Full Composite damage Add-on (Academic and industrial usage)

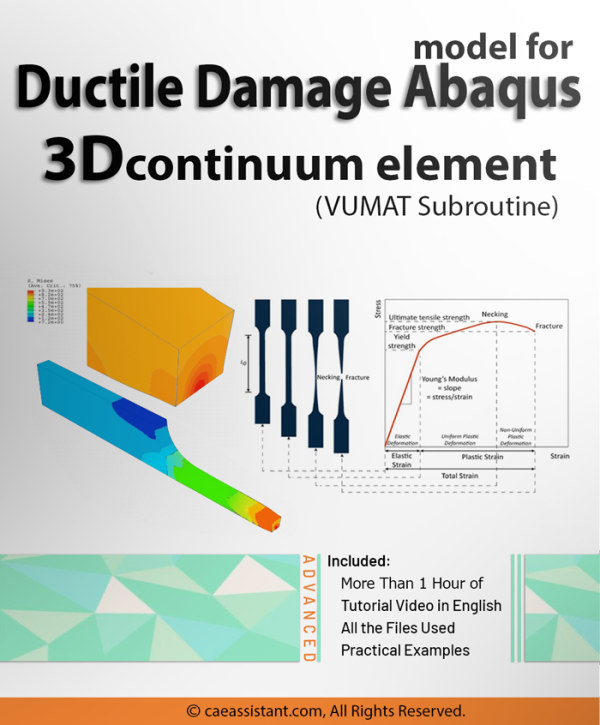

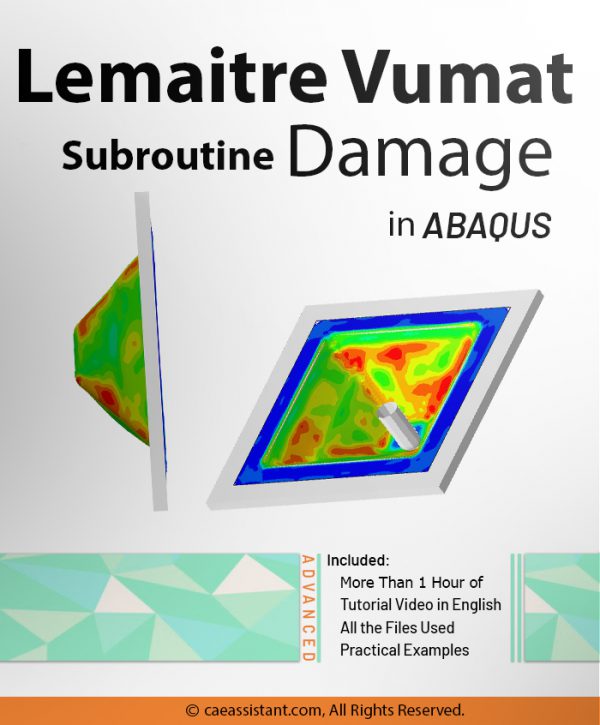

Ductile Damage Abaqus model for 3D continuum element (VUMAT Subroutine)

