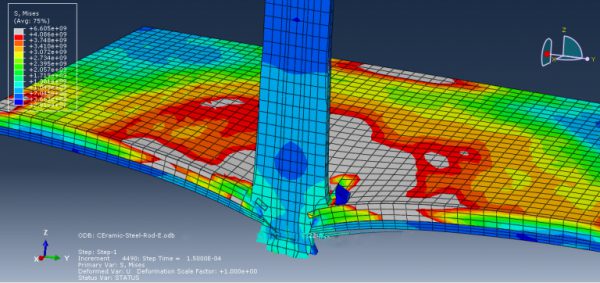

Johnson-Holmquist damage model in Abaqus

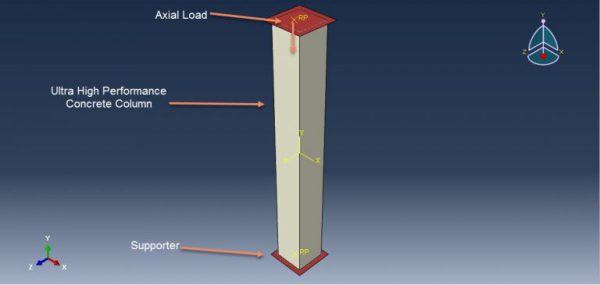

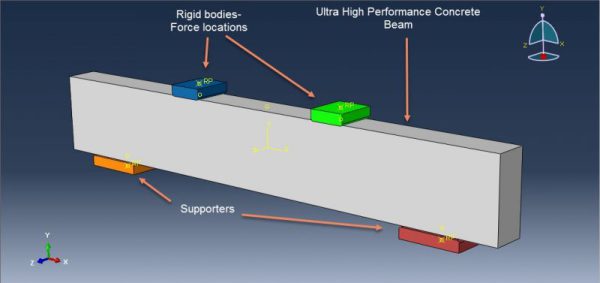

UHPC (Ultra-High Performance Concrete) structures simulation in Abaqus

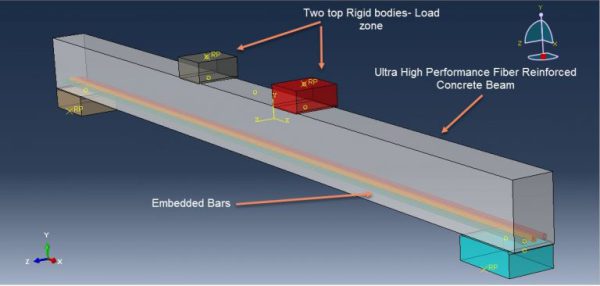

Ultra-High Performance Concrete (UHPC) beams simulation in Abaqus

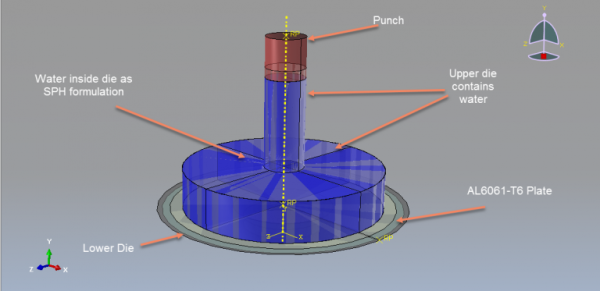

Hydroforming simulation in Abaqus

Arc welding simulation in Abaqus

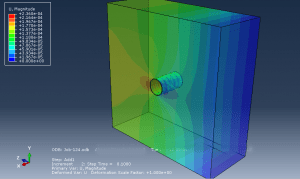

Tunnel excavation simulation using TBM in Abaqus

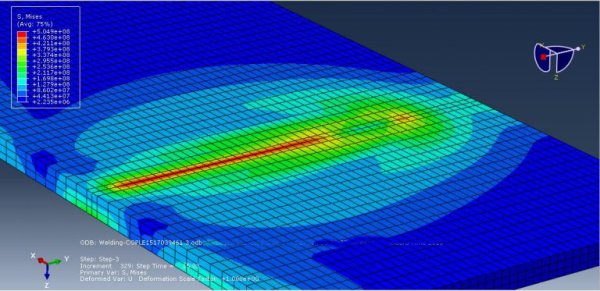

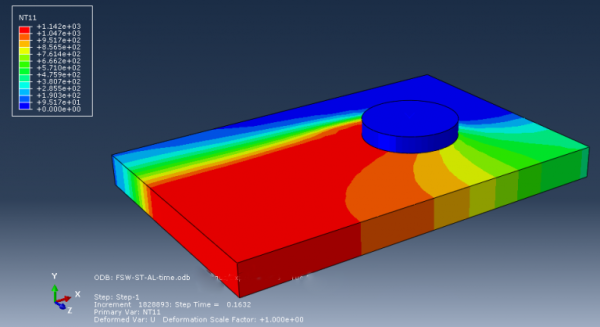

Friction Stir Welding (FSW) Simulation in Abaqus

Soil Impact Analysis in Abaqus

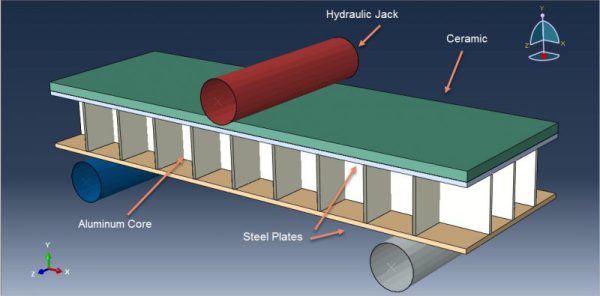

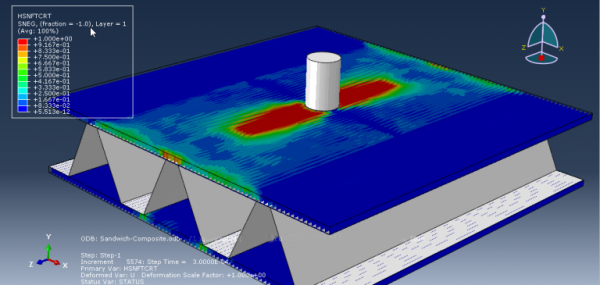

Low-Velocity Impact simulation

UHPFRC (Ultra-High-Performance Fiber Reinforced Concrete) structures in Abaqus

High Velocity Impact Simulation

Car part industrial simulation

Piezoelectric simulation in Abaqus

Eulerian Abaqus and CEL modeling

Cold spray & Shot peening simulation in Abaqus

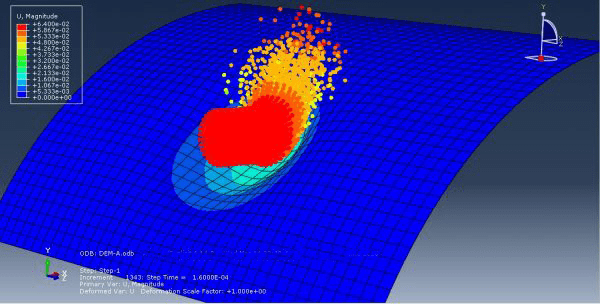

9 Practical Workshops for SPH in Abaqus💡 | Abaqus SPH Tutorial