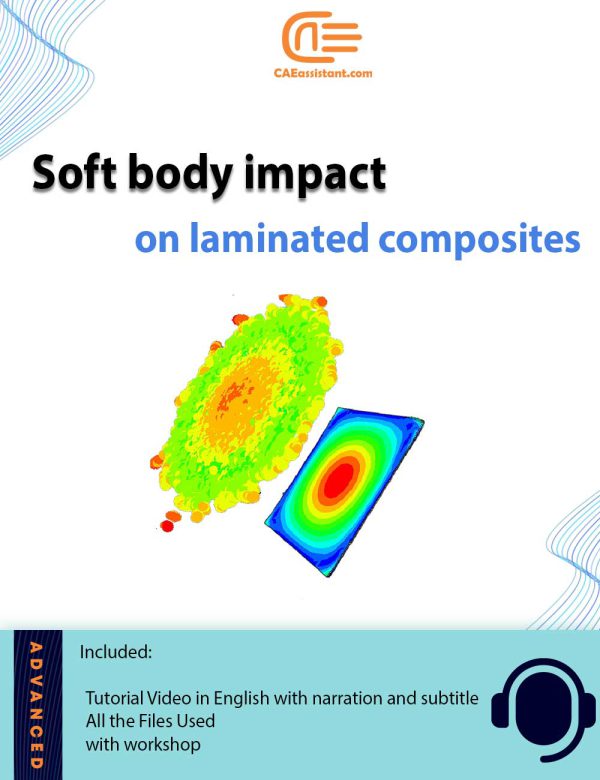

A Comprehensive Tutorial for Soft Body Impact Composites Simulation

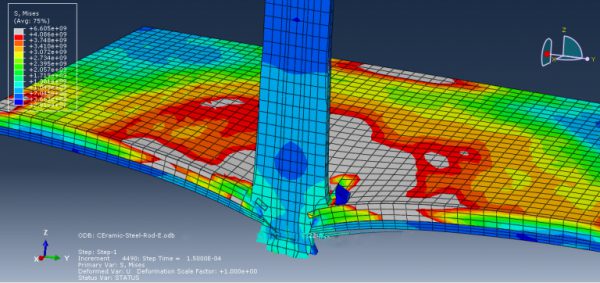

This comprehensive tutorial package focuses on simulating soft body impact composites on laminated composite materials using the Finite Element Method (FEM) in Abaqus. The course covers key topics such as soft body modeling, metal material modeling, composite material modeling, composite to composite interface modeling, metal to composite interface modeling, interaction between soft bodies and FML, interaction between layers, and Python scripting for parametric studies. Users will explore different material models and learn about impact failure mechanisms, including matrix failure, fiber failure, shear failure, and delamination. The course is structured into lessons that cover theoretical aspects, followed by hands-on workshops to model soft body impacts, apply material properties, and analyze post-processing results such as forces, displacements, and energy dissipation. It also includes an advanced section on Python scripting, enabling users to automate parametric studies for complex simulations. This package is ideal for engineers, researchers, and students looking to deepen their understanding of soft body impact phenomena and composite material behavior.