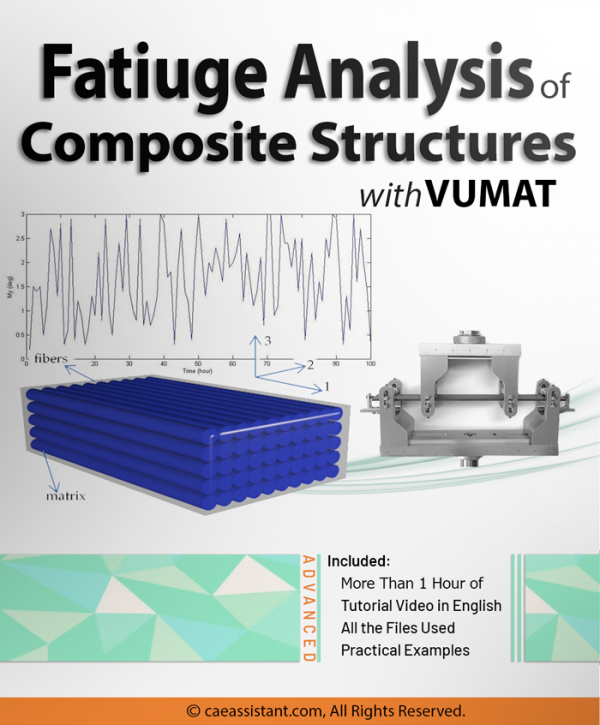

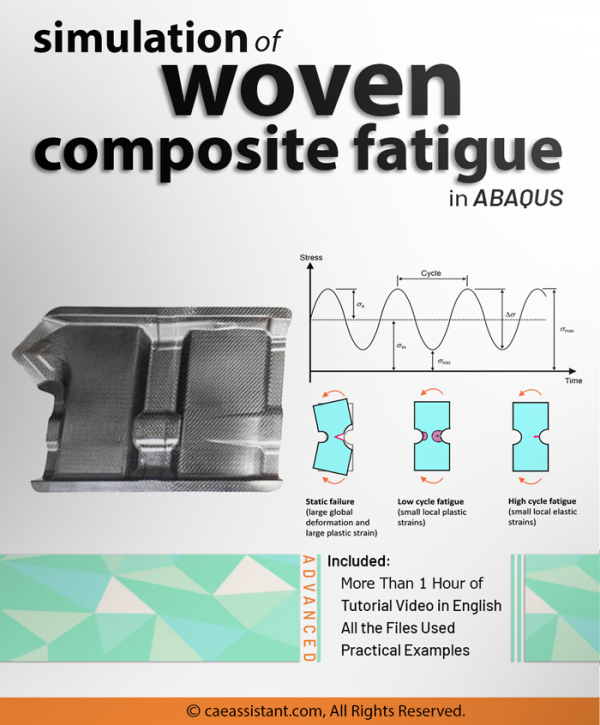

Composite Fatigue Simulation with VUMAT Subroutine in ABAQUS

Composite simulation for experts-Part-3

Pay attention to the syllabus and availability file details. some of the packages are fully available and some of them are partially available. If this is partially available it takes at least two months to be completely available.

If you are a graduate or Ph.D. student, if you are a university professor or an expert engineer in the industry who deals with simulation software, you are definitely familiar with the limitations of this software in defining the material properties, loading or meshing, interaction properties, and etc. You have certainly tried to define the properties of materials based on advanced fracture theories in finite element software and are familiar with their limitations and problems. Now, here is your solution. Start writing subroutines in finite element software and overcome the limitations. With the tutorials in the Golden Package, you will learn how to write 8 subroutines in Abaqus software professionally.Composite simulation for experts-Part-2

