variables.

The user subroutine UEXPAN is called twice per element point in each iteration during coupled thermal-electrical-structural or coupled temperature-displacement analyses.