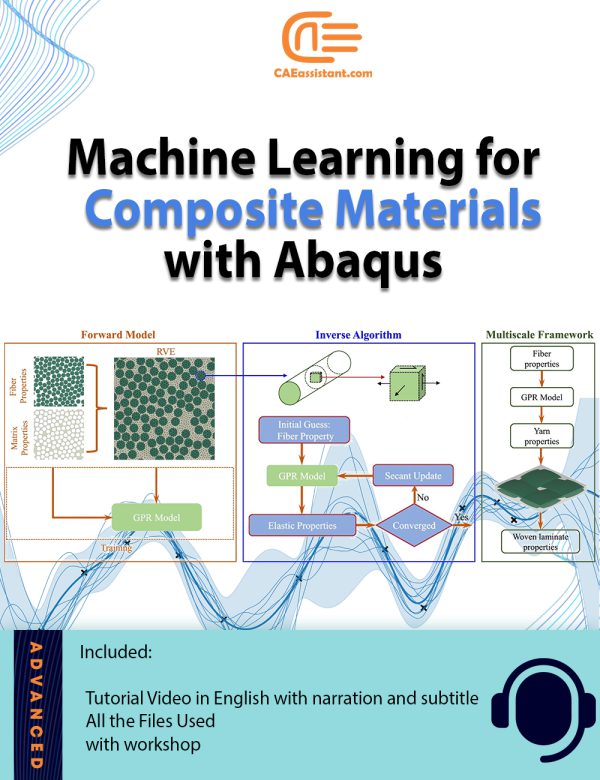

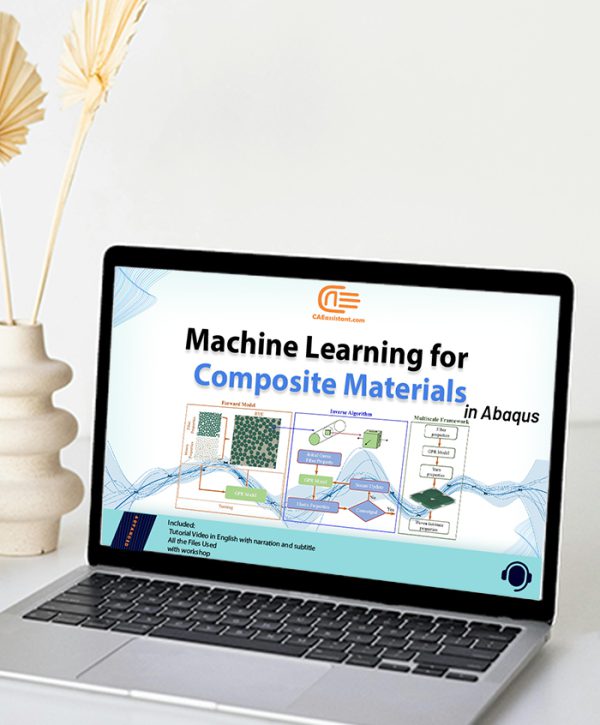

Machine Learning for Composite Materials with Abaqus

This tutorial package delves into an advanced inverse modeling approach for predicting carbon fiber properties in composite materials using a machine learning (ML) technique. Specifically, it covers the use of Gaussian Process Regression (GPR) to build a surrogate model for accurate predictions of fiber properties based on data from unidirectional (UD) lamina. By leveraging Finite Element (FE) homogenization, synthetic data is generated for training the GPR model, accounting for variations in fiber, matrix properties, and volume fractions. This framework’s efficiency and accuracy are validated using real-world data, highlighting its potential as a computational alternative to traditional experimental methods. The package includes detailed explanations, case studies, and practical exercises, equipping users with hands-on experience in applying this ML-based approach to composite material analysis.

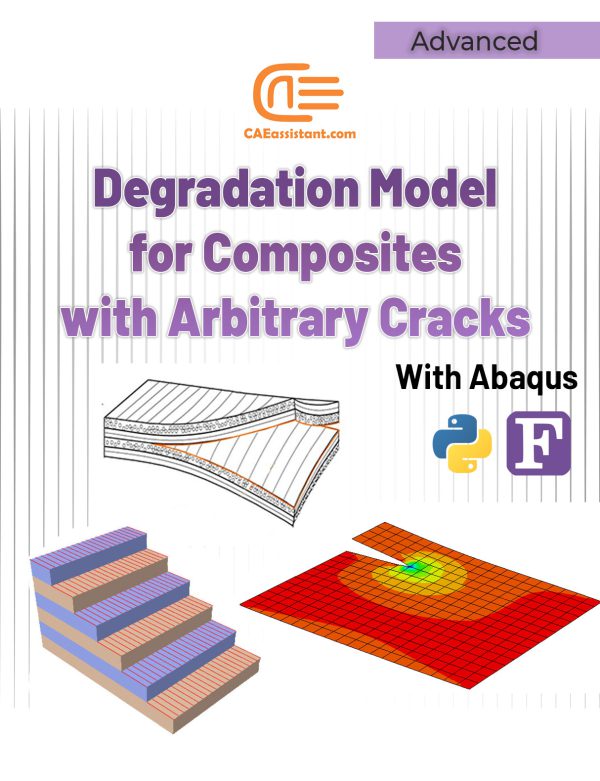

An Efficient Stiffness Degradation Composites Model with Arbitrary Cracks | An Abaqus Simulation