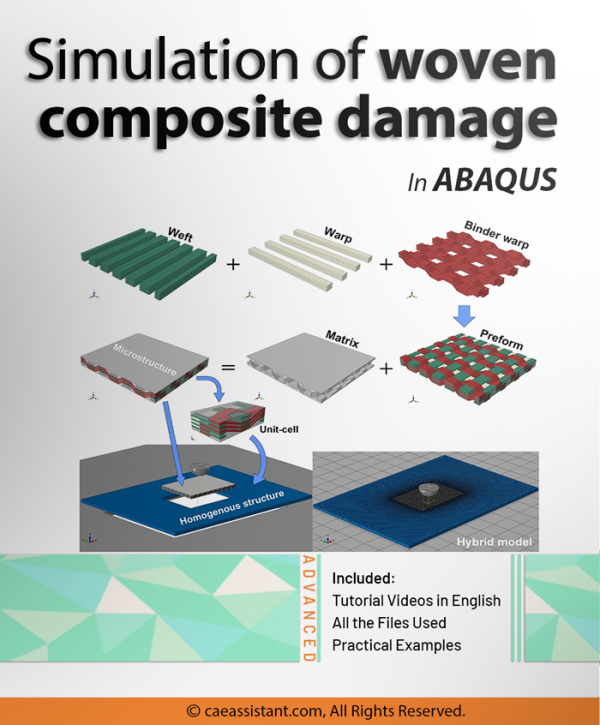

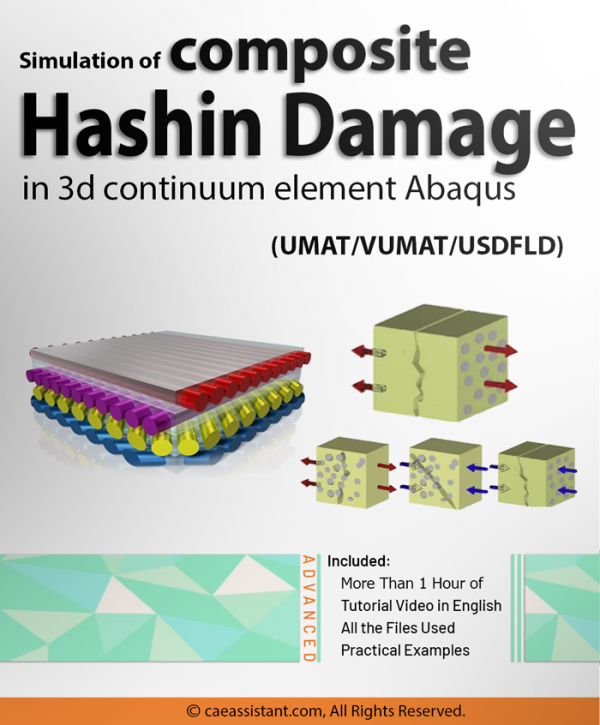

If you are a researcher, student, university professor, or Engineer in the company in the field of composite materials, this training package in simulating these materials in Abaqus software is the best selection. This training package is the second part of the composite for expert package and is focusing on the Simulation of woven composite damage in Abaqus, Composite Fatigue Simulation, Analysis of Composite pressure vessel with Semi-Geodesic winding, Simulation of composite Hashin damage in 3d continuum element (UMAT-VUMAT-USDFLD), and Abaqus composite modeling of Woven & Unidirectional + RVE method.

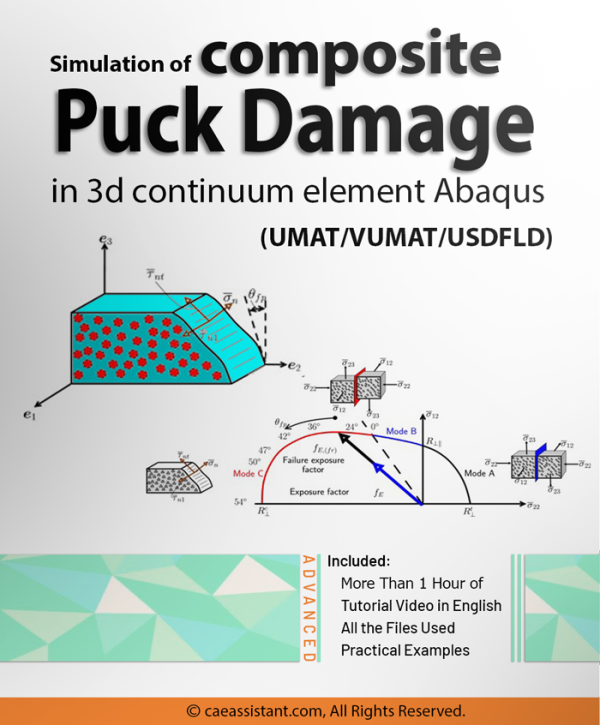

Simulation of composite Puck damage in 3d continuum element in Abaqus (UMAT-USDFLD-VUMAT)