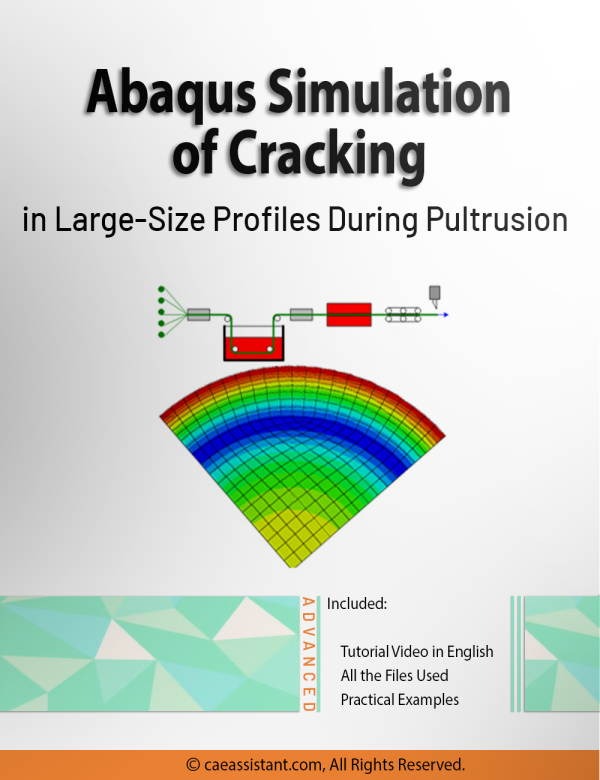

Pultrusion Crack Simulation in Large-Size Profiles | Pultrusion Abaqus

Pultrusion is a crucial task for producing constant-profile composites by pulling fibers through a resin bath and heated die. Simulations play a vital role in optimizing parameters like pulling speed and die temperature to enhance product quality and efficiency. They predict material property changes and aid in process control, reducing reliance on extensive experimental trials. However, simulations face challenges such as accurately modeling complex material behaviors and requiring significant computational resources. These challenges underscore the need for precise simulation methods to improve Pultrusion processes. This study employs ABAQUS with user subroutines for detailed mechanical behavior simulations, including curing kinetics and resin properties. Key findings include insights into crack formation (pultrusion crack simulation), material property changes, and optimization strategies for enhancing manufacturing efficiency and product quality. This research (pultrusion Abaqus) provides practical knowledge for implementing findings in real-world applications, advancing composite material production.

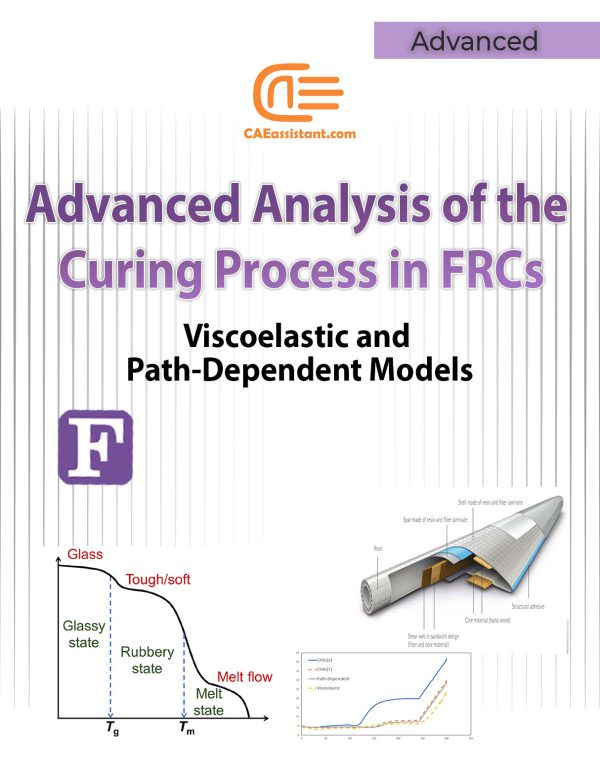

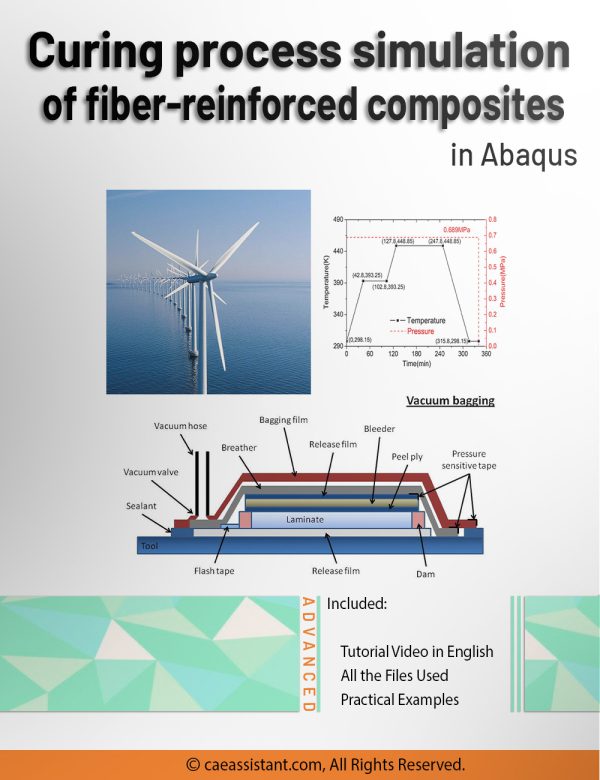

Curing process simulation in Abaqus

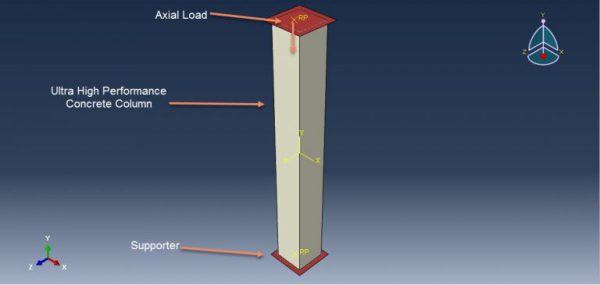

UHPC (Ultra-High Performance Concrete) structures simulation in Abaqus

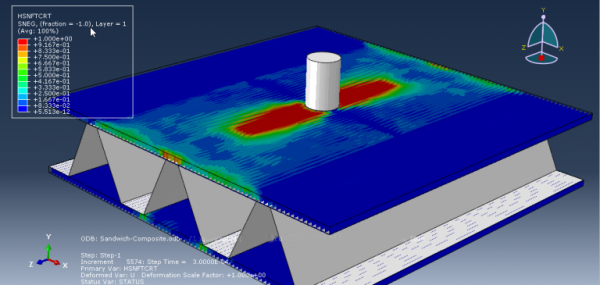

Low-Velocity Impact simulation

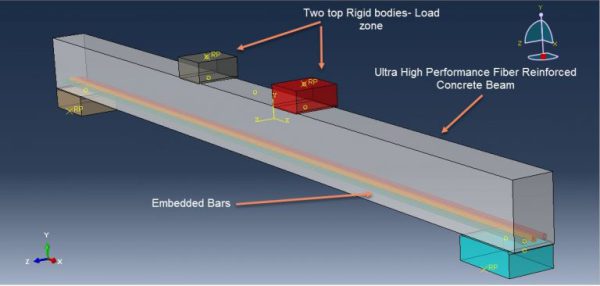

UHPFRC (Ultra-High-Performance Fiber Reinforced Concrete) structures in Abaqus

High Velocity Impact Simulation

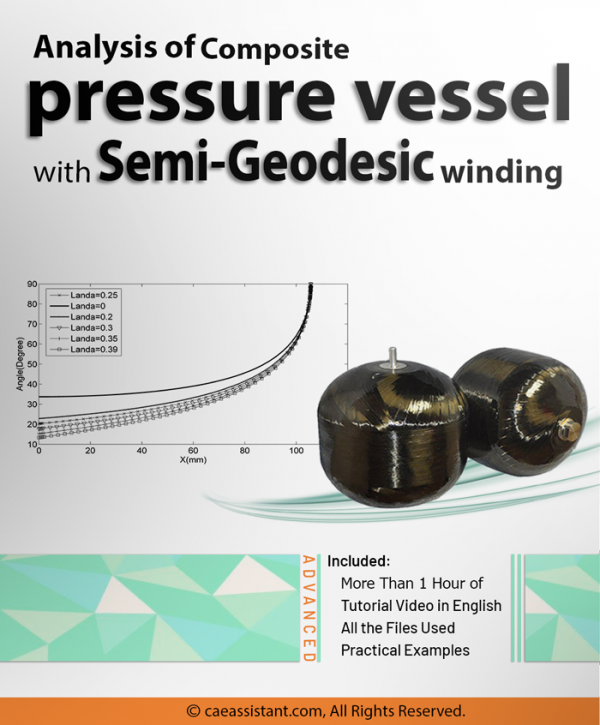

Composite pressure vessel analysis with Semi-Geodesic winding

Full Composite fatigue Add-on (Academic and industrial usage)

Full Composite damage Add-on (Academic and industrial usage)

Composite Fatigue Simulation with VUMAT Subroutine in ABAQUS

Composite simulation for experts-Part-3

Pay attention to the syllabus and availability file details. some of the packages are fully available and some of them are partially available. If this is partially available it takes at least two months to be completely available.