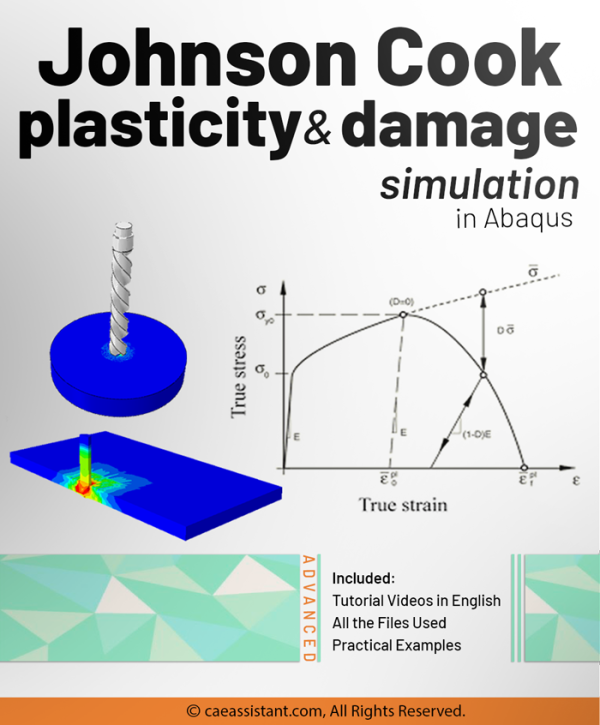

Johnson Cook plasticity and damage simulation

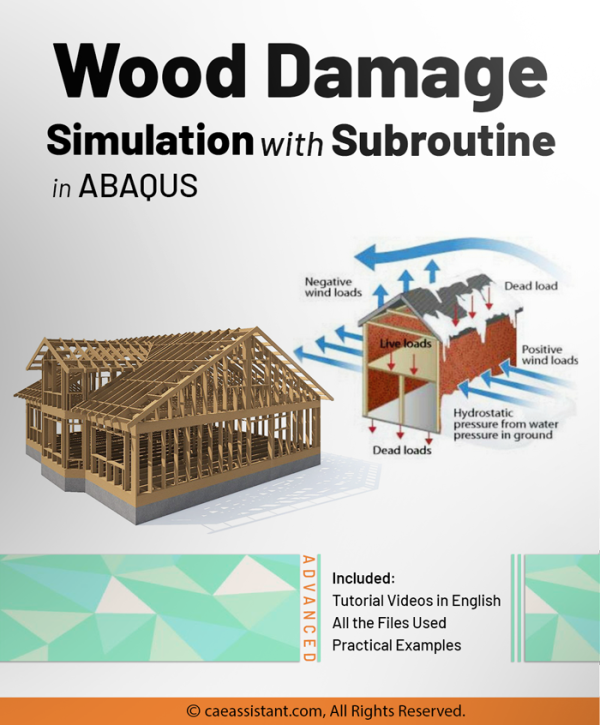

Simulation of woven composites damage in Abaqus

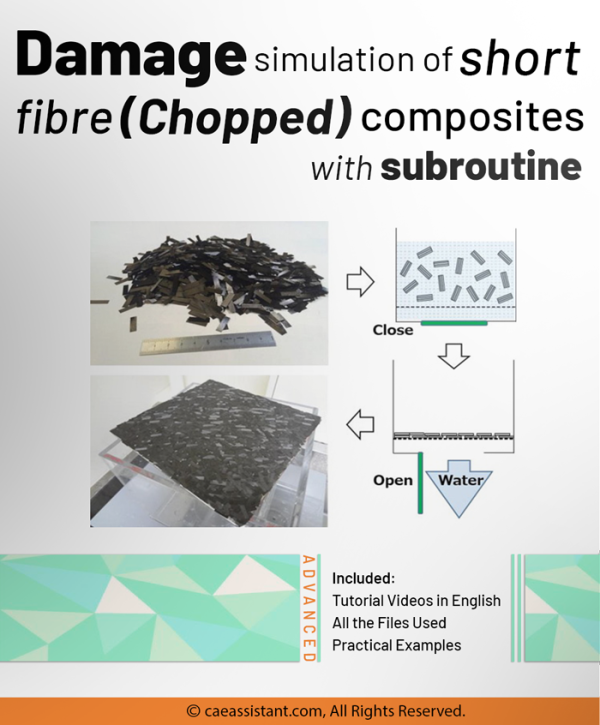

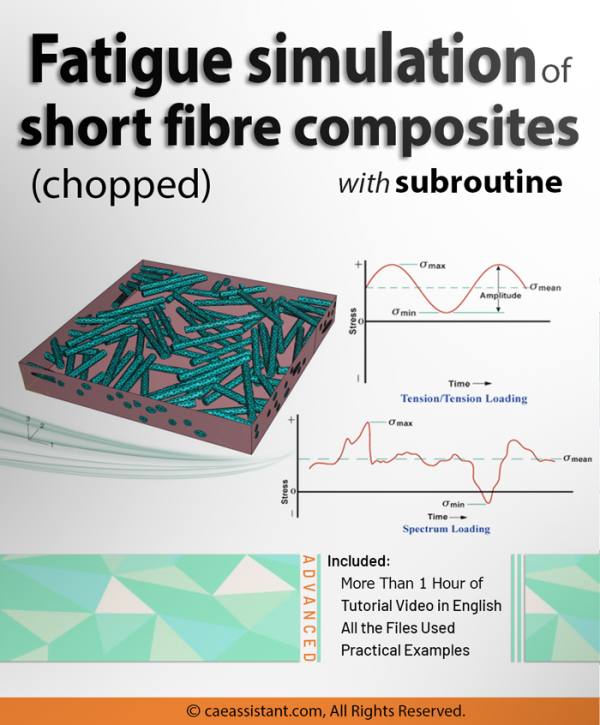

Damage simulation of short fibre composites with subroutine