If you are a graduate or Ph.D. student, if you are a university professor or an expert engineer in the industry who deals with simulation software, you are definitely familiar with the limitations of this software in defining the material properties, loading or meshing, interaction properties, and etc. You have certainly tried to define the properties of materials based on advanced fracture theories in finite element software and are familiar with their limitations and problems. Now, here is your solution. Start writing subroutines in finite element software and overcome the limitations. With the tutorials in the Golden Package, you will learn how to write 8 subroutines in Abaqus software professionally.Composite simulation for experts-Part-2

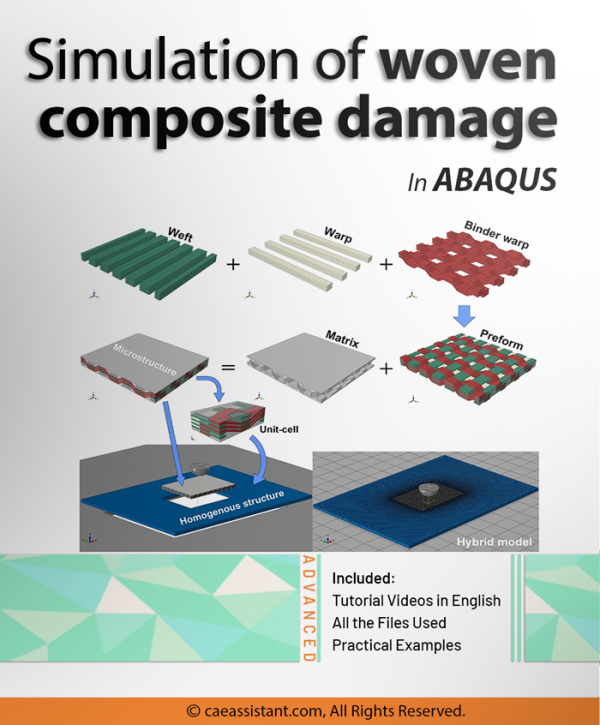

If you are a researcher, student, university professor, or Engineer in the company in the field of composite materials, this training package in simulating these materials in Abaqus software is the best selection. This training package is the second part of the composite for expert package and is focusing on the Simulation of woven composite damage in Abaqus, Composite Fatigue Simulation, Analysis of Composite pressure vessel with Semi-Geodesic winding, Simulation of composite Hashin damage in 3d continuum element (UMAT-VUMAT-USDFLD), and Abaqus composite modeling of Woven & Unidirectional + RVE method.

Masonry wall Abaqus simulation

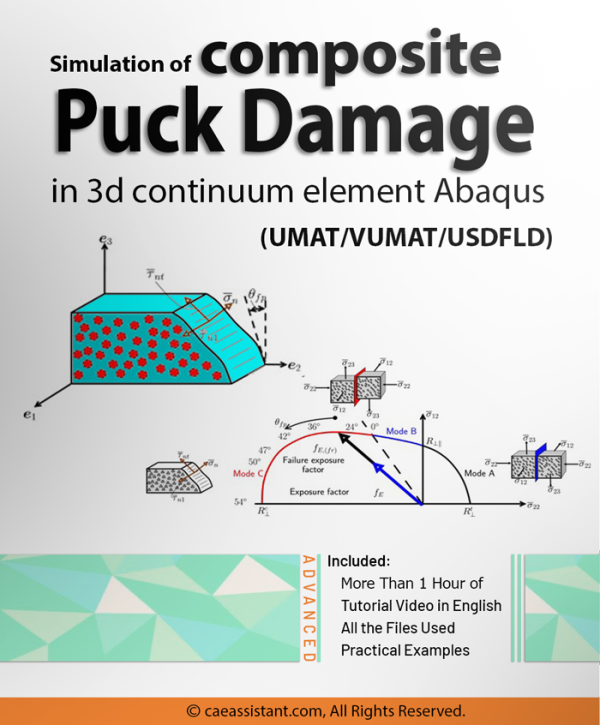

Simulation of composite Puck damage in 3d continuum element in Abaqus (UMAT-USDFLD-VUMAT)