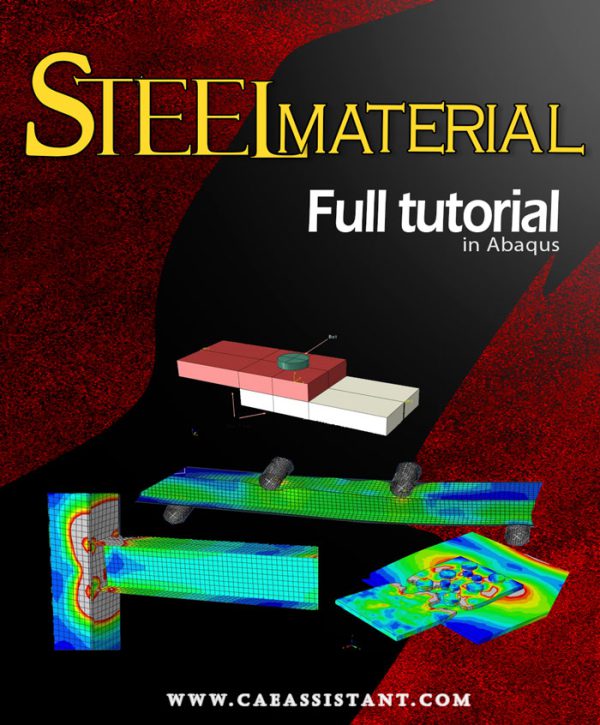

Abaqus steel material and structures Full Tutorial

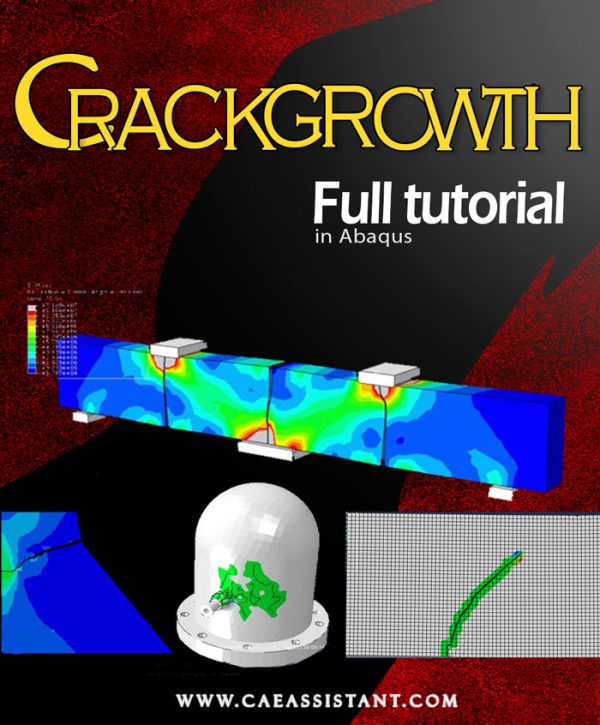

Abaqus Crack Growth Full Tutorial

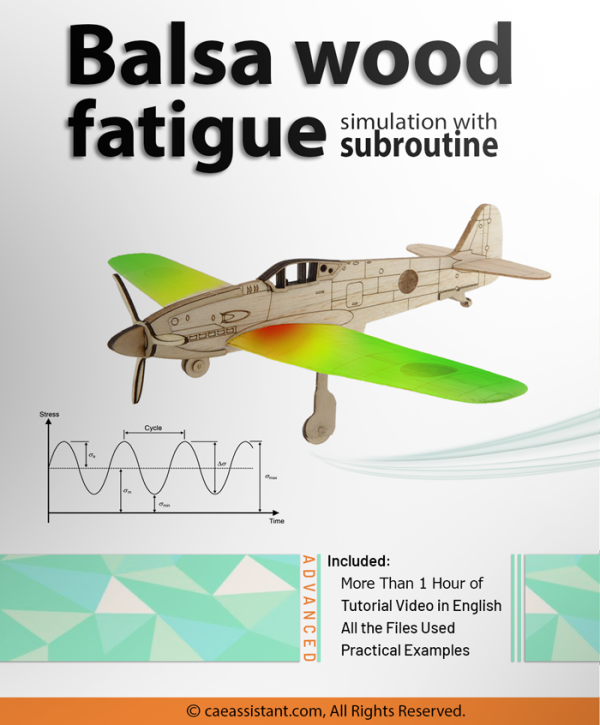

Balsa wood fatigue simulation with Abaqus subroutine

Fatigue damage simulation of short fibre composites with subroutine

Simulation of woven composite fatigue in Abaqus

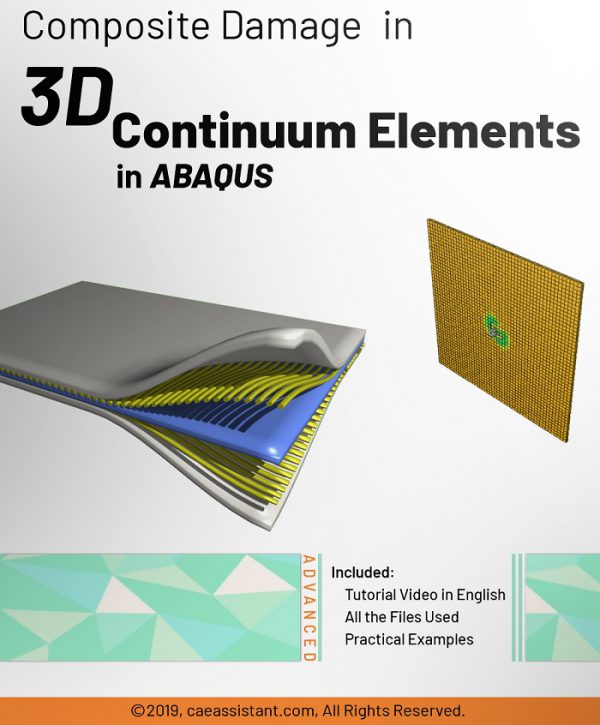

Simulation of composite Hashin damage in 3d continuum element in Abaqus (UMAT-VUMAT-USDFLD)

Lemaitre Damage model implementation with VUMAT Abaqus

Composite simulation for experts-Part-1

3D continuum Abaqus HASHIN progressive Damage for composite materials (VUMAT Subroutine)