Simulation of woven composites damage in Abaqus

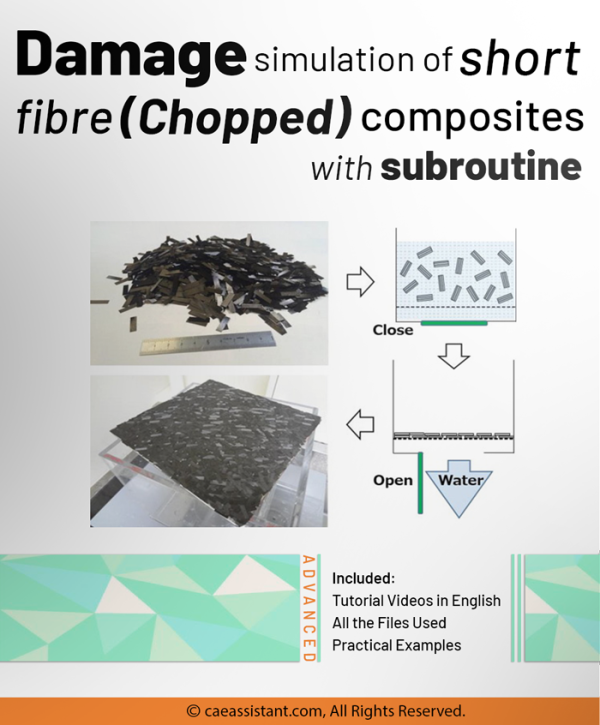

Damage simulation of short fibre composites with subroutine

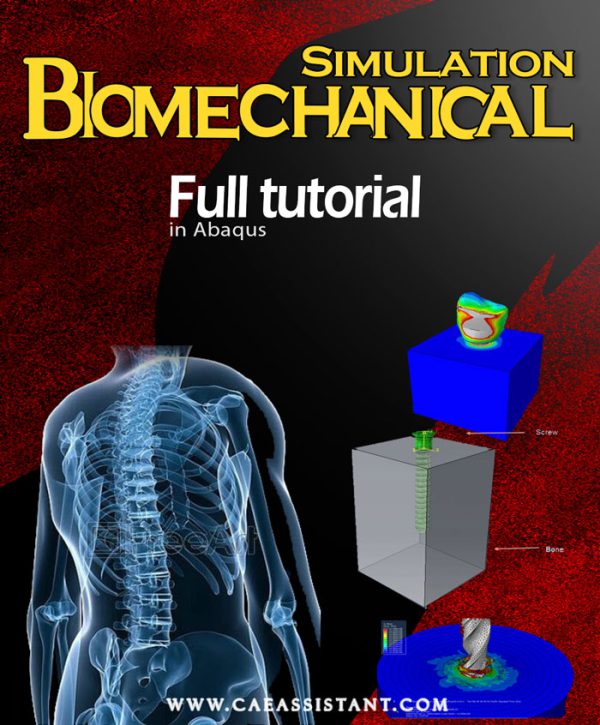

Bio-Mechanical Abaqus simulation Full package

This video tutorial package offers a comprehensive guide to biomechanical simulations using Abaqus, covering a range of applications from dental to orthopedic and cardiovascular analyses. The workshops delve into finite element method (FEM) simulations, exploring static loading on human teeth, crack growth in bones under bending, bone drilling, and the behavior of titanium foam implants. Each tutorial emphasizes the importance of precise modeling and meshing techniques, utilizing dynamic explicit procedures, Johnson-Cook material models, and various contact and boundary conditions to simulate realistic biomechanical behaviors. Additionally, the package includes fluid-structure interaction (FSI) simulations for blood flow within coronary vessels, addressing both Newtonian and non-Newtonian models, and demonstrates the integration of computational fluid dynamics (CFD) with structural analysis for enhanced accuracy. The lessons complement the workshops by introducing fundamental FEM concepts, solver selection, explicit analysis considerations, and damage modeling, ensuring users gain a solid understanding of both theoretical and practical aspects of biomechanical simulations in Abaqus.